Thursday June-26 2025 14:14:27

Inorganic pigment lab test analyzer sieve (with ultrasonic Device) is a lab analysis instrument that combines traditional vibration sieving and ultrasonic sieving, and is suitable for particle size detection, sieving and grading, and impurity removal of fine powder-level (such as 325 mesh ~ 2500 mesh) inorganic pigments. The diameter is commonly φ200mm or φ300mm, and 3~8 layers of sieves can be stacked for particle size grading.

The ultrasonic device helps disperse particles by generating high-frequency vibrations to prevent fine particles from agglomerating or adhering to the sieve during sieving, thereby ensuring more accurate sieving results. This type of sieving instrument is particularly suitable for materials with very fine particles or high viscosity

The inorganic pigment lab test analyzer sieve (with ultrasonic device) is a lab vibration screening equipment designed for fine screening and particle size detection of inorganic pigment powders. Its main feature is that it combines the standard test sieve structure with the ultrasonic screening system, which is suitable for accurate detection of particle size distribution and micro powder screening test.

Inorganic pigment powder: such as iron oxide, titanium dioxide, chrome yellow, cobalt blue, etc.;

Nano or submicron powders;

Materials that require fine particle size analysis;

Viscous, light and easy to agglomerate powders.

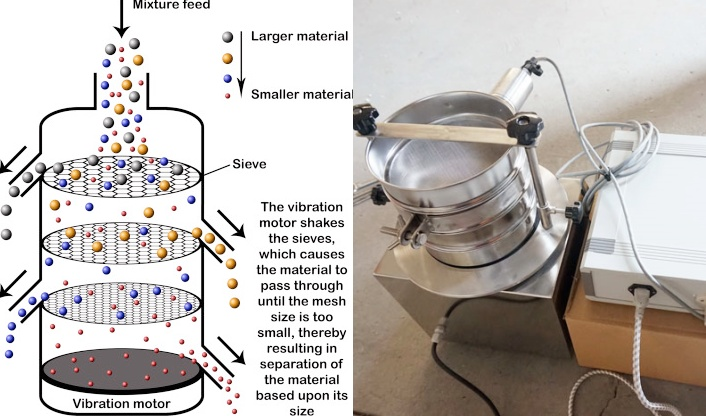

The sample is separated into different particle size levels through a series of sieves with different apertures. The sieves are arranged from top to bottom according to the aperture size. The larger particles remain on the upper sieve, while the smaller particles pass through the sieve to the lower level.

The main function of the ultrasonic device is to disperse the particles by generating high-frequency vibrations. When dealing with very fine or highly viscous materials, particles tend to clump or adhere to the sieve, which significantly reduces screening efficiency and accuracy. Ultrasonic vibration can effectively break up these agglomerates, giving each particle a chance to pass through the appropriate sieve hole.

The ultrasonic device plays a core auxiliary role in the inorganic pigment lab test analyzer sieve. It improves the particle dispersion and screening efficiency during the screening process through high-frequency vibration. The specific functions are as follows:

① Break particle agglomeration and improve dispersion effect: Inorganic pigments (such as titanium dioxide, iron oxide) often agglomerate due to surface charge, van der Waals force, etc. The mechanical force generated by high-frequency vibration can instantly destroy the agglomerate, so that the particles exist in the form of single particles, avoiding particle size test deviations caused by agglomeration.

② Improve the accuracy of particle size classification and achieve precise separation of fine particles: For ultrafine inorganic pigments, traditional vibration screening has weak Brownian motion of particles and low probability of screening. High-frequency vibration makes it easier to pass through the corresponding sieve hole, and the uniform vibration field avoids local screening blind spots.

③ Prevent sieve clogging and ensure screening efficiency: Inorganic pigment particles may get stuck in the sieve holes due to electrostatic adsorption, irregular shape or fine powder accumulation. High-frequency vibration causes the sieve to deform slightly, forcing the particles stuck in the sieve holes to bounce off, allowing the fine powder to pass through the sieve faster.

④ Shorten test time and improve lab efficiency: When processing 100g of iron oxide pigment, traditional screening takes more than 45 minutes, and the sieve needs to be cleaned manually many times. Under the same conditions, ultrasonic waves can shorten the time to 15-20 minutes without stopping in the middle, which is especially suitable for batch sample testing.

In the inorganic pigment lab, the test analyzer sieve is the core equipment for particle size detection and quality control, and the application scenario runs through the entire process of pigment research and development and production.

For example, in the batch detection of iron oxide red pigment, the analyzer sieve can accurately screen through the 500 mesh (25μm) sieve to separate the ultra-coarse particle impurities, ensure the uniformity of the particle size of the pigment powder, and avoid the precipitation of color blocks in the coating application; for the weathering pretreatment experiment of chrome yellow pigment, the analyzer sieve can screen out samples in a specific particle size range; in the pigment mixing ratio test, the combination of 200 mesh (75μm) and 325 mesh (45μm) sieves can accurately control the particle grading of different components in the composite pigment to ensure the consistency of the coloring power and hiding power of end products such as coatings and plastics.

The inorganic pigment lab test analyzer sieve (with ultrasonic device) is mainly used for particle size analysis of inorganic pigments. Its working principle combines the traditional mechanical screening method and modern ultrasonic technology. This test analyzer sieve greatly improves the accuracy and efficiency of screening fine particle materials, and is particularly suitable for occasions requiring fine particle size analysis.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Ultrasonic test sieve for graphite screening

Graphite particles are easy to adsorb, agglomerate, have strong viscosity and high static electricity. These characteristics make ordinary...

Jun 26, 2025

Inorganic Pigment Lab test Analyzer Sieve with Ultrasonic Device

Inorganic Pigment Lab Test Analyzer Sieve (with Ultrasonic Device) is an instrument that combines tra...

Jun 25, 2025

Ultrasonic test sieve for graphite screening

Graphite powder is easy to adsorb and agglomerate; the particle size distribution range is wide; it i...

Jun 24, 2025

Silicon powder ultrasonic test sieve

Silicon powder ultrasonic test sieve is a laboratory equipment used for high-precision screening of f...

Jun 23, 2025

Copper powder ultrasonic test sieve

The copper powder ultrasonic test sieve can be adapted to a variety of mesh sizes, including 80 mesh,...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap