![[field:title/]](/uploads/allimg/250612/2-250612164T00-L.png)

Belt conveyor motor is the core power device that drives the belt conveyor to operate. It is usually an electric motor. It drives the conveyor belt to move by providing rotational torque and is used to transport materials.

Function: Convert electrical energy into mechanical energy

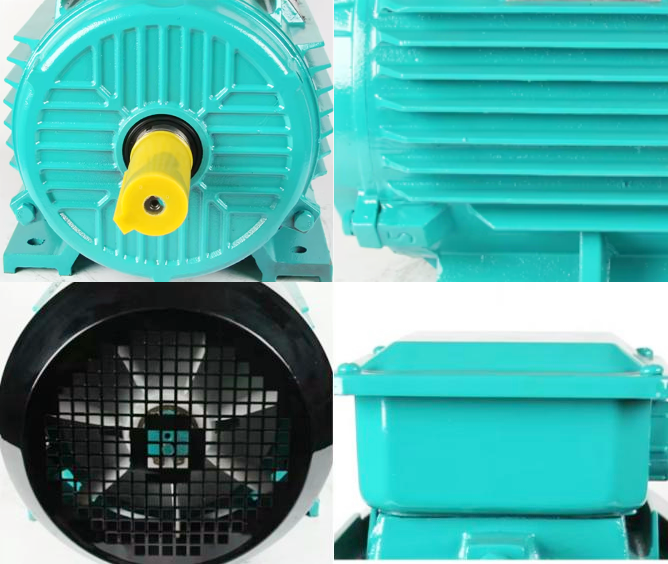

Voltage: 380V three-phase AC

Protection level: Commonly IP54 and IP55, outdoor type may be higher

Installation method: Horizontal installation is the most common, some use flange installation or vertical structure

Belt conveyor motor refers to an electric drive device installed on the belt conveyor to drive the conveyor belt to operate, thereby realizing continuous transportation of materials. It is one of the core power sources of belt conveyors and is usually used in conjunction with reducers, drive rollers and other components.

Belt conveyor motor is an electric device that converts electrical energy into mechanical energy, drives the conveyor belt to rotate through a drive device, and realizes material handling. It is generally a three-phase asynchronous motor, but explosion-proof motors, speed-regulating motors or variable-frequency motors can also be used in special occasions.

The belt conveyor motor is the core component of the belt conveyor, responsible for providing power to drive the conveyor belt.

①Provide driving force: overcome various resistances (friction, lifting resistance, inertia, etc.) in the operation of belts and materials, and drive the belt to move continuously.

②Control speed: determine the belt running speed through the motor speed (usually with a reducer), thereby controlling the conveying volume.

③Start and stop control: realize the start, stop and possible speed regulation of the conveyor (if a variable frequency motor is used).

In most industrial belt drive applications, three-phase AC induction motors are the most common choice, usually used in conjunction with a reducer to form a gear motor. For occasions where speed regulation is required, a frequency converter will be additionally equipped. DC motors are mostly used in belt drive systems that require speed control accuracy and response speed.

①AC induction motor: This is the most common and widely used motor type in belt drive systems. High efficiency, especially three-phase induction motors have high efficiency under rated load; wide range of applications, from small conveyors to heavy industrial equipment. Applicable to most belt drive applications, especially those that require constant speed operation and do not require high speed control accuracy, such as general belt conveyors

②AC synchronous motor: In some specific applications, synchronous motors are also used for belt drives. Accurate speed synchronization: The rotor speed is strictly synchronized with the power frequency without slip; high efficiency and high power factor, excellent performance under rated load, suitable for occasions with extremely high speed synchronization requirements, such as the coordinated operation of multiple devices

③DC motor: By adjusting the voltage or current, a wide range and smooth speed adjustment can be achieved, and the starting torque is large, which is suitable for applications that require frequent start and stop and fast response. Suitable for conveyors that require precise speed control (such as assembly lines) and belt drive systems that require frequent start and stop, forward and reverse rotation.

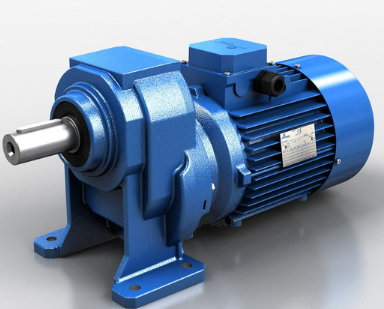

④Gear motor: Gear motor is an integrated combination of motor and reducer (gearbox). The reducer converts the high speed of the motor into a low speed, high torque output, which is very suitable for driving heavy-load belts. Applicable to most belt conveyors that use a combination of motor and reducer, especially in situations where large torque and lower conveying speed are required.

|

Conveyor model |

motor power |

conveying capacity |

conveying length |

matching reducer |

|

B500 fixed belt conveyor |

2.2kW |

60t/h |

10m |

RV worm gear reducer |

|

B650 mobile belt conveyor |

3kW |

100t/h |

15m |

F series reducer |

|

B800 explosion-proof belt conveyor |

5.5kW |

150t/h |

20m |

explosion-proof motor + K series |

Belt conveyor motors are usually used in conjunction with reducers to form a drive device. Its basic working principle is as follows:

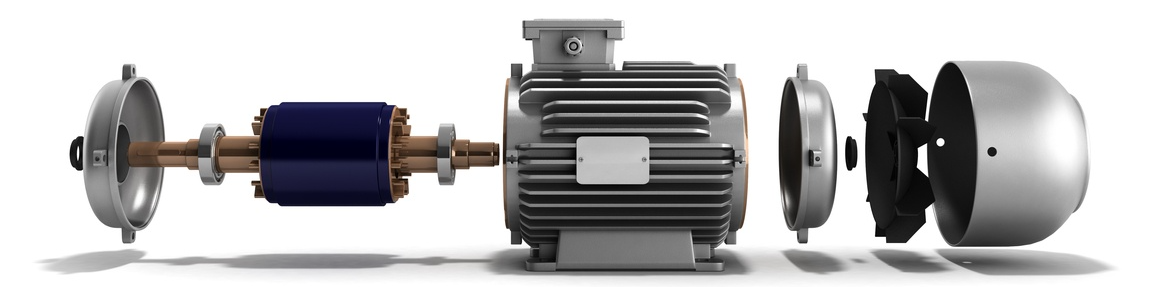

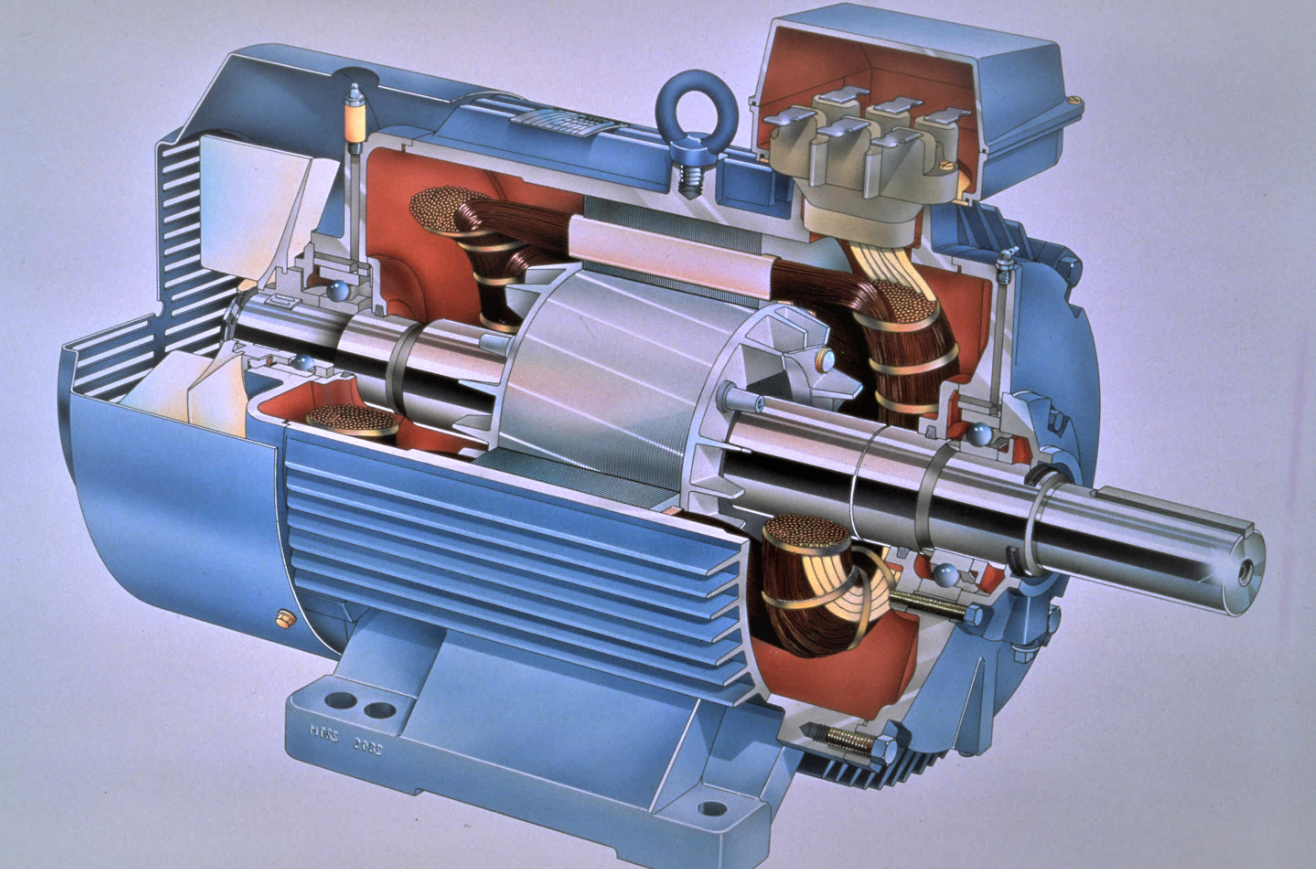

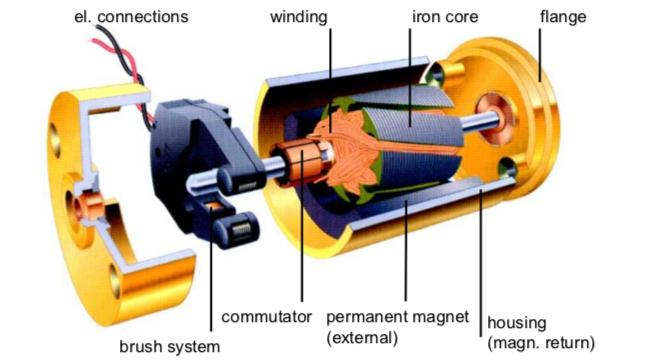

①The motor converts electrical energy into rotational mechanical energy. When the stator coil inside the motor is energized, a rotating magnetic field is generated to drive the rotor to rotate.

②The reducer reduces the speed and increases the torque. The output speed of the motor is usually high. Through the gear transmission of the reducer (such as a gear reducer, planetary reducer, etc.), the speed is reduced to the working speed required by the conveyor belt, and the torque is greatly increased to overcome the resistance of the conveyor belt and the material.

③ Power is transmitted to the drive roller. The output shaft of the reducer is connected to the drive roller of the belt conveyor, and the friction between the roller and the conveyor belt drives the conveyor belt to run continuously.

Heavy industry: high-power asynchronous motors (above 100kW) are used for mine belt conveyors to cope with heavy loads of ore;

Light industry: servo motors are used in assembly lines in electronics factories to achieve 0.1mm positioning accuracy;

Food and medicine: DC motors with stainless steel housings meet hygiene standards (such as IP69K) to prevent pollution;

Logistics and warehousing: variable frequency asynchronous motors + PLC control, dynamically adjust speed according to cargo flow, save energy and reduce consumption.

The motor of the belt conveyor is usually installed at the driving end of the conveyor as a set with the reducer. Common locations include:

Connected to the head roller (driving roller)

Installed separately on the frame and connected to the roller through a coupling

Some conveyors also use electric rollers, that is, the motor is built into the roller to achieve the integration of the motor, reducer and roller

Dahan Machinery is a manufacturer specializing in the production of conveying and lifting equipment. It has rich experience and technology in the field of belt conveyors and can provide various types and specifications of belt conveyor equipment and supporting motors.

Company Profile: Xinxiang Dahan Machinery Co., Ltd. has gone through 12 years of growth, and its service chain runs through preliminary consultation, scheme design, equipment production, installation and commissioning, and accessories supply.

Product Features: Dahan Machinery's belt conveyor motor adopts a low-power design, which can save up to 60% of electricity and significantly reduce operating costs. It has high conveying efficiency and a speed of up to 120m/min, which is 40% faster than similar products and has a larger conveying volume per unit time.

User Guarantee: Provide users with 30-day price guarantee, 30-day quality problem refund, and 365-day free maintenance. We also provide free machine trials with materials, reception by dedicated personnel, regular return visits, after-sales tracking, and 7×24 hours online customer service. If you need to know the quotation or specific model configuration, you can get the latest information through Dahan Machinery's official website or official sales channels.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

Chemical Material Standard Laboratory Vibrating Sifter

Chemical Material Standard Laboratory Vibrating Sifter is a precision equipment used for particle size analysis and screening and grading of chemical materials. It uses electric vib...

The main purpose of the herbal powder lab sieve is to achieve particle size classification and impurity separation of herbal powder, ensuring that the powder meets the preparation r...

Fine aggregate test sieve is a special tool for analyzing the particle gradation of fine aggregate (such as natural sand and machine-made sand) in building material testing. The cha...

Soil sieving analysis is done by dry or wet sieving, using a series of standard sieves to separate soil particles by size. Dry sieving is suitable for coarse-grained soils, with dir...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap