Thursday August-14 2025 10:13:44

0.075mm soil sieve is primarily used for soil particle size analysis, separating and classifying particles by size. 0.075mm is considered the critical demarcation between coarse-grained soils (such as sand) and fine-grained soils (such as silt and clay). This sieve is typically made of woven wire mesh and can be used with a variety of screening methods, including dry and wet sieving. Accurate screening provides data on the concentration of particles of varying sizes in the soil, providing essential information for subsequent soil classification, engineering design, and material evaluation.

The 0.075mm soil sieve is a key tool for fine-grained soil analysis. Its types and uses are primarily determined by the sieving method and sieve material. Dry and wet sieving are two different analytical methods, each suited to different soil characteristics. Woven wire mesh is the standard structure for these high-precision sieves.

Wire Mesh

Working Principle: This sieve is woven from fine metal wire (usually stainless steel) to form precise square mesh openings. A 0.075mm sieve has a mesh size of 75 microns, woven from very fine wire.

Applicability: Almost all sieves used for soil particle size analysis, whether dry or wet, use this mesh structure. This mesh ensures uniformity and precision in mesh size and is the core component of international standard analytical sieves.

Advantages: Durable and corrosion-resistant (made of stainless steel), with precise mesh size, it is the basis for standardized testing.

Dry Sieving

Working Principle: A dry soil sample is placed in the sieve. Vibration or shaking is used to force particles smaller than the mesh size through the sieve, while particles larger than the mesh size remain on the sieve surface.

Applicability: Suitable for soils with weak cohesion between particles, such as sand and gravel.

Advantages: Simple and quick operation, requiring no additional equipment (other than a screening machine). Limitations: Dry sieving is not effective for soils containing fine particles (such as clay and silt) with a certain degree of cohesion. These fine particles may aggregate or adhere to the sieve mesh, resulting in incomplete sieving and affecting the accuracy of the results.

Wet Sieving

How it works: The soil sample is soaked in water and a dispersant is added. Agglomerated particles are then completely dispersed through stirring or ultrasonic vibration. Then, with the aid of a water flow, the fine particles are forced through the sieve mesh, while the coarse particles are retained on the sieve surface.

Applicability: This is a common method for analyzing fine-grained soils such as clay and silt, especially when accurate determination of the content of particles below 75 microns is required. A 0.075 mm sieve is often used as a delimiting sieve in wet sieving.

Advantages: It effectively separates particles in cohesive soils, resulting in more accurate particle size distribution results.

Limitations: The process is relatively complex and time-consuming, requiring additional equipment and steps, such as an ultrasonic cleaner and a water tank.

The advantage of the 0.075mm soil sieve lies in its importance as a critical dividing line between coarse-grained and fine-grained soils. Its standardization ensures the reliability of experimental results. Furthermore, this sieve is versatile, adaptable to various analytical methods, including dry and wet sieving. Its advantages are primarily reflected in the following aspects:

High precision, key to soil particle demarcation: 0.075mm is a crucial particle size cutoff in soil engineering and geology. It separates coarse-grained soils (such as sand and gravel) from fine-grained soils (such as silt and clay). Using this sieve, the fine fraction of the soil can be accurately measured, which is crucial for determining soil engineering properties such as permeability and shear strength.

Standardization ensures reliable experimental results: 0.075mm is an internationally recognized standard sieve aperture size that complies with standards. This standardization ensures comparability of experimental results across different laboratories and over time. Using a 0.075mm sieve that meets the standard ensures reliable and consistent particle size distribution data. Versatile and suitable for a variety of analytical methods: 0.075mm sieves can be used for both dry and wet sieving. Dry sieving processes dry, coarse-grained soils without cohesion, quickly separating the fine fraction. For cohesive soils containing clay and silt, wet sieving effectively disperses the particles and allows for precise separation. The 0.075mm sieve plays a key role in this method. The water flow removes the fine particles, leaving the coarse particles behind.

Durable material and long service life: High-quality 0.075mm soil sieves are typically constructed from corrosion-resistant, high-strength wire, such as stainless steel. This material ensures that the mesh maintains its precision and structural integrity even after repeated use and cleaning (especially during wet sieving), significantly extending its service life.

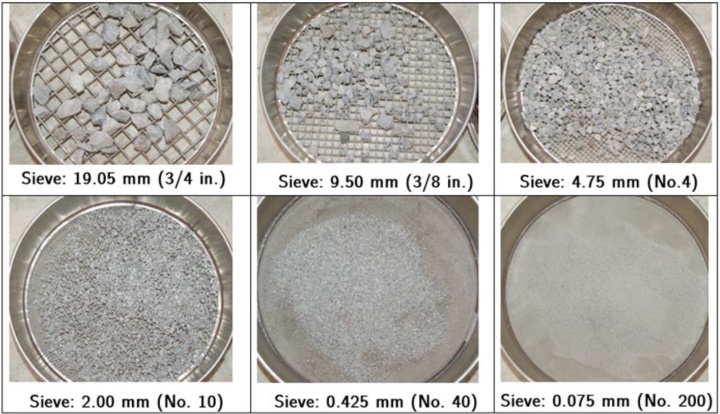

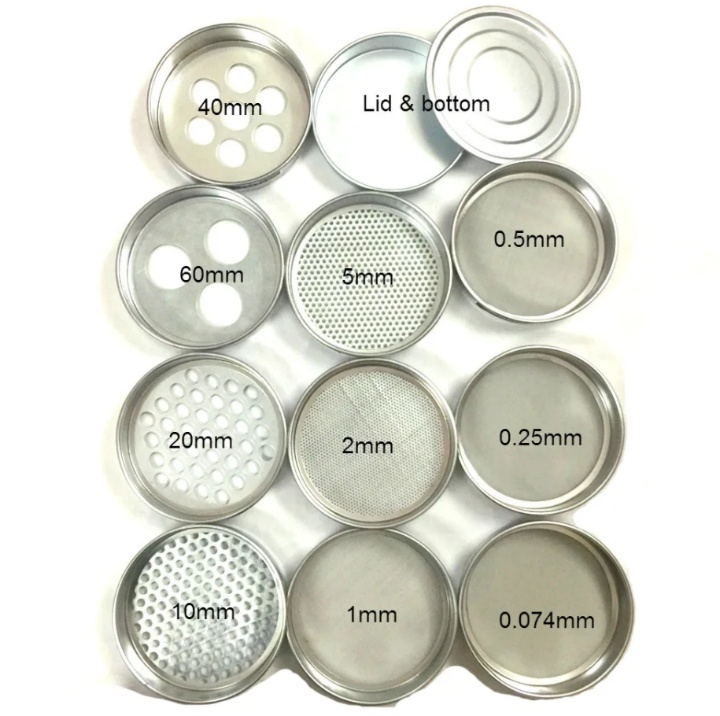

A 0.075mm soil sieve typically consists of three parts: the sieve frame, the mesh, and the sieve cover and bottom. The sieve frame is the main structure of the sieve and is typically made of corrosion-resistant materials such as stainless steel or brass. Its primary function is to support and secure the sieve mesh and ensure a secure and airtight seal when stacked. The mesh, the core component of the sieve, is woven from metal wire. Its precision directly determines the accuracy of the screening results. For a 0.075 mm sieve, the mesh aperture is 75 microns. Stainless steel wire is typically used due to its excellent corrosion resistance, strength, and durability, and its ability to withstand wear and tear from washing and vibration. The mesh mesh is woven with extreme precision to ensure that each mesh size is as uniform as possible. This is crucial for ensuring standardized and reproducible particle size analysis. The sieve cover and sieve bottom are auxiliary components of the sieving tower, used in conjunction with the sieve frame. Placed at the top of the sieving tower, they prevent sample splashing during sieving and also provide a secure and airtight seal. The sieve bottom, placed at the bottom of the sieving tower, collects all particles that pass through the finest mesh (i.e., silt and clay particles with a size less than 75 microns). The sieve bottom is typically a non-porous container that matches the size of the sieve frame. When conducting a sieving test, multiple sieves of varying apertures are typically stacked in descending order, with the sieve cover at the top and the sieve bottom at the bottom. A soil sample is placed on the top coarse sieve and vibrated by a vibrating sieve shaker, separating soil particles of varying sizes layer by layer. The soil's particle size distribution is then determined by weighing the residue remaining on each layer of sieves.

The 0.075mm soil sieve plays a fundamental role in civil engineering, environmental science, geology, and agriculture. Its core applications are soil particle analysis, material quality control, and scientific research. It provides a deep understanding of soil's physical properties, providing critical data support for engineering design, environmental assessments, and scientific exploration.

Soil Particle Analysis

Soil particle analysis, also known as sieving testing, is fundamental to understanding soil physical properties. Using the 0.075mm soil sieve, we can separate soil into coarse particles (larger than 0.075mm) and fine particles (smaller than 0.075mm). Coarse-grained soils, primarily sand and gravel, have larger particles and are highly permeable. Fine-grained soils, primarily silt and clay, have smaller particles and are less permeable. This distinction is crucial for determining soil engineering properties, such as bearing capacity, compressibility, and permeability.

Material Quality Control

In construction and road construction, a 0.075mm soil sieve is used to check the quality of fillers and aggregates. Sieving tests ensure that the particle composition of these materials meets engineering design requirements, thereby ensuring the stability and durability of the project. For example, when formulating asphalt mixtures or concrete, the content of fine particles must be precisely controlled.

Scientific Research

In scientific research, a 0.075mm soil sieve is a key tool for conducting various experiments. For example, in soil improvement research, researchers use sieve tests to determine soil particle size distribution, providing data to support improvements to soil structure and fertility. In environmental pollution research, by analyzing the concentration of pollutants in soil particles of different sizes, their migration and distribution patterns can be assessed. In geological sediment analysis, sieving tests can help analyze the origin, formation, and transport history of sediments.

The 0.075mm soil sieve plays a central role in current soil analysis due to its unique structural characteristics and functional advantages. Its standardized size ensures reliable and comparable particle size analysis results, which is fundamental to any engineering or scientific assessment. Furthermore, its precision mesh, constructed of durable materials, not only meets the requirements of both dry and wet sieving methods, but also ensures accuracy and durability after repeated use and cleaning.

Aug 14, 2025

What is 0.075mm soil sieve ? The 0.075mm soil sieve is primarily used for soil particle size analysis...

Aug 12, 2025

What is 4.75mm soil sieve ? The 4.75mm soil sieve is primarily used for particle grading analysis of ...

Aug 09, 2025

What is 2mm soil sieve? A 2mm soil sieve is a fundamental and crucial tool. Its primarily used for pr...

Aug 04, 2025

Size sieve for soil mainly refers to the sieve frame diameter (commonly used 200mm, 300mm, etc.) and ...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap