![[field:title/]](/uploads/250705/2-250F51F44O25.png)

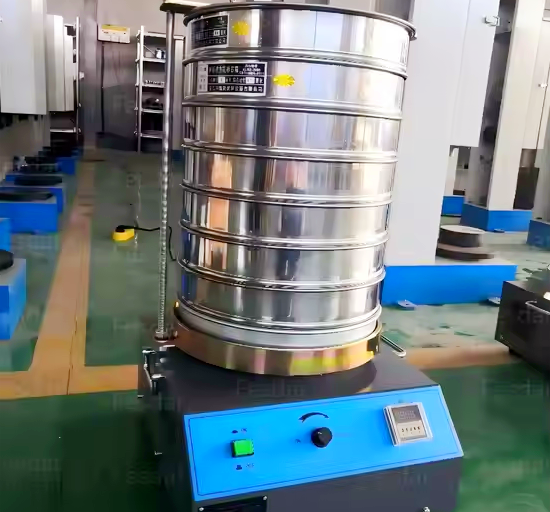

Electromagnetic sieve vibrator is a device used to screen and grade granular materials. It generates periodic exciting force through the electromagnetic drive device to make the screen vibrate, thereby realizing the movement and stratification of materials on the screen surface.

Price: $500.00-$1.200.00/Set

Amplitude adjustable range: 0.5mm to 5mm

Vibration frequency: 3000 times/minute

Voltage: 220V/380V

Sieve mesh: 20 to 325 mesh

Electromagnetic sieve vibrator is a key component that uses electromagnetic force to drive the vibration of screening equipment. It is widely used in various screening machines, especially for the screening of high-precision powders and granular materials. Through the principle of electromagnetic induction, the electrical energy is converted into high-frequency vibration, which drives the screen to achieve precise screening and adapts to the full range of 20-500 mesh screen requirements. Electromagnetic sieve vibrator is used for low-mesh coarse screening (such as 20-40 mesh), the excitation force and frequency can be adjusted to ensure that large particles pass through the screen quickly; for high-mesh fine screening (such as 325-500 mesh), it can provide a stable and high-frequency vibration source, and cooperate with the ultrasonic auxiliary system to effectively prevent fine powder from blocking the screen and ensure screening efficiency and accuracy.

The device generates an alternating magnetic field in the electromagnetic coil through an alternating current, attracts and releases the matching armature system, and forms continuous high-frequency mechanical vibration. The vibration frequency is generally 3000 times/minute (50Hz) or 3600 times/minute (60Hz), and the amplitude is adjustable. The advantage of an electromagnetic Sieve Vibrator lies in its precise adjustment of vibration frequency and amplitude to suit the screening requirements of different materials. Its simple structure, lacking complex mechanical transmission components, reduces maintenance requirements and ensures stable and reliable operation. Furthermore, an electromagnetic Sieve Vibrator typically possesses strong excitation force, making it effective for handling difficult-to-screen and high-viscosity materials. It is suitable for accurately screening and grading dry materials such as granular, powdered, and lumpy materials.

The working principle of the electromagnetic sieve vibrator is based on electromagnetic induction. Usually, it contains an electromagnetic coil (or electromagnet) and a movable armature (or vibrating body), which are connected by a spring. When alternating current passes through the electromagnetic coil, a periodically changing magnetic field is generated. This changing magnetic field produces attraction and repulsion on the armature, causing the armature to reciprocate at a certain frequency and amplitude, thereby driving the screen to vibrate. The core of the electromagnetic sieve vibrator is to convert electrical energy into vibration energy to achieve material screening. It is mainly composed of electromagnetic coils, armatures, springs and other components.

After power is turned on, the electromagnetic coil generates an alternating magnetic field, attracting the armature to move in the direction of the coil; when the power is turned off, the magnetic field disappears, and the armature is reset under the elastic force of the spring. Repeatedly, the armature will generate high-frequency reciprocating vibration.

This vibration is transmitted to the screen surface through the transmission mechanism, driving the screen to vibrate at high frequency, causing the material on the screen surface to continuously jump and roll, and particles smaller than the screen aperture pass through the screen to achieve graded screening.

Electromagnetic sieve vibrator supports the full range of 20-500 mesh screens. The coarse mesh (20-100 mesh) screening can quickly process large particles. The fine mesh (325-500 mesh) screening is matched with the ultrasonic system, which can effectively solve the problem of screen blocking of ultrafine powder (such as below 45μm). It is suitable for powder, granular materials and other materials. It uses the principle of electromagnetic induction to generate high-frequency reciprocating vibration to adapt to the screening needs of different mesh sizes.

High screening efficiency: high-frequency vibration helps materials to quickly stratify and pass through the sieve holes, especially for fine, sticky or difficult-to-screen materials.

High frequency and low amplitude: electromagnetic vibrating screens usually have a higher vibration frequency (e.g. 3000-3600 times per minute) and a smaller vibration amplitude, which helps to improve screening efficiency, especially for fine particle materials.

Adjustable amplitude: The amplitude of the vibrator can be easily adjusted through the controller to adapt to the needs of different material characteristics and processing volume, and achieve accurate feeding or screening.

Precise control: The vibration amplitude and frequency are adjustable, which can be optimized according to material characteristics and process requirements to achieve accurate screening or feeding.

|

Model |

Applicable screen frame diameter |

Vibration frequency |

Maximum number of screens |

Adjustable amplitude |

Power |

Voltage |

Dimensions (mm) |

Remarks |

|

DH-200 |

Φ200mm (8 inches) |

3000 times/minute |

8 layers |

Yes (mechanical knob) |

50W |

220V/50Hz |

400×300×400 |

Laboratory standard screen vibrator |

|

DH-300 |

Φ300mm |

3000 times/minute |

6 layers |

Yes |

80W |

220V/5 0Hz |

450×350×450 |

Can be used for medium batch material screening |

|

DH-315 (reinforced type) |

Φ315mm |

3000 times/minute |

6 layers |

Yes |

100W |

220V/50Hz |

480×370×480 |

Enhanced stability design |

| Items | Name | Unit | Data |

| 1 | Layers | Layer | 1-7 |

| 2 | Sieve Diameter | Mm | Φ75 Φ100 Φ200 |

| 3 | Granularity | Mm | 0.02-80 |

| 4 | Noise | DB | ≤50 |

| 5 | Feeding capacity (once) | G | ≤200 |

| 6 | Amplitude | V | 220 50/60Hz |

| 7 | Voltage | V | 220 50/60Hz |

| 8 | Speed | R/min | 3000 |

| 9 | Power | Kw | 0.5 |

| 10 | Overall dimension | Mm | 390×410×620 |

| 11 | Weight | Kgs | 46 |

|

Comparison items |

Electromagnetic screen vibrator |

Ultrasonic test screen |

|

Picture |

|

|

|

Vibration principle |

Electromagnetic force drives the armature to generate high-frequency mechanical vibration |

Use high-frequency ultrasonic oscillator to transfer vibration energy to the screen |

|

Vibration frequency |

Generally 3000~3600 times/minute (50~60Hz) |

Up to 18,000~40,000 times/second (18~40 kHz) |

|

Amplitude range |

large amplitude, generally 0.5~1mm, adjustable |

extremely small amplitude, usually within a few microns |

|

Main uses |

laboratory particle size detection, electromagnetic powder, light powder screening |

fine powder (such as nano powder, metal powder) screening, anti-blocking net |

|

Applicable mesh range |

20 mesh~200 mesh (general) |

100 mesh~600 mesh and above high-precision screen |

|

Applicable material characteristics |

ordinary powder, granules, easy-flowing granules |

fine powder, light powder, agglomerated powder, statically charged materials |

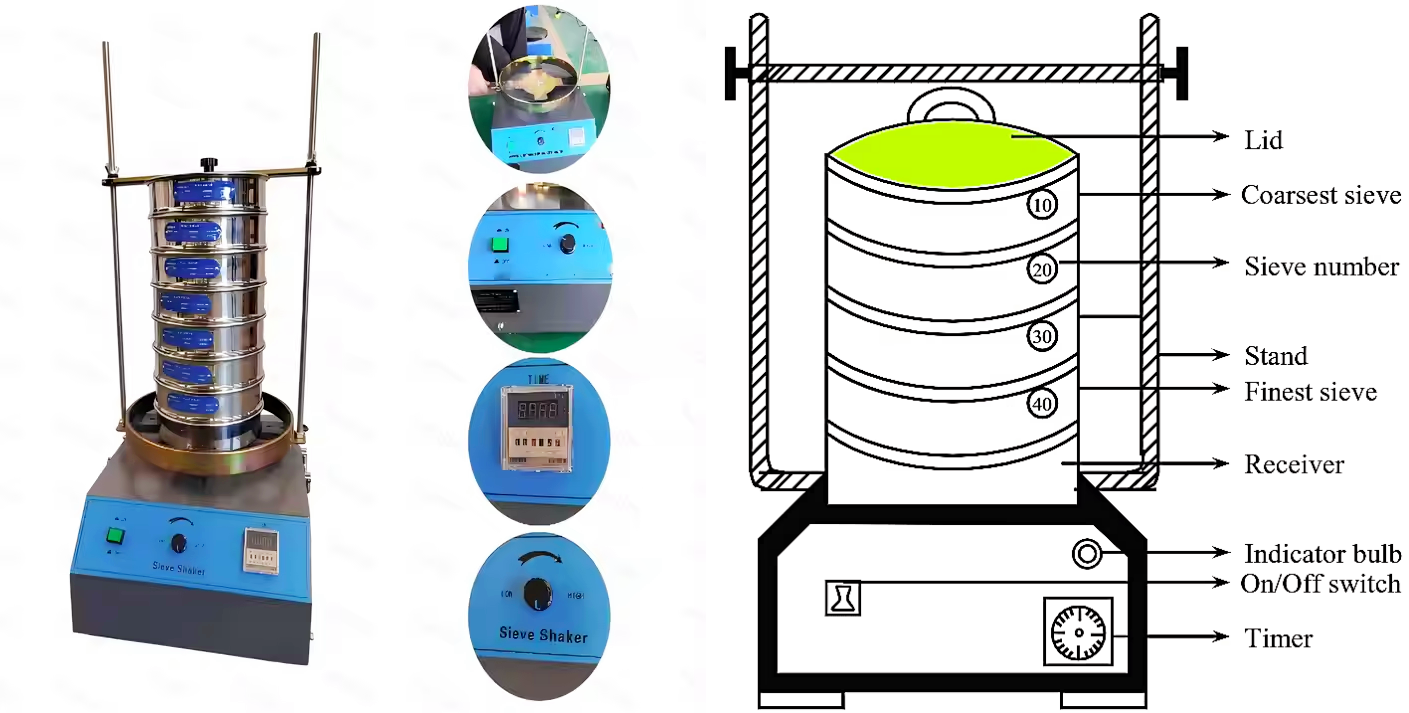

The electromagnetic coil (excitation coil) is wound by enameled copper wire, and generates an alternating magnetic field through alternating current. It is the driving core of the vibrator; the metal part of the armature (moving iron core) attracted by the electromagnetic force is periodically attracted and released under the action of the magnetic field to generate mechanical vibration

The fixed iron core (stator) cooperates with the armature to generate a magnetic circuit loop, which is a key component for forming electromagnetic attraction; Spring sheet or rubber shock-absorbing pad ensures that the armature can be quickly reset after being attracted, and plays a shock-absorbing and buffering role between the armature and the base

The base (machine base) carries the basic frame of all parts, usually made of cast iron or thick steel plate, with high stability; vibration guide plate (vibration table) transmits the vibration of the vibrator to the test screen, directly driving the screen body to vibrate

Amplitude adjustment device:Change the vibration intensity by adjusting the air gap, spring stiffness or voltage (some models have); power input interface generally 220V AC input, used with the controller

Electromagnetic sieve vibrator is a device that generates high-frequency vibration through electromagnetic drive. It is mainly used to drive laboratory or small industrial screening equipment to make the screen vibrate continuously, thereby realizing the screening, grading or detection of powder or granular materials.

In the chemical industry, the electromagnetic sieve vibrator can finely screen 325 mesh titanium dioxide to ensure the consistency of powder particle size and improve the uniformity and hiding power of the coating. The high-frequency vibration of the electromagnetic sieve vibrator combined with the ultrasonic function can effectively avoid fine powder blocking the screen and ensure screening efficiency. In food processing, flour mills screen wheat flour with 100-200 mesh to remove impurities and agglomerate particles to ensure product quality and safety. The stable vibration frequency and amplitude of the electromagnetic sieve vibrator can quickly screen the flour without destroying the fineness of the flour.

In the laboratory, the electromagnetic sieve vibrator performs particle size analysis on scientific research samples. Screens from 20 mesh to 500 mesh may be used. The adjustability and accuracy of the electromagnetic sieve vibrator can meet the screening needs of different mesh sizes, making the experimental data more reliable.

The process flow of electromagnetic sieve vibrator (electromagnetic vibrating screen) mainly involves the screening, separation and processing of materials, and is widely used in the classification, impurity removal or filtration of powder, granular or liquid materials.

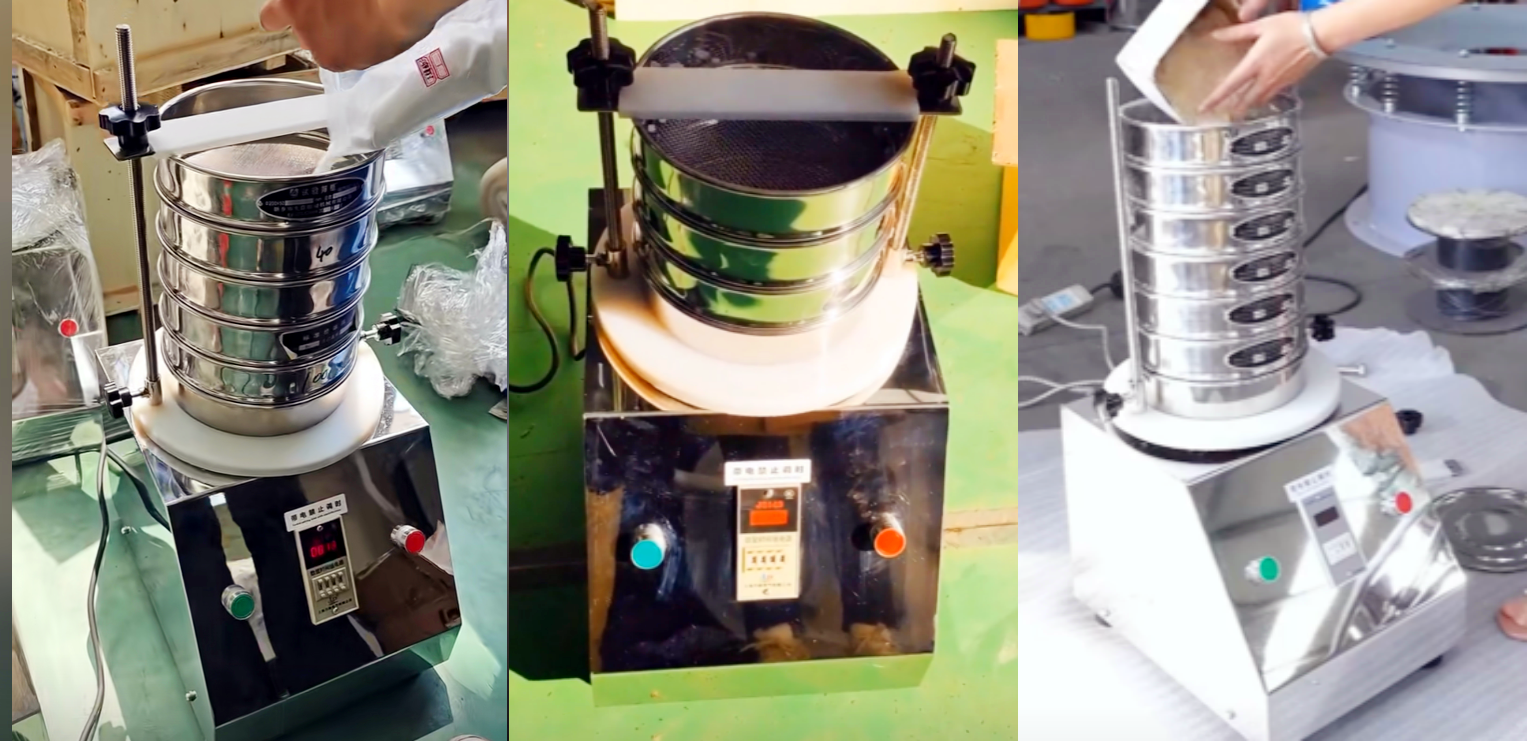

The material (powder, granular or liquid) is evenly placed on the top of the screening equipment through the feed port or hopper.

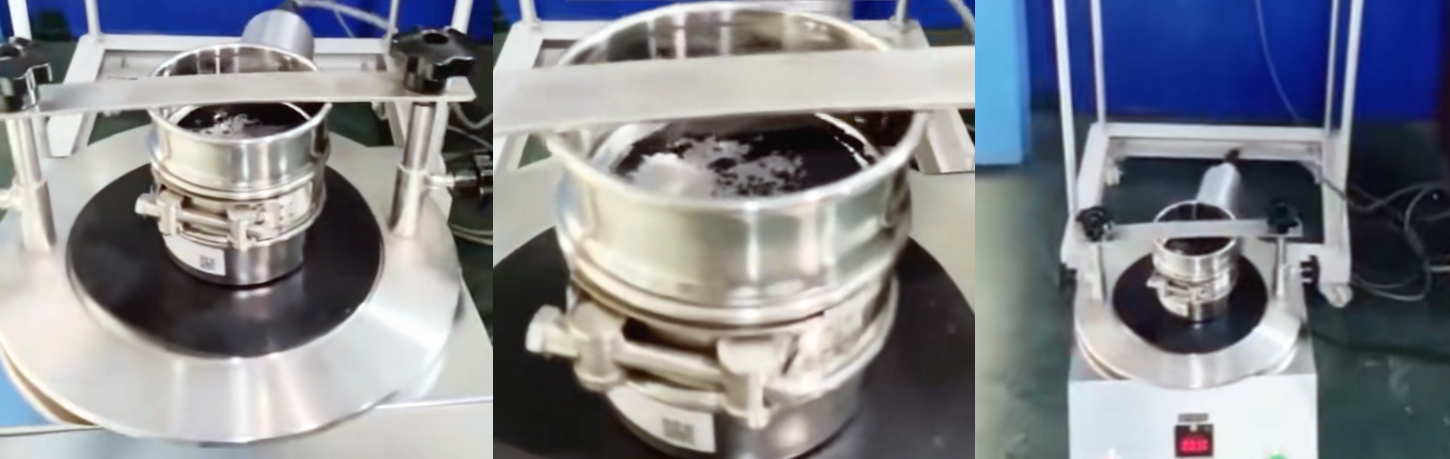

When the electromagnetic vibrator is powered on, it generates high-frequency electromagnetic excitation force (usually 3000 times/minute). The vibration is transmitted to the screen through the screen body, and the screen surface produces three-dimensional movement (horizontal, vertical and inclined), so that the material is evenly distributed on the screen surface and "jumps". The material is layered according to the particle size: particles smaller than the mesh aperture fall through the mesh into the lower collection container or the next level mesh; particles larger than the aperture remain on the mesh surface and are discharged through the discharge port.

Depending on the number of mesh layers (usually 1-8 layers), the material can be separated into 2-7 different particle size segments. The aperture of each layer of mesh decreases from top to bottom to achieve grading from coarse to fine.

Electromagnetic screen vibrators are widely used in laboratories and are suitable for screening various powders and granular materials. For example, when screening lime powder in the laboratory, it can be used to remove particles that do not meet the requirements to ensure that the particle size distribution of the final product meets the standards. Due to its efficient screening capacity and good screening effect, it has been favored by many schools.

A university research institute uses an electromagnetic standard vibrating screen to screen various test materials, with an electromagnetic vibrator as the vibration source. Electromagnetic sieve vibrator can drive the base of the screen to vibrate, and then transmit the vibration to the standard test screen, so that the material vibrates at a high frequency on the screen surface. At the same time, the lower device can also spread the material to achieve efficient screening. The equipment can hold 1-7 layers of test sieves and can effectively screen, grade, and filter materials. It solves the problem of ultra-fine powder dry screening and can screen to 20um (635 mesh). It is widely used in scientific research units, laboratories, etc. in many industries such as food, medicine, chemical industry, and abrasives. It is used for inspection, screening, and particle size analysis of solids, powders, slurries, and other materials.

Electromagnetic sieve vibrator suppliers are mainly concentrated in the vibrating sieve equipment manufacturing industry, especially those serving laboratory testing equipment and powder screening equipment manufacturers. Not only can they provide standard models of electromagnetic vibrators, but they can also provide customized services according to the requirements of screen size, amplitude frequency, voltage environment, etc.

With its adjustable vibration characteristics, an electromagnetic Sieve Vibrator can flexibly adapt to varying material and screening accuracy requirements, providing suitable solutions for everything from coarse-grained bulk materials to fine powders. Its wide range of applications depends primarily on the nature of the material being processed and the required screening accuracy. For example, in the mining and metallurgical industries, an electromagnetic Sieve Vibrator is commonly used to grade various ores, slag, and metal powders. For coarse-grained materials, a lower mesh size (e.g., 10-50 mesh) is typically used to quickly separate large impurities. For processes requiring the recovery of fine mineral powders, a higher mesh size (e.g., 80-200 mesh) is employed for more precise particle size classification. In the building materials industry, such as cement and sand grading, Electromagnetic Sieve Vibrators are capable of processing dry powdered materials. A wide range of mesh sizes, from tens to hundreds, are commonly used to meet the particle size requirements of different products. In abrasive manufacturing, particle size classification of various corundum and abrasive powders is crucial. Electromagnetic Sieve Vibrators precisely control the sieving process, ensuring the uniformity of the abrasive products. In the ceramics industry, they are also used to screen ceramic raw materials, glazes, and other materials to ensure the quality of the finished product. These applications typically involve fine screening, with mesh sizes often exceeding 100 mesh. In summary, Electromagnetic Sieve Vibrator plays an important screening role in many industrial fields with its unique vibration principle and adjustable performance.

Usually they produce various particle size analysis equipment, such as test sieves, ultrasonic sieves, vibration platforms, etc., and can match screens of various sizes (Φ200mm, Φ300mm, Φ400mm, etc.). The electromagnetic vibrator models are complete (such as EM-3, ZD series, etc.), and support different frequencies and excitation forces. Meet the differentiated needs of different materials (such as metal powder, drug powder, food powder, soil samples, etc.) and different industries (pharmaceuticals, metallurgy, agriculture, scientific research, building materials) in terms of screening accuracy, cleaning standards, and ease of operation.

What is the price of electromagnetic screen vibrator

The price of electromagnetic sieve vibrators varies greatly due to different models, configurations, and application scenarios, and usually fluctuates between $100 and $1,000...

Size sieve for soil mainly refers to the sieve frame diameter (commonly used 200mm, 300mm, etc.) and the sieve hole size (ranging from 0.075mm to 60mm). The sieve frame diameter is ...

Soil sieve prices range from $3 to $500. A soil sieve is a tool used to separate materials such as soil, sand, and compost by particle size. It is used in a variety of applications,...

The primary function of a perforated plate soil sieve is to analyze and separate various types of granular materials. Using precisely controlled pore sizes, a mixed sample is separa...

Standard Test Sieve is a commonly used particle analysis tool in laboratories and industrial sites. Its Sizes specification is the basis for ensuring the accuracy and comparability ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap