Monday September-15 2025 15:41:15

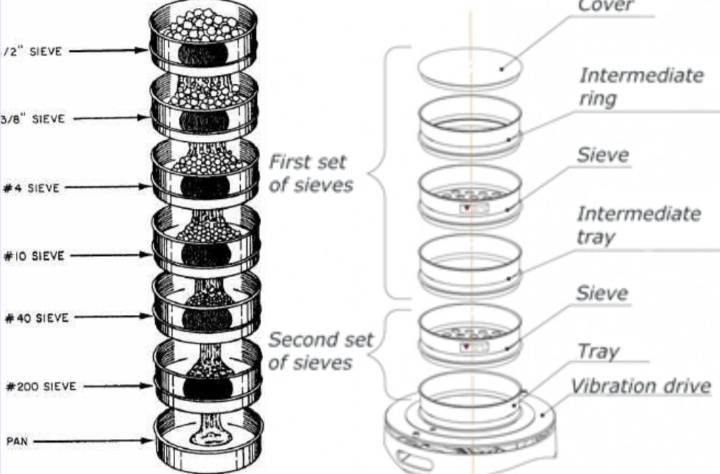

Civil engineering soil sieve is a fundamental tool for particle analysis. Its primary function is to separate and classify soil samples by particle size to obtain particle size distribution data. Depending on the test procedure, sieving methods are categorized into dry sieving and wet sieving. The former is suitable for easily dispersed coarse-grained soils, while the latter is for soil samples containing a high concentration of fine particles. Sieves are further categorized by pore size: coarse sieves for coarse-grained soils and fine sieves for fine-grained soils. Coarse sieves typically have pore sizes larger than 4.75 mm, while fine sieves have pore sizes smaller than 4.75 mm. Common fine sieve mesh sizes range from 2 mm to 0.075 mm.

Civil engineering soil sieves are primarily used for particle analysis of soil samples to determine their particle size distribution. This is a crucial step in evaluating soil engineering properties. Soil sieves are generally categorized by their pore size and intended use.

Coarse and Fine Sieves

Coarse sieves (coarse-grained soil sieves): These sieves have larger pore sizes and are used to separate coarse-grained soils such as gravel and coarse sand. Common sieve sizes include 75mm, 37.5mm, 19mm, 9.5mm, and 4.75mm.

Fine sieves (fine-grained soil sieves): These sieves have smaller apertures and are used to separate fine sand and silt. Common sieve sizes include 2mm, 1mm, 0.425mm, 0.25mm, and 0.075mm. In particular, the 0.075mm sieve (also known as the No. 200 sieve) is the dividing sieve that distinguishes coarse-grained soil from fine-grained soil.

Wet Sieving vs. Dry Sieving

In addition to the above classifications, soil sieving tests are further categorized into dry sieving and wet sieving methods depending on how the soil sample is prepared.

Dry sieving: Suitable for soil samples with low cohesive particles that are easily dispersed. After drying, the soil sample is vibrated and sieved through a series of sieves with different apertures. The mass of soil on each sieve is then measured. Wet sieving: Suitable for fine-grained soil samples containing a high concentration of clay or silt, which tend to clump and be difficult to sieve when dry. Typically, the soil sample is first soaked in water, a dispersant is added, and then washed through a 0.075 mm sieve to separate the coarse and fine particles. The oversize fraction is then dry-sieved, while the undersize fraction is analyzed by sedimentation analysis (such as a hydrometer or pipette method) to determine the particle size distribution.

The Civil Engineering Soil Sieve offers advantages such as ease of use, low cost, high accuracy, minimal data error, and the ability to combine results with other tests.

With high accuracy, the Civil Engineering Soil Sieve can accurately separate soils of different particle sizes according to standard particle sizes, such as 20mm, 10mm, and 2mm, preventing misclassification of gradations caused by mixed particles and providing reliable data support for soil classification, such as gravel and sand.

The data is highly reproducible, minimizing deviations in results after multiple sieving of the same soil sample. This reduces test errors, ensures consistency in subsequent calculations of engineering parameters such as compaction and bearing capacity, and ensures compatibility between design and construction.

The results are highly visualized, allowing for intuitive interpretation of the mass percentage of each particle size and clearly presenting soil gradation curves. This facilitates quick determination of soil compliance with project requirements, such as the gradation range for roadbed fillers, providing a direct basis for adjusting construction plans.

The results have excellent correlation, and the screening data can be combined with density, moisture content and other tests to comprehensively reflect the engineering properties of soil, providing a comprehensive and systematic reference for engineering decisions such as foundation treatment and slope protection, thereby reducing engineering risks.

The sieving process for civil engineering soil sieves is typically divided into two methods: dry sieving and wet sieving. The specific method used depends on the properties of the soil sample. The following are detailed steps for both methods:

Dry Sieving (Suitable for coarse-grained soils)

Dry sieving is primarily used for soil samples with low viscosity and ease of dispersion, such as sand and gravel.

Steps: Prepare the soil sample. First, air-dry the soil sample to be analyzed or dry it in a 105°C oven to a constant weight. Then, gently break up the soil sample with a mallet or other tool to remove any lumps, but be careful not to damage the soil particles themselves. Weigh: Accurately weigh a certain amount of dry soil sample and record the total mass (m). To prepare for sieving, stack a set of standard sieves on the sieve base in descending order of aperture, with the largest aperture sieve on top. Common sieve sizes include 75mm, 37.5mm, 19mm, 9.5mm, 4.75mm, 2mm, 1mm, 0.5mm, 0.25mm, and 0.075mm. For vibratory sieving, pour the weighed soil sample onto the top sieve and cover the sieve lid. Then, vibrate the sieve by hand or using a specialized vibrating sieve machine for approximately 15-20 minutes, until the mass of soil sample removed from each sieve does not exceed 1% of the total soil sample within one minute. For weighing and calculation, after vibration, accurately weigh the mass of soil sample remaining on each sieve and the mass of soil sample on the sieve bottom plate. The sum of these masses should approximate the total mass. Based on the mass remaining on each sieve, calculate the cumulative percentage of soil sample passing through each sieve, thereby plotting a particle size distribution curve.

Wet Sieving Method (for Fine-Grained Soils)

The wet sieving method is primarily used for soil samples such as clay and silt that contain a large number of fine particles and are prone to clumping.

Steps: Soil Sample Preparation: Soak the air-dried soil sample in water for at least 24 hours to fully soften it. Dispersion: Place the soaked soil sample in a dispersion cup, add an appropriate amount of dispersant (such as sodium hexametaphosphate solution) and distilled water, and stir with an electric stirrer to fully disperse the soil particles. After washing and sieving, the dispersed soil sample is passed through a 0.075mm (No. 200) sieve. The soil sample is repeatedly rinsed with distilled water until the water passing through the sieve becomes clear. For drying and weighing, the soil sample remaining on the sieve (i.e., the portion larger than 0.075mm) is transferred to a container, dried in an oven to a constant weight, and then weighed. For subsequent analysis, the soil sample passing through the 0.075mm sieve (i.e., the portion smaller than 0.075mm) is typically subjected to further sedimentation analysis using a hydrometer or pipette method to determine a finer particle size distribution. Combining the wet sieving and sedimentation analysis data, a complete particle size distribution curve is constructed. Both methods provide civil engineers with fundamental data for evaluating soil engineering properties, such as foundation bearing capacity, permeability, and compaction performance.

In the application of Civil Engineering soil sieve, coarse screens usually use square hole metal woven screens or steel plate punching screens with a pore size greater than 0.075mm, such as 200mm, 100mm, etc.; fine screens usually use square hole metal woven screens with a pore size less than or equal to 0.075mm, such as 0.075mm, 0.05mm, etc.

Determining Soil Classification: Based on the particle size distribution curve, engineers can accurately classify soil as gravel, sand, silt, or clay. This is the first step in subsequent engineering design (such as foundations, roadbeds, and embankments). Screening results can also be used to determine whether the soil is coarse-grained or fine-grained.

Assessing Foundation Bearing Capacity: The particle size distribution of soil directly affects its density and shear strength. Well-graded soil (i.e., a uniform mix of particle sizes) generally compacts more densely and has a higher bearing capacity, which is crucial for building foundation design.

Predicting Permeability: Soil permeability (water permeability) is closely related to particle size. Coarse-grained soils (such as gravel and coarse sand) have high permeability, while fine-grained soils (such as clay) have low permeability. Screening tests allow engineers to predict the effectiveness of earth dams, cutoff walls, or underground drainage systems. Controlling Compaction Quality: Roadbeds and fills require compaction in highway, airport runway, and landfill projects. Sieve testing can help determine whether the particle size distribution of the compacted soil meets design requirements, thereby ensuring density and stability after compaction.

Guiding the Design of Filter and Inverter Layers: In hydraulic engineering projects, filter and inverter layers are used to prevent upstream soil particles from being carried away by the water flow. The particle size of these filter layer materials must precisely match the soil being protected. Soil sieve testing is the fundamental basis for designing the particle size distribution of these filter layers.

Civil engineering soil sieves are primarily used for fundamental assessments of soil properties. Sieve testing can generate a soil particle size distribution curve, which helps understand the soil's physical composition. This method is straightforward and repeatable, and is widely used in real-world projects to verify that fill, foundation, or roadbed materials meet design specifications. It provides concrete data support for engineering decisions, such as determining whether a particular soil material is suitable for roadbed fill or determining the type of foundation soil. Its existence enables engineers to conduct standardized comparisons of soil samples from different sources through simple physical means.

Dahan Machinery provides soil sieves of various specifications and models to meet the screening needs of different particle sizes and...

Laboratory Sieve Shaker Machine Price

Laboratory sieve shaker machine is a device used for laboratory sieving and particle analysis...

Soil sieve price vary widely, ranging from $3 to $500. Small, handheld garden sieves are generally cheaper due to...

Environmental soil sieves are a key tool whose core function is to physically separate soil samples based on particle size...

Sep 15, 2025

Civil engineering soil sieve is used to analyze soil particle size distribution by vibrating the part...

Sep 13, 2025

Soil sieves range in price from $3 to $500.This device separates materials such as soil, sand, and co...

Sep 09, 2025

Environmental soil sieve Common sieve sizes for environmental soil sieve include: coarse sieve 4.75mm...

Sep 06, 2025

Construction soil sieve can separate particles of different sizes in the soil, detect soil particle g...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap