![[field:title/]](/uploads/allimg/250603/2-2506031R4170-L.png)

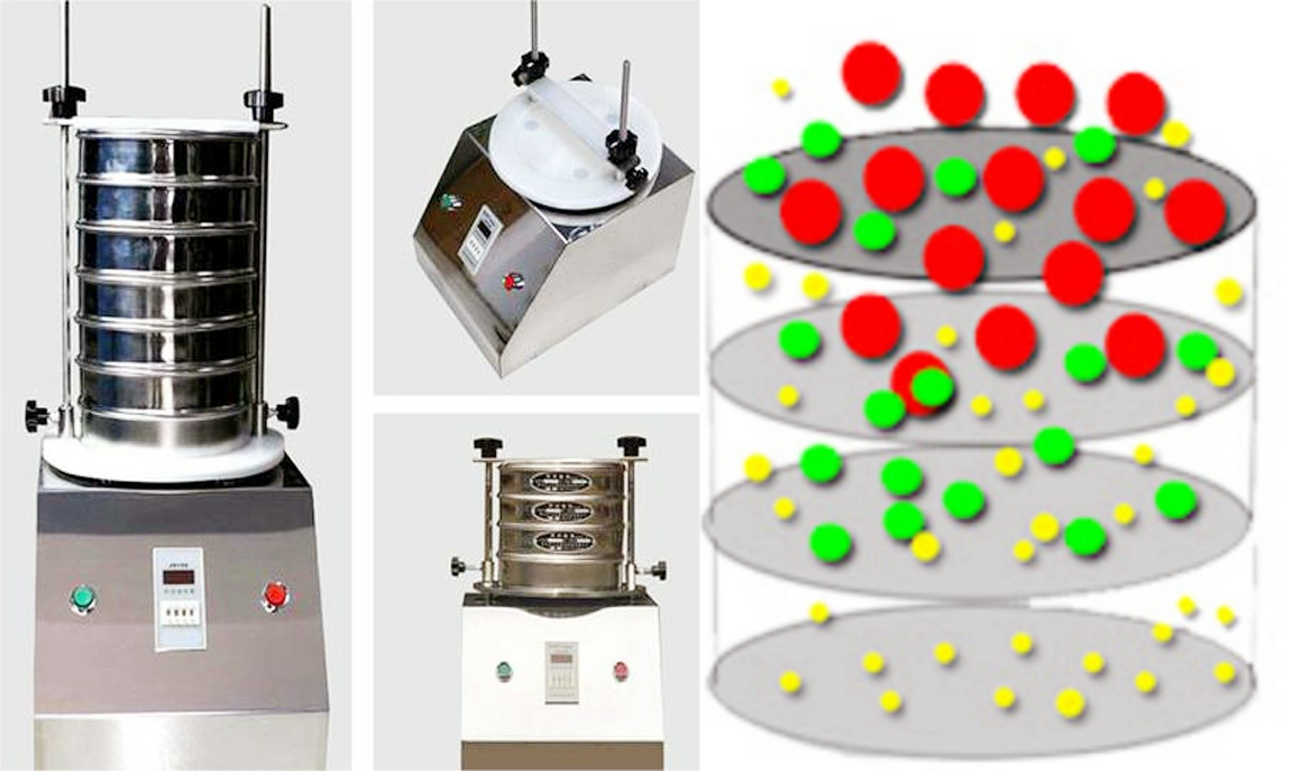

Laboratory equipment is a special small vibration sieving device used for particle size classification, distribution analysis and precision screening of powder or granular materials. It is often used in scientific research units, quality inspection institutions, university laboratories and other occasions. This type of equipment has the characteristics of compact structure, simple operation, high screening accuracy, and adaptability to small sample volume. It is suitable for rapid screening of trace samples.

Sieving level: 1 to 8 layers

Common mesh range: 20 mesh to 500 mesh (corresponding to a particle size of about 850μm to 25μm)

Applicable materials: Suitable for a variety of materials such as granular and powdered materials, such as metal powder, ore powder, chemical raw materials, pharmaceutical intermediates, food particles, etc.

Laboratory equipment is an instrument specially used for material particle size analysis and separation in a laboratory environment. Its main feature is that it can accurately control the sieving process and usually has the ability to stack multiple layers of sieves to achieve multi-level particle size classification of samples. It is suitable for a wide range of materials, from powders, granules to slurries, etc., but the specific choice depends on the type and design of the equipment. The core component is a screen with different mesh numbers. The higher the mesh number, the finer the mesh, and the smaller the particle size that can be separated. For example, a high-mesh screen is suitable for separating fine powders, while a low-mesh screen is suitable for separating larger particles.

By selecting a combination of screens with appropriate mesh numbers and adjusting the operating parameters of the equipment (such as vibration frequency, amplitude, etc.), laboratory screening equipment can efficiently and accurately separate mixed materials into components of different particle sizes, providing a basis for subsequent analysis and research.

|

Classification dimension |

Ultrasonic test sieve |

Laboratory sieve (standard test sieve) |

Slap sieve |

Magnetic suspension test sieve |

Electromagnetic test sieve |

|

Picture |

|

|

|

|

|

|

Screening particle size range |

20μm–3mm |

20μm–125mm |

20μm–100mm |

5μm–1mm |

10μm–2mm |

|

Processing capacity (kg/h) |

0.05–10 (depending on the material) |

0.1–50 (small batch test) |

0.2–20 |

0.01–5 |

0.01–10 |

|

Screening method |

Ultrasonic vibration + mechanical vibration |

Vertical vibration |

Slap + vibration |

Magnetic suspension non-contact vibration |

Electromagnetic vibration |

|

Applicable materials |

Easy to block the net, lightweight, ultra-fine powder |

All kinds of powders and particles |

Granular and block materials |

Ultrafine powder, magnetic material |

light or trace powder |

|

Screen diameter |

usually 200mm/300mm |

75mm/100mm/200mm, etc. |

200mm or 300mm |

generally 200mm |

200mm or customized |

|

Screening accuracy |

high (with ultrasonic device |

medium-high |

medium |

extremely high |

high |

|

Automation level |

medium (settable time) |

medium (timing + mechanical vibration) |

low (manual intervention required) |

high (intelligent control) |

medium |

|

Main application areas |

nanomaterials, medicine, chemical industry |

standard screening test, particle size distribution analysis |

coal, metallurgy, building materials |

High-precision experiments, scientific research units |

precision screening, material analysis |

The working principle of laboratory equipment is mainly to achieve graded screening of materials on multi-layer screens through vibration or other excitation methods.

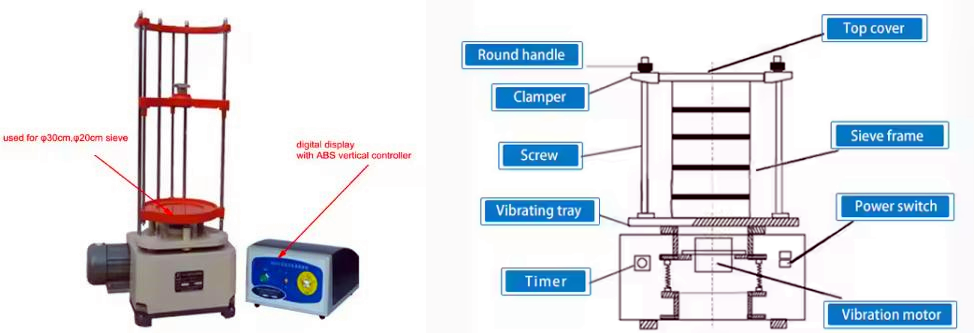

The material to be tested is placed in the top screen, which is usually a set of standard screens with the same diameter and different mesh sizes, stacked in order from large to small. After starting the equipment, the motor drives the eccentric wheel or electromagnetic drive device to produce vertical or horizontal vibration, or achieves high-frequency excitation through a slapping mechanism or a magnetic suspension device.

Under the action of vibration or excitation, the material jumps and rolls on the screen. The particles are compared with the screen aperture according to their own particle size. The particles smaller than the screen aperture pass through the screen and fall into the next layer, while the particles larger than the screen aperture remain in the original screen layer. The multi-layer screen can divide the sample into several particle size levels at one time, and each layer corresponds to a particle size range, realizing efficient particle size distribution analysis.

The experimenter can set the screening time (usually 1-10 minutes) according to the characteristics of the sample, and the screening After the separation, weigh the residues of each layer separately to analyze the particle size composition of the material. For fine powders that are easy to agglomerate or block the screen, an ultrasonic generator or electromagnetic vibrator can be optionally equipped to make the screen surface amplitude higher frequency and more uniform, effectively avoid blockage, and improve screening efficiency and accuracy.

High-precision particle size analysis: Laboratory equipment can provide accurate particle size distribution data. By using sieves with different mesh sizes, particles in different size ranges can be effectively separated, which is crucial for applications that require strict control of material particle size.

Multi-level screening capabilities: These devices usually support multi-level screening, that is, multiple sieves with different aperture sizes can be used in one operation, so as to obtain a complete particle size distribution from coarse to fine at one time. This function greatly improves work efficiency while ensuring the accuracy of the results.

Wide applicability: Laboratory equipment is suitable for a variety of materials, including but not limited to powders, granular substances, and fibers. Whether it is food, pharmaceuticals, Whether in the chemical or mineral processing industries, you can find suitable screening equipment to meet your specific needs.

Customized solutions: According to different application requirements, manufacturers can provide customized screening solutions, including the selection of special material screens, adjustment of screening capacity, etc., to meet the requirements of specific experimental or production environments.

|

No. |

Name |

Unit |

Parameter |

|

01 |

Screen frame |

Layer |

1~8 |

|

02 |

Screen frame diameter |

mm |

Φ200 |

|

03 |

Screening particle size |

mm |

0.025~3 |

|

04 |

Noise |

dB |

less than 50 |

|

05 |

Amplitude |

mm |

0~3 |

|

06 |

Vibration frequency |

times/min |

1440 |

|

07 |

Dimensions |

length, width, height |

350:350:300+N*50 |

|

08 |

Power supply |

V;HZ |

220;50 |

|

09 |

Machine weight |

Kg |

36 |

|

10 |

Vibration motor |

power |

0.12KW |

|

Number |

mesh (mm) |

Number |

mesh (mm) |

Number |

Mesh (mm) |

Number |

Mesh (mm) |

|

2 |

13 |

26 |

0.71 |

90 |

0.16 |

260 |

0.06 |

|

3 |

6.5 |

28 |

0.63 |

100 |

0.154 |

280 |

0.055 |

|

4 |

5 |

30 |

0.6 |

110 |

0.14 |

300 |

0.054 |

|

5 |

4 |

32 |

0.55 |

115 |

0.13 |

320 |

0.048 |

|

6 |

3.2 |

36 |

0.5 |

120 |

0.12 5 |

325 |

0.045 |

|

7 |

2.8 |

40 |

0.45 |

130 |

0.111 |

350 |

0.041 |

|

8 |

2.5 |

45 |

0.4 |

140 |

0.105 |

360 |

0.4 |

|

9 |

2.2 |

50 |

0.355 |

150 |

0.1 |

400 |

0.0385 |

|

10 |

2 |

55 |

0.315 |

160 |

0.098 |

500 |

0.03 |

|

12 |

1.6 |

60 |

0.3 |

180 |

0.09 |

|

|

|

14 |

1.43 |

65 |

0.25 |

190 |

0.08 |

|

|

|

16 |

1.25 |

70 |

0.22 |

200 |

0.075 |

|

|

|

18 |

1 |

75 |

0.2 |

220 |

0.07 |

|

|

|

20 |

0.9 |

80 |

0.18 |

240 |

0.065 |

|

|

|

24 |

0.8 |

85 |

0.17 |

250 |

0.063 |

|

|

|

Specifications of stainless steel sample sieves. If you need special specifications, please contact online customer service for consultation. |

|||||||

In the pharmaceutical industry, ultrasonic test sieves are used to screen fine powders to ensure uniform particle size to optimize drug efficacy; in the food industry, laboratory sieves are used to detect the particle size of flour, milk powder, etc. to ensure consistent product texture; in the metallurgical field, slapping sieves analyze ore particles (such as iron ore and manganese ore) for mineral processing. Provide data; in the research and development of lithium battery materials, electromagnetic test sieves accurately classify graphite powder or zinc oxide to ensure the performance of battery materials; in environmental monitoring, magnetic suspension test sieves separate particles in soil or sediments and analyze the particle size distribution of pollutants.

These devices support multi-layer screening (2-7 layers), with mesh sizes ranging from 20 to 635, suitable for fine powders, particles and slurries. Some equipment such as ultrasonic sieves can solve the problem of sticky material blockage. They are widely used in university laboratories, enterprise quality inspections (such as food processing plants) and scientific research institutions (such as geological exploration), providing reliable support for product quality control and scientific research.

Dahan Machinery is a manufacturer specializing in the production of screening equipment, especially in It has a certain reputation in the field of laboratory screening equipment. The products we provide include but are not limited to ultrasonic test sieves, slap screens, magnetic suspension test sieves and electromagnetic test sieves, which are suitable for fine screening of various granular materials. Dahan Machinery is committed to providing users with high-quality screening solutions, and is known for the high reliability, precision and advanced technology applications of its products.

These devices are widely used in many industries such as chemical, pharmaceutical, food, and mineral processing to help users with quality control, new product development, and production process optimization. By using Dahan Machinery's laboratory screening equipment, users can achieve accurate analysis of the particle size distribution of materials, which is very important for ensuring product quality and improving production efficiency. It is of great significance.

In addition, we also provide customized services to meet the specific needs of different users, such as the selection of special material screens, the manufacture of screening equipment of specific specifications, etc. If you have specific needs or want to know more information, you can contact us directly for detailed information and support.

There are many types of laboratory screening equipment, each with its own application scenarios and advantages. Choosing the most suitable equipment requires comprehensive consideration of sample properties, analysis requirements, standard compliance and budget. Standard test sieves are the basis, while vibrating screen machines (mechanical, electromagnetic, slapping) are key tools for efficient, accurate and automated screening. The correct selection and use of screening equipment is essential for obtaining reliable and reproducible particle size analysis results.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

Wheat flour ultrasonic test sieve

Wheat flour is easy to clog ordinary sieves due to easy agglomeration and electrostatic adsorption. The ultrasonic test sieve effectively inhibits agglomeration and adsorption by su...

Millet sand ultrasonic test sieve

Millet sand ultrasonic test sieve is suitable for fine powder materials above 400 meshes, which can accurately separate different particle sizes. It is a high-precision screening eq...

200 micron brass mesh soil sieve set with frame

200 micron brass mesh soil sieve set with frame is a soil sieving tool with a pore size of 200 microns (about 70 meshes). It is made of corrosion-resistant brass mesh and has a stab...

0.5mm stainless steel soil sieve for lab testing

0.5mm stainless steel soil sieve for lab testing refers to a stainless steel soil sieve with a sieve hole size of 0.5 mm. This sieve is often used to separate soil particles of diff...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap