![[field:title/]](/uploads/250523/2-250523164950153.png)

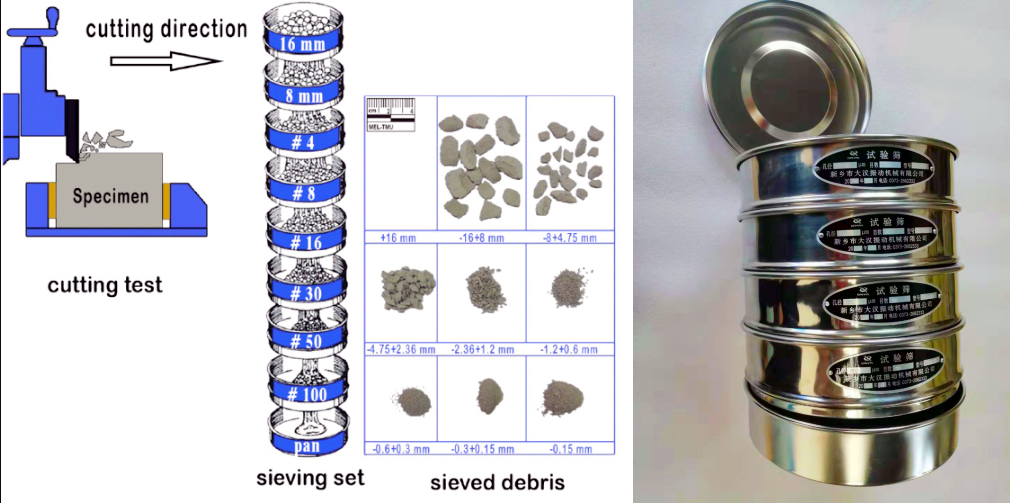

An aggregate test sieve is an experimental apparatus used to determine the particle size distribution in building materials. It consists of a series of metal sieves with different aperture sizes. By sieving step by step, the proportion of particles of each size in the aggregate can be determined, thereby evaluating its particle size distribution, uniformity, and applicability.

Screen mesh size 0.075~50mm, ensuring precise sieving.

Made of stainless steel, wear-resistant and corrosion-resistant.

Multi-layer design, diameter 200~450mm available.

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

Aggregate test sieves are typically multi-layered for particle size classification. Common test sieves generally have five to seven layers, with each layer having progressively smaller mesh sizes, from top to bottom: 40mm, 25mm, 19mm, 9.5mm, 4.75mm, 2.36mm, 0.6mm, etc. Particles remaining on the sieve are considered particles of that layer and fall to the next layer for further classification. Each layer corresponds to a different mesh size; for example, 4.75mm is approximately 4 mesh, 2.36mm is approximately 8 mesh, and 0.6mm is approximately 30 mesh. Multi-layered sieving allows for accurate determination of aggregate particle size distribution, providing data for concrete or asphalt mixture design.

Aggregate is a general term for granular materials such as sand and stone in building materials. Its particle gradation and other characteristics directly affect the strength and construction performance of concrete and mortar. Aggregate test sieve is a special equipment used to determine the particle gradation of aggregates. It is usually composed of multiple sieve layers with different sieve hole sizes, arranged in order from large to small. The sieve hole size covers multiple levels from 63mm to 0.075mm, which can classify coarse aggregate and fine aggregate.

Sieve analysis is a key tool in civil engineering to measure the particle size distribution of soils, especially coarse aggregates and gravel. Sieve analysis is more than just a tool to measure size; it is a critical quality parameter that ensures the structural integrity of building materials. The process requires the use of a series of sieves of varying mesh sizes arranged in descending order. The sample is sieved through these sieves, which determines the distribution of different particle sizes.

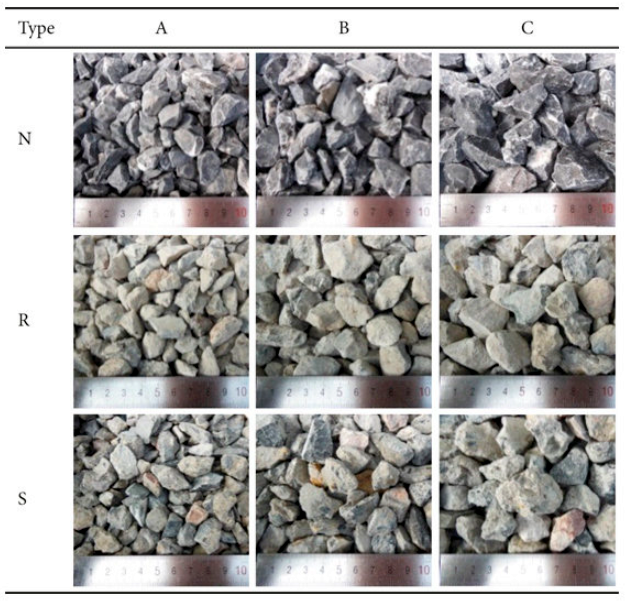

Another important aspect of sieve analysis is the distinction between coarse and fine aggregates through coarse sieve analysis. Coarse aggregates with diameters greater than 0.19 inches are primarily used as non-reactive fillers in concrete. Fine aggregates are more rounded in shape and smaller in size and are used to fill voids in materials such as mortar, stucco, and concrete. Sieve analysis of these aggregates gives us an idea of their particle size distribution, ensuring they are suitable for their intended use.

|

Project |

Coarse aggregate test sieve |

Fine aggregate test sieve |

|

Image |

|

|

|

Test object |

Coarse aggregate (such as crushed stone, pebbles) |

Fine aggregate (such as medium sand, fine sand) |

|

Sieve size range |

Generally 4.75mm and above (common sieve holes: 63mm, 31.5mm, 16mm, 8mm, 4.75mm) |

Generally 4.75mm and below (common sieve holes: 2.36mm, 1.18mm, 0.6 mm, 0.3mm, 0.15mm, 0.075mm) |

|

Number of screen layers |

usually fewer, coarser screen layers |

usually more, finer screen layers |

|

Screen material |

usually woven steel wire mesh or punched steel plate |

usually woven stainless steel wire mesh |

|

Main uses |

analyze the gradation of crushed stone and pebbles for concrete |

analyze the fineness modulus and gradation of sand for concrete |

|

Screening levels |

3-10 layers (adjusted according to standards, such as 5-20mm continuous gradation requires 5 layers) |

6 -8 layers (fineness modulus measurement needs to cover the entire particle size range) |

|

Purpose of particle grading |

Control aggregate particle size distribution to ensure concrete structural performance |

Control sand fineness modulus to affect concrete workability and strength |

Aggregate test sieves come in three types: tapping sieves, top-impact sieves, and experimental sieves. The differences between these three types in terms of material characteristics, number of sieve layers, and functions are as follows:

Tapping Sieve:Typically has 1 to 8 layers. Material is passed through the sieve mesh by tapping the sieve frame from top to bottom or side to side. The action is gentle, minimizing powder damage. Used for particle size distribution analysis and checking sieve uniformity. Suitable for medium-sized, dry particles such as sand, gravel, and ore powder.

Top-Impact Sieve:Typically has 1 to 8 layers. The sieve frame rotates horizontally and vertically with slight collisions, resulting in high sieving efficiency. Larger particles are less likely to clog the mesh. Used for precision particle size analysis and checking mixing uniformity. Suitable for coarse or irregularly shaped materials such as crushed stone and coarse sand.

Experimental Sieve:Typically has 1 layer (single-layer sieve) or 2 to 4 layers (multi-layer sieve). Manual or vibratory sieving is used. The sieve mesh can be quickly changed, making operation simple. Used for rapid sieving and particle size distribution testing in the laboratory. Suitable for dry powders, small particles, or materials with uniform particle size, such as cement, fly ash, and fine sand.

The main structure of an aggregate test sieve includes a sieve frame, a sieve mesh, a support frame, and a base. The sieve frame is used to fix the sieve mesh, which determines the particle size to be sieved. The support frame ensures the stability of the sieve frame, and the base bears the weight and facilitates vibration operation.

Sieve frame: generally round or square, made of stainless steel or brass, inner diameter and height set according to standards;

Screen: woven wire mesh or punched plate, precise sieve hole size, in line with relevant standards (such as 0.075mm to 63mm);

Screen cover and receiving tray: prevent sample scattering during screening and facilitate collection of undersize;

Pour a certain mass of aggregate sample into the top sieve, vibrate or shake to make aggregate particles fall in layers according to particle size, particles with particle size smaller than the sieve aperture pass through the sieve, and the final aggregate mass ratio retained by each sieve is the particle content in the particle size range, thereby drawing the aggregate particle grading curve.

Sample preparation: Dry the aggregate sample to constant weight, remove impurities, and weigh the sample of specified mass.

Assemble the sieve group: Stack the sieves in order from large to small aperture, place the receiving tray at the bottom, and cover the top.

Screening operation: Pour the sample into the top sieve, fix the sieve group and perform vibration screening (usually for 10-15 minutes) until the amount of passing through per minute does not exceed 0.1% of the total mass of the sample.

Weighing and calculation: Weigh the mass of aggregate retained by each sieve separately, and calculate its percentage of the total mass of the sample, which is the particle grading of the particle size range.

The Aggregate Test Sieve is characterized by its variety of sieve specifications, which can be selected according to particle size; its stable structural design, with the sieve frame and support frame closely fitted; and its flexible operation, which can be done manually or with vibration.

Standardization of sieve specifications: The sieve aperture strictly follows the relevant standards. Common apertures of sand detection sieves include 0.075mm, 0.15mm, 0.3mm, 0.6mm, 1.18mm, 2.36mm, 4.75mm, etc. Common apertures of stone detection sieves include 2.36mm, 4.75mm, 9.5mm, 16mm, 19mm, 26.5mm, 31.5mm, 37.5mm, etc. The sieve material is mostly metal wire (such as stainless steel), which is wear-resistant and corrosion-resistant.

Professional structural design: It is usually composed of multiple sieves with different apertures, with a base and a top cover to form a complete screening device. Common specifications of sieve diameters are 300mm, 200mm, etc. The height is adjusted according to the number of sieves, which is convenient for laboratory operation and batch testing.

Diversified operation methods: Suitable for small-scale testing or teaching scenarios, screening is completed by manually shaking the sieve group. Automated screening is achieved with the help of a vibrating screen machine (such as a top-impact vibrating screen machine), which is more efficient and suitable for large-scale testing.

| Particle Category | Nominal Particle Size Range | Standard Test Sieves | Usage |

|---|---|---|---|

| Coarse Aggregate | > 4.75 mm | 100, 80, 63, 40, 31.5, 25, 20, 16, 10, 5 mm | Forms the skeleton of the mixture and provides the main mechanical strength. |

| Fine Aggregate | 0.15 – 4.75 mm | 2.36, 1.18, 0.6, 0.3, 0.15 mm | Fills the voids between coarse aggregates to increase mixture density. |

| Filler / Powder | < 0.15 mm | 0.075 mm (sieve bottom) | Plays a key role in binding in asphalt mixtures; excessive amounts may affect overall performance. |

Depending on the level of automation and the size of the sieve assembly, the market price of a standard tapping sieve typically ranges from $1,000 to $4,000. The top-impact sieve, as a classic model, has a relatively simple structure and is more affordable, with a complete set generally costing between $1,500 and $2,500. As for the core consumables, the price of a standard metal-framed test sieve (usually 8 inches in diameter) is closely related to the mesh size and material. A single sieve made of ordinary stainless steel costs approximately $80 to $150, while a complete standard sieve assembly costs between $500 and $1,200.

|

serial number |

name |

Numerical value |

unit |

|

1 |

Can put sieve |

1~8 |

layer |

|

2 |

Screen diameter |

φ200/φ100/φ75 |

mm |

|

3 |

Sieve particle size |

0.025~3 |

mm |

|

4 |

noise |

less than 50 |

dB |

|

5 |

amplitude |

0~3 (stepless adjustment) |

mm |

|

6 |

electromagnetic vibration frequency |

3000 |

times/min |

|

7 |

Motor vibration frequency |

1400 |

times/min |

|

8 |

Dimensions |

435*350*720 |

length*width*height |

|

9 |

power supply |

220;50 |

V;HZ |

|

10 |

Total Weight |

55 |

KG |

Aggregate test sieve solutions typically begin by selecting standard test sieves, such as multi-layer sieves with an upper diameter of 100mm and a lower diameter of 5mm. A representative aggregate sample is then placed on the top sieve and vibrated for a certain period using a vibrating sieve machine to separate the particles by size. Finally, the weight of each sieve layer is weighed.

For example, in a project conducting gradation testing on crushed stone, a sample size of 10kg is taken using sieves with sizes of 50mm, 25mm, 10mm, and 5mm. After vibrating for 5 minutes, the residues on each sieve are recorded as 1.2kg, 3.5kg, 4.0kg, and 1.0kg, respectively. By calculating the percentages and plotting the sieve analysis curve, it can be determined whether the aggregate meets the construction requirements.

Aggregate test sieves play a key role in the entire aggregate industry chain. In the sand and gravel production process, enterprises use aggregate test screens to test the particle grading of freshly mined or processed aggregates, and judge whether the products meet the specifications based on the aggregate quality data retained at the screening level. For example, when producing machine-made sand, a test screen with an aperture of 0.075mm-4.75mm is used. If too much is retained in a certain particle size segment, the crusher and screening machine parameters can be adjusted in time to avoid poor grading leading to unsalable products.

At the concrete mixing station, technicians use aggregate test screens to conduct random inspections on the incoming sand and gravel to ensure that the aggregate grading is consistent with the concrete mix design. If the crushed stone is screened by a 2.36mm-37.5mm aperture sieve, and the particle size distribution deviates from the standard range, it will cause the concrete fluidity to deteriorate and the strength to be insufficient. Timely detection can avoid concrete quality defects caused by aggregate problems.

Before the construction of the road project, quality inspectors need to test the crushed stone used for base paving and use the test sieve to determine whether its gradation meets the density and strength requirements. In scientific research institutions, researchers use aggregate test sieves to carefully screen aggregates from different origins and processing technologies, analyze the relationship between particle gradation and material properties, and provide data support for the development of new aggregates or the optimization of existing production processes.

Fine aggregate test sieve is a special instrument for determining the particle gradation of fine aggregates...

test sieve for aggregate particle size

The test sieve for aggregate particle size is a set of wire mesh sieves that meet specific standards...

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

Test sieve sugar powder size detection

Test sieve sugar powder size detection is a physical detection method that uses multiple layers of standard sieves to grade and screen sugar powder particles to obtain particle size...

Test sieves for reliable sieve analysis

Test sieves for reliable sieve analysis use high-precision stainless steel test sieves with mesh conforming to international standards, ensuring accurate and reliable particle size ...

Laboratory woven wire mesh sieves

Laboratory woven wire mesh sieves are screening tools made of 250 mm stainless steel frame and precision woven wire mesh. The high quality of the equipment ensures reliable screenin...

Sieve Mesh is a metal or non-metal device used to separate materials. Its mesh count refers to the number of holes per square inch. It sorts powders by particle size through vibrati...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap