Friday June-27 2025 14:00:01

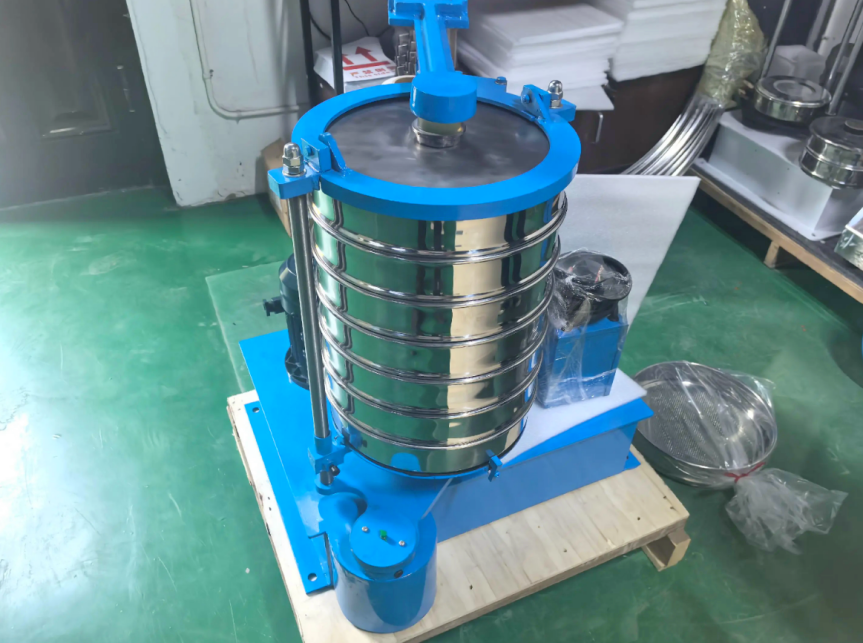

Diamond micro-powder has improved extremely high hardness (Mohs hardness 10) and fine particle size (0-250μm). In the screening process, the equipment requirements are strict. Ordinary vibrating screens are difficult to meet its needs, so diamond slap sieves are used. Through vibration and slapping, the production of strong effect, promotes the diamond micro-powder to pass through the screen quickly, solves the problems of particle agglomeration and mechanical clogging of the screen holes, and is particularly suitable for precise classification of ultra-fine particles (such as 1-10μm).

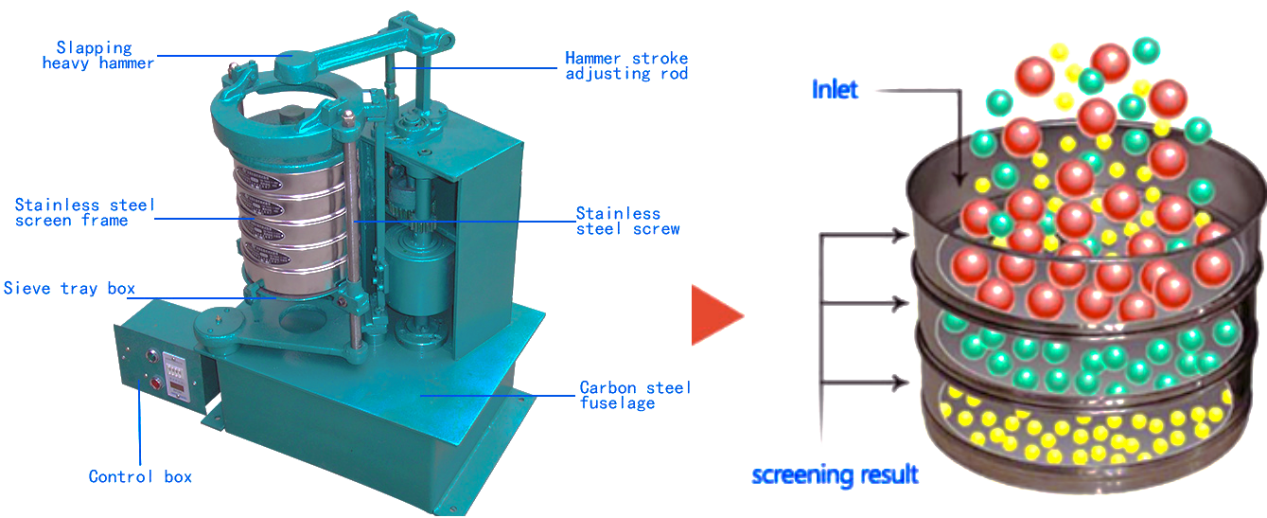

Diamond slap sieve mainly uses the motor to drive the eccentric mechanism, so that the screen body produces periodic slapping vibration in the vertical direction, and cooperates with horizontal reciprocating vibration. The screen frame of the screen machine drives the screen and the material to move relative to each other under the action of slapping and reciprocating, thereby promoting the stratification and grading of diamond particles on the screen.

When the material is placed on the upper screen, the equipment starts to work, and the slapping device regularly slaps the screen to loosen the diamond powder or particles adhering to the screen, which helps the particles pass through the screen holes; at the same time, the horizontal vibration of the screen frame pushes the material to move forward along the screen surface to achieve continuous screening.

Diamonds have high hardness, high value and precise particle size requirements. Problems such as clogging of the screen holes, inaccurate grading and large equipment wear are prone to occur during screening. In response to these, the diamond slap sieve cleverly responds with a unique design. It adopts a dual motion mode of "reciprocating shaking with slapping vibration". The high-frequency vibration makes the diamond particles fully roll and disperse on the screen surface, avoiding the blockage of the screen holes due to particle agglomeration and accelerating the feeding speed.

The particle size range of diamond micropowder (such as 0-0.5μm to 50-250μm) requires extremely high precision, and the screening equipment must ensure accurate particle classification to avoid particle size mixing. The slap sieve is usually equipped with multiple layers of screens with different apertures (such as 36/54μm, 10/20μm, etc.) to achieve step-by-step separation and ensure accurate particle size distribution.

For the screening of diamond micropowder, very fine particles are usually involved, so the commonly used screen mesh number will be relatively high. Generally speaking:

Conventional diamond micropowder classification: For common diamond micropowder, such as for grinding and polishing, the mesh selection range may be between 400 mesh and 2000 mesh. For example, some patents mention that diamond micropowders of 400-800 mesh can be sorted.

Ultrafine diamond powder classification: If more precise ultrafine diamonds need to be classified, such as for high-precision polishing or nanomaterials, the mesh may need to reach 2500 mesh or even higher (such as 3000 mesh, 4000 mesh, 6000 mesh, or even higher mesh nano-scale sieves). When choosing ultra-high mesh sieves, the efficiency and practical feasibility of screening should also be considered.

The diamond slap sieve is widely used for precision classification of precision diamond micropowders to meet the needs of precision industry. In the production of artificial diamonds, it is used to classify coarse particles of 50-250μm into 100-400 mesh, which is suitable for the manufacture of carbide tools and ceramic cutting tools to ensure cutting efficiency and surface quality. In the field of precision polishing, such as optical glass, sapphire and semiconductor processing, the slap sieve separates 5-15μm ultrafine powder through 800-2000 mesh sieves to provide high-brightness polishing effect. In gem processing, 1250-5000 mesh screens are used for grading 1-10μm micro powder marks to ensure that the surface is scratch-free. In addition, in the preparation of composite materials, such as diamond precision processing or abrasive paste production, the slap sieve achieves high-precision particle size control through multiple layers of screens (such as 200/400/800 mesh combination) to optimize product performance.

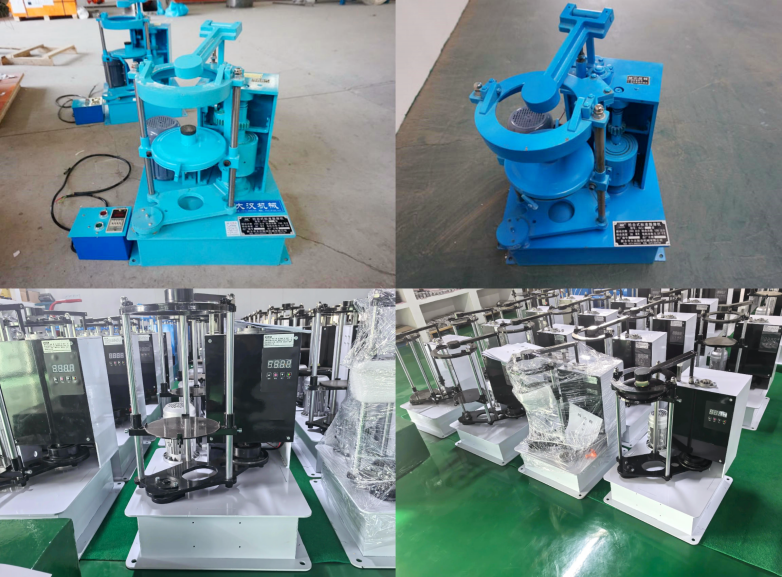

The accuracy of the diamond slap sieve can usually reach 25 microns. The slap sieve uses a specific shaking and slapping frequency to make the material fully move on the screen surface to achieve accurate screening. For example, the SPB-200 slapping standard vibrating screen has a screening accuracy of 25 microns, a shaking frequency of 290±5 times/min, a slapping frequency of 156±3 times/min, and a slapping height of 38±8 mm.

As the hardest substance in nature, diamonds need to be accurately screened in industrial applications to meet the strict requirements of particle size in different fields. The use of a slap sieve to process diamonds is mainly due to its unique vibration and impact mechanism, which can complete this task efficiently and accurately. Therefore, in the process of diamond raw material preparation, abrasive screening and micro powder particle size control, the use of a slap sieve is an important means to improve screening quality and ensure product performance.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Dahan Machinery provides soil sieves of various specifications and models to meet the screening needs of different particle sizes and outputs, suitab...

Jun 27, 2025

Diamond slap sieve is a special screening equipment. It combines reciprocating shaking with periodic ...

Jun 27, 2025

Dahan Machinery provides a variety of soil sieves, from laboratory to industrial level, covering a va...

Jun 26, 2025

Soil sieves price varies greatly, mainly depending on its purpose, material, size and precision.......

Jun 26, 2025

Inorganic Pigment Lab test Analyzer Sieve with Ultrasonic Device

Inorganic Pigment Lab Test Analyzer Sieve (with Ultrasonic Device) is an instrument that combines tra...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap