Sieve testing equipment, also known as sieve analysis equipment, is a device that detects the particle size composition of materials and analyzes the particle size content. It is often used in the laboratory to accurately analyze the particle size structure of powder and granular materials, screen and detect solids and impurities in liquids, and can screen samples within 2kg.

$650.00 - $800.00/SetChat Now

International standard: ISO3310-1:1990 R20/3, R20, R40/3 series

Screen diameter: 75mm, 100mm, 200mm, 300mm, 400mm, 500mm

Screening particle size: 0.025-3mm

Feeding amount: 200g

Screen frame: 1-8 layers

Materials: testing and grading of aggregate, sand, soil, grain, flour, coal and other materials.

1.high degree of corrosion resistance and easy cleaning thanks to high-alloy stainless steel

2.sieve mesh sizes from 20 µm to 125 mm

3.0-99 minutes timing function

4.It can be accurately separated into 2 to 7 particle segments at the same time.

Port: Any port in China (Mainland)or as you need.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Sieve Testing Equipment, also called sieve analysis equipment, is a testing equipment used to understand the particle size characteristics of materials and analyze the content of each particle size. It can be used for particle size classification and detection of the composition of various powders and granular materials such as aggregates, sand, minerals, and grains.

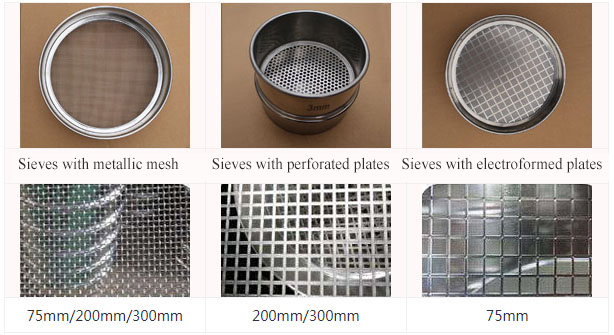

Sieve testing equipment screen frame is made of 304/316 stainless steel, brass and nylon; screen mesh includes metal woven mesh, metal punching plate mesh and electroforming mesh; the diameter of the screen frame is 75mm, 100mm, 200mm, 300mm, 400mm, etc. , can also be customized according to user needs, the sieving range is 4mm-38μm.

Sieve testing equipment is used to determine material gradation (the size distribution of material particles in a given sample) to determine compliance with design, production control requirements and validation specifications.

Sieving pearl powder: 3 layers for sieving of pearl powder fine powder

Corn flour is divided into different grades of finished products

Metal powder rotap sieve shaker: The finished metal powder is 140 mesh, 200 mesh, 230 mesh, 325 mesh.

Sieve Testing Equipment—Standard Sieve

Standard sieve testing equipment, also called standard test sieve, is a sieve analysis tool with standard sieve holes and a tool or basis for testing other particle size testing methods. The sieves used in laboratory sieve testing equipment are test sets of sieves with different sieve sizes made according to the relevant standards in the table, namely standard sieve. It is composed of a screen frame and a screen mesh with a diameter of 15-450mm and a height of 25-50mm, and the screen frame is made of stainless steel plate. Sieve testing equipment is a set of sieves that are stacked on top of another sieve. The sieve hole of the upper sieve is large, and the sieve hole of the lower sieve is small. Add a cover to the upper part and a chassis to the lower part to reduce dust and loss. The chassis is also used to accept the fine-grained product that passes through the latter sieve.

| category | Standard Pharmacopoeia Screen | Standard Soil Sieve | Nylon Test Sieve | Copper mesh analysis sieve | Wet Sieve Test |

| picture |  |

|

|

|

|

| use | Classification and screening process for Chinese and Western medicine granules | For sieving and testing of various soils | All made of PVC, no metal components, corrosion-resistant, suitable for screening zirconia, phosphors and some special chemical additives | It has certain anti-oxidation and anti-corrosion, suitable for screening and grading of laboratory items | Used to separate the coarse particles of agglomerated, sticky materials from water or other liquids for dry sieving of difficult-to-screen materials |

| Mesh/Aperture | No. 1-9, 10-200 mesh | 0.075mm、0.25mm、0.5mm、1mm、2mm、2.5mm、3mm、4mm、5mm、6mm、7mm、8mm、9mm、10mm、12mm、13mm、20mm、40mm、60mm | 10-35-40-45-50-60-80-100-120-140-160-180 200-250-300-325-350 mesh | 10-35-40-45-50-60-80-100-120-140-160-180 200-250-300-325-350 mesh | 20 microns-5 mm |

Sieve Testing Equipment—Laboratory Test Sieves

| Electric Sieve Testing Equipment | Electromagnetic Sieve Testing Equipment | Ultrasonic Sieve Testing Equipment | Slap Sieve Testing Equipment | Top-strike Sieve Testing Equipment |

|

|

|

|

|

| Suitable for coarse material detection within 300 mesh | Sieve to 600 mesh (20 microns), fine up to 5 microns | High-precision powder within 500 mesh, no mesh blocking | Suitable for coarse material within 500 mesh | Suitable for coarse material within 500 mesh |

| Universal Sieve Testing Equipment(Material classification of screen mesh) | Dedicated Sieve Testing Equipment(Classification of material characteristics) | |||||

| Metal woven mesh | Metal perforated screen mesh | Electroforming mesh | 75mm Test Sieve | 200mm Abrasive Particle Size Checking Sieve for Coated Abrasives | Sieve Testing Equipment for Foundry | |

| use | High-precision screen, commonly used in the diamond industry | Detection for particle size analysis of large particle materials | For fine powder inspection | For inspection of particle size composition of superhard materials | For the manufacture of sandpaper, abrasive cloth, abrasive belt, abrasive disc, etc., the particle size composition (coarse grain, coarse grain, basic grain, mixed grain, fine grain) of abrasive for coated abrasives is detected | For determining the particle size of molding materials |

| diameter | 75mm、200mm、300mm | 200mm、300mm | 75mm、200mm | 75mm | 200mm | 200mm |

| mesh size | 0.02mm-2.36mm | 1mm-125mm | 5µm-500µm | A set of 37 sieves in total, including 12 wire woven mesh sieves with a mesh size of 300µm-2000µm, and 25 precision electroforming sieves with a mesh size of 41μm-455μm. | Particle size marking P12-P220. 15 particle size numbers/set, sieve number 6#~270# (without 7#), 24 pieces/set | 0.053mm-3.35mm, a full set of 11 |

Sieve Testing Equipment can be used to characterize and classify various materials within 0.025mm-3mm, such as sand, aggregate, soil, grain, coal, etc., with accurate and repeatable classification test results, and can detect and analyze particle size and size.

Chemical industry: resin, paint, medicine, medicine, cosmetics, fire extinguishing agent, plastic powder, abrasive glass, etc.

Ceramic industry: abrasives, alumina, porcelain mud, clay mud, glass powder, refractory materials, quartz sand, PVC resin powder, citric acid, polyethylene powder, washing powder, etc.

Food industry: sugar, monosodium glutamate powder, salt, fruit juice, starch, milk powder, food, soy milk, egg powder, rice noodles, soy sauce, fish meal, pineapple juice, etc.

Metallurgical industry: carbon black, cosolvents, activated carbon, pearls, etc.

Suitable for dry and wet sieving, the opening size is from 5 inches (125 mm) to 635 mesh (20 microns), and the screening accuracy is high.

3D screening motion, high separation efficiency, no blind zone for screening, no mechanical moving parts

0-99 minutes digital control, easy operation, accurate data, "closed loop" total amplitude control to ensure repeatable screening

Easy-to-use screen scraping system

Holds up to 8 full-height sieves for small size and easy mobility

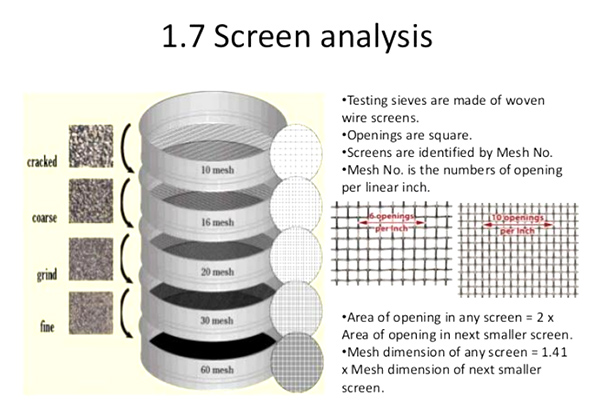

Sieve testing equipment divides a specific sample material into two parts, one part is retained by the sieving medium (rejected material/sieving) and the other part is passed through the opening (fines). When sieving non-spherical particles, the process is more complicated because particles close to the nominal pore size of the sieve will only pass in favorable locations and will not pass if they appear on the sieve in other locations.

The sieving process can be divided into two stages: particles significantly smaller than the nominal pore size are first removed, and then particles with sizes close to the nominal pore size are separated. Both stages require that all particles placed on the sieving media have a chance to pass through the openings. Ideally, each particle would be presented individually to an opening, like the larger opening, but this is impractical for most particle sizes.

| NO. | Name | Unit | Parameter |

| 1 | frame diameter | mm | φ200 |

| 2 | the number of layer | s | 1~8 |

| 3 | sieve size | mm | 0.025-3 |

| 4 | vibrating amplitube | mm | 1~4 |

| 5 | vibration frequency | n/min | 1440 |

| 6 | power supply | V;HZ;KW | 220;50;0.12 |

| 7 | outside dimension | L*W*H | 350*350*(300+n*56) |

| 8 | machine weight | kg | 36 |

| 9 | time alarm | s | 999 |

| 10 | noise | db | Less than 50 |

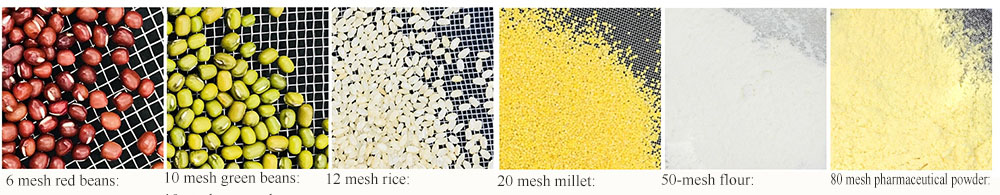

| mesh size | Mesh | mesh size | Mesh |

| 4.75mm | 4 mesh | 0.355mm | 45 mesh |

| 4.00mm | 5 mesh | 0.300mm | 50 mesh |

| 3.35mm | 6 mesh | 0.250mm | 60 mesh |

| 2.80mm | 7 mesh | 0.212mm | 70 mesh |

| 2.36mm | 8 mesh | 0.180mm | 80 mesh |

| 2.00mm | 10 mesh | 0.150mm | 100 mesh |

| 1.70mm | 12 mesh | 0.125mm | 120 mesh |

| 1.40mm | 14 mesh | 0.106mm | 140 mesh |

| 1.18mm | 16 mesh | 0.090mm | 170 mesh |

| 1.00mm | 18 mesh | 0.0750mm | 200 mesh |

| 0.850mm | 20 mesh | 0.0630mm | 230 mesh |

| 0.710mm | 25 mesh | 0.0530mm | 770 mesh |

| 0.600mm | 30 mesh | 0.0450mm | 325 mesh |

| 0.500mm | 35 mesh | 0.0374mm | 400 mesh |

| 0.425mm | 40 mesh |

1. Weigh the sample to the nearest 0.1 g based on the total weight of the sample. This weight will used to check for any material loss after sample grading. Select the appropriate screen size according to the specification.

2. Arrange the sieves in order of size from top to bottom and start stirring and shaking the sample for sufficient time.

3. For coarse aggregate, the most commonly used is large sieve testing equipment. The unit provides a clamping mechanism that holds the screen in place for agitation during the process. A 5 minute run is required for size 9 or larger shakers, and 10 minutes for sizes smaller than 9.

For fine aggregate, round 8" (203.2 mm) or 12" (304.8 mm) sieves are commonly used. These sieves are self-nesting and are supported during shaking by various mechanisms that clamp and/or hold on top and bottom. This type of small sieve testing equipment requires 15 minutes of shaking time to adequately grade the fine aggregate samples.

The following is an example of testing aggregate; report table of fine and coarse aggregate sieving analysis:

| sieve size | Weight of aggregate retained(g) | % agg retained of total weight | Cumulative % agg retained of total weight | % agg Passing of each sieve |

| 4.78mm | 206 | 24 | 24 | 76 |

| 2.36mm | 236 | 27.5 | 51.51 | 48.48 |

| 1.18mm | 330 | 38.46 | 89.97 | 10.02 |

| 600μm | 70 | 8.15 | 98.13 | 1.86 |

| 300μm | 15 | 1.75 | 99.88 | 0.11 |

| 150μm | 1 | 0.11 | 100 | 0 |

| Pan | 0 | 0 | 100 | 0 |

1. Determine the test sieve to be selected according to the inspected material and the corresponding standard.

2. Stack the test sieves on the tray seat in order from large to small, from bottom to top, and position the test sieves by grooves or positioning screws.

3. Put the material to be tested into the test sieve at the top, (or cover the upper cover of the test sieve), then press the test sieve with the sieve head set on the wire column, and screw it tightly.

The nut on the spool to compress the test sieve. (Note: Both sides should be the same force, and then use the locking screw to lock.)

4. Put the timer switch in the corresponding required position, (pay attention to reading the timer description, the time set by different settings is different) and then turn on the power switch,

The test sieve starts working.

5. After the standard test sieve stops working, unscrew the nut on the wire column, remove the sieve head, and carefully remove the test sieve.

Dahan Sieve Testing Equipment manufacturer produces various laboratory materials Sieve Testing Equipment, such as: motor type, electromagnetic type, ultrasonic type, flapping type, top impact type, magnetic levitation type, etc. The model specifications are 75mm, 100mm, 200mm, 300mm, 400mm ,500mm, 2-2000-mesh sieve mesh is optional, the sieve frame material is stainless steel, brass, we support special design according to user needs, welcome to buy!

Laboratory Sieve Shaker Machine

Tools for detecting particle size composition and particle size of powdery, granular and liquid materials from 20µm to 125mm

Measuring range: 20µm-125mm

Price: $600.00 - $980.00/Set

Particle size determination, separation and classification of powders, bulk goods and suspensions in the laboratory

Mesh sizes: 20 µm - 40 mm

Price: $523.00 - $936.00/Sets

Use water or other liquids to remove fines from the separation process and detect the particle size of insoluble materials.

Mesh sizes: 20 microns-5 mm

Price: $656.00 - $975.00/Sets

Particle separation and particle size distribution detection for various materials

Measuring range: 20µm-25mm

Price: $600.00/Set

Sieve Testing(Analysis) Equipment Price

The price of Sieve Testing Equipment is $150-$2000 Sieve Testing Equipment is mainly used in various laboratories to separate and classify powders, granules, and suspensions. There ...

Types of Sieve Testing Equipment

Sieve Testing Equipment is divided into four types: conventional models (200mm, 300mm, 400mm, etc.), ultrasonic laboratory vibrating sieves, slapping vibrating sieves, and magnetic ...

Conversion table between classification of standard test sieve and mesh aperture

standard test sieve is mainly used in various laboratories, laboratories, research institutes, inspection rooms, etc., for random inspection, inspection and testing of small samples...

What is the use of sieve shaker in laboratory?

Laboratory Sieve Shaker Machine is an instrument used for material particle classification, particle size detection and analysis....

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap