Monday May-19 2025 17:31:41

Determine the particle size distribution of calcium carbonate;

Detect the particle size stability of different batches of products;

Pre-classify powder samples;

Provide reference data for the selection of industrial sieve equipment.

During the production and testing of calcium carbonate powder, lab sieve equipment is used to analyze its particle size distribution, control product fineness, and ensure stable product quality. According to different sieve principles and structures, this type of equipment can be divided into the following four types:

1. Standard test sieve

Equipment overview: The standard test sieve is the most commonly used particle size detection equipment in the lab. It is usually composed of a sieve frame, an electric vibration device, a timer and a clamping device, and is used with a set of standard sieves

Scope of application: It is suitable for basic particle size classification of dry calcium carbonate particles and powder samples, especially in heavy calcium carbonate with a sieve particle size between 75μm and 2000μm

Features: Multiple layers of sieves can be superimposed for multi-stage sieve; sieve structure The results can be used for particle size distribution statistics

2. Ultrasonic vibration screen

Equipment overview: Ultrasonic vibration screen is based on ordinary vibration screen, adding high-frequency ultrasonic excitation device, so that fine powder forms ultrasonic vibration on the surface of the screen, reducing the phenomenon of blocking and adhesion

Scope of application: Suitable for calcium carbonate powder with high fineness, easy adsorption or light specific gravity, such as light calcium carbonate or nano-scale calcium carbonate sieve

Features: Suitable for samples with a particle size of less than 100μm; high sieve accuracy, low probability of blocking; can be used with 200mm or 300mm test sieves; suitable for dry sieve.

3. Magnetic suspension test sieve

Equipment overview: Magnetic suspension test sieve is a new type of lab sieve device. The magnetic suspension motor drives the screen body to vibrate without contact, eliminating the noise and wear caused by traditional mechanical contact, and the sieve process is smoother and more stable.

Scope of application: Suitable for precise sieve of ultra-fine calcium carbonate samples with strict particle size requirements and the need to reduce mechanical interference. It can also be used for high-precision analysis of the particle size distribution of powder materials in scientific research institutions.

Features: low noise, no wear; uniform vibration, good sieve repeatability; high control system accuracy; relatively high equipment cost, suitable for fine experimental needs.

4. Slap Screen

Equipment Overview: The slap screen drives the eccentric wheel driven by the motor to drive the screen body to vibrate up and down and slap, simulating manual sieve action, suitable for sieve calcium carbonate samples with strong viscosity or easy to agglomerate.

Scope of application: Suitable for calcium carbonate samples with poor fluidity and wide particle size distribution, such as modified calcium carbonate after adding organic additives or samples after wet drying.

Features: Simulate manual sieve method to improve separation efficiency; use with standard screen, high sieve accuracy; suitable for medium particle size range (75μm~1000μm); less mechanical impact on samples.

Comparison

|

Type |

Vibration mode |

Applicable particle size |

Suitable sample characteristics |

Is it suitable for ultrafine powder |

|

Standard test sieve |

Electromagnetic/mechanical vibration |

75μm~2000μm |

General dry powder, granular sample |

No |

|

Ultrasonic vibration screen |

High frequency ultrasound + vibration |

20μm~150μm |

Easy to adhere, fine powder |

Yes |

|

Magnetic suspension test sieve |

Magnetic vibration |

20μm~500μm |

Ultrafine, high purity, scientific research sample |

Yes |

|

Slap screen |

Mechanical slap |

75μm~1000μm |

High viscosity, agglomerate sample |

Partially applicable |

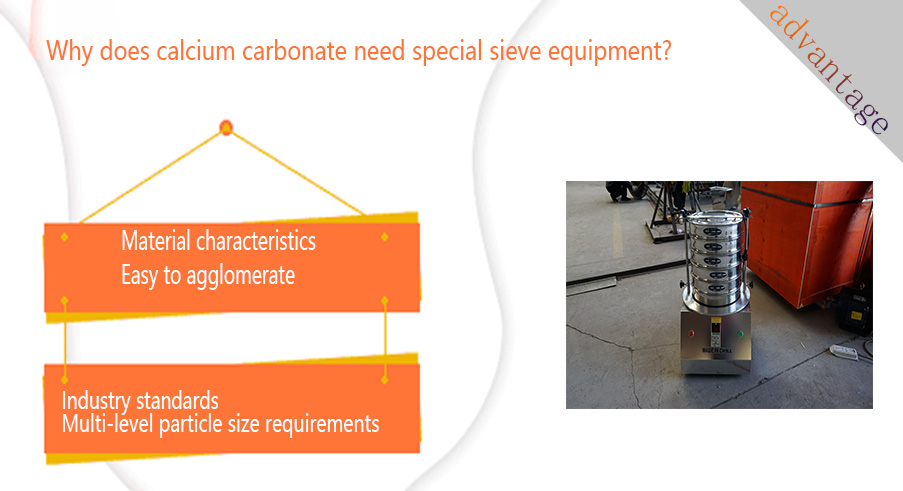

Material characteristics: Calcium carbonate powder may have the following properties:

Dry and easy to raise dust: Equipment with good sealing is required to prevent pollution.

Easy to agglomerate: Ultrasonic vibration screen can break up particles.

Multi-level particle size requirements: For example, the particle size of industrial fillers and pharmaceutical-grade calcium carbonate is very different.

Industry standards: Different application scenarios (such as coatings, plastics, and pharmaceuticals) have strict standards for calcium carbonate particle size, which requires precise sieve.

Although ordinary vibration sieving instruments can also be used for particle size analysis of calcium carbonate, due to the high fineness, easy agglomeration, possible static electricity and other characteristics of calcium carbonate, as well as higher requirements for sieve accuracy and efficiency, the use of special or more sophisticated equipment such as ultrasonic vibration screens, magnetic suspension test screens, and slap screens can often obtain more accurate and efficient sieve results, better meeting the analysis needs of laboratories.

In the lab sieve process of calcium carbonate, common problems include: small powder particle size and easy floating, low sieve efficiency of light powder, easy agglomeration of samples, easy clogging of screens, etc. These problems will affect the accuracy of particle size analysis and the repeatability of sieve. In response to these challenges, different types of lab sieve equipment have been used to address these challenges through technical means:

① Ultrasonic vibrating screens effectively reduce the problems of fine powder blocking and electrostatic adsorption by superimposing high-frequency ultrasonic vibration on the screen, which is particularly suitable for light or ultra-fine calcium carbonate;

② Magnetic suspension test screens use non-contact magnetic drive to avoid mechanical wear and vibration interference, and are suitable for scientific research purposes with extremely high particle size requirements and strict sieve repeatability requirements;

③ The slap screen simulates manual sieve action and is suitable for calcium carbonate samples with strong agglomeration or moisture absorption, which can effectively break the adhesion between particles;

④ The standard test sieve completes multi-level particle size classification through mechanical vibration, which is suitable for calcium carbonate with coarse particles and good fluidity, and is used for basic particle size detection.

⑤ By selecting appropriate equipment according to material characteristics, lab sieve of calcium carbonate can effectively improve accuracy and sieve efficiency, and meet the testing needs in different application scenarios.

lab sieve equipment for calcium carbonate is mainly used for particle size distribution analysis and classification of calcium carbonate samples, and is an important tool for evaluating its product quality and process stability. In industries such as plastics, rubber, and papermaking, calcium carbonate of different particle sizes has a significant impact on performance. Therefore, companies often use standard test sieves for basic particle size determination in R&D and quality inspection, and use ultrasonic vibrating screens to screen light calcium carbonate to prevent clogging and incomplete sieve. When processing nano calcium carbonate or agglomerated materials, magnetic suspension or slapping equipment is also used to achieve high-precision classification. These sieve equipment help users accurately grasp the sample particle size and optimize the formula and production parameters.

Calcium carbonate can be divided into heavy calcium carbonate, light calcium carbonate, and nano calcium carbonate according to the preparation method. Different types of calcium carbonate have different particle sizes, morphologies, and fluidity, and the types of lab sieve equipment they are suitable for are also different. For example:

Heavy calcium carbonate (GCC): commonly used standard test sieves or slapping screens;

Light calcium carbonate (PCC): poor fluidity, ultrasonic vibrating screens are recommended;

Nano calcium carbonate: fine particle size, easy to agglomerate, suitable for magnetic suspension test sieves or airflow screens.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

test sieve for sieving corundum

The test sieve for sieving corundum is a laboratory screening tool used to detect the particle size distribution of corundum particles. It is widely used in abrasives...

May 19, 2025

Lab Sieve Analysis Equipment for Calcium Carbonate

lab sieve equipment for calcium carbonate is a key instrument for accurately analyzing and grading th...

May 17, 2025

test sieve for sieving corundum

The test sieve for sieving corundum is a laboratory tool widely used in abrasives, building materials...

May 16, 2025

Test Analysis sieves For Fine-Grained Soil

The test analysis sieve for fine-grained soil is a key tool for determining the particle size distrib...

May 15, 2025

Test sieve for flour quality control

The test sieve is an indispensable key screening equipment in flour quality control. It can grade and...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap