![[field:title/]](/uploads/allimg/250312/2-2503121A934U6-lp.png)

Ceramic materials test sieve refers to a test sieve used for grading, screening or performance testing of ceramic materials particles. This equipment is usually used in the ceramic industry or related scientific research fields to ensure that the particle size distribution of ceramic raw materials or finished products meets specific standards.

Number of layers: 1-8 layers

Screening particle size: 0.025mm-20mm

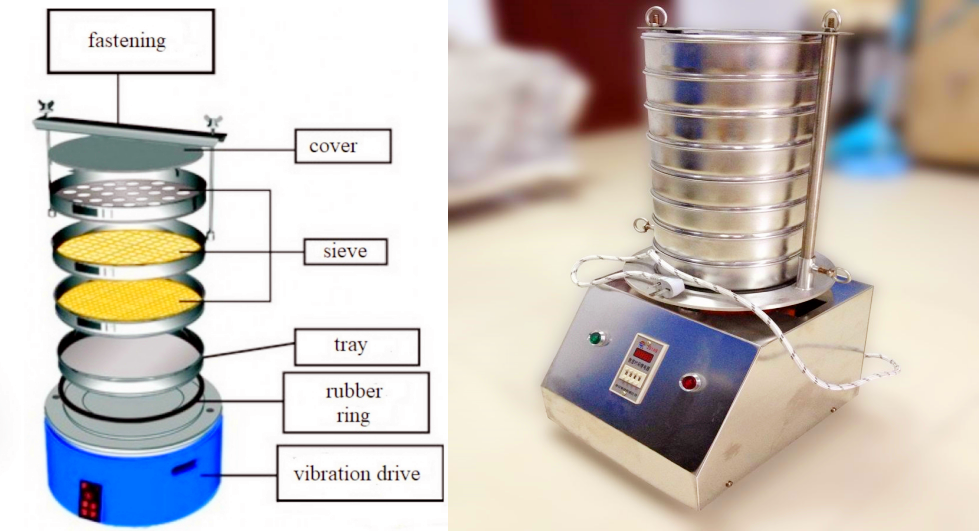

Structural composition: screen frame, screen, vibration motor, ultrasonic system (optional), control system, base and bracket.

Port: Any port in China (Mainland)or as you need.

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

Ceramic materials test sieve is a high-precision screening device used to detect and grade the particle size distribution of ceramic raw materials (such as kaolin, alumina powder, silicon carbide powder, ceramic glaze, etc.) to ensure that the materials meet the process requirements of ceramic manufacturing. The equipment is widely used in the ceramic industry, powder materials research, laboratory analysis, quality control and other fields.

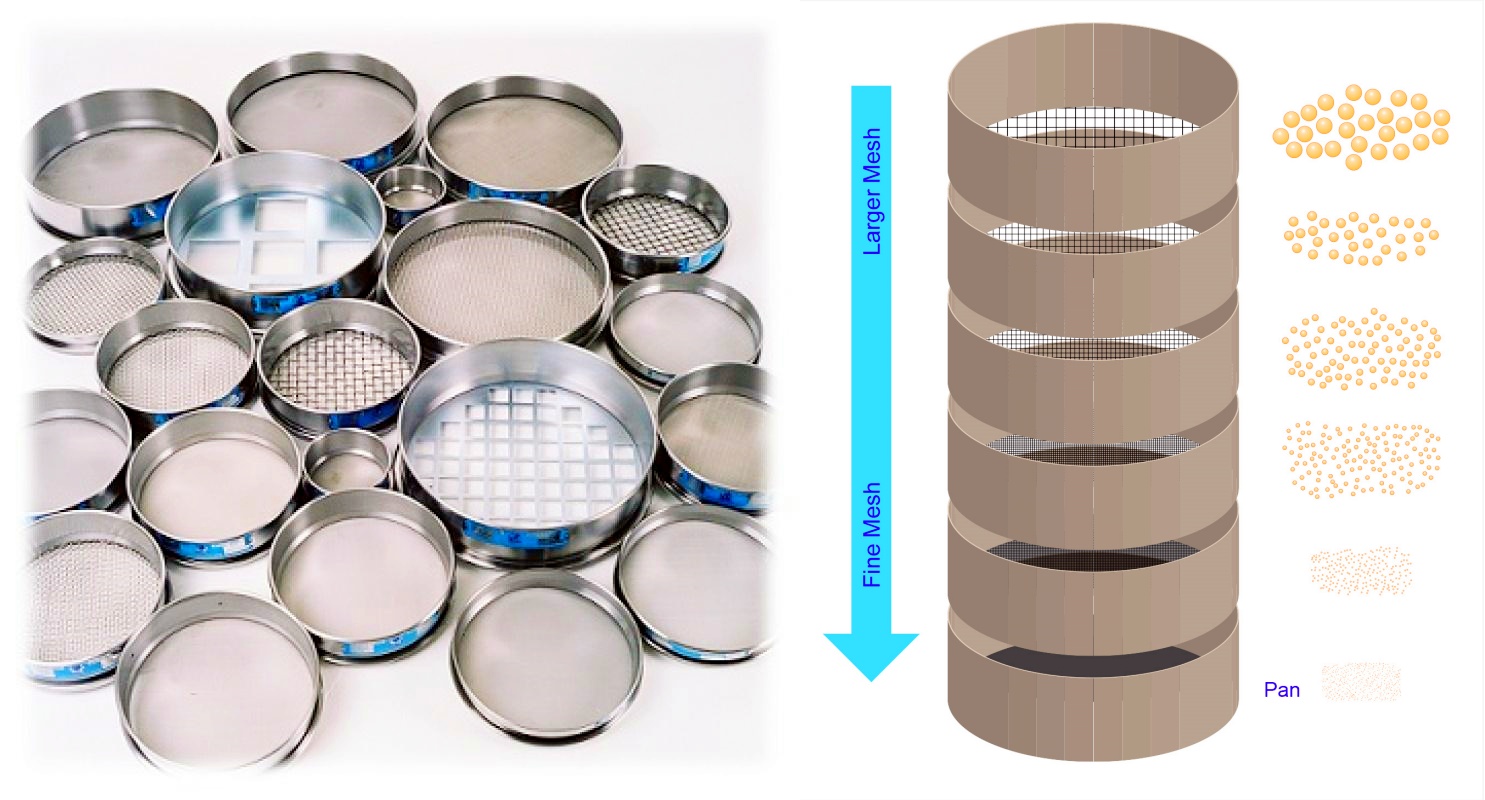

1. Screening process:

① Ceramic materials test sieve moves ceramic powder or particles on the sieve by vibration or shaking.

② Particles smaller than the sieve hole will fall through the sieve, while particles larger than the sieve hole will remain on the sieve.

③ By using sieves with different apertures, multi-level particle size classification of ceramic materials can be achieved.

2. Vibration mode: Ceramic materials test sieve is usually driven by a vibration motor or exciter to produce horizontal, vertical or three-dimensional vibration. The vibration frequency and amplitude can be adjusted to meet the screening needs of different ceramic materials.

1.Classification by screening method:

|

Screening method |

Picture |

Applicable materials |

Features |

|

Ordinary vibration screening |

|

Ceramic powder, glaze, granular ceramic |

Depends on vibration motor drive, suitable for most ceramic materials |

|

Ultrasonic screening |

|

Nano ceramic powder, electronic ceramic powder |

Applicable to ultrafine powder, prevent agglomeration, blockage, and improve screening accuracy |

|

Wet screening |

|

Ceramic glaze, slurry |

Applicable to liquid materials, prevent particle deposition,and improve glaze uniformity |

2. Classification by screen materials:

|

Materials |

Picture |

Features |

Applicable scenarios |

|

Stainless steel screen |

|

Corrosion-resistant, durable, suitable for general ceramic materials screening |

Screening of coarse and medium-grained ceramic materials |

|

Nylon screen |

|

Good elasticity, not easy to block, suitable for fine-grained ceramic materials screening |

Screening of fine and ultra-fine-grained ceramic materials |

|

Polyurethane screen |

|

Wear-resistant, impact-resistant, suitable for high-hardness ceramic materials screening |

Screening of high-hardness ceramic materials (such as ceramic abrasives) |

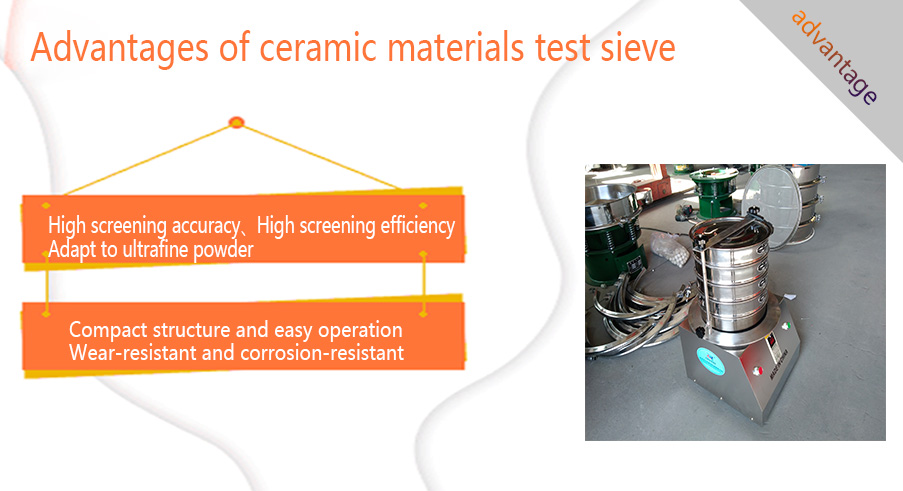

High screening accuracy: can screen to 200-500 mesh, meeting the fine screening needs of the ceramic industry.

High screening efficiency: using high-frequency vibration and ultrasonic cleaning technology to prevent screen blockage and improve screening effect.

Adapt to ultrafine powder: can be used for nano-level ceramic powder screening to ensure uniform distribution of ceramic powder.

Compact structure and easy operation: suitable for laboratories and small batch production, easy to change screens and easy to clean.

Wear-resistant and corrosion-resistant: made of stainless steel, suitable for high-purity ceramic powder screening.

|

Model |

sieve frame diameter (mm) |

sieve mesh number (mesh) |

sieve layer number |

sieve materials |

sieve frame materials |

screening method |

application scope |

|

DH-200 |

200 |

20 mesh-800 mesh |

1-8 layers |

304/316L stainless steel, nylon mesh |

304 stainless steel/PP plastic |

electromagnetic vibration |

laboratory fine screening, ceramic powder analysis |

|

DH-300 |

300 |

20 mesh-600 mesh |

1-6 layers |

304 stainless steel |

304 stainless steel/carbon steel |

motor vibration |

small batch ceramic powder screening, quality inspection |

|

DH-400 |

400 |

20 mesh-500 mesh |

1-5 layers |

304/316L stainless steel |

304 stainless steel |

vibration screening |

ceramic raw materials classification, fine ceramic powder screening |

|

DH-500 |

500 |

20 mesh-400 mesh |

1-4 layers |

304 stainless steel |

304 stainless steel |

vibration screening |

electronic ceramics, fine chemical powder screening |

|

DH-600 |

600 |

20 mesh-325 mesh |

1-3 layers |

304 stainless steel |

304 stainless steel |

vibration screening |

ceramic glaze screening, powder mixing |

|

DH-800 |

800 |

20 mesh-200 mesh |

1-3 layers |

304 stainless steel |

304 stainless steel/carbon steel |

vibration screening |

large batch ceramic raw materials screening, production testing |

Ceramic materials test sieves play an important role in ceramic raw materials screening, powder grading, abrasive screening, electronic ceramic materials screening, ceramic coating materials screening, nano-ceramic materials screening, product quality control, and scientific research and laboratory applications. Through precise screening and grading, the uniformity, purity and performance of ceramic materials can be ensured to meet the high requirements of different application scenarios.

|

Mesh number (Mesh) |

pore size (μm) |

pore size (mm) |

applicable scenarios |

recommended use |

|

10 |

2000 |

2.00 |

coarse-grained ceramic raw materials (such as refractory materials) |

preliminary screening, large particle classification |

|

16 |

1180 |

1.18 |

medium-grained ceramics (such as building ceramic aggregates) |

coarse particle classification |

|

20 |

850 |

0.85 |

ceramic raw materials initial screening |

medium particle classification |

|

30 |

600 |

0.60 |

ceramic particle classification |

medium to fine particle screening |

|

40 |

425 |

0.425 |

conventional ceramic powder |

conventional particle size analysis |

|

60 |

250 |

0.25 |

medium-fine ceramic powder |

medium-fine particle classification |

|

100 |

150 |

0.15 |

Fine-grained ceramic raw materials |

fine powder screening, impurity detection |

|

200 |

75 |

0.075 |

fine ceramic powder (such as alumina) |

ultrafine powder classification, particle size detection |

|

325 |

45 |

0.045 |

high-performance ceramics (such as zirconium oxide) |

ultrafine powder preparation |

|

400 |

38 |

0.038 |

ultrafine ceramic powder |

high-precision particle size analysis |

|

500 |

25 |

0.025 |

nanoscale ceramic powder |

special ultrafine powder screening |

The mesh number selection of ceramic materials test sieve needs to be determined according to the specific ceramic materials type and purpose:

Coarse screening (20-80 mesh) → particle size range is above 100μm, remove impurities and large particles, suitable for ceramic raw materials, such as ceramic abrasives, ceramic fillers, etc.

Fine screening (100-325 mesh)→particle size range is 45μm to 100μm, suitable for conventional ceramic powders, such as alumina powder, silicon carbide powder, etc.

Ultrafine screening (400-800 mesh)→particle size range is 15μm to 45μm, suitable for high-precision applications such as electronic ceramics, 3D printing ceramic powders, etc.

The working process of ceramic materials test sieve can be summarized as:

feeding→vibration→particle classification→cleaning and anti-blocking→materials output. Different screening methods can select suitable test sieve equipment according to the particle size, fluidity, water content and other characteristics of ceramic materials.

|

Ceramic manufacturing companies |

ceramic manufacturing companies use ceramic materials test sieves to screen and separate ceramic particles of different particle sizes to ensure product quality and production efficiency |

|

Ceramic laboratories |

ceramic research laboratories use ceramic materials test sieves for particle analysis and experiments to study the characteristics and applications of ceramic materials |

|

Ceramic particle suppliers |

ceramic particle suppliers use ceramic materials test sieves to separate and classify ceramic particles of different particle sizes to meet customer needs |

|

Ceramic engineering companies |

ceramic engineering companies use ceramic materials test sieves for particle analysis and screening in projects to ensure the smooth progress of engineering projects |

|

Ceramic research institutes |

Ceramic research institutes use ceramic materials test sieves for experiments and research to promote the development and innovation of the ceramic materials field |

Price advantage: Direct sales from the manufacturer, no middlemen, lower prices.

Technical advantage: 30 national patents, advanced equipment and technology.

Quality advantage: 23 years of production experience, products are exported to more than 70 countries.

Service advantage: Perfect pre-sales and after-sales service to build corporate reputation.

Customization advantage: Professional R&D team, tailor-made, perfect matching production line.

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control, and is widely used in food, chemical, pharmaceutical and o...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy...

Ultrasonic test sieve for wheat flour

Ultrasonic test sieve for wheat flour is a special device that combines ultrasonic technology with traditional screening principles to efficiently screen wheat flour. The device can...

Laboratory Lactose Stainless Steel Test Sieve

Laboratory lactose stainless steel test sieve is a device used to accurately determine the size distribution of lactose particles. It is often used for laboratory particle analysis ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap