![[field:title/]](/uploads/allimg/250313/2-2503131F135H7-lp.jpg)

Detergent Powders Test Sieve is a device used to detect the particle size distribution of detergent powder. It separates the detergent powder sample into components of different particle sizes through a series of sieves with different apertures, thereby evaluating the quality and uniformity of the detergent powder.

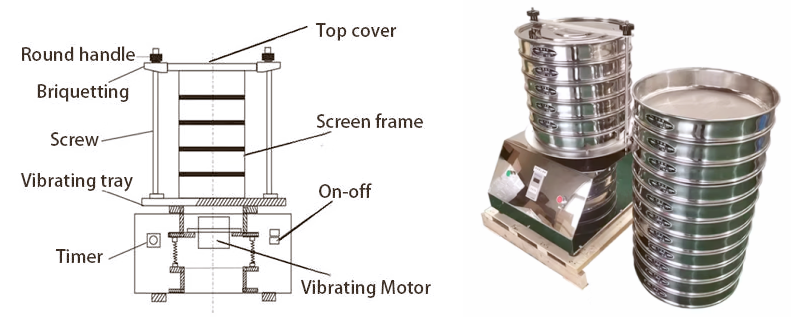

Number of layers: 1-8 layers

Screening particle size: 0.025mm-20mm

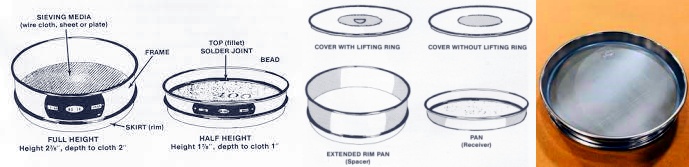

Structural composition: screen frame, screen, vibration motor, ultrasonic system (optional), control system, base and bracket.

Port: Any port in China (Mainland)or as you need.

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

Detergent Powders Test Sieve is a device used for screening, analysis and quality control of detergent powders. It is usually used in laboratories, production lines or quality inspection departments to ensure the uniformity of particle size and quality stability of detergent powders. As a fine powders material, the screening test of detergent powders can help manufacturers adjust the formula, improve product quality and meet relevant standard requirements.

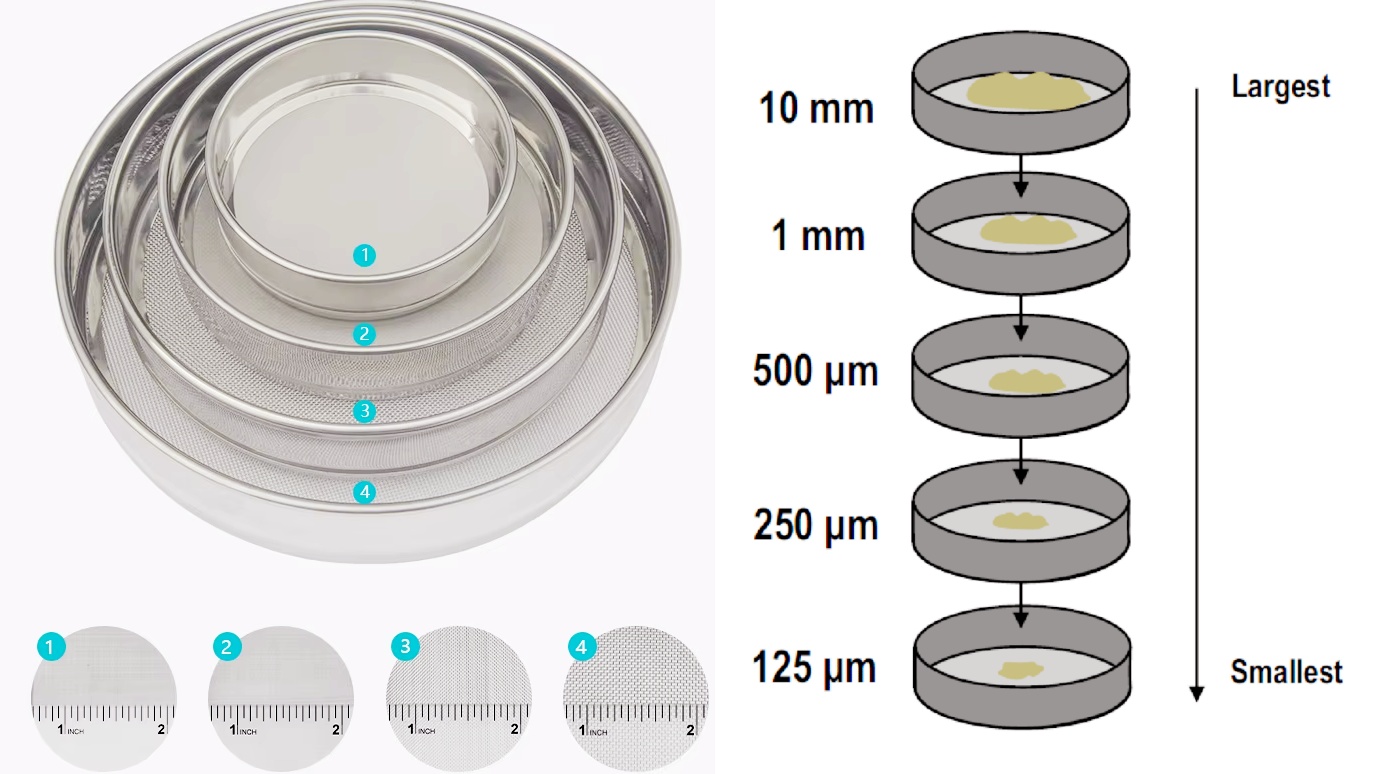

1. Screening: Place a certain amount of detergent powders sample evenly on the sieve surface of the test sieve, start the equipment, and use the centrifugal force and gravity generated by vibration to make the detergent powders sample pass through the sieve and layer according to the particle size distribution.

2. Screening process: After the sieve is screened layer by layer, detergent powders with different particle size ranges is obtained. Larger particles will be retained in the upper sieve, while smaller particles will pass through the sieve into the lower layer.

3. Result analysis: By weighing the sample weight in different sieve layers, analyzing the distribution of each particle size segment, calculating the particle size distribution curve of the detergent powders, and evaluating the product quality.

1. Classification according to the screen structure:

|

Classification |

Wire woven screen |

Punch screen |

Laminated test sieve |

|

Image |

|

|

|

|

Principle |

Woven by wire, uniform aperture, high precision |

Punch by metal plate, large aperture |

Stacked by multiple layers of screens, can screen multiple particle size ranges at the same time |

|

Applicable scenarios |

Applicable to the screening of ordinary detergent powders |

Applicable to the screening of coarse detergent powders |

Applicable to occasions where multi-level particle size analysis is required |

|

Features |

Easy to clean, good wear resistance |

Sturdy structure, good durability |

Improve screening Efficiency and time saving |

2. Classification by screening method:

Ultrasonic test sieve

① Working principle: Use ultrasonic vibration to make the screen produce high-frequency micro-vibration to prevent the screen from clogging

② Features: Suitable for screening of sticky and easily agglomerated materials, high screening accuracy, suitable for ultra-fine powders

② Application scenarios: Particle size analysis of high-viscosity laundry detergent and research and development experiments of ultra-fine laundry detergent

Slap test sieve

① Working principle: Through the combination of slapping and vibration, the laundry detergent particles move quickly on the sieve to achieve efficient screening

② Features: Fast screening speed, suitable for large batches of samples. Adjustable slapping force to adapt to different material characteristics

② Application scenarios: Rapid detection and laboratory particle size analysis in laundry detergent production, suitable for laundry detergent that is easy to agglomerate

Electromagnetic vibrating sieve machine

① Working principle: High-efficiency screening is achieved through mechanical vibration, with adjustable amplitude and frequency (commonly 3000 times/minute)

② Features: Stainless steel, anti-static, reduce laundry detergent adhesion

② Application scenarios: Analyze the particle size distribution of finished laundry detergent products, with an amplitude of 1-3mm, suitable for fine laundry detergent particles

1. Particle sorting: Detergent powders test sieve can be used to sort the particles in the detergent powders according to size, helping manufacturers understand the particle distribution of the product.

2. Quality control: By performing a test sieve analysis on the detergent powders, it is possible to evaluate whether the particle size of the product meets the standard requirements, thereby performing quality control and improving the production process.

3. Product improvement: According to the results of detergent powders test sieve, manufacturers can adjust the production process and optimize the product formula to improve the quality and market competitiveness of the detergent powders.

Detergent powders test sieve test sieve is usually composed of a sieve frame, a sieve, a vibrating device, and a bracket. Detergent powders is sorted on the sieve through vibration. Larger particles will be retained by the sieve, while smaller particles will fall through the sieve into the container below.

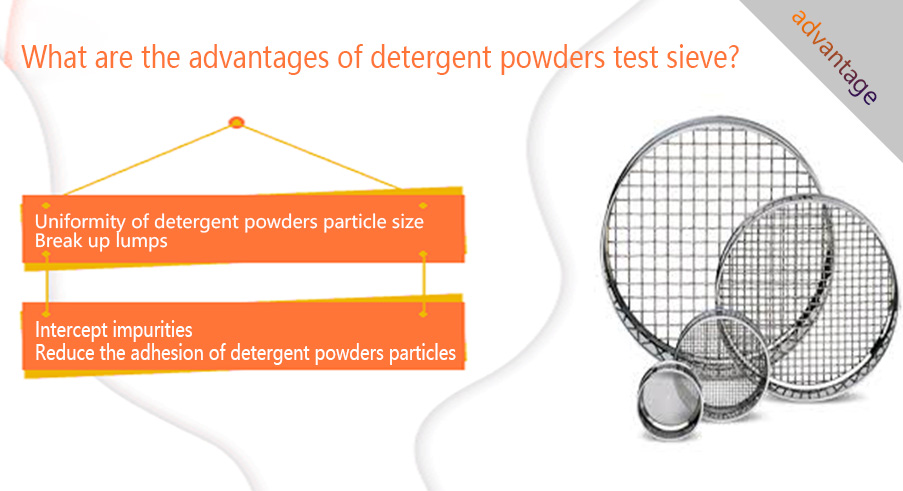

1. Uniformity of detergent powders particle size: Through the screening of the detergent powders test sieve, detergent powders with uniform particle size distribution can be obtained. This uniformity not only improves the use effect, but also makes the detergent powders more stable during packaging and transportation, reducing breakage and waste.

2. Break up lumps: Detergent powders test sieve usually has a vibration function. During the material conveying process, the high-frequency vibration of the sieve body driven by the vibration motor can cause relative movement between the detergent powders particles, thereby breaking up the lumped detergent powders.

3. Intercept impurities: The screen of the detergent powders test sieve can intercept various impurities mixed in the detergent powders, such as foreign matter in the raw materials, metal chips generated by wear of production equipment, etc.

4. Reduce the adhesion of detergent powders particles: Detergent powders test sieve can help detect whether there is a problem of adhesion of particles. If it is found that the particles are seriously adhered, the shape and texture of the particles can be improved by adjusting the formula or production process to reduce the adhesion of particles.

Detergent powders test sieve is widely used in production, research and development, quality control, batch inspection, market analysis and other links. It can help manufacturers ensure the particle size consistency of detergent powders, improve product quality, optimize formula, and ensure compliance with standards and regulations. Through particle size analysis, detergent powders test sieve is not only an important tool for quality inspection, but also a key equipment for product improvement and production optimization.

|

Parameter |

Description |

Common specifications |

|

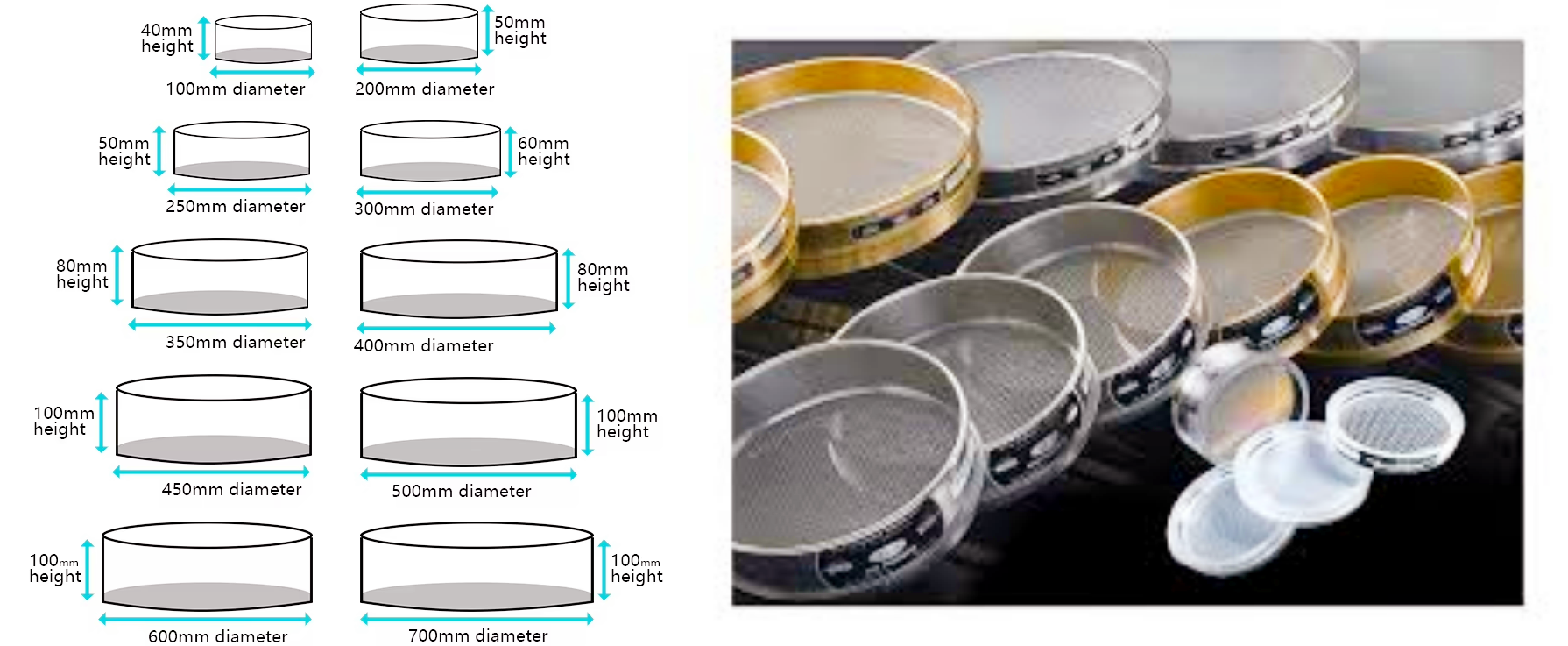

Screen diameter |

Diameter of the screen |

200 mm, 300 mm (or other customized sizes) |

|

Screen material |

Screen material |

Stainless steel, brass, wire mesh, punching plate |

|

Screen aperture |

Size of the screen hole |

Select according to the particle size range of detergent powders, the common range is tens of microns to several millimeters |

|

Number of screen layers |

Number of screen layers in the test sieve |

1 to 8 layers (or more, depending on the model and demand) |

|

Screening method |

Screening movement mode |

Manual shaking, electric vibration, swinging movement |

|

Vibration frequency (electric) |

Vibration frequency of electric test sieve |

Adjustable range, for example: 5 0-300 times/minute |

|

Amplitude (electric) |

Amplitude of electric test sieve |

Adjustable range, for example: 1-3 mm |

|

Timing range (electric) |

Timing range of electric test sieve |

0-99 minutes (adjustable) |

|

Power requirement (electric) |

Power required for electric test sieve |

220V/50Hz (or other specifications) |

|

Equipment material |

Material of the test sieve body |

Stainless steel, steel, plastic |

|

Dimensions |

Overall dimensions of the test sieve |

Varies according to model and number of layers |

|

Weight |

Weight of the test sieve |

Varies according to model and number of layers |

|

Applicable materials |

Material suitable for screening |

Detergent powders, powders, granular materials |

|

Standards |

Standards that meet |

GB/T 6003.1 (wire woven test sieve), ISO 3310-1 (wire woven test sieve), etc. |

|

Serial number |

name |

unit |

parameter |

|

01 |

sieve frame |

layer |

1~8 |

|

02 |

sieve frame diameter |

mm |

Φ200 |

|

03 |

screening particle size |

mm |

0.025~3 |

|

04 |

noise |

dB |

less than 50 |

|

05 |

amplitude |

mm |

0~3 |

|

06 |

vibration frequency |

times/min |

1440 |

|

07 |

outline dimensions |

length, width and height |

350:350:300+N*50 |

|

08 |

power supply |

V;HZ |

220;50 |

|

09 |

machine weight |

Kg |

36 |

|

10 |

vibration motor |

power |

0.12KW |

①Sample preparation: The sample is not dried, and two samples are taken with a conical sample divider for standby use.

②Sieve group assembly: select a set of clean and dry sieves with specified apertures according to the requirements, overlap them from bottom to top in the order of aperture from small to large, place the sieve group on the chassis, and install them together on the electric oscillator.

③Weigh the sample: weigh 100g of the sample separated by the sample divider, place it in the upper sieve, and cover the sieve.

④Start oscillation: start the oscillator, if a parallel reciprocating oscillator is used, the sieve vibrates for (4±0.5)min; if a vertical oscillator is used, the sieve vibrates for (8±0.5)min. After stopping the oscillation, remove the chassis and sieve group, collect and weigh the sample mass on each sieve and in the chassis respectively.

⑤Repeat the test: take another sample separated by the sample divider and repeat the above test. The average value of two tests is taken as the test result, and the sum of the masses of the residual samples on each layer of sieve and the samples in the bottom plate should not decrease by more than 1% compared with the mass of the input samples, otherwise the test must be repeated. At the same time, the deviation of the two test results should not exceed 1.5g.

|

Number |

mesh (mm) |

Number |

mesh (mm) |

Number |

mesh (mm) |

Number |

mesh (mm) |

|

2 |

13 |

26 |

0.71 |

90 |

0.16 |

260 |

0.06 |

|

3 |

6.5 |

28 |

0.63 |

100 |

0.154 |

280 |

0.055 |

|

4 |

5 |

30 |

0.6 |

110 |

0.14 |

300 |

0.054 |

|

5 |

4 |

32 |

0.55 |

115 |

0.13 |

320 |

0.048 |

|

6 |

3.2 |

36 |

0.5 |

120 |

0.125 |

325 |

0.045 |

|

7 |

2.8 |

40 |

0.45 |

130 |

0.111 |

350 |

0.041 |

|

8 |

2.5 |

45 |

0.4 |

140 |

0.105 |

360 |

0.4 |

|

9 |

2.2 |

50 |

0.355 |

150 |

0.1 |

400 |

0.0385 |

|

10 |

2 |

55 |

0.315 |

160 |

0.098 |

500 |

0.03 |

|

12 |

1.6 |

60 |

0.3 |

180 |

0.09 |

|

|

|

14 |

1.43 |

65 |

0.25 |

190 |

0.08 |

|

|

|

16 |

1.25 |

70 |

0.22 |

200 |

0.075 |

|

|

|

18 |

1 |

75 |

0.2 |

220 |

0.07 |

|

|

|

20 |

0.9 |

80 |

0.18 |

240 |

0.065 |

|

|

|

24 |

0.8 |

85 |

0.17 |

250 |

0.063 |

|

|

|

Specifications of detergent powders test sieve. If you need special specifications, please contact online customer service for consultation. |

|||||||

1.Equipment inspection: Before use, make sure that all parts of detergent powders test sieve are intact, the screen is not damaged, and the electric oscillator can work normally.

2. Material handling: Make sure that the detergent powders is not stuck together. Detergent powders that is too wet or contains too many impurities should be pre-treated to avoid affecting the screening effect.

Dahan Machinery focuses on the research, design, production and sales of vibration screening equipment, and provides various types of vibration screens, which are suitable for screening of various powders and granular materials, and are widely used in chemical, food, medicine, building materials and other industries. You can consult our sales staff through Dahan Machinery's official customer service or email to obtain product information and quotations.

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control, and is widely used in food, chemical, pharmaceutical and o...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy...

Ultrasonic test sieve for wheat flour

Ultrasonic test sieve for wheat flour is a special device that combines ultrasonic technology with traditional screening principles to efficiently screen wheat flour. The device can...

Laboratory Lactose Stainless Steel Test Sieve

Laboratory lactose stainless steel test sieve is a device used to accurately determine the size distribution of lactose particles. It is often used for laboratory particle analysis ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap