Saturday April-26 2025 18:47:20

Standard test sieves are key tools for particle size analysis and follow standards such as ISO3310-1 or ASTME11. The core lies in the precise mesh size, which is usually expressed in mesh number or micron (µm). The higher the mesh number, the smaller the aperture. For example, the aperture of a 200-mesh sieve is about 75 microns. Common specifications include 200mm/300mm diameter, full-height/half-height sieve frame, and stainless steel/brass material. When selecting, the appropriate mesh number should be determined based on the sample particle size range and the required accuracy to ensure the accuracy and comparability of the analysis results. Standard test sieves are widely used in quality control, research and development and other fields.

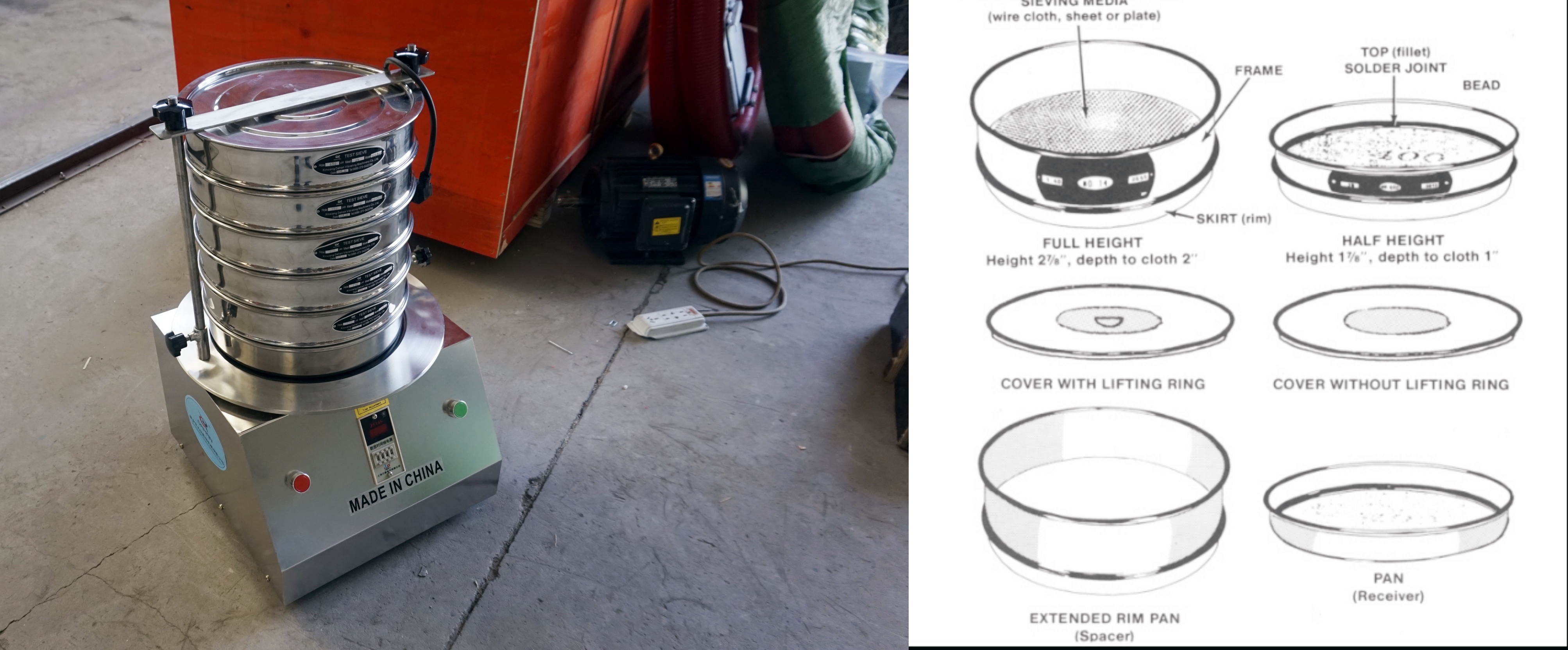

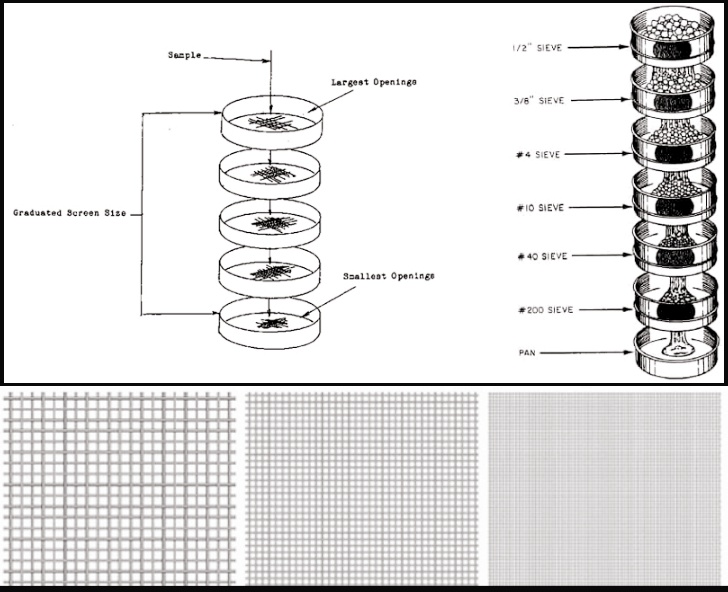

Place the material to be tested on the top sieve, and stack the sieves with the largest apertures to the smallest apertures in sequence.

The material is layered by particle size through a standard test sieve(electromagnetic vibration, ultrasonic vibration or mechanical vibration) or manual shaking.

Each layer of sieve intercepts particles of a specific particle size, and the particle size distribution is calculated after weighing, which is often used to analyze whether the particles meet the requirements (such as <50μm).

Standard test sieves are the core tools for particle size analysis of granular materials. They classify samples through sieves of different apertures and are widely used in quality control and research and development in metallurgy, chemical industry, building materials, food, medicine and other fields. Its core function is to accurately determine the particle size distribution of materials and provide data support for production process optimization and product performance evaluation.

(1) Comparison of mesh number and aperture (ISO 3310-1 standard)

|

Mesh number (mesh/inch) |

nominal aperture (μm) |

typical application materials |

typical application materials |

|

20 |

850 |

±25 |

coarse sand, gravel classification |

|

50 |

300 |

±15 |

cement, quartz sand |

|

100 |

150 |

±7.5 |

flour, talcum powder |

|

200 |

75 |

±4.0 |

metal powder, pigment |

|

400 |

38 |

±2.5 |

ultrafine powder (such as nanomaterials) |

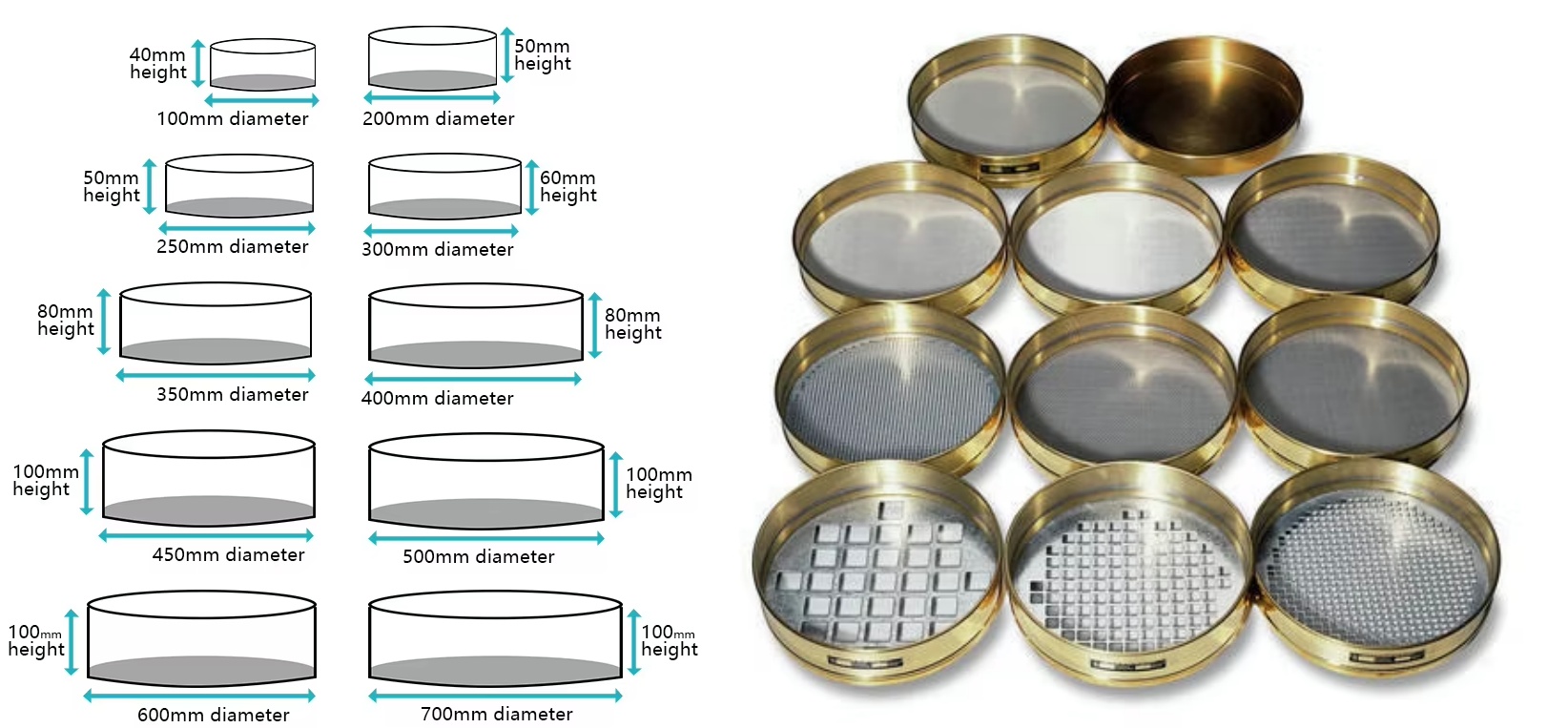

(2) Screen frame size and capacity

|

Screen frame diameter (mm) |

height (mm) |

single layer volume (L) |

applicable scenarios |

|

75 |

25 |

0.1 |

micro sample (<50g) laboratory analysis |

|

200 |

50 |

1.5 |

routine testing (100g~1kg) |

|

300 |

75 |

5. 0 |

Industrial batch screening (>5kg) |

(3) Screen weaving method and accuracy

Plain weave: standard method, suitable for most materials, aperture range 20μm~5mm

Twill weave: Enhanced screen strength, suitable for high-impact particles (such as metal chips)

Electroforming screen: laser drilling, accuracy ±1μm (for ultra-fine screening with aperture <20μm)

(4) Screen aperture specifications: Tyler system (Tyler) and international standard system (ISO) comparison

|

Tyler mesh number (Mesh) |

Aperture (μm) |

ISO standard sieve number (Rounded) |

Typical application scenarios |

|

10 |

2000 |

- |

Coarse particle pre-grading (such as ore) |

|

20 |

850 |

- |

Building sand and gravel grading |

|

40 |

425 |

ISO 45 (R40/3) |

Cement raw material control |

|

60 |

250 |

ISO 63 (R40/3) |

Metal powder particle size detection |

|

100 |

150 |

ISO 100 (R40/3) |

Pigment dispersion evaluation |

|

200 |

75 |

ISO 200 (R40/3) |

Pharmaceutical particle analysis (such as API) |

|

325 |

45 |

ISO 325 (R40/3) |

Nanomaterial agglomerate detection |

Aperture accuracy:

Adopting electroforming process screen, aperture deviation ≤±2μm (high precision series).

Laser perforated screen, aperture consistency of more than 98%, suitable for strict particle size control (such as semiconductor materials).

Sieve frame diameter: common 200mm, 300mm

Sieve mesh: commonly used from 5 mesh (4000μm) to 400 mesh (38μm), which can cover the screening needs from coarse particles to ultrafine powders.

Sieve hole accuracy: the allowable error of the aperture is generally within ±2%, ensuring the accuracy of screening detection.

|

Parameter |

Recommended range |

Influence |

|

Sieving time |

5-15 minutes (automatic vibrating screen machine amplitude 1~3mm, frequency 1400rpm) |

Time is too short → classification is not thorough; too long → particle crushing |

|

Sample amount |

Sieve area × 0.2 (g/cm²), such as 200mm sieve frame ≤200g |

Excessive→Sieve blockage, efficiency decreases |

|

Environmental temperature and humidity |

Temperature 20±5℃, humidity <70% |

High humidity→Particles agglomerate, screening error increases |

The standard test sieve is a precision screening tool for particle size analysis, manufactured according to standards, and used in laboratories or production sites to classify powder and granular materials and detect particle size distribution.

Typical applications:

Gradation analysis of building materials (sand, cement)

Quality control of chemical powders (pigments, catalysts)

Particle size detection in the food industry (flour, powdered sugar)

Screening efficiency verification in the mining industry (ore, coal powder)

The standard test sieve provides traceable quantitative data for particle analysis through precise aperture control and strict manufacturing standards, and is an indispensable basic tool in the field of materials science.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Apr 26, 2025

Introduction and related specifications of standard test sieves

Standard test sieves are the core tools for particle size analysis. They are used to grade and detect...

Apr 25, 2025

Micro silica powder particle size analysis test sieve

The micro silica powder particle size analysis test sieve is a laboratory equipment designed specific...

Apr 25, 2025

Mineral analysis multi-layer slap sieve

Mineral analysis multi-layer slap sieve is a sieveing equipment specifically used for mineral particl...

Apr 21, 2025

A laboratory or small batch screening equipment designed for fine, sticky or hygroscopic pharmaceutic...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap