![[field:title/]](/uploads/allimg/250317/2-25031G62409334-lp.png)

Cosmetic powders test sieve is a device used to detect the particle size distribution of cosmetic powders, and plays an important role in the production and research and development of cosmetics.

Screening particle size: 0.025mm-20mm

Function: Screening and grading cosmetic powders raw materials

Application: Cosmetic industry, especially the quality control and research and development stage of powders products

Port: Any port in China (Mainland)or as you need.

Quantity(sets) |

1-2 |

>2 |

Delivery time(days) |

5 |

To be negotiated |

Cosmetic powders test sieve is a special device used to detect the particle size distribution of cosmetic powders (such as foundation, loose powders, eye shadow powders, etc.). It classifies the powders according to the particle size by sieving to ensure that the uniformity and quality of the cosmetic powders meet the standards.

Through the particle size distribution analysis and quality control of cosmetic fine powder (such as loose powder, foundation powder, highlight powder, setting powder, etc.), cosmetic powder test sieve separates powder particles of different particle sizes to ensure product uniformity, fineness and quality stability, which plays a vital role in ensuring the quality and performance of cosmetics. It is widely used in the cosmetic production process, especially in the research and development, quality inspection and grading screening stages of powder products.

1. Powders raw materials: such as talcum powders, kaolin, mica powders, etc.

2. Pigment powders: such as various pigment powders used in cosmetics such as eye shadow, blush, lipstick, etc.

3. Functional powders: such as titanium dioxide and zinc oxide powders with sunscreen function, and activated carbon powders with adsorption, etc.

4. Plant powders: Some cosmetics will add plant extract powders, such as pearl powders, pollen, Chinese herbal medicine powders, etc.

5. Polymer powders: such as acrylic polymer powders used in products such as setting powders and hair powders

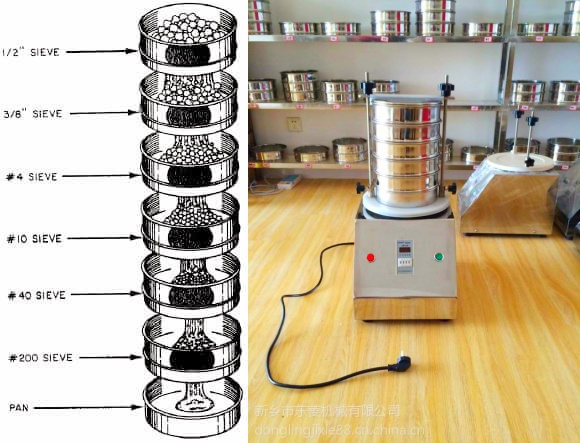

Put the cosmetic powders sample into the top sieve, start the vibration device, and the powders gradually passes through the sieve hole under the action of vibration. Powders of different particle sizes will be separated by sieves of different specifications, and finally powders samples graded by particle size will be obtained.

一.Classification by sieve material:

① Stainless Steel Sieve

Features: Good corrosion resistance and wear resistance, suitable for screening powders of various chemical components.

Application: Widely used for screening cosmetic powders, mineral powders, etc., especially in humid or acidic and alkaline environments.

② Nylon Sieve

Features: Lightweight, good wear resistance, but not as high temperature resistant as stainless steel.

Application: Suitable for screening light powders or powders with larger particles, especially when the requirements for corrosion resistance are not high.

③ Brass Sieve

Features: Strong corrosion resistance, suitable for screening slightly corrosive powders.

Application: Used for screening some special cosmetic powders, such as special raw material powders that require higher corrosion resistance.

④ Polyester Sieve

Features: Strong wear resistance, long service life, and suitable for finer screening.

Application: Commonly used for screening of fine powders, especially when a long service life is required.

二. Classification by structure and working principle:

| Type | Picture | Features | Applicable scenarios |

| Mechanical vibration test sieve |  |

Automatic screening is achieved by driving the sieve frame to vibrate through a motor | Quality control in cosmetic production |

| Electromagnetic vibration sieve |  |

Use electromagnetic force to drive the sieve frame to vibrate, and the vibration frequency is adjustable | High-precision particle size analysis (such as nano-scale powders), suitable for fine powders detection |

| Sonic vibration sieve |  |

Usually used for precise separation of small volume and particle size samples as fine as 3μm, the screening efficiency is increased by 30-50% | Suitable for powders, fine granular materials and "special" Cosmetic powders materials |

| Single-layer test sieve |  |

Only one sieve layer, suitable for simple screening or single particle size detection | Used for initial screening of cosmetic powders raw materials |

| Multi-layer test sieve |  |

Composed of multiple sieves with different mesh sizes, it can simultaneously separate powders of various particle size ranges | Analyze the distribution of powders particle size in the research and development stage |

三. Classification by standards:

①Taylor standard sieve: It is one of the commonly used standard sieve systems in the world. There is a specific correspondence between its sieve hole size and mesh number. It is also used in cosmetic powders test sieves. It is often used for particle size detection of imported raw materials or products that refer to international standards.

②Chinese Pharmacopoeia standard sieve: It is divided into sieves No. 1-9, and different sieve numbers correspond to different mesh numbers and sieve hole sizes.

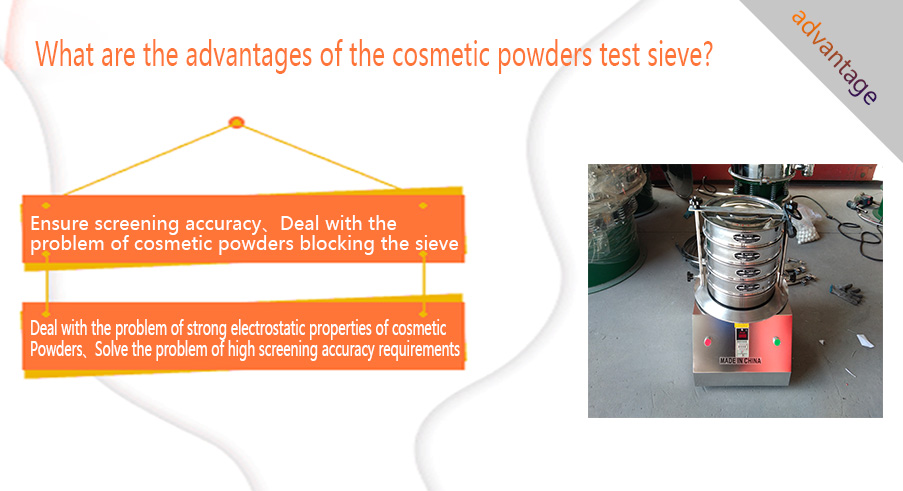

1. Ensure screening accuracy: Select high-precision sieve materials such as electroforming sieves, whose mesh size is uniform and consistent, with minimal error, and can accurately grade the particle size of cosmetic powders to ensure that the particle size of the powders after screening meets the product quality requirements.

2. Deal with the problem of cosmetic powders blocking the sieve: Cosmetic powders are usually very fine and easy to block the sieve. The high-frequency vibration generated by the cosmetic powders test sieve can effectively prevent the powders from blocking the sieve and improve the sieve

3. Deal with the problem of strong electrostatic properties of cosmetic powders: Cosmetic powders usually have strong electrostatic properties and are prone to agglomeration. Use sieves made of anti-static materials to reduce static electricity and reduce the possibility of powders agglomeration.

4. Solve the problem of high screening accuracy requirements: The particle size distribution of cosmetic powders has an important influence on product performance, and high-precision screening results are required. Use high-precision metal wire mesh to ensure the accuracy of the sieve aperture.

50-100 mesh (about 150-300 microns): suitable for initial screening or removal of larger impurities, such as removing coarse particles that may be mixed in when screening talcum powders or mica powders raw materials. This mesh size is suitable for the initial processing of talcum powders or basic powders raw materials.

200-400 mesh (about 38-75 microns): suitable for fine screening of most cosmetic powders, such as regular production of loose powders, foundation or blush.

500-800 mesh (about 20-25 microns): suitable for high-end products or scenes requiring ultra-fine particles, such as light setting powders, highlight powders or sunscreen powders.

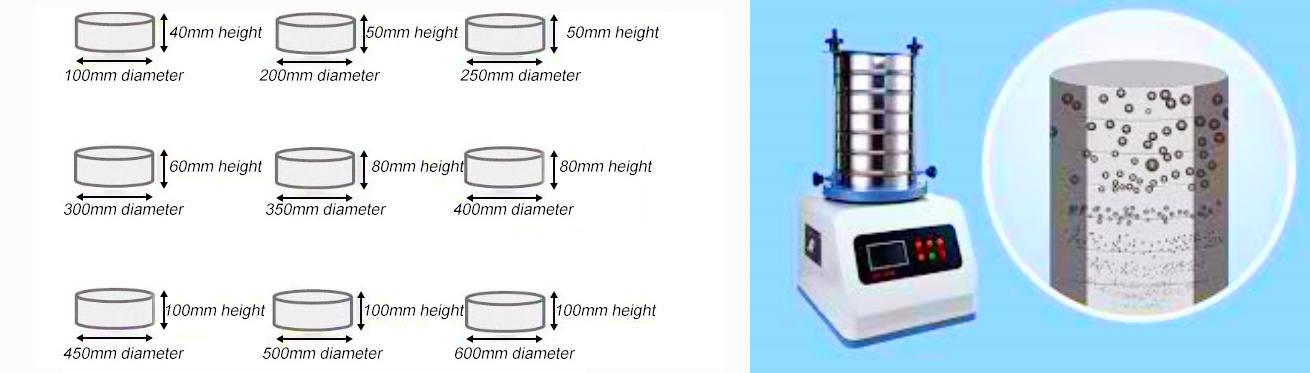

| Number | Name | Unit | Data |

| 1 | Layers | Layer | 1-8 |

| 2 | Diameter | mm | 200 |

| 3 | Granularity | mm | 0.038-3 |

| 4 | Noise | dB | 50 |

| 5 | Feeding Capacity(once) | G | 200 |

| 6 | Amplitude | mm | 5 |

| 7 | Voltage | v | 220 |

| 8 | Speed | R/min | 1420 |

| 9 | Power | Kw | 0.125 |

| 10 | Overall Dimension | mm | 360*300*736 |

| 11 | Weight | Kg | 45 |

| Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) |

| 2 | 13 | 26 | 0.71 | 90 | 0.16 | 260 | 0.06 |

| 3 | 6.5 | 28 | 0.63 | 100 | 0.154 | 280 | 0.055 |

| 4 | 5 30 | 0.6 | 110 | 0.14 | 300 | 0.054 | |

| 5 | 4 32 | 0.55 | 115 | 0.13 | 320 | 0.048 | |

| 6 | 3.2 | 36 | 0.5 | 120 | 0.125 | 325 | 0.045 |

| 7 | 2.8 | 40 | 0.45 | 130 | 0.111 | 350 | 0.041 |

| 8 | 2.5 | 45 | 0.4 | 140 | 0.105 | 360 | 0.4 |

| 9 | 2.2 | 50 | 0.355 | 150 | 0.1 | 400 | 0.0385 |

| 10 | 2 | 55 | 0.315 | 160 | 0.098 | 500 | 0.03 |

| 12 | 1.6 | 60 | 0.3 | 180 | 0.09 | ||

| 14 | 1.43 | 65 | 0.25 | 190 | 0.08 | ||

| 16 | 1.25 | 70 | 0.22 | 200 | 0.075 | ||

| 18 | 1 | 75 | 0.2 | 220 | 0.07 | ||

| 20 | 0.9 | 80 | 0.18 | 240 | 0.065 | ||

| 24 | 0.8 | 85 | 0.17 | 250 | 0.063 | ||

Cosmetic Powders Test Sieve specifications, if you need special specifications, you can contact online customer service consultation. |

|||||||

The structure of the cosmetic powders test sieve includes core components such as the sieve frame, sieve mesh, chassis, and cover, supplemented by functional components such as a vibration device or an ultrasonic generator.

Cosmetic powders is precisely applied in the fields of sun protection, oil control, texture, and carrier through technologies such as particle size control, surface treatment, and functional compounding. The application of cosmetic powders test sieves runs through the entire process of research and development, production, and quality inspection. Specific scenarios include laboratory formula optimization, production line raw material screening, compliance testing, and personalized product customization.

|

|

|

| Cosmetic powder R&D laboratory (particle size analysis) | Automatic screening is achieved by driving the sieve frame to vibrate through a motor | Quality control in cosmetic production |

|

|

|

| Screening and removal of powder products such as highlighters and contouring | Raw material storage and finished product delivery inspection process |

1. Ensure consistent powders particle size

The particle size of cosmetic powders directly affects the texture, application effect, and skin comfort of the product. For example, particles that are too large may cause uneven makeup and affect the makeup effect; particles that are too small may cause the powders to clump or affect the feel of use when applied.

2. Remove impurities

During the production process of cosmetic powders, the powders may contain particles that do not meet the specifications, impurities, or other impurities (such as foreign matter, lumps, etc.). Test sieves can effectively screen out these impurities to ensure the purity and quality of the final product. Go

3. Improve production efficiency and consistency

If the powders screening process in cosmetic production is not accurate, it will lead to inconsistent powders particle sizes in different batches, affecting the final quality of the product. Test sieves can improve the accuracy of screening and ensure that each batch of cosmetic powders meets the predetermined specifications.

4. Control the fluidity and dispersibility of powders

The fluidity and dispersibility of powders are crucial in cosmetic applications. For example, if the particles of cosmetic powders such as flour, blush powders and eye shadow powders are too large or uneven, it may affect their dispersibility, making them uneven or piled up during application.

Dahan Machinery focuses on the research and development and manufacturing of vibration screening equipment and has many years of industry experience. You can contact our sales team by email or online consultation to get more information and quotes.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control, and is widely used in food, chemical, pharmaceutical and o...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy...

Ultrasonic test sieve for wheat flour

Ultrasonic test sieve for wheat flour is a special device that combines ultrasonic technology with traditional screening principles to efficiently screen wheat flour. The device can...

Laboratory Lactose Stainless Steel Test Sieve

Laboratory lactose stainless steel test sieve is a device used to accurately determine the size distribution of lactose particles. It is often used for laboratory particle analysis ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap