Saturday June-21 2025 18:04:02

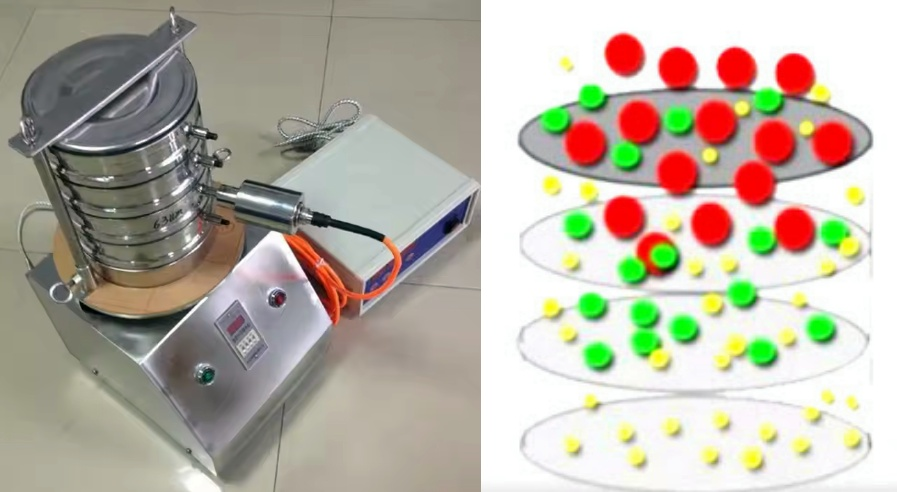

Corundum powder ultrasonic test sieve is a high-precision screening equipment used to detect and classify high-hardness, easy-to-block fine powders (corundum powder). Due to the hardness, irregular shape, small particle size and high specific gravity of corundum powder, conventional screening equipment is prone to problems such as blocking, adhesion and incomplete screening. The ultrasonic test sieve effectively solves these problems by superimposing high-frequency micro-vibration on the sieve.

The equipment supports multi-layer stacking sieves, which can realize the step-by-step classification of corundum powder. The commonly used sieve mesh ranges from 80 mesh to 500 mesh, which is especially suitable for screening ultra-fine corundum powder with a fineness below 45μm, such as micro-powder corundum powder used in photovoltaic polishing, electronic abrasives and other occasions. The ultrasonic test sieve can be configured with up to 8 layers of sieve frames to achieve multi-level particle size distribution analysis. It is an important tool for particle size detection and grading screening of corundum powder in laboratories and quality control links.

Due to its high hardness (Mohs hardness 9-9.5), easy to generate static electricity and agglomeration, conventional vibrating screens are difficult to achieve efficient screening. Ultrasonic test sieves can: effectively break the static adsorption and agglomeration between materials through high-frequency vibration. Improve screening accuracy and are suitable for particle size analysis and quality inspection. Prevent clogging of the mesh of sieve parts to ensure that corundum powder passes through the sieve quickly.

The ultrasonic test sieve achieves efficient screening through the combined action of the ultrasonic system and the vibration motor system:

① Ultrasonic system: It consists of an ultrasonic generator, a transducer and a resonance ring. The generator generates high-frequency electrical oscillations (usually 18KHz or higher, with a vibration frequency of up to 36,000 times per second), which are converted into high-frequency mechanical vibrations through the transducer and transmitted to the sieve. This vibration can effectively prevent mesh blockage and solve the screening problem of corundum powder caused by static electricity or agglomeration.

② Vibration motor system: The screen frame is driven by an upright vibration motor to make the material vibrate three-dimensionally at a low frequency on the screen. After superimposing ultrasonic vibration, the screening accuracy and efficiency are significantly improved.

③ Screening effect: Compared with traditional vibrating screens, the screening pass rate of ultrasonic test screens can reach more than 99.5%, and the output is increased by 0.5-10 times, which is suitable for fine screening of 80-600 mesh (about 25-180μm).

The vibration of the corundum powder ultrasonic test screen can keep the corundum powder particles suspended on the screen, reduce the agglomeration and adhesion between particles, prevent the screen from being blocked, and greatly improve the screening efficiency. Compared with ordinary test screens, its screen pass rate can be increased by 50%-400%, and there is no need to frequently stop the machine to clean the screen. It is not only suitable for the screening of corundum powder, but also for other fine powder materials with similar characteristics, such as silicon carbide, alloy powder, molybdenum powder, etc. For corundum powder of different mesh sizes, from coarse particles to 600 mesh or even finer powder, it can achieve good screening effect.

The equipment can achieve high-precision screening, effectively control the particle size distribution of corundum powder, and ensure the consistency of product quality. For example, for some corundum powder products with strict particle size requirements, it can accurately screen out particles that meet the requirements and reduce product performance differences caused by uneven particle size.

The mesh size of the corundum powder ultrasonic test sieve is recommended. The appropriate sieve needs to be selected according to the particle size grade of the corundum powder.

|

Carbon sand particle size range (μm) |

Recommended mesh number (mesh) |

Remarks |

|

>1000μm |

10 mesh, 12 mesh, 14 mesh |

Coarse particle size, suitable for coarse screening |

|

850~1000μm |

16 mesh, 18 mesh |

Common coarse particle detection |

|

500~850μm |

20 mesh, 25 mesh, 30 mesh |

Medium coarse particle size |

|

250~500μm |

35 mesh, 40 mesh, 50 mesh |

Common medium particle size |

|

125~250μm |

60 mesh, 70 mesh, 80 mesh |

Medium and fine particle screening |

|

75~125μm |

10 0 mesh, 120 mesh |

fine particle screening |

|

45~75μm |

150 mesh, 170 mesh, 200 mesh |

micro-fine particle size |

|

25~45μm |

270 mesh, 300 mesh, 325 mesh |

ultra-fine particle size screening |

|

<25μm |

400 mesh, 450 mesh, 500 mesh |

ultrasonic assistance is recommended to prevent |

Particle size analysis in the laboratory of corundum manufacturers;

Quality testing of grinding materials and sandblasting materials;

Particle grading control in the new material research and development department;

Inlet and outlet inspection of powder processing workshop.

Generally, the price of a small corundum ultrasonic test sieve with a small screen frame diameter and relatively basic functions is about US$300-900. For example, some basic laboratory sieves may have a sieve frame diameter of about 200-300mm, which is suitable for particle size analysis of a small amount of corundum powder samples, and the price may be $300-600; while small equipment with more comprehensive functions and adaptable to a variety of sieve specifications and mesh sizes may cost $600-900.

For corundum powder ultrasonic test sieves with moderate processing capacity and suitable for small production or R&D departments, the price is usually $1200-3600. The sieve frame diameter of this type of equipment may be around 500-800mm, with good screening accuracy and certain production efficiency, which can meet the needs of some enterprises or scientific research institutions with high requirements for corundum powder particle size.

The corundum powder ultrasonic test sieve has the characteristics of high precision, no clogging, fine classification, and wide application. It is an indispensable equipment for hard powder materials such as corundum powder in laboratories and quality control links.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Negative electrode material ultrasonic test sieve

Negative electrode material ultrasonic test sieve is a high-precision sieving equipment designed for negative electrode materials of lithium batteries. It is widely used...

Jun 21, 2025

Corundum powder ultrasonic test sieve

Corundum powder ultrasonic test sieve is a laboratory equipment used for corundum powder particle siz...

Jun 19, 2025

Negative electrode material ultrasonic test sieve

The negative electrode material ultrasonic test sieve is a laboratory sieving equipment used for high...

Jun 18, 2025

Soil sieve size is a key parameter for soil particle analysis, for soil classification or engineering...

Jun 12, 2025

Test sieve sugar powder size detection

Test sieve sugar powder size detection is a physical detection method that uses multiple layers of st...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap