Monday November-24 2025 14:33:00

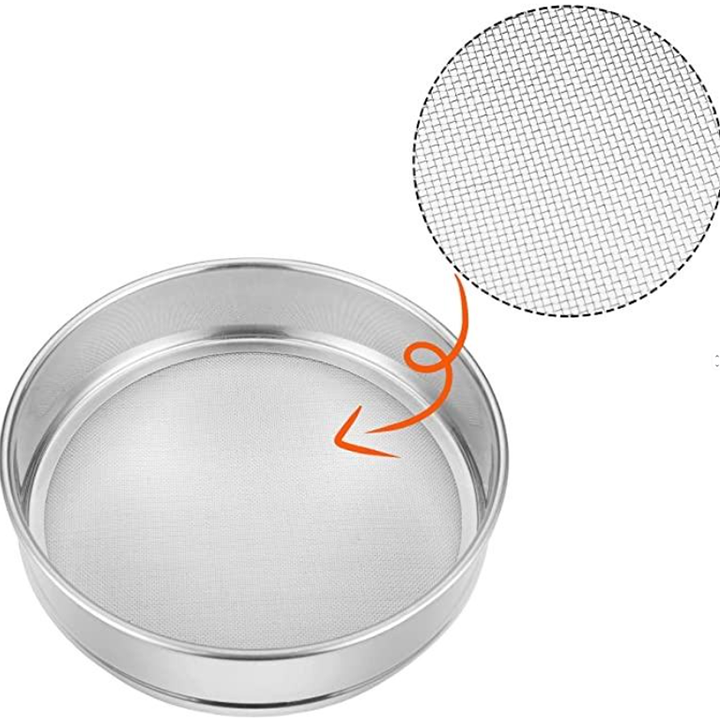

Laboratory test sieves are essential tools for particle size analysis, used to measure the particle size of soil, sand, and various powders. Available in 3-inch and 8-inch diameters, these sieves offer a variety of mesh sizes, such as 110 and 200 mesh, and comply with US standard test sieve specifications, making them ideal for laboratory particle size analysis. A single 200mm/8-inch sieve costs between $20 and $60 USD, while For Laboratory Sieves Price from $200 to $60 USD, depending on the sieve diameter, mesh range, material, and quantity.

Material is a key factor in determining the For Laboratory Sieves Price, directly affecting cost, durability, and applicable applications. carbon steel is prone to rust, stainless steel is a commonly used material, special alloys are the most expensive, nylon is lightweight, and brass is antistatic.below is a price guide for different materials.

Inexpensive plain carbon steel rusts easily and is only suitable for dry, non-corrosive materials, such as ordinary, dry soil, sand, grain, coal, and some mineral raw materials. Prices range from $10 to $30 USD. Moderately priced stainless steel (such as 304 or 316) is the most versatile choice due to its excellent corrosion resistance and hygienic properties. It is used for screening flour, powdered sugar, pharmaceutical raw materials, cement, and other water-sensitive or mildly corrosive materials, with prices ranging from $40 to $100.

Expensive specialty alloys or pure metals, which can withstand extreme environments like strong acids and alkalis, are specifically used for screening highly corrosive chemicals, highly alkaline minerals, and specific military and explosive materials. However, their high raw material and processing costs make these screens the most expensive, at around $200.

Polyester and nylon meshes are lightweight, flexible, acid- and alkali-resistant, and non-magnetic, making them suitable for screening delicate or wet materials such as chemical powders, food, and medicinal herbs. They cost around $20 to $70.

Brass meshes, due to their moderate cost and anti-static properties, are commonly used for screening plastic granules, synthetic fibers, and flammable and explosive powders. Their price typically lies between that of plain carbon steel and stainless steel, ranging from $25 to $60.

| Sieve Mesh (Micron) | Sieve Opening (mm) | Sieve Diameter | Approximate Unit Price (USD) |

|---|---|---|---|

| No. 4 | 4.75 mm | 8" (200mm) | $85 - $120 |

| No. 8 | 2.36 mm | 8" (200mm) | $90 - $125 |

| No. 10 | 2.00 mm | 8" (200mm) | $95 - $130 |

| No. 16 | 1.18 mm | 8" (200mm) | $100 - $140 |

| No. 20 | 850 μm | 8" (200mm) | $105 - $150 |

| No. 30 | 600 μm | 8" (200mm) | $110 - $155 |

| No. 40 | 425 μm | 8" (200mm) | $115 - $160 |

| No. 50 | 300 μm | 8" (200mm) | $120 - $170 |

| No. 60 | 250 μm | 8" (200mm) | $125 - $175 |

| No. 80 | 180 μm | 8" (200mm) | $135 - $190 |

| No. 100 | 150 μm | 8" (200mm) | $145 - $205 |

| No. 140 | 106 μm | 8" (200mm) | $160 - $230 |

| No. 200 | 75 μm | 8" (200mm) | $180 - $260 |

| No. 325 | 45 μm | 8" (200mm) | $220 - $320 |

| Sieve Pan | - | 8" (200mm) | $60 - $90 |

| Sieve Lid | - | 8" (200mm) | $55 - $85 |

The price of equipment varies primarily due to differences in the manufacturing process. specialized manufacturing processes can increase the For Laboratory Sieves Price.the following are prices for various types of sieves, including woven wire mesh sieves, perforated plate sieves, micro-perforated plate sieves, wet washing sieves, and diamond sieves.

Woven wire sieves are the most common and economical type. Made from woven metal wire, they offer a high porosity and excellent screening efficiency. They typically cost between $20 and $150 and are suitable for most dry, non-sticky powders and granular materials, such as sand, cement, and grain. Their screening range ranges from a coarse 20 mesh to a fine 500 mesh.

Perforated plate sieves are made from punched metal plates, resulting in durable, non-deformable mesh openings. They cost approximately $50 to $300. They are designed for handling large, hard, or heavy materials that can easily wear out the woven sieve, such as in mineral analysis, plastic pellets, or seed grading. Their screening range is coarse, typically ranging from 4 to 125 mesh (4 mm to 120 μm).

Microporous plate sieves are manufactured through precision processes such as electroforming, resulting in extremely precise meshes and smooth pore walls. Due to their complex manufacturing process, they are expensive, costing approximately $200 to $500 or more. They are primarily used for applications requiring extremely fine powders and high precision, such as high-end coatings, printing toners, and precision ceramic powders. The screening range typically ranges from 150 to 1500 mesh (100μm to 10μm), addressing fine particles.

Wet-washed sieves are designed for wet screening. Their construction is similar to woven wire sieves, but they feature special seals and clamping devices to prevent slurry leakage. They are slightly more expensive than standard woven sieves, costing approximately $30 to $180. They are specifically designed for slurry materials that require water dispersion and transport, such as ceramic glazes, mineral slurries, or suspensions. They offer a sieving range of 20 to 500 mesh, eliminating the problems of sticking and clumping that dry sieves cannot handle.

Diamond sieves are specialty sieves with diamond particles embedded in the sieve ring as an abrasive layer. They are not used for sieving, but for sample preparation and crushing. They can cost anywhere from $400 to over $1,000. They are primarily used to simultaneously grind and crush hard, agglomerated samples, such as soil and sintered ore, while screening. They are used in conjunction with standard test sieves to grind difficult-to-pass agglomerated samples to a size that can pass through a specified mesh size.

For Laboratory Sieves Price Sieve Sets vary significantly depending on factors such as brand, specification, material, and the number of sieves in the set. A standard sieve set typically includes 5-12 sieves of varying mesh sizes, a base, and a cover. Prices range widely, with economy models starting at approximately $50-80, while high-precision wire mesh standard sieves can cost from $200 to over $500. Specific pricing should be determined based on your specific mesh size range, frame material, and compliance with international standards (such as ASTM or ISO).

The following are examples of sieve analyzers used in laboratory particle size analysis. Case 1: To test the fineness of cement powder, the operator stacks a set of standard sieves according to their aperture size from top to bottom. A 100g cement sample is placed on the top layer, sealed, and then placed in a vibrating sieve machine. After timed vibration, the weight of the residue on each sieve is measured. By calculation, the distribution ratio of cement in different particle size ranges can be obtained, thus determining whether its quality is up to standard. Case 2: Before concrete mixing, a 500g dried sand sample is placed in a sieve set consisting of sieves with apertures of 4.75mm, 2.36mm, etc., from top to bottom. After manual or mechanical sieving, the mass of the residue at each sieve level is recorded. Based on the data, a gradation curve is plotted to determine the fineness and distribution of the sand, ensuring optimal workability and strength of the concrete.

Dahan Machinery specializes in providing high-quality laboratory test sieves, vibrating screens, and complete screening solutions that meet international standards. As a leading manufacturer, For Laboratory Sieves offers competitive pricing. Our product range includes a variety of types, including woven wire mesh sieves and electroformed microporous sieves. Customizable products can be customized based on sieve assembly diagrams and screening analysis equipment lists. With superior screening accuracy, excellent durability, and stable repeatability, our products serve particle size analysis applications in a variety of fields, including food and scientific research. We are committed to providing comprehensive support, from product to technical support.

For Laboratory Sieves Price depends on many factors. The selection process involves choosing the screen material, mesh accuracy, and whether to choose a single screen or a set of screens, based on the characteristics of the material being screened and the purpose of the screening.This ensures long-term reliability and data accuracy.

material test sieve with sample

material test sieve with sample analyzes samples such as sand, quartz, fertilizer, and seeds to analyze particle size...

Dahan Machinery provides soil sieves of various specifications and models to meet the screening needs of different particle sizes and...

Nov 24, 2025

For Laboratory Sieves Price ranges from $100 to $500 USD, and the price varies depending on the sieve...

Nov 22, 2025

laboratory sieve with material

Laboratory sieves with materials include brass, stainless steel, or a brass frame with a stainless st...

Nov 22, 2025

laboratory sieve with material

Laboratory sieves with materials include brass, stainless steel, or a brass frame with a stainless st...

Nov 21, 2025

material screening test sieve consists of a robust stainless steel sieve frame and a wire mesh, with ...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap