![[field:title/]](/uploads/250409/2-2504091P253b1.png)

Conveyor belt for material handling are key equipment for achieving continuous and efficient material handing in industrial production. They are continuous material loops driven by pulleys or drive devices to transport goods. Conveyor belts for material handling are widely used in various material handling fields, including food and beverage processing, manufacturing, mining, packaging and power transmission.

Belt width: 400/500/650/600/800/1000/1200/1500mm

Conveying speed: 1.25-2m/s

Conveying length: 10 meters

Belt material: PVC/PU rubber

Angle: 0°-90°

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

Conveyor belt for material handling is a device used to transport raw materials, inventory, and finished goods within manufacturing plants and warehouses. These conveyors are distinguished from other conveying systems by their construction and the fact that they are typically used to transport piece materials rather than bulk materials. Conveyor belts for material handling are typically lightweight and modular in design, making them easy to move and reconfigurable when production or material transport routes change. Most conveyors belt for material handling also feature a fine-tuning speed control mechanism that allows the transport speed to be adjusted for different processes and loads.

There are many types of conveyor belts for material handling in use today, with roller conveyor belts for material handling, slat conveyor belts for material handling, and drag chain conveyor belts for material handling being the more common ones. Most conveyor belts for material handling also feature a fine-tuning speed control mechanism that allows the transport speed to be adjusted for different processes and loads.

|

Type |

Picture |

Features and advantages |

Applicable materials/industries |

Common materials |

|---|---|---|---|---|

|

Drum conveyor belt for material handling |

|

It can be used for light/medium/heavy loads; suitable for flat or gentle slope conveying |

Packaging, logistics, electronic assembly, boxes, pallets, etc. |

Rubber belt, PVC belt + carbon steel or stainless steel roller |

|

Slat conveyor belt for material handling |

|

High strength, suitable for load-bearing and irregular objects; be used in high temperature or impact conditions |

Metallurgy, glass, food cooling line, drying, stamping parts, etc. |

Stainless steel slats, carbon steel, engineering plastics |

|

Drag chain conveyor belt for material handling |

|

Suitable for conveying bulk materials or granular materials, adaptable to complex working conditions |

Grain, coal, fertilizer, mineral powder, granules, garbage disposal, etc. |

Steel chain + carbon steel/stainless steel scraper/hopper |

Rotational motion: Material conveyor belts generate rotational motion via a motor-driven pulley.

Friction: Friction between the pulley and the belt converts the rotational motion into linear motion of the belt.

Continuous loop: Continuous belts allow for a continuous flow of material.

Support: The idler pulleys of material conveyor belts support the belt and load, ensuring efficient motion.

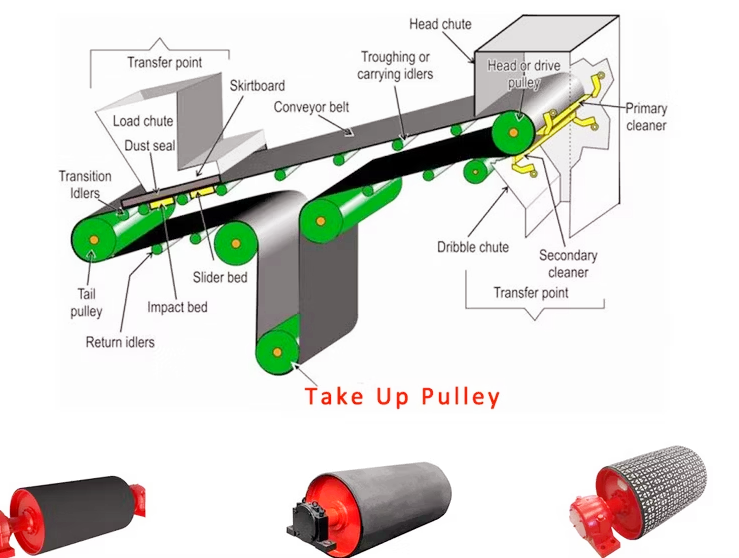

The main components of the conveyor belt for material handling include conveyor belt, drive device, rollers and drums, tensioning device, rack and bracket, etc. These components work together to ensure efficient and stable warehouse handling.

Conveyor belt: The core component for carrying and transferring materials. Common materials include rubber, PVC, etc., which are selected according to the requirements of temperature resistance and wear resistance.

Drive device: It includes motor, reducer, coupling and drive roller to provide power.

Rollers and rollers: Rollers support conveyor belts and materials. Rollers are divided into drive rollers (active), redirection rollers (driven) and tensioning rollers.

Tensioning device: Maintain the tension of the conveyor belt to prevent slipping. Common forms include spiral, heavy hammer and hydraulic.

Rack and bracket: Steel structure that supports the entire conveying system.

|

Parameters |

Roller conveyor belts for material handling |

Slat conveyor belts for material handling |

Drag chain conveyor belts for material handling |

|---|---|---|---|

|

Conveyor belt speed |

0.1 ~ 2.5 m/s (adjustable) |

0.1 ~ 1.0 m/s (slower) |

0.05 ~ 0.5 m/s (low speed) |

|

handling inclination |

0° ~ 20° (can be larger with skirt) |

0° ~ 30° (need to be equipped with baffle) |

0° ~ 45° (suitable for climbing) |

|

Carrying capacity |

Light and medium materials, ≤500kg/m |

Medium and heavy materials, ≤1000kg/m |

Bulk materials/granules/powders, ≤2000kg/m |

|

Ambient temperature |

-10℃ ~ 80℃ |

-20℃ ~ 200℃ (depending on the material) |

-20℃ ~ 120℃ |

|

Drive mode |

motor+drive roller |

motor+sprocket or shaft drive |

motor+sprocket or hydraulic drive |

|

Cleaning and maintenance |

simple and convenient |

need to clean oil or debris regularly |

need to pay attention to chain lubrication and tension |

Continuous handing: conveyor belts for material handing can realize continuous and efficient long-distance material handing

High degree of automation: conveyor belts for material handing are integrated with automatic sorting, weighing, packaging systems, etc. to improve production efficiency

Energy saving and manpower saving: conveyor belts for material handing reduce manual handling, improve the degree of automation of production lines, and reduce costs

Stable operation: after reasonable configuration of conveyor belts for material handing, they can operate stably for a long time with low failure rate

Wide environmental adaptability: conveyor belts for material handing have special conveyor belts suitable for complex environments such as high temperature, corrosion resistance, moisture resistance, and explosion resistance

Conveyor belt for material handling can efficiently and stably complete the handling tasks of various materials through diversified structural designs, material selection and driving methods. Its flexibility and adaptability make it a core equipment in industrial production, logistics warehousing, food processing and other fields.

Bulk material handling: Conveyor belts for material handling are used for long-distance transmission of large-particle materials such as coal, ore, sand and gravel.

Packaging material handling: Automated handling of regular materials such as bags, pallets, cartons, etc.

Process coordination: Conveyor belts for material handling are linked with baking, cooling, sorting and other equipment to achieve continuous production.

If you are looking for conveyor belts for material handling, look no further than Dahan Machinery Conveyor Belts.

We have been manufacturing conveyor systems for material handling for many years. Our experts design, manufacture, deliver and install the systems you need for safe and seamless material handling. We also provide assistance with repairs, maintenance, installation and spare parts to ensure your system is up and running for the long term. Our automated solutions have been trusted by countless industries, including logistics, warehousing, retail and e-commerce.

Our material handling equipment conveyor systems are cost-effective and reliable solutions that can meet your facility, budget and throughput needs. Please contact our team to discuss your needs.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

What is the wet sieving process?

Wet sieving is a screening process assisted by liquid, mainly used to more effectively separate fine particles, sticky materials or remove liquids bound to particles. Wet screening ...

Stainless Steel Sieve Shaker Model Features

Stainless steel sieve shaker, an essential tool for particle size analysis, is characterized by its high-quality 304 stainless steel construction, ensuring corrosion resistance, wea...

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control, and is widely used in food, chemical, pharmaceutical and o...

Laboratory Lactose Stainless Steel Test Sieve

Laboratory lactose stainless steel test sieve is a device used to accurately determine the size distribution of lactose particles. It is often used for laboratory particle analysis ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap