Thursday June-05 2025 16:33:16

ASTM standard soil analysis sieve is a special test sieve manufactured according to the American Society for Testing and Materials (ASTM) E11 standard, mainly used to accurately determine the particle size distribution of soil particles. This type of sieve has a series of strictly calibrated meshes. The common sieve frame diameter is 8 inches or 12 inches. The sieve aperture ranges from 4 inches (about 101.6mm) to No. 400 (about 38μm). Commonly used No. 4, No. 10, No. 40, No. 200, etc. meet the screening needs of coarse-grained to fine-grained soil samples.

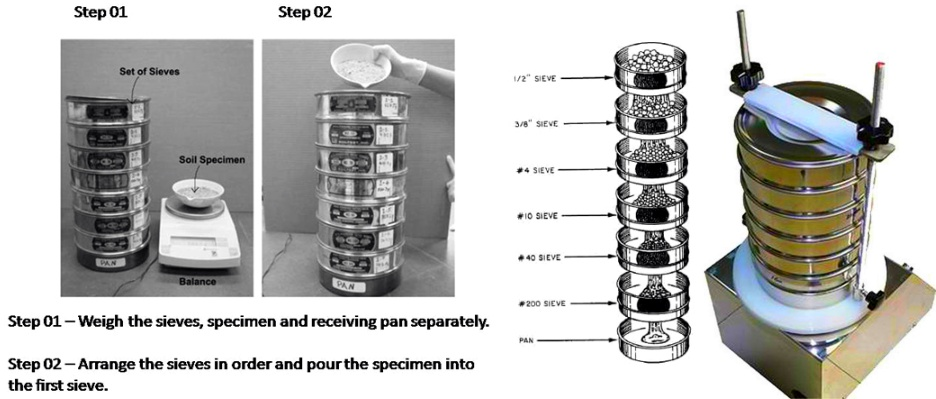

During the screening process, multiple sieves are stacked in order from large to small according to the aperture, and soil particles of different particle sizes are separated by manual or mechanical vibration. They are used in engineering and scientific research fields such as soil classification, foundation design, and particle size distribution analysis. The sieve is equipped with a cover and a receiving tray to prevent sample scattering and ensure the integrity and accuracy of the screening process.

ASTM (American Society for Testing and Materials) international standards, especially ASTM E11 standards, specify the specifications of test sieves. This means that the mesh size, wire diameter, frame material and manufacturing tolerance of the sieve must meet these strict requirements to ensure the accuracy and repeatability of the analysis results.

Common diameters of ASTM test sieves are 8 inches (203 mm) and 12 inches (305 mm). There are also other sizes such as 3 inches, 6 inches, 10 inches, 18 inches, etc., depending on the test requirements and sample volume. The height of the sieve frame is also standard height and half height to accommodate samples of different volumes. Common particle size number examples (ASTM No.):

|

ASTM sieve number |

mesh size (mm) |

|

No. 4 |

4.75 mm |

|

No. 10 |

2.00 mm |

|

No. 40 |

0.425 mm |

|

No. 100 |

0.150 mm |

|

No. 200 |

0.075 mm |

ASTM standard soil analysis sieves are mainly divided into round hole sieves and square hole sieves according to their mesh shape. These two types of sieves have their own characteristics and scope of application, and play different roles in soil particle size analysis.

The sieve surface of the round hole sieve is made of a perforated plate with circular holes. This sieve is usually used to screen coarse particles with larger particle sizes, such as gravel, coarse sand, and coarse aggregates in building materials. Due to the characteristics of the round hole, it can more accurately control the size of the maximum passing particles, especially suitable for screening applications with strict requirements on particle shape. In soil analysis, round hole sieves are often used for preliminary large particle separation, such as separating stones and gravel larger than 4.75mm (about 4 mesh) or even larger from soil samples. Its mesh range is relatively wide, ranging from large apertures of millimeters (such as 20mm, 10mm, 5mm, etc.) to smaller millimeters (such as 1mm), but it is usually not used for very fine powder screening. The advantage is that its screening results are more uniform and not easy to clog, which is suitable for samples with irregular particle shapes.

The screen surface of the square hole sieve is composed of a woven wire mesh with square mesh. The pore size range is very wide, from large pores (such as 75mm, about 3 inches) to micron-sized pores (such as 75µm, i.e. 200 mesh; 45µm, i.e. 325 mesh; and even smaller 20µm, i.e. 635 mesh). This type of sieve is widely used in soil particle size analysis, and can accurately separate soil samples into different particle sizes such as sand, silt and coarse particles of clay. In soil analysis, a series of square hole sieves are usually used for continuous screening, such as No. 4 sieve (4.75mm) down to No. 10 sieve (2.00mm), No. 40 sieve (425µm), No. 200 sieve (75µm), etc.

The frame of ASTM standard sieves is usually made of brass or stainless steel, and the screen is mostly stainless steel wire mesh. Stainless steel is more durable and corrosion-resistant, suitable for a variety of applications. A complete set of soil analysis sieves usually includes:

A series of sieves (Sieves): These sieves have square meshes of different sizes (usually expressed in millimeters, microns or mesh numbers) and are used to separate soil particles of different particle sizes. Common sieve sizes range from large apertures (such as 75mm, 50mm, 25mm, etc.) to small apertures (such as 4.75mm, 2.00mm, 850µm, 425µm, 75µm, etc.).

Pan: Located at the bottom of the sieve stack, it is used to collect the finest particles that pass through all sieves (usually particles smaller than 75µm, which may need to be further analyzed by hydrometer method).

Lid (Lid/Cover): Placed at the top of the sieve stack to prevent the sample from spilling or being contaminated during the sieving process and to maintain the sealing of the sieving process.

The discs and covers equipped with ASTM standard soil analysis sieves play an important role in soil particle size analysis, not only protecting the integrity of the sample, but also ensuring the accuracy of the experimental results.

The cover of the sieve can effectively prevent the flying or loss of fine particles during the sieving process, which is essential for maintaining the original state of the sample, especially when performing precise analysis. The collection tray at the bottom is used to collect fine-grained soil that passes through the sieve for subsequent processing and analysis. This design is particularly suitable for laboratory environments and field studies, such as evaluating soil texture in the agricultural field to determine the most suitable soil conditions for the growth of specific crops; in construction projects, understanding the particle composition of soil is important for foundation stability and drainage system design; in environmental protection research, it can be used to monitor the distribution of pollutants in soils of different particle sizes. In addition, in the field of materials science, these sieves can also be used to perform particle size analysis on non-soil materials such as sand and gravel to support the research and development and application of new materials.

ASTM standard soil analysis sieves (with discs and covers) are indispensable experimental equipment for accurate and repeatable soil particle size analysis. If you need to know more about specific models, prices, applicable materials, specifications and related parameters, we can query and provide you with detailed information.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Ultrasonic Sieve test for Juice Powder

The ultrasonic sieve test for juice powder is a fine screening equipment designed for delicate, moisture-absorbing, and agglomerated materials...

Jun 05, 2025

ASTM standard soil analysis sieves with pan and cover

The main function of the ASTM standard soil analysis sieve (with pan and cover) is to accurately sepa...

Jun 04, 2025

Ultrasonic Sieve test for Juice Powder

Ultrasonic sieve test for juice powder is suitable for screening high-sugar juice powder that is easy...

Jun 04, 2025

Wheat flour ultrasonic test sieve

Wheat flour is easy to clog ordinary sieves due to easy agglomeration and electrostatic adsorption. T...

May 30, 2025

Millet sand ultrasonic test sieve

Millet sand ultrasonic test sieve is suitable for fine powder materials above 400 meshes, which can a...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap