Friday February-28 2025 19:01:44

Ceramic powder slap sieve is a device used for precise screening and particle size analysis of ceramic powder. It combines two modes of motion: vibration and flapping, which can effectively disperse and separate ceramic powder. It separates ceramic powder according to particle size to ensure the accuracy and reliability of screening results.

Ceramic powder slap sieve is particularly suitable for the following types of materials:

1. Fine powder: such as ceramic powder, metal powder, medicinal powder, flour, etc.

2. Materials that are prone to clogging: such as fibrous, flaky or sticky materials (such as starch, pigments, resins, etc.).

3. High-precision screening requirements: such as chemical raw materials, food additives, electronic materials, etc.

4. Wet or sticky materials: such as wet sand, mud, sticky powder, etc.

Ceramic powder slap sieve is placed through a series of screens with different pore sizes. Under the action of vibration and flapping, the powder particles pass through the sieve holes smaller than their size and are separated into the lower screen or receiving tray. By sieving layer by layer, ceramic powders with different particle size ranges can be obtained.

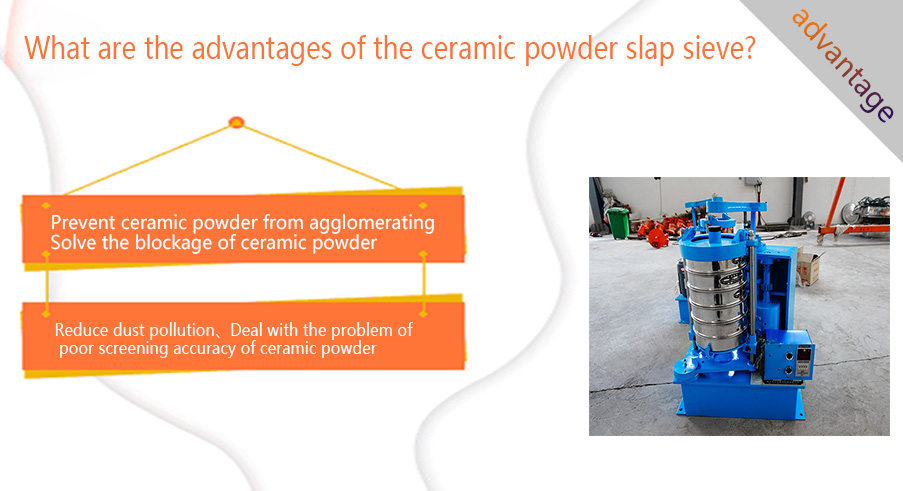

1. Prevent ceramic powder from agglomerating: Ceramic powder slap sieve impacts and vibrates the powder through the slap plate or slap ball on the screen. This action can effectively distribute the powder evenly on the screen surface, prevent the powder from agglomerating during the screening process, promote its dispersion movement, and avoid local accumulation.

2. Solve the blockage of ceramic powder: The vibration of ceramic powder slap sieve can make the ceramic powder particles attached to the edge of the screen hole fall off, preventing the particles from getting stuck in the screen hole and causing blockage.

3. Reduce dust pollution: Ceramic powder will generate dust during the screening process, which may cause pollution to the environment and operators. Ceramic powder slap sieve can reduce the generation and diffusion of dust and reduce dust pollution through closed design and dust suppression device.

4. Deal with the problem of poor screening accuracy of ceramic powder: Ceramic powder has a wide range of particle size distribution, and it is difficult to obtain accurate particle size classification. The vibration parameters and impact force of ceramic powder slap sieve can be precisely controlled to achieve high-precision particle size classification.

1. Particle size analysis of ceramic raw materials: Ceramic powder slap sieve is used to detect the particle size distribution of ceramic raw materials to ensure that the quality of raw materials meets the requirements. For example, when producing precision ceramics, the particle size of zirconium oxide powder needs to be strictly controlled to ensure the density and strength of the product.

2. Ceramic powder preparation: In the process of ceramic powder preparation, the ceramic powder slap sieve is used to control the particle size of the powder and improve the uniformity and dispersibility of the powder. When preparing electronic ceramic powder, the particle size of the powder needs to be strictly controlled to ensure the electrical properties of the product.

3. Ceramic product quality control: Ceramic powder slap sieve is used to detect the powder particle size of ceramic products to ensure the stability and consistency of product quality. When producing ceramic tableware, the particle size of the glaze needs to be controlled to ensure the surface finish and wear resistance of the product.

4. Scientific research and teaching: When studying new ceramic materials, ceramic powder slap sieve needs to analyze the particle size distribution of the raw materials to optimize the material preparation process. Through powder modification experiments and powder particle size analysis, detailed particle size data can be obtained, providing important experimental basis for material research.

Ceramic powder slap sieve can effectively solve the blockage problem in the screening process through the synergistic effect of slapping and vibration, improve screening efficiency and accuracy, and is widely used in food, chemical, pharmaceutical, ceramic and other industries.

Fertilizer belt conveyor is a kind of conveying equipment specially used for conveying fertilizer. It is usually composed of belts, rollers...

What Is An Electromagnetic Sieve Shaker?

Electromagnetic sieve shaker is a screening equipment used for testing and laboratory research. It is often used to screen and classify small batches...

Test sieve shaker is a laboratory equipment used for particle screening and classification, also known as laboratory shaker or laboratory vibrating...

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

High precision subdivision test sieve

High precision subdivision test sieve is a device used in the laboratory to perform fine particle size analysis on granular and powdery...

Feb 28, 2025

Ceramic powder slap sieve is a precision screening device that utilizes vibration and flapping motion...

Feb 27, 2025

Phosphate test sieve is used to screen different particle sizes in phosphoric acid samples and detect...

Feb 27, 2025

Baking powder test sieve is used to detect the distribution of powder particle size and evaluate the ...

Feb 27, 2025

Liquid food test sieves are used to screen solid particles, impurities or extract required ingredient...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap