Monday June-23 2025 17:50:29

Copper powder is a reddish-brown metal fine powder with a wide range of particle sizes (generally 10μm~200μm), fine texture, easy oxidation, and good conductivity. It is easy to adsorb and agglomerate during the screening process, and there is stickiness between the particles; the particles are slightly irregular and easy to clog the sieve; the screening accuracy requirements are high, and the commonly used sieve mesh is between 100-500 mesh (about 150μm-25μm).

Copper powder ultrasonic test sieve is a screening device for particle size analysis of copper powder (such as electrolytic copper powder, atomized copper powder, etc.), which solves the screening problem by combining ultrasonic vibration technology with traditional screening principles. The core is to use ultrasonic high-frequency vibration to generate additional energy on the screen, prevent particles from clogging the screen holes, and improve screening efficiency and accuracy.

Copper powder is easy to agglomerate due to its high surface activity. Ultrasonic vibration can destroy the adsorption force between particles and make it dispersed for screening. Copper powder has strong conductivity. Traditional screening is easy to block holes due to electrostatic adsorption. Ultrasonic vibration can eliminate static electricity and clean the screen. Copper powder ultrasonic test sieve is suitable for 80-600 mesh copper powder screening, with a screening accuracy of more than 99.5%, and an output of 0.5-10 times higher than that of ordinary vibrating screens.

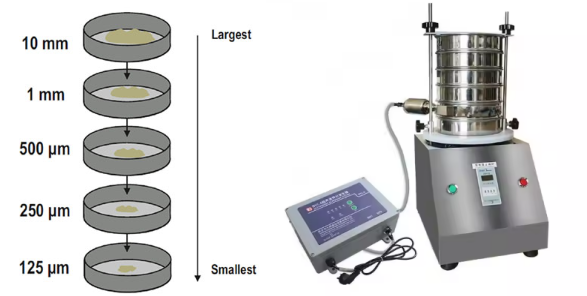

Through the high-frequency micro-vibration effect, the screen surface is always kept in a vibrating state, and copper powder is not easy to deposit or adhere, which greatly reduces the phenomenon of clogging. It can support the installation of multi-layer screen frames (such as 2~6 layers) to achieve multi-level particle size screening or particle size distribution analysis, which is particularly suitable for laboratory copper powder particle size detection and research needs. High screening efficiency can reduce repeated screening or reprocessing of unqualified products and reduce material loss.

The ultrasonic generator converts 220V, 50Hz (or 110V, 60Hz) electrical energy into 18KHz high-frequency electrical energy.

The high-frequency electrical energy is converted into high-frequency mechanical vibration (ultrasonic vibration) through the transducer, and the amplitude is usually in the micron level.

The vibration is evenly transmitted to the screen through the resonance ring, causing the screen surface to produce high-frequency, low-amplitude ultrasonic vibration waves.

The copper powder is suspended on the screen surface by the ultrasonic wave, reducing adhesion, friction and agglomeration.

Ultrasonic vibration allows the copper powder to pass through the mesh quickly, effectively preventing the screen from being blocked, especially suitable for 80-600 mesh fine screens.

The copper powder is layered through the screen according to the particle size to complete the classification or remove impurities.

The vibration motor generates low-frequency, high-amplitude mechanical vibration, drives the overall movement of the screen body, and promotes the uniform distribution of copper powder on the screen surface.

The recommended mesh number of copper powder ultrasonic test sieve needs to be determined according to the specific use and particle size requirements of copper powder:

100-200 mesh: suitable for screening of coarse copper powder, such as powder metallurgy and preparation of ordinary copper-based materials. It has high screening efficiency and is suitable for copper powder with a particle size of 75-150μm. It rarely blocks the mesh and is suitable for preliminary classification or impurity removal of copper powder in industrial production.

200-325 mesh: suitable for medium-fine copper powder, such as electronic components, conductive paste or primary powder for 3D printing, with a particle size range of about 45-75μm. Ultrasonic vibration can effectively prevent electrostatic agglomeration, suitable for medium and high-precision screening, suitable for laboratory particle size analysis or preparation of medium and high-end copper powder products.

325-450 mesh: suitable for high-precision copper powder, such as high-precision 3D printing, microelectronic materials or high-end powder metallurgy. The particle size is 25-45μm, and the ultrasonic cleaning effect is significant. It is suitable for ultrafine powder screening, high-precision grading, quality inspection or special-purpose copper powder.

450-600 mesh: suitable for ultrafine copper powder screening, such as nano-level or near-nano-level copper powder (particle size <25μm). The mesh aperture is extremely small, and the ultrasonic system must operate efficiently to prevent clogging. The screening accuracy can reach more than 99.5%, which is suitable for high-end laboratory research, precision electronic coating or special alloy powder.

Ultrasonic test sieves are widely used in the field of copper powder. They are mainly used to solve the problems of easy agglomeration, clogging, and high precision requirements of copper powder during screening. They are suitable for raw material screening, finished product testing, particle size control and fine grading.

Finished product screening in copper powder production: After the copper powder is pressed or electrolytically prepared, unqualified particles (such as large particles and agglomerates) must be removed by screening.

Particle size analysis and laboratory testing of copper powder materials: The particle size is segmented and screened through multi-layer ultrasonic vibrating screens to obtain the proportion of each particle size range.

Pre-treatment screening of high-purity copper powder slurry: Before copper powder is used to prepare conductive slurry (such as solar cell back electrode, conductive ink), the particle size must be strictly controlled to remove impurities and coarse particles.

The copper powder ultrasonic test sieve is a device used to accurately screen fine particle materials such as copper powder. This sieve uses ultrasonic vibration to improve screening efficiency and accuracy, and is particularly suitable for screening fine powders. In the application of copper powder, the ultrasonic vibrating screen not only improves the screening efficiency and accuracy, but also ensures the particle size stability, finished product consistency and downstream performance of copper powder in multiple key links.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Corundum powder ultrasonic test sieve

Corundum powder ultrasonic test sieve is a high-precision screening equipment used to detect and classify high-hardness, easy-to-bl...

Jun 23, 2025

Copper powder ultrasonic test sieve

The copper powder ultrasonic test sieve can be adapted to a variety of mesh sizes, including 80 mesh,...

Jun 21, 2025

Corundum powder ultrasonic test sieve

Corundum powder ultrasonic test sieve is a laboratory equipment used for corundum powder particle siz...

Jun 19, 2025

Negative electrode material ultrasonic test sieve

The negative electrode material ultrasonic test sieve is a laboratory sieving equipment used for high...

Jun 18, 2025

Soil sieve size is a key parameter for soil particle analysis, for soil classification or engineering...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap