Thursday April-17 2025 19:03:46

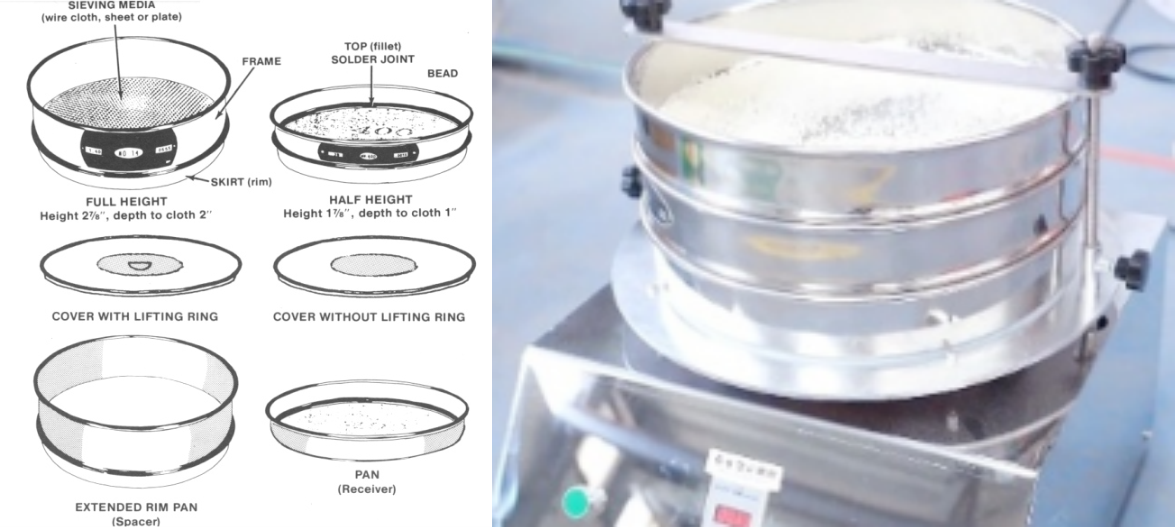

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness in powdered materials. Its working principle is usually based on the method of physical separation. By applying mechanical force (such as vibration), the powder sample is passed through a series of precision sieves with known mesh sizes, and the amount of material remaining on each sieve is accurately weighed, thereby determining the proportion of fines powder smaller than a specific mesh size in the total sample.

Fines content tester is a special device used to measure the fines powder content in powder materials. Its main functions are:

Determine the percentage of fines powder content below a specific particle size in a powder sample

Analyze the particle size distribution of powder materials

Evaluate the physical properties of powders such as fluidity and dispersibility

Different types of fines powder content testers use slightly different methods. The principle is as follows:

Pour the sample into the built-in standard sieve of the instrument, sieve it for a certain period of time through the built-in vibration device, collect the fines powder under the sieve and weigh it or read the sensor result.

It is mostly used for powder materials and dry granular products, such as daylily powder, flour, cinnamon powder, tea leaves, etc.

Reduce deterioration or loss of fines powder

Fines powder (such as spice powder and medicinal powder) contains volatile components. Long-term sieving or high-temperature vibration may cause the components to volatilize or oxidize. Ultrasonic vibrating screens and airflow sieving instruments have low amplitude and less friction heat, which reduces the loss of volatile components.

Solve the problem of agglomeration of fines powder materials

Agglomerated particles may be mistakenly screened as coarse particles, resulting in inaccurate detection of fines powder content and affecting product quality. Fines content tester breaks up the agglomerated particles of fines powder by vibration to promote uniform screening.

Improving the accuracy of fines powder testing

Traditional screening methods have low resolution for ultrafine powders (<10μm), making it difficult to accurately measure the fines powder content.

Impact: Applications that cannot meet high-precision requirements, such as particle size distribution analysis of inhaled drugs or 3D printing powders. It supports multi-level sieve combinations (such as 200 mesh + 325 mesh + 400 mesh) to analyze the fines powder content step by step.

Solve the problem of fines powder screen clogging

Fines powder particles (especially <45μm) are easy to adhere to the sieve holes due to static electricity, viscosity or hygroscopicity, resulting in sieve clogging. Fines content tester is equipped with a pulse screen cleaning device to clean the screen surface regularly.

Relatively coarse fines powder: less than 100 mesh as the limit. Applied in building materials or abrasive industries.

Medium fines powder: between 200 mesh and 500 mesh, used in chemical, ceramic or food powder industries.

Very fines powder: above 500 mesh or even up to 1000 mesh or higher, used in medicine, fines chemicals, nanomaterials and other fields.

Fines content tester is an instrument specially used to detect the content of fines powder (fines particles) in materials, which is widely used in building materials, mining, metallurgy, chemical industry, environmental protection and other fields.

Cement and building materials industry: fines powder content (usually refers to particles less than 45μm) directly affects the strength, setting time and construction performance of cement. Fines content tester is used to detect the proportion of fines powder in raw materials, clinker or finished cement.

Pharmaceutical industry: Too much fines powder may lead to increased hygroscopicity or poor fluidity of drugs, affecting tableting or capsule filling. It is used to detect the particle size distribution of active pharmaceutical ingredients or excipients. For example, an antibiotic powder needs to ensure that 80% of the particles are within the range of 10-50μm to ensure the dissolution rate.

Food industry: (flour, cocoa powder) Too much fines powder may cause powder agglomeration or blockage of processing equipment, while too little may affect the product texture. Fines content tester is used to detect the proportion of fines powder in flour (<75μm), increase the fines powder content from 15% to 20%, and improve product quality.

Chemical and mineral processing: The fines powder content in chemical raw materials (such as pigments, catalysts) or mineral powders (such as talcum powder, kaolin) affects the dispersibility, reactivity and storage stability of the product. Fines content tester is used to detect the proportion of fines powder in titanium dioxide or carbon black (<10μm) to ensure the dispersibility and hiding power of the pigment in the coating.

Fines content tester is an important tool for improving material quality, optimizing process parameters, controlling product performance and meeting environmental protection requirements. Different fields have different concerns about fines powder, but their impact is crucial. By scientifically detecting and controlling the fines powder content, product reliability and engineering safety can be greatly improved.

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to screen vitamin powder. It screens materials through mechanical vibration and slapping...

Stainless steel sieve shaker model features

Stainless steel sieve shaker is an important tool for particle size analysis. Its model features are mainly reflected...

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Brass Sieve Shaker manufacturer

One of the manufacturers of brass sieve shakers is Xinxiang Dahan Vibration Machinery Co., Ltd. (referred to as "Dahan Machinery"). Our company...

Agricultural gruesos Test sieves

OAgricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Apr 17, 2025

Fines content tester is a device used to quickly and quantitatively analyze the fines powder content ...

Apr 15, 2025

Nylon sieve shaker mesh is a mesh filter material woven from nylon material (usually nylon 6, nylon 6...

Apr 14, 2025

Stainless steel frame and woven cloth

The stainless steel frame provides a sturdy support structure, while the precision-woven stainless st...

Apr 11, 2025

Agricultural gruesos Test sieves

Agricultural gruesos test sieve is a kind of experimental equipment specially used to analyze the par...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap