Tuesday September-09 2025 15:07:56

Environmental soil sieves are a key tool whose core function is to physically separate soil samples based on particle size. They are typically made of various materials, such as stainless steel, brass, or plastic, to suit different analytical needs and environmental conditions. Common soil sieves available on the market come in a variety of sizes, including sieves with diameters of approximately 20 cm (8 inches) or 30 cm (12 inches), commonly used in laboratories. Using varying mesh sizes, they can precisely separate particles from coarse (e.g., a No. 4 sieve with approximately 4.75 mm openings) to fine (e.g., a No. 200 sieve with approximately 75 μm openings).

Each type of environmental soil sieve, made of different materials, such as stainless steel, brass, and plastic, offers unique advantages and applications. They differ not only in size and mesh size, but also in their suitability for different sieving methods. Below is a detailed introduction to three different types:

Stainless Steel Sieves

Stainless steel sieves are commonly used in environmental soil analysis due to their durability and corrosion resistance. Size: Stainless steel sieves come in a wide range of sizes, from small sieves (e.g., 8-inch diameter) for laboratory analysis to large sieves (e.g., 12-inch or larger) for large-scale field screening.

Sieving Mesh: Stainless steel sieves offer very fine screening, with a wide range of mesh sizes, from coarse (e.g., 4 mesh, or 5 mm) to very fine (e.g., 270 mesh, or 53 microns), and even finer, to meet a variety of soil particle size analysis needs.

Sieving Methods: Due to their durability, stainless steel sieves are suitable for a variety of sieving methods, including dry sieving (often using a vibrating sieving machine, such as an electromagnetic vibrator, for precise results) and wet sieving (for soils with high clay or silt content to prevent particle agglomeration).

Brass Sieve

Brass sieves are also a common soil sieve, especially in certain laboratory applications. While not as durable as stainless steel, they can be an economical choice in certain situations, such as for the analysis of non-corrosive substances.

Size: Brass sieves are generally available in similar sizes to stainless steel sieves, with 8-inch and 12-inch diameters being common in laboratories. Sieving Mesh: Brass sieves also have a wide range of mesh sizes, but are typically used within a more general mesh range, such as 4 to 200 mesh. They are commonly used for general soil particle size analysis and particle size classification.

Sieving Method: Brass sieves are primarily used for dry sieving, but can also be used with vibrating sieving machines. However, because brass is softer than stainless steel, it is not recommended for abrasive samples or wet sieving, as the water and chemicals involved in wet sieving may corrode the brass, affecting the accuracy of the mesh size.

Plastic Sieve

Plastic sieves are typically made of high-strength plastics such as polypropylene. Their uses are more specialized, typically not for precise laboratory particle size analysis, but rather for rapid field screening, primary classification, or specialized chemical applications.

Size: Plastic sieves are typically larger for handheld or field use, such as in handheld sieving buckets.

Sieving Mesh: Plastic sieves typically have larger mesh sizes and smaller mesh sizes, and are primarily used for coarse screening. For example, common sieves may have mesh sizes larger than 1 mm and are used to remove large rocks, tree roots, and other debris from the soil. They are not suitable for fine particle screening requiring high precision.

Sieving Methods: Plastic sieves are primarily used for simple dry or wet sieving. They are typically used for manual screening on-site, such as in archaeology, geological exploration, or gardening. Because they are lightweight, easy to clean, and rust-resistant, they are very convenient in certain situations.

Environmental soil sieves offer several advantages in soil analysis and environmental monitoring. These advantages primarily include data accuracy, efficiency, standardization, and versatility. The following are its key advantages:

Data Accuracy and Reliability: Environmental soil sieves are a fundamental tool for particle size analysis, accurately separating soil samples into fractions of varying particle sizes. This is crucial for understanding soil texture, predicting its physicochemical properties, and assessing the distribution of pollutants in soils of varying particle sizes. Using standardized sieves ensures reproducible and reliable experimental results.

Improved Work Efficiency: With the help of automated equipment such as vibrating sieving machines, soil sieves can complete large sample sieving processes in a short period of time, significantly saving manpower and time. This is particularly important for laboratory and field work that require processing large numbers of samples.

Standardization and Compliance: International standards exist for soil sieving methods. Using soil sieves that meet these standards ensures that analytical results are globally recognized, which is crucial for academic research, engineering projects, and compliance with environmental regulations.

Versatility: Soil sieves are used for more than just basic particle size analysis; their applications are extensive. For example, in environmental monitoring, they can be used to screen and separate microplastics, heavy metals, or other pollutants in soil; in agricultural science, they can be used to assess soil aggregate stability; and in geology, they can be used for sediment analysis.

Cost-Effectiveness and Durability: Soil sieves made of materials such as stainless steel and brass offer excellent durability and corrosion resistance. They are reusable and require low maintenance, making them highly cost-effective in the long run.

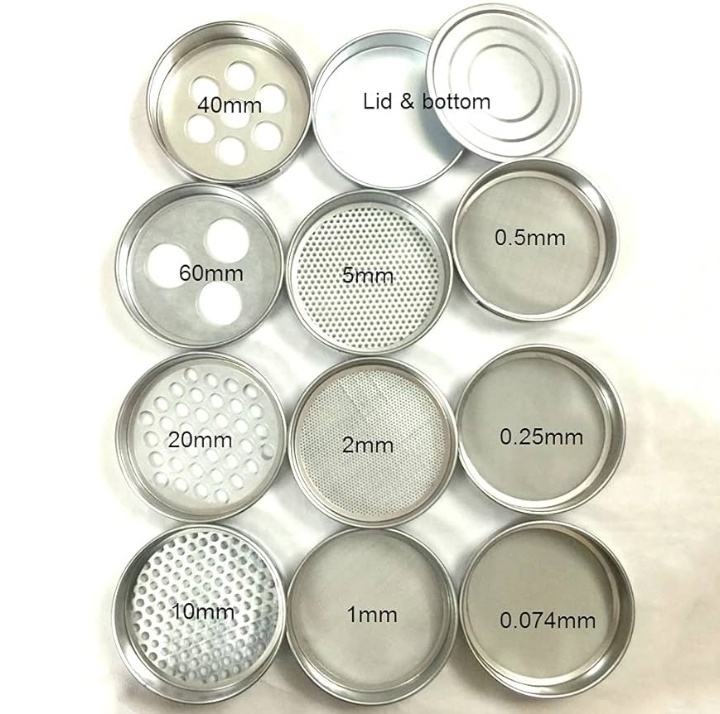

An environmental soil sieve typically consists of three main components: a sieve frame, a screen mesh, and a base. These three components combine to form a complete screening unit for accurate particle size analysis of soil samples.

Sieve frame: The sieve frame is the outer structure of the soil sieve. It is typically round and serves to secure and support the screen mesh. The sieve frame provides the overall structure of the sieve, ensuring the mesh remains flat and stable during the sieving process. It also determines the sieve's diameter and height, both of which are crucial for screening efficiency and sample capacity. Common sieve frame materials include stainless steel, brass, and galvanized steel. Stainless steel is the most common choice because it is corrosion-resistant, durable, and easy to clean, ensuring long-term stability and accuracy.

Sieve mesh: The sieve mesh is the core component of the soil sieve. It is woven from fine metal wires to form a precise mesh. The sieve mesh is the component that actually performs the screening work, and its mesh size determines the particle size that can pass through. Different mesh sizes correspond to different mesh sizes, enabling precise classification of soil particles. The sieve mesh is typically made of the same material as the sieve frame, most commonly stainless steel wire. Stainless steel wire offers high strength and wear resistance, effectively resisting friction from soil particles and maintaining a stable mesh size over time.

Base Pan: The base pan is located at the bottom of the sieve stack and is a flat container. It collects all soil particles that pass through the fine mesh (often referred to as "pan" or "fines"), preventing sample loss. This ensures that all sample components are collected and weighed for a comprehensive mass balance calculation. The base pan is typically constructed of the same material as the sieve frame and sieve mesh to ensure durability and compatibility.

Environmental soil sieves have a wide range of applications. While they are commonly used across a variety of industries, their core functionality and application principles are common. The following are some key uses of environmental soil sieves, not specifically industry-specific:

Soil particle size analysis: Using a set of sieves with varying apertures, soil samples can be separated into different particle sizes, such as sand, silt, and clay. This analysis is crucial for determining whether a soil is sandy, loamy, or clay, which is the first step in soil classification and understanding its physical properties. For predicting soil properties, soil particle size composition directly affects its water-holding capacity, aeration, fertility, and ability to adsorb pollutants. For quality control and assessment, particle size analysis is used to ensure the homogeneity of soil samples during research or experiments, minimizing experimental errors caused by sample variability.

Contaminant distribution studies: Environmental soil sieves are a key tool for studying the behavior of pollutants in soil. For pollutant enrichment analysis, many pollutants, such as heavy metals and organic pollutants, tend to adsorb onto finer particles in soil. Sieving allows for separate analysis of pollutant concentrations in soils of different particle sizes, thereby identifying the locations of pollutant accumulation. For environmental risk assessment, understanding the distribution of pollutants in soil helps assess their mobility and bioavailability, providing a scientific basis for environmental risk assessment and the development of remediation plans.

Soil improvement and treatment: Additive mixing: Soil improvement requires thorough mixing of additives such as organic matter, lime, or fertilizers with the soil. Using sieves ensures uniform dispersion of additives and prevents large clumps of material from affecting the improvement effect.

Soil remediation: Certain soil remediation techniques, such as soil washing, require sieving contaminated soil to isolate the finer particles for targeted treatment, thereby reducing the total volume and cost of treatment.

Sediment classification: In geological studies of rivers, lakes, or coastal areas, soil sieves are used to analyze the particle size distribution of sediments, helping scientists understand geological history, depositional environments, and erosion processes.

Sediment tracing: By comparing the particle size characteristics of sediments from different regions, their origins can be traced, which is very useful in environmental archaeology and geological exploration.

Environmental soil sieves should be selected based on industry needs. For the environmental monitoring industry, standard sieves are preferred. The sieve frame diameter is 200-300mm, and the material is corrosion-resistant 304 stainless steel. Mesh sizes range from 10-200, suitable for precise laboratory particle size analysis and rapid screening of batch samples. For the agricultural planting industry, lightweight and practicality are preferred. Plastic or galvanized steel sieves are primarily selected. Mesh sizes range from 10-40 (10 mesh for removing stones, 40 mesh for fine screening of seedling soil). These meet the needs of field soil improvement and seedling medium preparation, balancing cost and portability. For the geological survey industry, highly wear-resistant manganese steel is selected. The sieve frame is reinforced to prevent deformation, and mesh sizes range from 2-100 (2 mesh for screening large rocks, 100 mesh for analyzing fine-grained soil). These portable sieves are suitable for field operations and must withstand complex working conditions to ensure accurate screening of geological samples.

Environmental soil sieves play a fundamental role in environmental monitoring and scientific research. From their material and size to the precision of the sieve mesh, every characteristic is directly related to the accuracy of soil analysis and the reliability of data. In practical applications, selecting the appropriate soil sieve based on the specific properties of the soil sample and the purpose of the analysis is critical to ensuring valid experimental results. Whether used for basic soil texture identification or for more complex pollutant distribution studies, soil sieves provide reliable support for researchers with their stable performance and repeatable classification capabilities.

Soil sieve price vary widely, ranging from $3 to $500. Small, handheld garden sieves are generally cheaper due to...

ASTM standard soil analysis sieves with pan and cover

ASTM standard soil analysis sieve is a special test sieve manufactured according to the American Society for Testing and Materials (ASTM) E11 standard...

0.5mm stainless steel soil sieve for lab testing

0.5mm stainless steel soil sieve for lab testing is a screening tool commonly used in soil particle analysis...

Construction soil sieves are used to size-classify bulk granular materials...

Sep 09, 2025

Environmental soil sieve Common sieve sizes for environmental soil sieve include: coarse sieve 4.75mm...

Sep 06, 2025

Construction soil sieve can separate particles of different sizes in the soil, detect soil particle g...

Sep 02, 2025

Agricultural soil testing sieve

Agricultural soil testing sieve uses a 2mm sieve to separate the fine particles in the soil in order ...

Aug 22, 2025

What is Stainless steel soil sieve? A stainless steel soil sieve is a basic tool used to classify and...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap