![[field:title/]](/uploads/250401/2-250401112005b6.jpg)

Brass sieve shaker is a specialized equipment used for screening particles and powder materials. Its screen mesh or frame is made of brass material, which has the characteristics of corrosion resistance, good conductivity, and easy processing.

model: Φ200mm、Φ75mm、Φ100mm

Supply cycle: 3-7 working days (please consult Dahan for details)

Technical parameters: Adopting the national standard GB6003.1-1997

Mesh size: 2.36mm-0.038mm

Application scope: Scientific research and production in metallurgy, powder, chemical, pharmaceutical, building materials, geology, national defense and other departments

Product Summary:

The frame material of brass sieve shaker is brass, and the mesh material is copper wire woven mesh

Adopting the national standard GB6003.1-1997

The basic size of the mesh is 2.36mm-0.038mm

Compliant with international standard ISO3310-1:1990 R20/3, R20, R40/3 series

Brass sieve shaker is a screening equipment made of brass material, mainly used for screening and grading materials such as powder and particles. Brass material is often used to make screen mesh due to its good conductivity, corrosion resistance, and ease of processing. Brass sieve shaker is a device that uses vibration generated by a vibration motor to make the material move in three dimensions on the brass sieve mesh, thereby achieving material screening and grading.

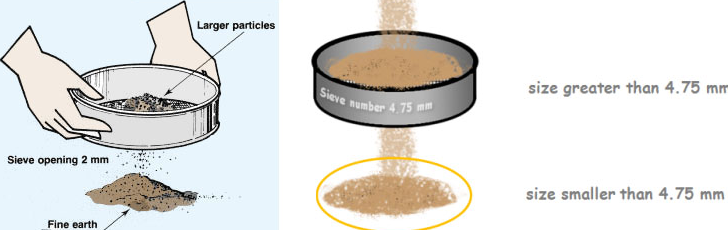

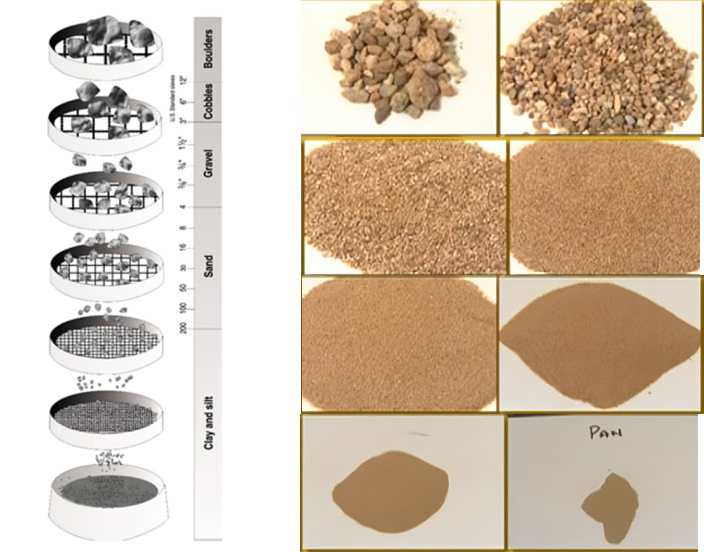

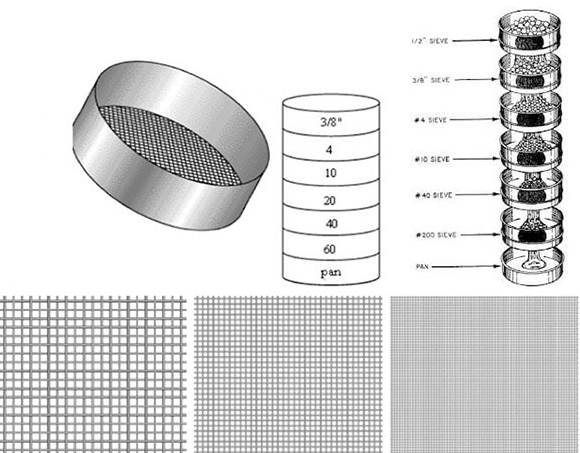

Brass sieve shaker generates vibration through a vibration motor and transmits it to the brass screen mesh. The material undergoes jumping, rolling, and other movements on the sieve. Materials smaller than the sieve aperture pass through the sieve, while materials larger than the sieve aperture are blocked on the sieve. By using multiple layers of screens with different pore sizes, multi-level grading of materials can be achieved.

1. Material grading: Brass sieve shaker separates materials according to particle size through brass mesh screens with different aperture sizes, obtaining materials with different particle size ranges.

2. Impurity removal: Brass sieve shaker can remove impurities and foreign objects from materials, improving the purity and quality of materials. For example, in the production process of metal powder, larger particles or impurities mixed in can be removed.

3. Product quality control: By screening, brass sieve shaker can ensure that the particle size distribution of material meets product quality standards, and improve the stability and consistency of product.

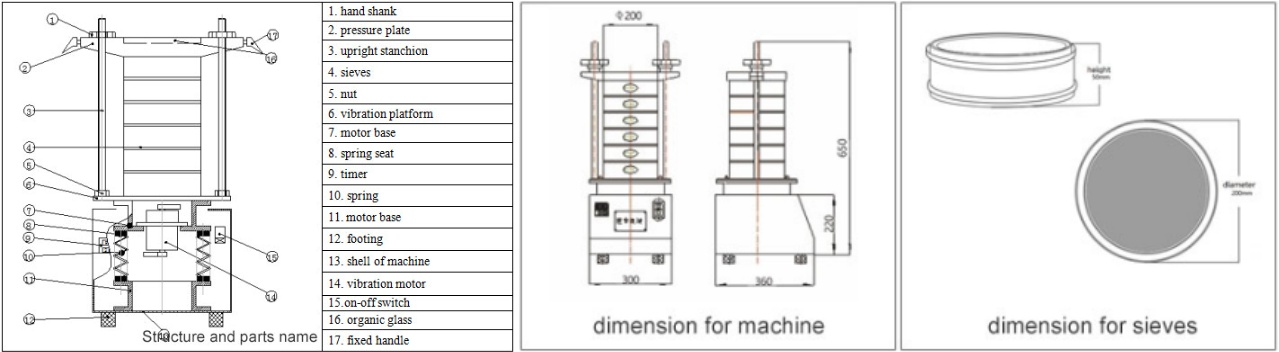

The design of the brass sieve shaker includes fixing brass nuts, pressure plates, and other components, all of which are made of high-quality SUS304 stainless steel refined and processed, and can be flexibly matched with each other. The whole machine is exquisitely designed, reliable in quality, lightweight, small in size, and easy to place and move for use. Accurate screening accuracy and high efficiency, capable of screening up to 0.025-3mm; Equipped with time relay control, the inspection time is accurate in minutes and seconds; Clever base shock absorption design can effectively shield the vibration of equipment on the workbench during operation.

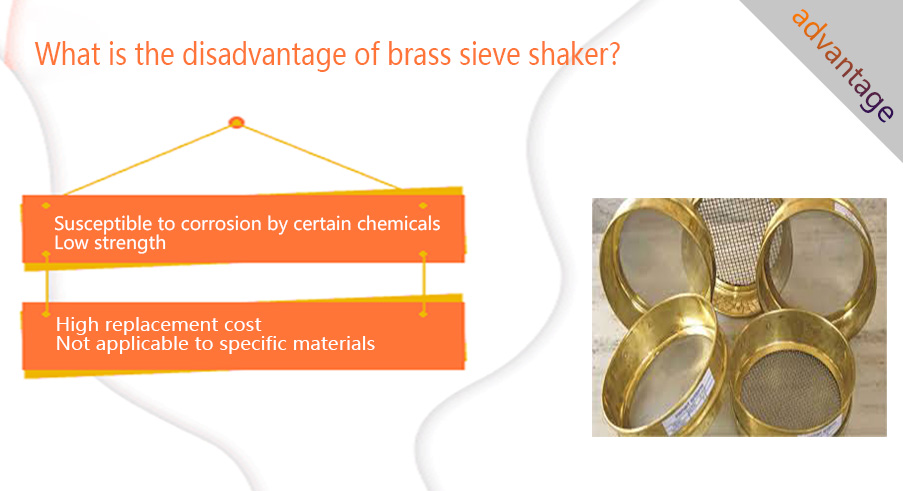

1. Susceptible to corrosion by certain chemicals: Although brass has good corrosion resistance to water and moisture, it may still corrode in strong acids, strong alkalis, or certain specific chemicals. In highly corrosive environments, the service life of brass sieve shakers may be shortened.

2. Low strength: Brass has lower mechanical strength than steel or other alloy materials, and is prone to deformation or damage under high loads or high-intensity vibrations. In high-intensity screening scenarios, the service life of brass sieve shakers may be shorter.

3. High replacement cost: When certain components of brass sieve shaker are severely worn and cannot be repaired, replacement is required. Due to the relatively high cost of brass materials and the cost of processing and manufacturing, the cost of replacing parts will also increase accordingly.

4. Not applicable to specific materials: Due to the characteristics of brass sieve shakers, they may not be suitable for screening certain materials with special requirements, such as particles sensitive to specific chemicals. Brass is susceptible to oxidation in air, which may lead to the formation of a surface oxide layer, affecting its appearance and performance

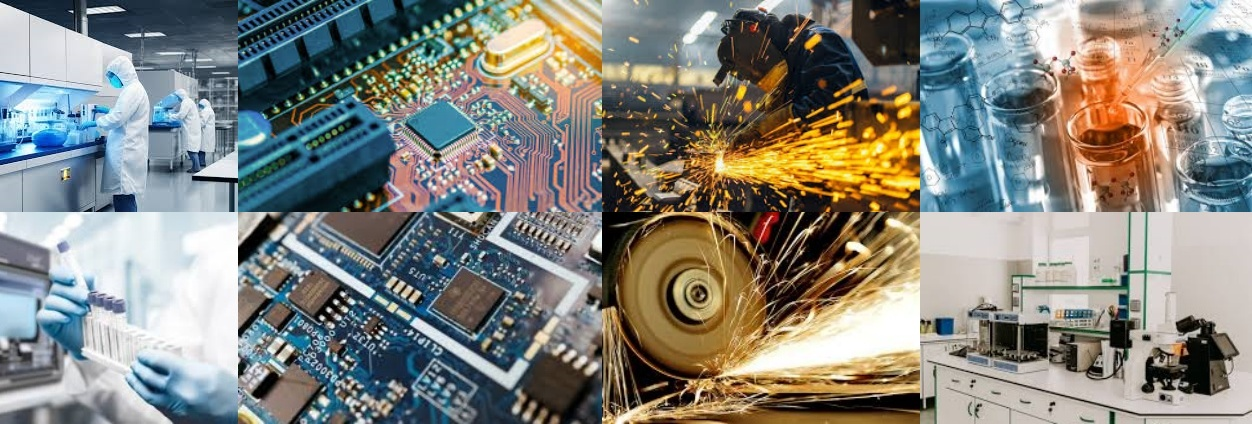

Laboratory applications: In the field of scientific research, brass screen vibrators can be used for laboratory research and analysis of granular materials, providing support for materials science and engineering research, and can also be used for screening and grading some special samples. For example, sieving samples that need to avoid electrostatic interference.

Electronic components industry: In the manufacturing process of electronic components, it is necessary to accurately screen some conductive powders. Brass screen vibrators can be used for screening these powders to ensure that the particle size meets the requirements. They can also be used for screening and grading powders, separating metal powders of different particle sizes to meet the requirements of different product specifications.

Abrasive and grinding tool industry: Brass screen vibrators are used for screening abrasives such as diamond sand, and are classified according to particle size. The wear resistance and corrosion resistance of brass mesh can meet the requirements of abrasive screening, which is used for screening and grading abrasives such as alumina, controlling the particle size of abrasives to meet the needs of different grinding processes.

1. Corrosion resistance: Brass sieve shakers have good corrosion resistance and are suitable for screening corrosive materials such as metal powders.

2. Conductivity: The good conductivity of brass sieve shakers helps eliminate the influence of static electricity on particles during the screening process, ensuring accurate screening results.

3. Stability: Brass sieve shaker has a stable structure, is wear-resistant, and can withstand long-term vibration without deformation or damage.

4. Wide applicability: Brass sieve shaker is suitable for screening various metal powders, such as copper powder, aluminum powder, etc., and can meet the screening needs of different granular materials.

|

Number |

Name |

Unit |

Parameter |

|

01 |

Screen frame |

Layers |

1-8 |

|

02 |

Screen frame diameter |

mm |

Φ200、Φ100、Φ75 |

|

03 |

Screening particle size |

mm |

0.038~5 |

|

04 |

Noise |

dB |

Less than 50 |

|

05 |

amplitude |

mm |

0~3 |

|

06 |

Vibration frequency |

times/minute |

1400 |

|

07 |

Dimensions |

Length, Width, and Height |

350:350:300+N * 50 |

|

08 |

Power Supply |

V; HZ |

220;fifty |

|

09 |

Whole machine weight |

Kg |

36 |

|

Mesh size |

Aperture(mm) |

Mesh size |

Aperture(mm) |

Mesh size |

Aperture(mm) |

|

2mesh |

12.5 |

45mesh |

0.4 |

220mesh |

0.065 |

|

3mesh |

8 |

50mesh |

0.355 |

240mesh |

0.063 |

|

4mesh |

6 |

55mesh |

0.315 |

250mesh |

0.061 |

|

5mesh |

6 |

60mesh |

0.28 |

280mesh |

0.055 |

|

6mesh |

4 |

65mesh |

0.25 |

300mesh |

0.050 |

|

8mesh |

3 |

70mesh |

0.224 |

320mesh |

0.045 |

|

10mesh |

2 |

75mesh |

0.2 |

325mesh |

0.043 |

|

12mesh |

1.6 |

80mesh |

0.18 |

340mesh |

0.041 |

|

14mesh |

1.43 |

90mesh |

0.16 |

360mesh |

0.040 |

|

16mesh |

1.25 |

100mesh |

0.154 |

400mesh |

0.0385 |

|

18mesh |

1 |

110mesh |

0.15 |

500mesh |

0.0308 |

|

20mesh |

0.9 |

120mesh |

0.125 |

600mesh |

0.026 |

|

24mesh |

0.8 |

130mesh |

0.112 |

800mesh |

0.022 |

|

26mesh |

0.71 |

140mesh |

0.105 |

900mesh |

0.020 |

|

28mesh |

0.68 |

150mesh |

0.100 |

1000mesh |

0.015 |

|

30mesh |

0.6 |

160mesh |

0.096 |

1800mesh |

0.010 |

|

32mesh |

0.58 |

180mesh |

0.09 |

2000mesh |

0.008 |

|

35mesh |

0.50 |

190mesh |

0.08 |

2300mesh |

0.005 |

|

40mesh |

0.45 |

200mesh |

0.074 |

2800mesh |

0.003 |

The price of brass sieve shaker may vary due to several factors, including size, capacity, function, brand, and purchasing region. The cost of brass sieve shaker depends on factors such as capacity, function, brand, and quality. For small-scale or laboratory use, prices may vary, while large-scale industrial applications may require advanced high-capacity experimental sieves. Before making a purchase, always evaluate your specific needs and compare options.

Brass Sieve Shaker drives the screening equipment through vibration, improving screening efficiency, accuracy, and stability, while solving problems such as screen clogging, particle agglomeration, and material pollution. Its unique material properties make it widely applicable in fields such as food, medicine, chemical engineering, and metal powder screening, and it is an indispensable key component in screening equipment.

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control, and is widely used in food, chemical, pharmaceutical and o...

Laboratory Lactose Stainless Steel Test Sieve

Laboratory lactose stainless steel test sieve is a device used to accurately determine the size distribution of lactose particles. It is often used for laboratory particle analysis ...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy...

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to sieve vitamin powder. It achieves sieving through vibration and slapping action. It is often used to remove impurities, grade part...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap