![[field:title/]](/uploads/250418/2-25041Q43206162.png)

Chemical powders test sieve is a device used to screen chemical powders in laboratory or small-scale production. It classifies chemical powders according to particle size through the vibration of the sieve, and is widely used in chemical, pharmaceutical, food, metallurgy and other industries.

Number of layers: 1-8 layers

Screening particle size: 0.025mm-20mm

Structural composition: screen frame, screen, vibration motor, ultrasonic system (optional), control system, base and bracket.

Port:ny port in China (Mainland)or as you need.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

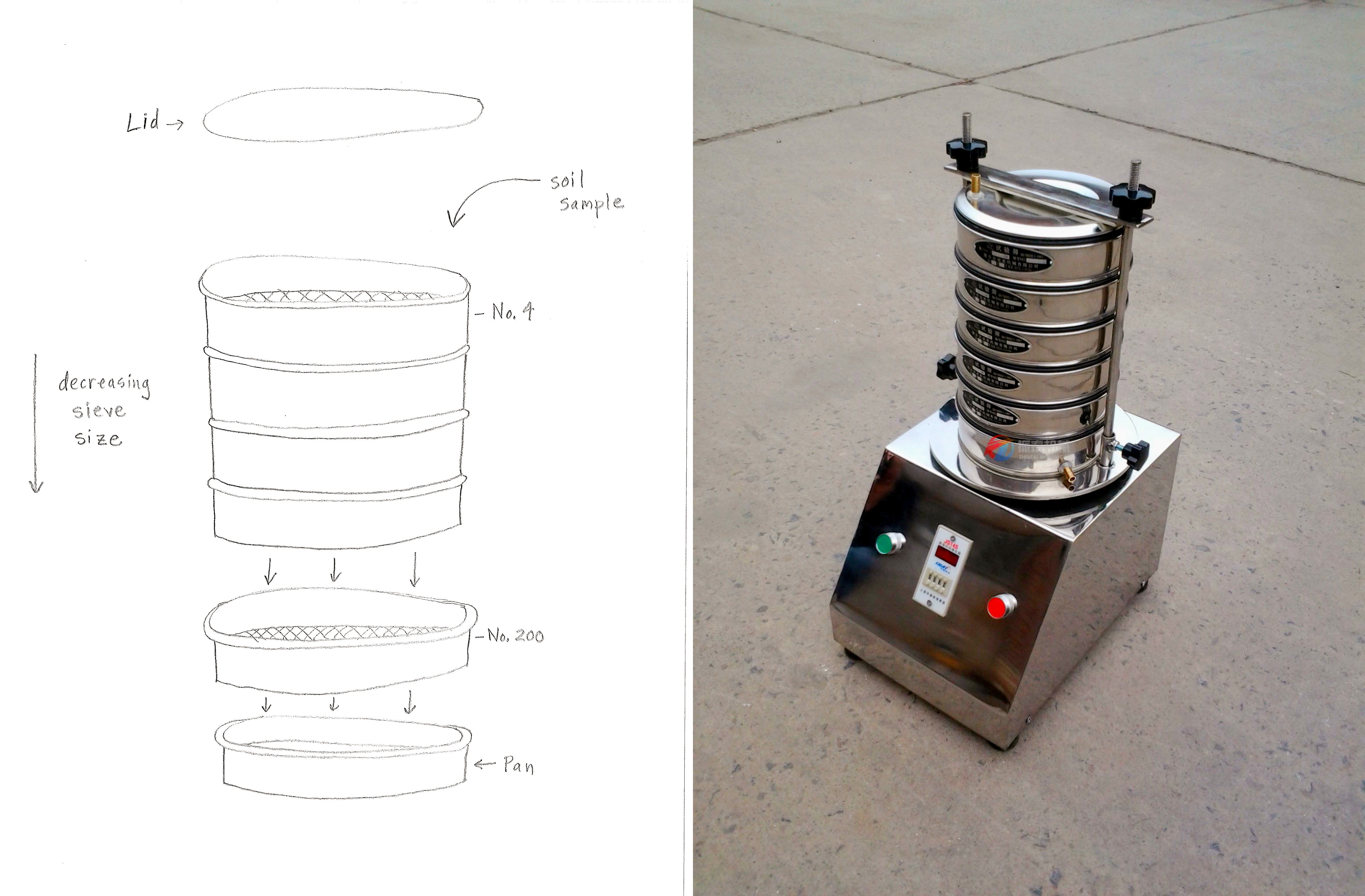

Chemical powders test sieve usually refers to a test sieve used for chemical powders particle size analysis, mainly used to determine the particle size distribution of powders by sieving. This equipment is widely used in chemistry, material science, pharmaceuticals, and powders metallurgy. Chemical powders test sieve is a device used in chemical laboratories and industrial production to perform particle size analysis and sieving of powdered chemicals. It separates powders samples into components of different particle sizes through a series of sieves with different mesh sizes, thereby determining the particle size distribution of the powders.

Sieving is the process of separating chemical powders particles of different sizes by using the mesh size of the sieve.

When the chemical powders sample passes through the sieve, the chemical powders particles smaller than the mesh size will pass through the sieve holes, while the chemical powders particles larger than the mesh size will be retained on the sieve.

By using a series of sieves with different mesh sizes, the chemical powders sample can be separated into components with multiple particle size ranges.

Classification by screen material and structure:

Chemical powders test sieves come in various types, each designed for specific applications and particle size ranges. Chemical powder test sieves are classified into various categories according to screen material, structure, screening method and application field.

| Wire mesh test sieve |

|

Screen made of wire | Most powders materials | Wide range of mesh size, widely used |

| Metal perforated plate test sieve |

|

Screen made of metal plate with holes | Large particles or high-density materials | Durable and wear-resistant |

| Electroforming thin plate test sieve |

|

Screen made by electroforming process | Ultrafine powders or high-precision requirements | Extremely high precision and uniform mesh |

Classification by screening method:

Standard Test Sieve

Features: Made of stainless steel or brass, usually a round frame with a diameter ranging from 75mm to 300mm.

Use: Widely used in laboratory particle size analysis, suitable for dry powders screening.

Applicable scenarios: Pharmaceutical (powders particle size detection), chemical (pigment classification), material science (powders distribution analysis).

Ultrasonic Test Sieve

Features: Adding an ultrasonic device to the vibrating screen, breaking the adhesion between powders through high-frequency sound waves, and can screen particles below 20μm

Purpose: Designed for ultrafine powders or high-viscosity powders.

Applicable scenarios: Nanomaterials (such as titanium dioxide), polymer chemical powders.

Electromagnetic sieve

Features: Generate high-frequency vibrations through electromagnetic exciters to make chemical powders move on the sieve to achieve particle size classification

Purpose: Applicable to chemical powders with a variety of particle size ranges

Applicable scenarios: Particle size analysis and quality control in chemical, pharmaceutical, food and other industries

Classification by application field:

| Standard soil sieve |

|

used to analyze the particle size distribution of soil | soil testing | accurate results, in line with soil analysis standards |

| Standard gravel sieve |

|

used to determine the particle size of sand, silt and clay | building material testing | applicable to the particle size analysis of gravel aggregates |

| Standard pharmacopoeia sieve |

|

used for analysis and testing of pharmaceutical powders, pharmaceuticals, and pharmaceutical particles | pharmaceutical industry | comply with pharmacopoeia standards to ensure drug quality |

Standard soil sieve used to analyze the particle size distribution of soil soil testing accurate results, in line with soil analysis standards

Standard gravel sieve used to determine the particle size of sand, silt and clay building material testing applicable to the particle size analysis of gravel aggregates

Standard pharmacopoeia sieve used for analysis and testing of pharmaceutical powders, pharmaceuticals, and pharmaceutical particles pharmaceutical industry comply with pharmacopoeia standards to ensure drug quality

| Application scenarios | Recommended mesh number range | Corresponding aperture range (μm) | Applicable powders examples | Remarks |

| Pharmaceuticals-powders particle size control | 60-200 mesh | 250-74 | Aspirin, starch, microcrystalline cellulose | Ensure solubility and tableting uniformity |

| Material science-nanopowder | 200-400 mesh | 74-38 | Titanium dioxide, aluminum oxide nanoparticles | Suitable for fine grading, requires ultrasonic vibration screen |

| Chemicals-pigment production | 80-325 mesh | 180-45 | Titanium dioxide, red iron oxide | Control color dispersion and coating texture |

| Food chemistry-additives | 100-250 mesh | 150-63 | Calcium carbonate, silicate | Avoid dust or affect food texture |

| Environmental science-Soil analysis | 50-200 mesh | 300-74 | Soil particles, heavy metal pollutants | Grading analysis of pollutant distribution |

| Powders metallurgy-Raw material screening | 40-120 mesh | 425-125 | Iron powders, copper powders | Ensure particle filling during pressing |

| Parameter name | Parameter range | Parameter name | Parameter range |

| Screening capacity | 0.1-100kg/h | Screen mesh | 4-400 mesh |

| Screen material | stainless steel, nylon, polyurethane, etc. | Vibration frequency | 10-60Hz |

| Amplitude | 0.5-5mm | Rotation speed | 10-100rpm |

| Ultrasonic frequency | 20-40kHz | Air flow speed | 1-10m/s |

| Motor power | 0.1-1.5kW | Equipment weight | 10- 100kg |

| Noise level | <75dB | Power requirement | 220V/380V, 50Hz/60Hz |

| Sieve frame diameter | 100-400mm | Number of screening layers | 1-5 layers |

| Screening accuracy | ±0.01-0.1mm | Cleaning method | manual cleaning, automatic cleaning |

| Safety protection | overload protection, emergency shutdown | Environmental adaptability | normal temperature, high temperature, low temperature |

Chemical powders test sieve is primarily used for particle size analysis and grading of powdered materials. It separates particles into different size ranges based on their dimensions, allowing for the determination of particle size distribution, which is critical for quality control, process optimization, and research in various industries.

Particle size analysis: Chemical powders test sieves are often used for particle size analysis. By screening sieves with different apertures, the size distribution of particles in chemical powders can be determined.

Particle separation: Chemical powders test sieves can separate particles of different sizes in chemical powders. By separating particles, the stability and effectiveness of drugs can be ensured.

Quality control: By testing the particle size and uniformity of chemical powders products, manufacturers can ensure that the products meet the specified quality standards.

Material screening: In material research and development, chemical powders test sieves can be used to screen materials of different particle sizes in order to select the most suitable materials for specific applications.

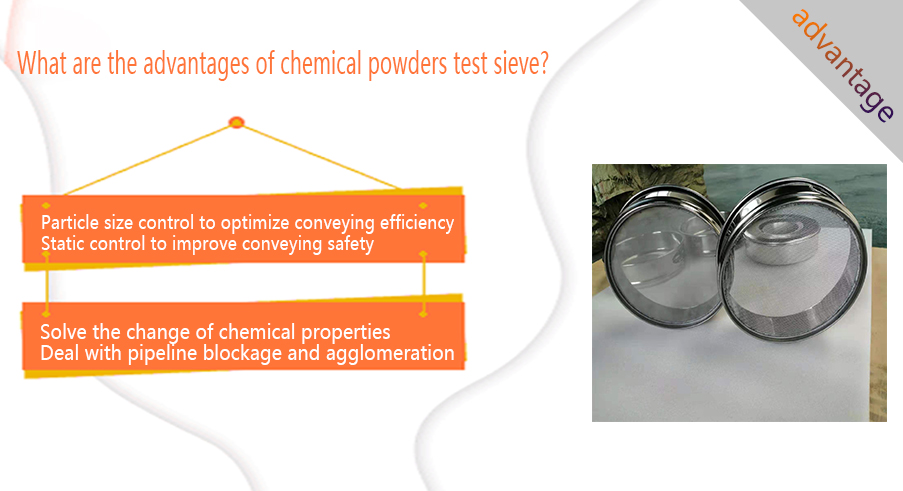

Particle size control to optimize conveying efficiency: Uneven particle size of chemical powders will cause problems such as blockage and bridging during conveying, reducing conveying efficiency. Too fine powders is easy to generate dust, which increases the difficulty of conveying. Through chemical powders test sieve for particle size analysis, the particle size distribution of the powders can be accurately grasped.

Static control to improve conveying safety: Some chemical powders are prone to static electricity during conveying, causing the powders to adsorb on the inner wall of the equipment and cause blockage. Chemical powders test sieve can analyze the static electricity generation characteristics of the powders and understand which particle size powders is more likely to generate static electricity.

Solve the change of chemical properties: Some chemical powders deteriorate due to friction, static electricity or oxidation during conveying, affecting performance. For powders that are prone to static electricity (such as plastic powders), chemical powders test sieve observes the adhesion during the test sieve screening, and adopts anti-static screens or grounding measures.

Deal with pipeline blockage and agglomeration: High viscosity or wet powders are prone to agglomeration in the conveying pipeline, causing blockage and affecting continuous production. Chemical powders test sieve can test the sieving efficiency of powders at different humidity levels and determine its agglomeration tendency.

Sieve frame: a frame used to fix the screen, usually made of stainless steel or plastic.

Sieve: select screens with different apertures according to the screening requirements to separate chemical powders of different particle sizes.

Vibration motor or rotating mechanism: provides vibration or rotation force to make the screen move.

Base: supports the entire equipment to ensure stable operation of the equipment.

Collection tray: used to collect sieved powders.

Chemical powders test sieve plays an important role in screening and analysis in many industries. It not only improves production efficiency, but also ensures product quality. In many fields such as chemical raw materials, pharmaceutical powders, food additives, plastic powders, nanomaterials, etc., chemical powders test sieves can provide accurate, efficient and stable screening services. By reasonably selecting screening equipment, material screening in the production process can be more efficient and meet industry standards.

|

|

|

| Quality control of pharmaceutical excipients | Optimizing pigment dispersion in coatings | Analyzing fertilizer particle size to ensure uniform application |

|

|

|

| Quality control of additives in polymer production | Specialty chemical raw material analysis | Environmental testing of chemical powders |

Dahan Machinery is a well-known manufacturer specializing in test sieves, vibrating screeners, and particle size analysis equipment, including sieves for chemical powders, pharmaceuticals, battery materials, and more.

Our company provides various types of chemical powder test sieves. If you want to know the specific content or price of our products, you can contact us by email. We also support product customization. You can provide us with the required product output, screening frequency, etc.

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

Vitamin powder slapping screen is a device used to screen vitamin powder. It screens materials through mechanical vibration and slapping action. It is particularly suitable for...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos, compost, organic fertilizer...

A laboratory or small batch screening equipment designed for fine, sticky or hygroscopic pharmaceutical excipients such as yeast powder. It achieves particle size classification, im...

Fines content tester is a device used to quickly and quantitatively analyze the fines powder content in materials. Fines powder usually refers to the part with a particle size small...

Nylon sieve shaker mesh is a mesh filter material woven from nylon material (usually nylon 6, nylon 66, nylon or polyester), which has the characteristics of high strength, wear res...

Stainless steel frame and woven cloth

The stainless steel frame provides a sturdy support structure, while the precision-woven stainless steel cloth ensures accurate particle size separation, making the test sieve an in...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap