Wednesday July-16 2025 15:26:07

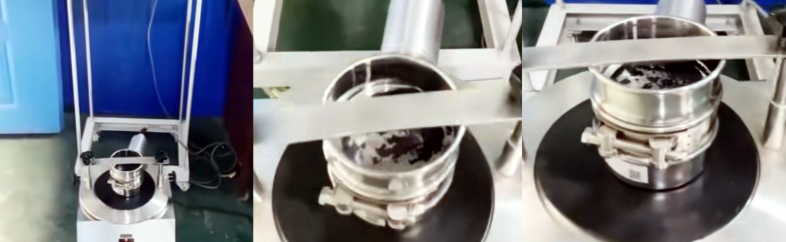

Electromagnetic powder ultrasonic test sieve is a high-precision screening equipment that integrates traditional electromagnetic vibration and ultrasonic technology. It is widely used in the fineness detection and screening of powder materials. With ultrasonic screen cleaning technology, it effectively solves the problems of agglomeration and screen blocking when screening fine powders above 325 mesh, and the screening accuracy can reach more than 99%. From 20 mesh coarse screening to 500 mesh ultra-fine grading, a rich selection of mesh numbers and customized screen configurations are suitable for various powder materials such as apatite, salts, and chemical raw materials.

Electromagnetic powder ultrasonic test sieve is an important tool in the field of fine powder analysis. This type of equipment usually uses high-quality stainless steel in material selection to ensure its corrosion resistance and high cleanliness. Its core advantage lies in the ingenious combination of electromagnetic vibration and ultrasonic technology, which can effectively solve the problem of fine powder clogging the screen and being difficult to separate completely in traditional screening, and significantly improve the screening efficiency and accuracy. In terms of processing volume, the sample processing volume of a single test is usually tens of grams to hundreds of grams.

The electromagnetic powder ultrasonic test sieve is mainly used for particle size analysis, graded screening and quality control of fine powders. It is particularly suitable for materials with high static electricity, easy agglomeration, strong adsorption or ultra-fine particle size, such as electromagnetic powder. For materials that are easy to clog the screen (such as high static electricity, strong adsorption powder), the ultrasonic system can improve the screening efficiency (pass rate of 99.5%) and output (0.5-10 times higher than ordinary vibrating screen).

Particle size detection and screening of electromagnetic powder and nanopowder

Ultrafine powder screening analysis in fine chemicals, medicine, food, electronic materials and other industries

Quality control and particle size analysis in laboratories and production processes

Electromagnetic powder is usually more than 200 meshes due to its fine particles, and its surface is prone to static electricity and agglomeration. In the traditional mechanical vibration screening process, electromagnetic powder is very easy to clog the screen hole, resulting in frequent clogging of the screen and low screening efficiency. At the same time, the powder is also easy to fly during the screening process, causing dust pollution and material loss.

The electromagnetic powder ultrasonic test sieve adds an ultrasonic vibration device to the traditional electromagnetic vibration screen, so that the screen generates high-frequency, micro-amplitude ultrasonic vibration, which effectively destroys powder agglomeration and electrostatic adsorption and prevents clogging of the screen holes. The synergistic effect of ultrasonic vibration and electromagnetic vibration enables the material to move and separate smoothly on the screen, greatly improving the screening efficiency and screening accuracy, especially suitable for 80-600 mesh ultrafine powder screening.

The recommended mesh number of electromagnetic powder ultrasonic test sieve mainly depends on the particle size distribution and screening accuracy requirements of the electromagnetic powder.

Generally speaking: for electromagnetic powder with coarse particle size, 100 mesh to 200 mesh (about 150 microns to 75 microns) screens are commonly used; for ultrafine electromagnetic powder, it is recommended to use 200 mesh or more, usually 250 mesh, 300 mesh or even 400 mesh (about 53 microns to 37 microns) screens.

|

Particle size range (micrometers) |

Recommended sieve mesh |

Applicable instructions |

|

150-75 |

100-200 |

Coarse to medium particle size electromagnetic powder screening |

|

75-53 |

200-250 |

Fine particle size electromagnetic powder screening |

|

53-45 |

250-300 |

Ultrafine electromagnetic powder screening |

|

45-37 |

300-400 |

Ultrafine electromagnetic powder and nano-powder screening |

Ultrasonic vibration can effectively prevent fine powder from blocking the screen, especially suitable for ultrafine powder screening above 200 mesh. Therefore, when the electromagnetic powder fineness is high, it is recommended to choose a sieve of about 300 mesh to ensure screening accuracy and efficiency. The specific mesh number should be selected in combination with the actual powder particle size distribution and screening target.

When choosing an electromagnetic powder ultrasonic test sieve, the adaptability of the mesh number is directly related to the test results and production quality. From a scientific research perspective, when studying nano-scale powder materials, a sieve with a mesh number of 500 or even higher is required to accurately separate ultrafine particles; in chemical production, if the raw materials are to be tested for particle size, a 200-300 mesh sieve can quickly screen out qualified particle sizes.

Preparation stage: Select a sieve suitable for the particle size distribution of electromagnetic powder (80-600 mesh is recommended, 200-400 mesh is commonly used). Place the electromagnetic powder sample evenly on the top sieve. Connect the ultrasonic generator and electromagnetic exciter, and check whether the power supply and circuit are normal.

Operation stage: Start the equipment, first turn on the electromagnetic vibration, so that the material moves three-dimensionally on the screen surface to promote dispersion. Generally 3-10 minutes, the specific time depends on the amount of material and the mesh size. After the screening is completed, turn off the equipment, collect the material in each layer of the sieve, and record the particle size distribution data.

Precautions: Please wear protective equipment during operation to avoid inhaling dust. Make sure the equipment is grounded to prevent static interference. Ultrafine powders (such as above 400 mesh) require increased ultrasonic power. If the screening efficiency is low, check the mesh size of the sieve or increase the screening time.

Electromagnetic powder ultrasonic test sieve combines traditional mechanical vibration with advanced ultrasonic technology, and is designed to solve common problems encountered in the powder screening process. Its main features are reflected in the following aspects:

Ultrasonic vibration assistance

The most notable feature of Electromagnetic powder ultrasonic test sieve is the integrated ultrasonic vibration system. The ultrasonic transducer converts high-frequency electrical energy into mechanical vibration and transmits it to the surface of the sieve. This high-frequency, micro-amplitude vibration can effectively solve the sieve blockage. For fine powder, light powder or powder that is easy to absorb moisture and agglomerate, ultrasonic vibration can destroy the adhesion between particles, prevent particles from "bridging" or adhering to the sieve holes, and significantly improve the patency of screening. Improve screening efficiency and accuracy. Ultrasonic vibration makes the particles more evenly dispersed on the sieve surface and pass through the sieve holes with less resistance, thereby shortening the screening time and obtaining more accurate particle size distribution data.

Multiple vibration modes

In addition to ultrasonic vibration, this type of test sieve usually also has traditional mechanical vibration modes (such as three-dimensional vibration or slapping vibration). This means that it can use ultrasound alone, mechanical vibration alone, or both vibration modes at the same time, depending on the characteristics and screening requirements of different powders. This flexibility allows the equipment to adapt to a wider range of powder materials and screening conditions.

Precision screening capabilities

Electromagnetic powder ultrasonic test sieve is equipped with a high-precision standard test sieve with strict sieve aperture tolerance. Combined with the auxiliary effect of ultrasound, it can screen micron-level fine powders with high precision to meet the needs of industries with strict requirements on particle size distribution (such as fine chemicals, metal powders, ceramics, etc.).

Reduce dust flying and material loss

Since ultrasound helps particles pass through the sieve more smoothly, it reduces the dust flying that may be caused by violent vibration or manual knocking in traditional screening. At the same time, reducing the residue of materials on the sieve also helps to reduce material loss and improve recovery rate.

|

NO. |

Name |

Unit |

Parameter |

|

1 |

frame diameter |

mm |

φ200 |

|

2 |

the number of layer |

s |

1~8 |

|

3 |

sieve size |

mm |

0.025-3 |

|

4 |

vibrating amplitube |

mm |

1~4 |

|

5 |

vibration frequency |

n/min |

1440 |

|

6 |

power supply |

V;HZ;KW |

220;50;0.12 |

|

7 |

outside dimension |

LWH |

350*350*(300+n*56) |

|

8 |

machine weight |

kg |

36 |

|

9 |

time alarm |

s |

999 |

|

10 |

noise |

db |

Less than 50 |

The application of Electromagnetic powder ultrasonic test sieve is mainly concentrated in the scenarios of particle size analysis and quality control of various powder materials. The core function of this type of equipment is to accurately classify powder samples according to particle size, so as to obtain its particle size distribution data, and provide a basis for material property evaluation and process optimization. This equipment is widely used in occasions where the particle size of fine powders needs to be accurately measured. Due to the fine particles of powders, traditional screening is prone to sieve hole blockage or "bridge" phenomenon, resulting in incomplete screening. Electromagnetic powder ultrasonic test sieve can effectively break up the agglomerated particles and prevent the sieve from being blocked by the additional ultrasonic vibration, ensuring that even nano- or micron-level fine powders can obtain accurate screening results. In addition, it is also suitable for handling powders that are easy to fly, easy to absorb moisture or have a certain viscosity. The introduction of ultrasonic waves makes it difficult for materials to adhere to the sieve or form electrostatic adsorption during the screening process, thereby reducing material loss and dust dispersion, and helping to improve the cleanliness of the operating environment. In some R&D and production links that require high material purity or uniformity, obtaining accurate particle size distribution through this test sieve can help engineers determine the batch consistency of materials, optimize the formulation, and predict its performance in subsequent processes (such as mixing, compaction, sintering, etc.). In general, the Electromagnetic Powder Ultrasonic Test Sieve is a tool for fine powder particle size analysis that can solve the problems of traditional screening when handling special powders, thereby improving the accuracy and efficiency of product quality control.

In addition, in actual operation, the problem of material blocking is often encountered. The efficiency of ordinary vibrating screens drops sharply under high mesh screening, while the ultrasonic cleaning function of the electromagnetic powder ultrasonic test sieve can effectively solve the problem of blocking when screening above 325 meshes, ensuring screening continuity.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy powder....

Jul 16, 2025

Electromagnetic powder ultrasonic test sieve

Electromagnetic powder ultrasonic test sieve combines traditional mechanical vibration with high-freq...

Jul 15, 2025

Powder test sieve is a laboratory device that physically separates powder samples according to partic...

Jul 14, 2025

Standard Test Method for Particle-Size Analysis of Soils

Size analysis of soils is a standard laboratory procedure used to determine the proportion by weight ...

Jul 08, 2025

Soil sieving analysis uses dry or wet sieving to separate soil particles by size. Dry sieving is suit...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap