![[field:title/]](/uploads/250530/2-250530162K44M.png)

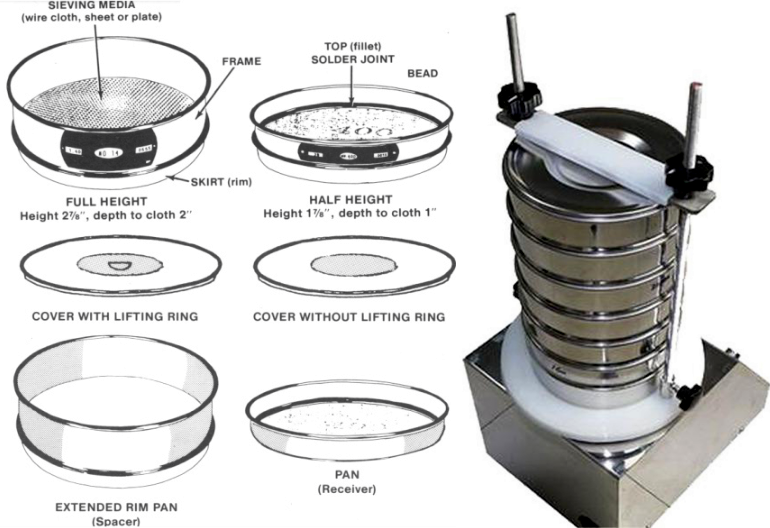

Laboratory Sieves is a standardized, high-precision screening tool in the laboratory. It uses mechanical vibration to grade and analyze a small amount of samples through sieves of different apertures. It is widely used in quality control, material research and various fields that require understanding of particle size distribution.

Vibration frequency: usually 1400-3000 times/min

Number of sieve layers: usually 1-8 layers are used in superposition

Sieving time: can be set, such as 0-99 minutes

Common diameter: 200mm, 300mm, 400mm, etc.

Application: scientific research institutions, quality inspection units, university laboratories, and pharmaceutical, chemical, metallurgical, food and other industries

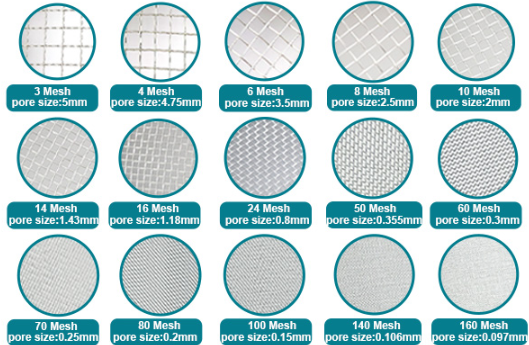

Sieve aperture range: from a few millimeters to tens of microns (such as 0.025mm-5.0mm)

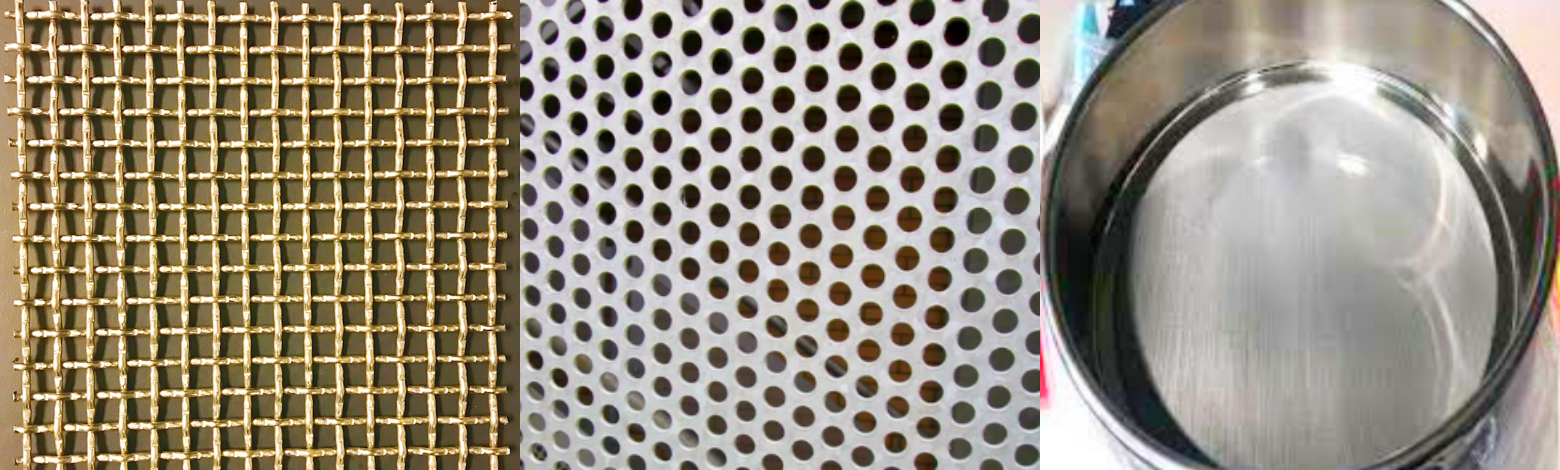

Laboratory Sieves are primarily used for precise particle size grading and separation of various powders, granules, and bulk materials. It come in several types, depending on their material and intended use. Commonly used are stainless steel sieves, which are corrosion-resistant, easy to clean, and durable. Brass sieves are known for their excellent electrical and thermal conductivity and are often used for screening non-corrosive materials. Nylon sieves (also known as polyester sieves), made of synthetic fibers, are lightweight and flexible, making them particularly suitable for screening materials that are static-sensitive or require non-metallic contact.

The laboratory sieves is a device dedicated to particle grading and particle size analysis of small batches of materials. It has the characteristics of compact structure, simple operation and high screening accuracy. The mesh has a wide range of apertures and is suitable for particle size detection and screening of materials in various forms such as powders, granules, and liquids. It is commonly used in pharmaceutical, chemical, food, metallurgy, scientific research and other industries.The screening process achieves efficient grading of multi-layer sieves through vibration drive, which can quickly separate materials of different particle sizes to ensure the accuracy and repeatability of the analysis results. It is suitable for materials with strict particle size requirements such as Chinese medicine powder, metal powder, cosmetic raw materials, and ceramic raw materials.

There are many types and specifications of laboratory sieves, and common ones are sieves with different diameters (such as 200mm, 300mm), different materials (such as stainless steel), and different mesh sizes. It is usually used in conjunction with a sieving instrument to achieve a more efficient and standardized screening process. In the laboratory, sieves are mainly used for particle size grading, particle size analysis (screening analysis) of granular materials, and separation of solids.

Classification by screen material

Wire woven mesh screen: woven from metal wire (such as stainless steel, brass, etc.), with precise aperture, suitable for fine to medium particle size analysis (∼0.02mmto2.36mm), widely used in most dry and wet screening.

Metal perforated plate screen: stamped from metal plate, with large aperture, round or square shape, suitable for larger particle size (1mmto125mm), such as coarse screening of ore and coal or occasions with extremely high requirements for sieve plate strength. It is rarely used in fine particle size analysis.

Electroforming screen: formed on the mold by electroplating metal, with very precise and uniform aperture, suitable for very fine particles (5μmto500μm), widely used in precise screening analysis of ultrafine powders (such as pigments, ceramic powders, and drug powders), with a fineness range that conventional Laboratory sieves woven meshes cannot reach.

Comparison table of commonly used sieves in laboratories

|

Material type |

Picture |

Material characteristics |

Applicable scenarios |

Advantages |

Disadvantages |

Corrosion resistance |

Common mesh range |

|

Brass test sieve |

|

Screen and sieve frame are brass or brass edging |

Suitable for dry screening, especially for samples that react to iron or are sensitive to conductivity |

Not easy to generate static electricity, good conductivity, wear resistance |

Easy to oxidize and discolor, the price is relatively high |

General |

4 mesh to 200 mesh |

|

Stainless steel test sieve |

|

Screen and sieve frame are made of stainless steel (commonly used 304/316L) |

Suitable for hygienic or corrosion Industries with high requirements for performance, such as medicine, food, and chemical industry |

corrosion resistance, high temperature resistance, high strength, easy to clean |

slightly higher cost |

excellent |

4 mesh to 500 mesh or even finer |

|

Nylon test sieve |

|

The mesh is made of nylon or polyester, and the sieve frame is mostly plastic or metal edging |

wet screening, or used for materials sensitive to metal contamination such as ceramics, powder metallurgy, etc. |

strong flexibility, not easy to break, light weight |

the accuracy is not as good as metal mesh, and it is easily affected by temperature |

good (acid and alkali resistant but not high temperature resistant) |

about 10 mesh to 400 mesh |

The Laboratory Sieves' core application lies in the precise classification and particle size analysis of powder and granular samples, making it a versatile and crucial tool across numerous industrial and scientific fields. From controlling flour fineness in the food industry, to determining the particle size distribution of pharmaceutical powders that influence drug absorption, to analyzing soil composition in geological research, Laboratory Sieves plays an indispensable role. Through physical separation, it provides critical data on particle size distribution, providing a solid foundation for process optimization, quality control, product development, and even scientific discovery.

The purpose of laboratory sieves is to perform particle size analysis and graded separation of solid particles to determine the particle size distribution of samples or separate particles by size.

Particle size distribution determination: analyze the proportion of particles of different particle sizes in the sample, which is used to study the physical properties of materials or quality control.

Particle separation: grade the sample by particle size to separate particles of a specific size to meet experimental or production needs.

Quality control: ensure that products (such as powders, soils, minerals, etc.) meet particle size specifications.

Research and development: Provide particle characteristics data for materials science, pharmaceuticals, food processing and other fields to support experimental research.

|

Product Name |

Laboratory Sieves |

|

Diameter |

200mm, 300mm |

|

Layers |

1-8 layers available |

|

Materials |

Stainless steel 304 or 316 |

|

Voltage |

220V, 50HZ, Single phase or As your require |

|

Power |

0.125KW |

|

Speed |

1440RPM |

|

Noise |

<50db |

|

Amplitude |

≤5mm |

|

Mesh size |

2-500mesh/ Can be customized |

|

Usage |

Classification, particle size distribution |

|

Overall dimension |

450×415×800mm |

|

Weight |

45kg |

| ASTM E11 | ISO 565/3310-1 | |

|---|---|---|

| Standard | Alternate | Size |

| 100.0mm | 4in | - |

| 90.0mm | 3 1/2in | - |

| 75.0mm | 3in | - |

| 63.0mm | 2 1/2in | 63.0mm |

| - | - | 56.0mm |

| 53.0mm | 2.12in | 53.0mm |

| 50.0mm | 2in | 50.0mm |

| 45.0mm | 1 3/4in | 45.0mm |

| - | - | 40.0mm |

| 37.5mm | 1 1/2in | 37.5mm |

| - | - | 35.5mm |

| 31.5mm | 1 1/4in | 31.5mm |

| - | - | 28.0mm |

| 26.5mm | 1.06in | 26.5mm |

| 25.0mm | 1in | 25.0mm |

| 22.4mm | 7/8in | 22.4mm |

| - | - | 20.0mm |

| 19.0mm | 3/4in | 19.0mm |

| 18.0mm | - | 18.0mm |

| 16.0mm | 5/8in | 16.0mm |

| - | - | 14.0mm |

| 13.2mm | 0.530in | 13.2mm |

| 12.5mm | 1/2in | 12.5mm |

| 11.2mm | 7/16in | 11.2mm |

| - | - | 10.0mm |

| 9.5mm | 3/8in | 9.5mm |

| - | - | 9.0mm |

| 8.0mm | 5/16in | 8.0mm |

| - | - | 7.1mm |

| 6.7mm | 0.265in | 6.7mm |

| 6.3mm | 1/4in | 6.3mm |

| 5.6mm | No. 3 1/2 | 5.6mm |

| - | - | 5.0mm |

| 4.75mm | No.4 | 4.75mm |

| - | - | 4.50mm |

| 4.00mm | No.5 | 4.00mm |

| 3.55mm | - | 3.55mm |

| 3.35mm | No.6 | 3.35mm |

| - | 1/8in* | - |

| 3.15mm | - | 3.15mm |

| 2.80mm | No.7 | 2.80mm |

| - | - | 2.50mm |

| 2.36mm | No.8 | 2.36mm |

| 2.00mm | No.10 | 2.00mm |

| - | - | 1.80mm |

| 1.70mm | No.12 | 1.70mm |

| - | - | 1.60mm |

| 1.40mm | No.14 | 1.40mm |

| - | - | 1.25mm |

| 1.18mm | No.16 | 1.18mm |

| - | - | 1.12mm |

| 1.00mm | No.18 | 1.00mm |

| - | - | 900µm |

| 850μm | No.20 | 850µm |

| - | - | 800µm |

| 710μm | No.25 | 710µm |

| - | - | 630µm |

| 600μm | No.30 | 600µm |

| - | - | 560µm |

| 500μm | No.35 | 500µm |

| - | - | 450µm |

| 425μm | No.40 | 425µm |

| - | - | 400µm |

| 355μm | No.45 | 355µm |

| - | - | 315µm |

| 300μm | No.50 | 300µm |

| - | - | 280µm |

| 250μm | No.60 | 250µm |

| - | - | 224µm |

| 212μm | No.70 | 212µm |

| - | - | 200µm |

| 180μm | No.80 | 180µm |

| - | - | 160µm |

| 150μm | No.100 | 150µm |

| - | - | 140µm |

| 125μm | No.120 | 125µm |

| - | - | 112µm |

| 106μm | No.140 | 106µm |

| - | - | 100µm |

| 90μm | No.170 | 90µm |

| - | - | 80µm |

| 75μm | No.200 | 75µm |

| - | - | 71µm |

| 63μm | No.230 | 63µm |

| - | - | 56µm |

| 53μm | No.270 | 53µm |

| - | - | 50µm |

| 45μm | No.325 | 45µm |

| - | - | 40µm |

| 38μm | No.400 | 38µm |

| - | - | 36µm |

| 32µm | No.450 | 32µm |

| 25µm | No.500 | 25µm |

| 20µm | No.635 | 20µm |

The main purpose of laboratory sieves is to classify and analyze the particle size of powder or granular samples. In practical applications, laboratory sieves are widely used in many fields. For example, in the food industry, sieving can be used to detect the coarseness of flour, ensure the fineness of sugar powder, or separate particles of different sizes in mixed materials, such as grain grading. In the pharmaceutical industry, sieving is used to control the particle size distribution of drug powders, which directly affects the solubility, absorption rate, and tablet compression processes of drugs.

In geological research, soil or sediment samples can be sieved to analyze the content of components of different particle sizes, thereby inferring geological processes. In the field of materials science, sieving can be used to prepare powder materials with a specific particle size range, such as raw materials for sintering or coating processes. In addition, in environmental monitoring, sieving is also often used to separate particle pollutants of different sizes in water or soil samples. In summary, laboratory sieves provide important particle size information for scientific research and industrial production through physical separation, thereby guiding process optimization and quality control.

Particle size distribution analysis (such as soil, powdered metal, abrasive, etc.)

Particle size control of pharmaceutical raw materials

Food particle screening (such as flour, powdered sugar, etc.)

Chemical raw material testing

Cement and sandstone particle analysis in the building materials industry

The price of Laboratory Sieves (also called standard test sieves or analytical sieves) varies depending on factors such as brand, model, material, sieve frame diameter, mesh size, and whether it is equipped with vibration screening equipment.

Single sieve: The price of ordinary standard test sieves (200mm or 300mm in diameter, made of stainless steel, noodles or phosphor bronze) usually ranges from tens to hundreds of yuan. For example, the price of a wire mesh sieve with a diameter of 200mm may be negotiable or between 100-500 RMB, depending on the mesh size and material.

Vibrating screening equipment: Laboratory vibrating screening machines (such as 200 or 300 models) usually cost between 1,000 RMB and several thousand RMB.

Complete test sieve set: The price of a standard test sieve set (for particle size classification) with graded sieves depends on the number of sieves and supporting equipment.

|

Material type |

common diameter |

mesh range |

single price reference (USD) |

|

Stainless steel test sieve |

200mm(8 inch) |

4–500mesh |

$10–$40/pc |

|

Brass test sieve |

200mm (8 inch) |

4–200 mesh |

$12–$35/pc |

|

Nylon test sieve |

200mm (8 inch) |

10–400 mesh |

$6–$20/pc |

|

Galvanized iron sieve |

200mm(8 inch) |

2–100 mesh |

$4–$12/pc |

|

High-precision laser sieve/electroforming sieve |

200mm |

100 mesh+ |

$70–$250/pc |

|

Small size test sieve |

100mm (4 inch) |

various mesh |

$5–$20/pc |

|

Large size test sieve |

300mm (12 inch) |

various mesh |

$15–$60/pc |

The core competitiveness of Laboratory Sieves suppliers lies not only in providing standardized products but also in meeting diverse customer customization needs. First, material customization is a common requirement. While stainless steel, brass, and nylon are relatively common materials, certain industries may require higher-grade materials, such as 316L stainless steel or specialized alloys, to ensure contamination-free and corrosion-resistant finishes. Suppliers need flexible production lines to accommodate the processing requirements of these specialized materials. Secondly, size and structure customization are also crucial. Standard Laboratory Sieves typically have a fixed diameter and height, but some specialized equipment may require non-standard sieve sizes. Suppliers must be able to manufacture sieves with precisely matched diameters, heights, and even frame shapes based on customer drawings or specific specifications. Furthermore, mesh customization is one of the most technically demanding customization services. While standard sieve mesh sizes adhere to international standards, many research and production processes require non-standard mesh sizes, or even unusual shapes (such as rectangular or diamond-shaped meshes). Suppliers must possess advanced electroforming technology, photolithography technology, or precision weaving technology to achieve precise mesh manufacturing from micron to millimeter levels and ensure the uniformity and consistency of mesh size. Finally, functional customization is also gaining increasing attention. For example, some applications require the sieve to be conductive to reduce electrostatic adsorption, or require special coatings to improve wear resistance or prevent adhesion. In summary, the core advantage of Laboratory Sieves suppliers lies in their ability to transcend the limitations of standard products and accurately respond to customers' unique needs in different application scenarios through multi-dimensional customization capabilities such as materials, sizes, meshes, and functions, thereby providing solid technical support for customers' scientific research and production.

Laboratory sieves are mainly used for particle size analysis to help determine the size distribution of granular materials. Proper use of laboratory sieves can not only improve work efficiency, but also ensure the accuracy of experimental results.

Preparation: Select sieves with appropriate apertures and materials according to the characteristics of the material and experimental requirements. For example, for fine powdery substances, you may need to choose a sieve with a finer aperture; for corrosive substances, you need to choose a sieve made of corrosion-resistant materials. Make sure the sieve is clean and free of impurities before use to avoid affecting the experimental results.

Sample preparation: Sampling correctly ensures that the sample is representative and avoids result deviations caused by uneven sampling. In some cases, pretreatment steps such as drying or crushing may be required to ensure the smooth screening process.

Sieving operation: Stack the required sieves in order from large to small sieve apertures, with the bottom cover at the bottom and the top cover at the top. Put an appropriate amount of sample into the top sieve, and be careful not to overdo it to avoid affecting the screening effect. If a mechanical screening machine is used, the parameters (such as vibration frequency, time, etc.) should be set according to the equipment manual, and then the equipment should be started for screening.

Result analysis: After the screening is completed, collect and weigh the weight of the materials on each sieve layer. Calculate the proportion of materials in different particle size ranges based on the weight of the sieve residue, and draw a particle size distribution curve.

Cleaning and maintenance: After the screening is completed, clean the residual materials on the sieve in time and clean it thoroughly. Check the sieve regularly for damage. If it is damaged, it should be replaced in time to ensure the accuracy of subsequent experiments.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

What is 2mm soil sieve? A 2mm soil sieve is a fundamental and crucial tool. Its primarily used for pre-processing and sorting soil samples, separating coarse particles (larger than ...

Size sieve for soil mainly refers to the sieve frame diameter (commonly used 200mm, 300mm, etc.) and the sieve hole size (ranging from 0.075mm to 60mm). The sieve frame diameter is ...

Soil sieve prices range from $3 to $500. A soil sieve is a tool used to separate materials such as soil, sand, and compost by particle size. It is used in a variety of applications,...

The primary function of a perforated plate soil sieve is to analyze and separate various types of granular materials. Using precisely controlled pore sizes, a mixed sample is separa...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap