Thursday May-08 2025 16:16:21

Herbal powder lab sieve shaker is an experimental instrument designed for the particle size classification of Chinese herbal medicine powder. Through the principle of vibration screening, it can quickly separate herbal powders of different finenesses to ensure sample uniformity and quality controllability. The commonly used sieve mesh range is 40 mesh to 400 mesh (aperture 38μm-425μm), realizing multi-level sorting. The equipment is usually equipped with stainless steel, with a diameter of 200mm-300mm, suitable for laboratory small batch sample processing.

Precise screening: According to the different particle sizes of herbal powder, it is accurately separated through a sieve with a specific mesh number to ensure that the particle size range of herbal powder in each sieve layer is relatively uniform.

Particle size analysis: After screening the herbal powder through a series of sieve combinations with different mesh numbers, the distribution of herbal powder in different particle size ranges can be intuitively understood.

Quality control: In the production and research process of herbal powder, it can be used to detect whether the particle size of herbal powder meets the quality standards, and to promptly discover abnormal conditions in the production process, such as particles that are too large or too small, so as to ensure the quality stability and consistency of herbal powder products.

Sample pretreatment: Provide samples with uniform particle size for subsequent experimental operations, such as mixing, extraction, and preparation of herbal powder, which is conducive to improving the accuracy and repeatability of the experiment and reducing experimental errors caused by differences in particle size.

|

Classification standard |

category |

picture |

description |

applicable scenarios |

|

Drive mode |

vibration screen |

|

vibration is generated by a vibration motor to make the powder move on the sieve and achieve separation |

applicable to various herbal powders that need to be graded and impurities removed |

|

electromagnetic vibration screen |

|

vibration is generated by electromagnetic force, usually with higher frequency and smaller amplitude, suitable for screening of finer powders |

applicable to precise screening of herbal powders with higher fineness requirements |

|

|

Number of screening layers |

single-layer sieve |

|

only one layer of sieve, used to separate powder into two parts |

applicable to simple coarse and fine separation or removal of impurities of a specific size |

|

multi-layer sieve |

|

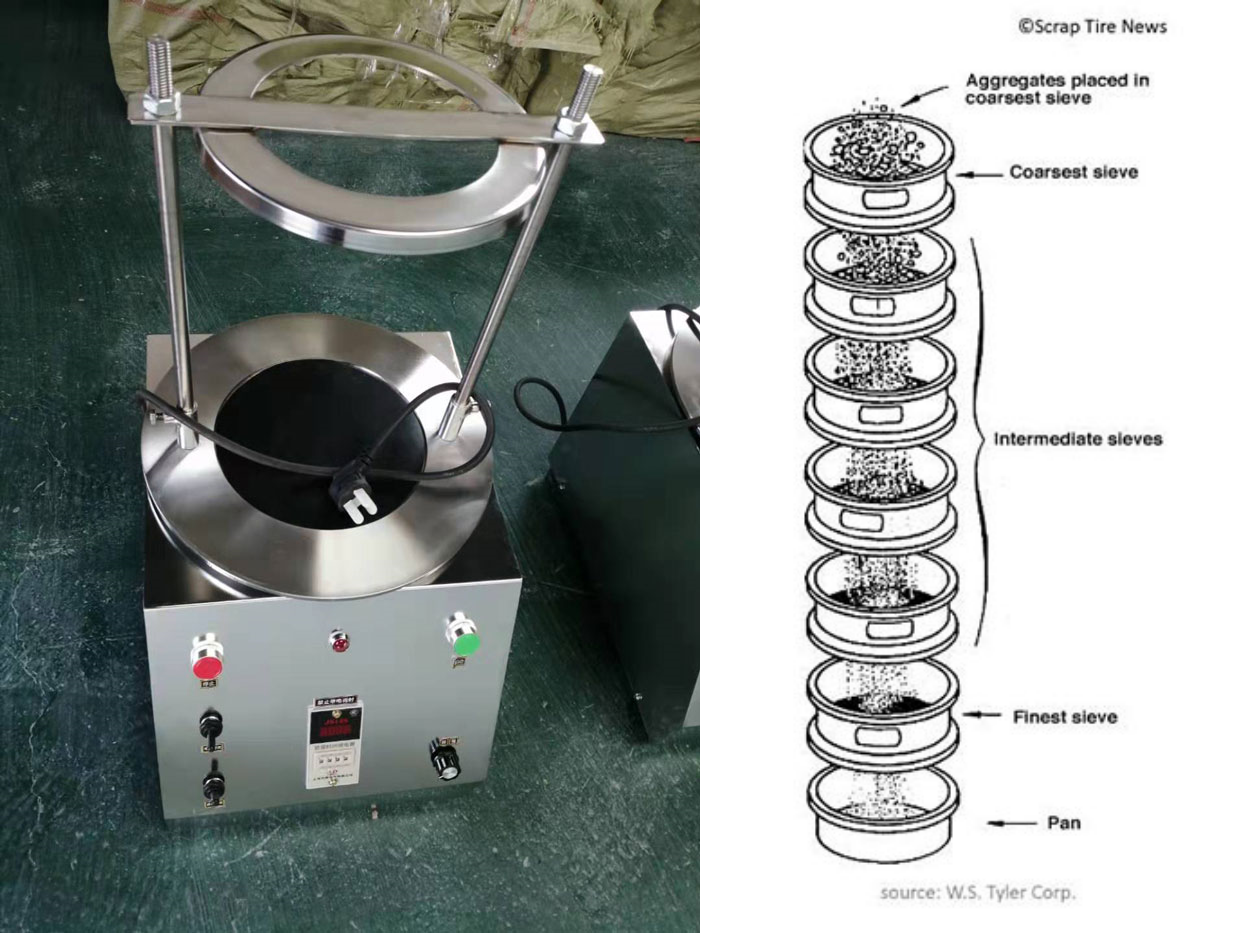

with multiple layers of sieves with different sieve mesh numbers stacked, the powder can be divided into multiple particle size ranges in one operation. |

It is suitable for the analysis of herbal powder by dividing it into multiple particle size segments. |

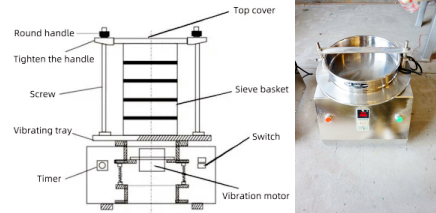

The working principle of the herbal powder lab sieve shaker is based on the screening process of the material, and the material is usually separated according to the particle size by vibration or rotation. The specific working principle is as follows:

①The screen frame is driven by the motor to vibrate, so that the screen produces up and down or left and right vibration movement.

②This vibration movement makes the material move and roll on the surface of the screen constantly, thereby continuously screening out particles of different particle sizes.

③Powders with larger particles are more difficult to pass through the screen due to gravity, while powders with smaller particles can pass through the screen, and finally achieve material classification.

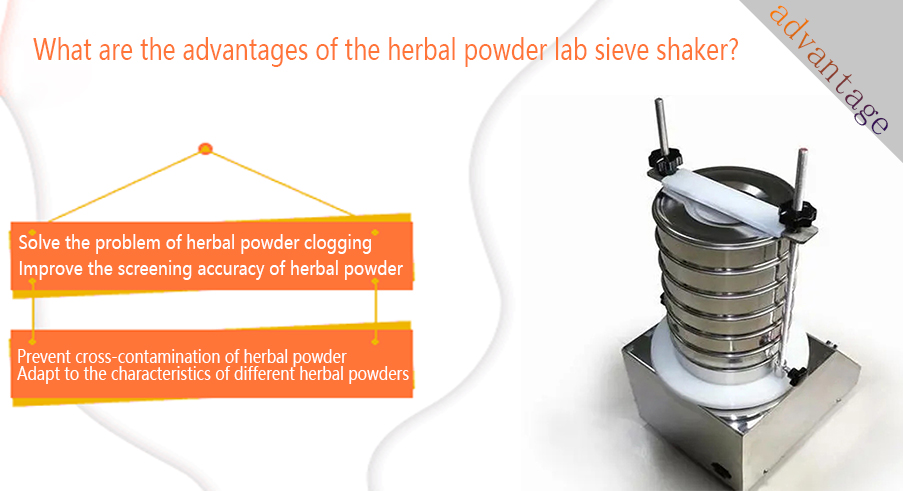

Solve the problem of herbal powder clogging: Choose a screen material with a smooth surface and not easy to adhere to herbal powder, such as stainless steel. The vibration of the herbal powder lab sieve shaker can make the herbal powder particles constantly jump and roll on the screen, preventing the particles from agglomerating and clogging the screen holes. Moreover, the appropriate vibration intensity and frequency can be adjusted according to the characteristics of different herbal powders to achieve the best screening effect.

Improve the screening accuracy of herbal powder: Laboratory sieving machines usually use a multi-layer screen stacking method, and the screens of different layers have different apertures, and the apertures gradually decrease from the upper layer to the lower layer. In this way, multi-level screening of herbal powder can be achieved, and herbal powders of different particle size ranges can be screened out separately, improving the screening accuracy and efficiency, so that herbal powders can be accurately screened according to the predetermined particle size specifications.

Prevent cross-contamination of herbal powder: The herbal powder lab sieve shaker usually adopts a fully enclosed shell structure, which completely encloses the screening process in an independent space. This can prevent external dust and impurities from entering the sieving machine, and also prevent herbal powder from flying into the surrounding environment during the sieving process, reducing the risk of cross-contamination, and avoiding residual herbal powder from causing cross-contamination during the next sieving process.

Adapt to the characteristics of different herbal powders: According to the characteristics of different herbal powders such as humidity, viscosity, particle shape, etc., some key parameters of the sieving machine such as vibration frequency, amplitude, sieving time, etc. can be flexibly adjusted. For example, for herbal powder with high humidity, the vibration frequency can be appropriately increased and the sieving time can be extended to overcome the sieving difficulties caused by its viscosity; for herbal powder with high brittleness, the amplitude needs to be adjusted to avoid the particles from breaking during the sieving process.

Coarse powder: If it is used in some occasions where the powder fineness is not high, such as some external herbal compresses, 80-100 mesh meets the requirements.

General fine powder: For common Chinese medicine powder, such as for making pills, powders, etc., 120-200 mesh sieving machines are more commonly used. For example, when making water pills, honey pills and other pills, a 150-200 mesh sieving machine is generally selected to sift herbal powder. Such powder particle size can ensure the molding and quality of the pills.

Fine powder: When herbal powder needs to be used in preparations such as granules, ointments, capsules, etc. that require high powder fineness, a sieving machine of about 300 mesh is required. However, too fine powder may also bring some problems, such as poor fluidity and easy agglomeration, and not all herbs need such fine powder to exert their medicinal effects.

The herbal powder lab sieve shaker is widely used in the research and production of herbal powder. The following are some specific application scenarios:

1. Particle size analysis of herbal powder

During the research and development of herbal powder, it is necessary to perform particle size analysis on herbal powder from different batches and different origins to determine its particle size distribution. The laboratory sieving machine can screen and separate herbal powder according to different particle size ranges and analyze the proportion of each particle size segment. For newly developed herbal powder products, the particle size distribution is analyzed by the sieving machine to provide data support for product formula optimization and production process adjustment.

2. Quality control of herbal powder

In the intermediate links and final product stages of herbal powder production, sieving machines are regularly used for sieving and testing to ensure the uniformity and consistency of the particle size of herbal powder. For example, for some herbal powders with strict particle size requirements, such as herbal powders used for capsule filling, particles that do not meet the particle size requirements are screened out by the sieving machine. When the herbal powder shows caking, agglomeration or other abnormal conditions, the sieving machine can help determine the change in its particle size.

3. Herbal powder mixing uniformity detection

When mixing multiple herbal powders into compound herbal powder, it is necessary to detect the mixing uniformity. Use the laboratory sieving machine to sieve the mixed herbal powder, observe the distribution of various herbal powders in different particle size ranges, and judge whether the mixing is uniform. If the content of a certain herbal powder in different sieve layers is quite different, it means that the mixing is uneven, and the mixing process needs to be further optimized to ensure the accurate proportion of each component in the compound herbal powder.

Herbal powder lab sieve shaker is a precision equipment used for screening, grading and impurity removal of small batches of Chinese medicine powder. It is widely used in Chinese medicine laboratories, scientific research institutions, pharmaceutical companies R&D departments and other places. Its main function is to control the particle size distribution of herbal powder and improve the consistency of samples.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Stainless Steel Grain Granule Test Sieve for Lab

Stainless steel grain granule test sieve for lab is an important tool for analyzing the size distribution of grains, seeds, and granular materials, screening impurities...

May 08, 2025

Herbal Powder Lab Sieve Shaker

The herbal powder lab sieve shaker is a laboratory equipment specially used for screening, impurity r...

May 07, 2025

Stainless Steel Grain Granule Test Sieve for Lab

Stainless steel grain granule test sieve for lab is a key analytical tool. Through different mesh siz...

May 06, 2025

Test sieve shaker for seed analysis

The test sieve shaker for seed analysis is an important seed analysis equipment, widely used in agric...

Apr 30, 2025

Laboratory Special Fine Powder Screening Equipment

Laboratory special fine powder screening equipment is especially suitable for precise particle size c...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap