Wednesday April-30 2025 17:13:45

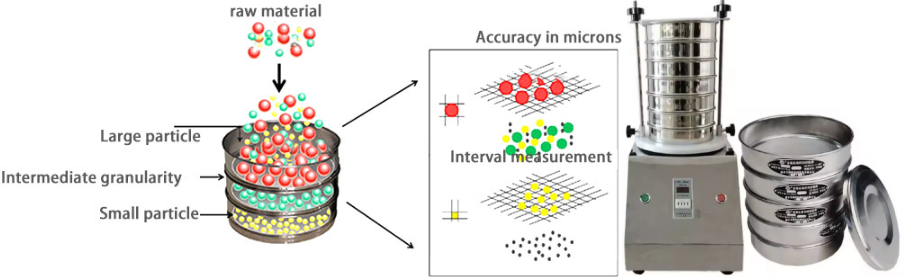

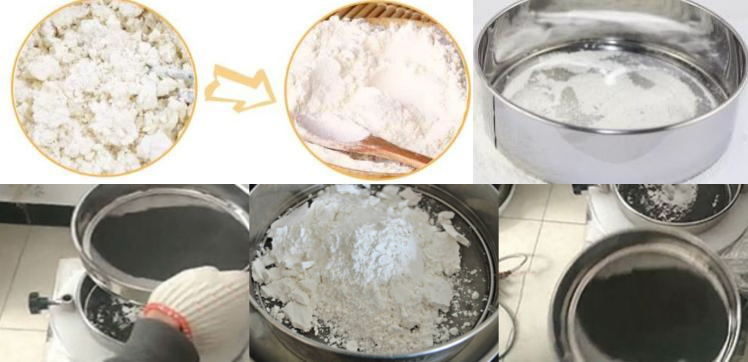

Laboratory special fine powder screening equipment is mainly used for accurate particle size classification and analysis of powder samples, especially for ultrafine powders (such as nanomaterials, pharmaceutical powders, chemical raw materials, etc.). On the basis of the traditional test sieve, it can better solve the screening problems of fine powders, easy to agglomerate, static electricity and other materials by superimposing ultrasonic energy, improve screening efficiency and accuracy, and can adapt to the experimental needs of small batch samples.

The ultrasonic test sieve consists of an ultrasonic generator and a transducer. The ultrasonic generator generates a high-frequency electrical signal, which is transmitted to the transducer installed on the sieve through a cable. The transducer converts electrical energy into high-frequency mechanical vibrations and transmits these vibrations to the sieve.

①Prevent mesh clogging: effectively disperse the fine powder attached to the sieve to make it easier to pass through the mesh.

②Improve screening accuracy: The surface of the screen forms a high-frequency micro-vibration (amplitude of about 1-10μm), which instantly breaks the agglomeration and electrostatic adsorption of the powder, so that particles with similar particle sizes can be better separated.

③Reduce the number of screening times: For materials that are difficult to screen, one ultrasonic screening may achieve the effect of multiple ordinary screenings.

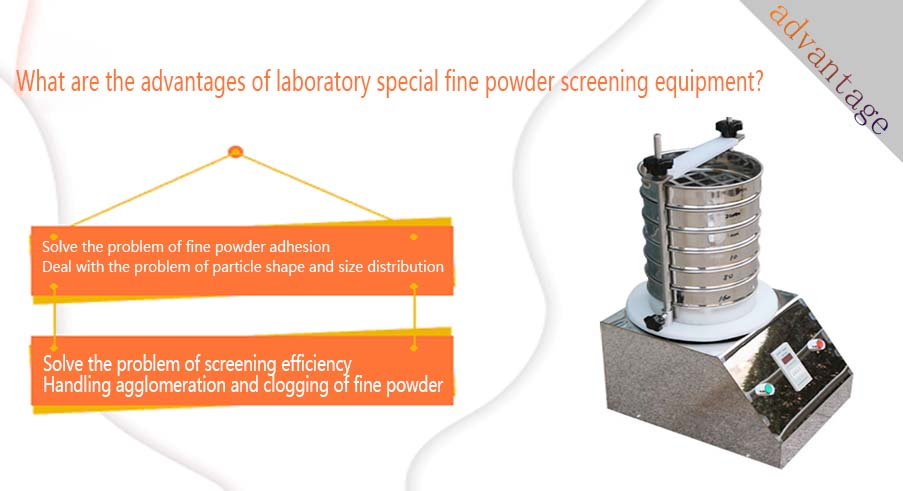

Solve the problem of fine powder adhesion: Fine powder usually has high adhesion and is easy to adhere to the surface of the screen, resulting in a decrease in screening efficiency. Reduce the adhesion of powder to the screen through mechanical vibration, and use ultrasonic vibration to keep the fine powder flowing on the surface of the screen to avoid adhesion.

Deal with the problem of particle shape and size distribution: The uneven particle shape and size distribution of fine powder may affect the screening effect. Laboratory fine powder screening equipment performs multi-stage screening by setting screens with different apertures to ensure more accurate particle separation.

Solve the problem of screening efficiency: Improving screening efficiency is the key goal of laboratory fine powder screening equipment. Laboratory special fine powder screening equipment usually adopts optimized screen design and selects appropriate materials and structures to improve permeability.

Handling agglomeration and clogging of fine powder: By applying high-frequency, low-amplitude ultrasonic vibrations on the screen, the attraction between powders is destroyed, so that they remain dispersed, effectively preventing agglomeration and mesh clogging. This continuous micro-vibration can also activate the powder on the screen surface, making it easier to pass through the mesh.

|

Industry field |

Applied fine powder type |

Recommended mesh size range |

Corresponding particle size range (μm) |

|

Pharmaceutical research and development |

Medical micropowder, flow aid |

100–400 mesh |

150–38μm |

|

New material development |

Alumina powder, nanoceramics, carbon materials |

200–635 mesh |

75–20μm (even finer) |

|

Fine chemicals/cosmetics |

Talc, titanium dioxide, color powder |

150–500 mesh |

100–25μm |

|

Food and nutrition |

Fruit and vegetable powder, protein powder, plant powder |

80–200 mesh |

180–75μm |

|

Environmental and geological analysis |

Soil powder, mineral samples, dust particles |

100–300 mesh |

150–50μm |

Laboratory special fine powder screening equipment is a high-precision separation tool developed for ultrafine powders (particle size is usually less than 100 microns). Its core value lies in achieving precise control of particle size distribution, avoiding agglomeration and ensuring sample purity.

Pharmaceutical industry: The particle size of fine powder is crucial to the solubility and bioavailability of drugs. Laboratory special fine powder screening equipment can be used to ensure the uniform particle size of drug raw materials and improve drug efficacy, such as lactose, starch, etc., to ensure the uniformity and quality of excipients.

Chemical industry: Fine powder screening in chemical products can affect reaction efficiency and product quality. The particle size of catalysts is strictly controlled to ensure the high efficiency of the reaction. It can also ensure the fineness of pigments and improve the color saturation and uniformity of coatings.

Food industry: Screening of fine powder helps to ensure the taste and quality of the product. Laboratory special fine powder screening equipment can ensure the uniformity of spices, enhance flavor, remove impurities, improve the fineness of flour, and ensure baking effect.

Materials Science: In the research and development of new materials, the characteristics of fine powders directly affect the performance of materials. The particle size distribution of nanopowders is controlled to optimize the performance of materials, ensure the uniformity of each component, and improve the strength and toughness of materials.

Laboratory special fine powder screening equipment plays an important role in many industries. Through screening technology, it ensures the quality and consistency of materials and promotes the research and development and production of various products. With the continuous improvement of the performance requirements of fine powder materials, the application prospects of laboratory special fine powder screening equipment will be broader.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Rosemary chemical reagent standard test sieve

Rosemary chemical reagent standard test sieve is a special device for particle size analysis and grading detection of rosemary powder, extracts ...

Apr 30, 2025

Laboratory Special Fine Powder Screening Equipment

Laboratory special fine powder screening equipment is especially suitable for precise particle size c...

Apr 29, 2025

Resemary Chemical Reagent Standard Test Sieve

Rosemary Chemical Reagent Standard Test Sieves is a device dedicated to analyzing and grading rosemar...

Apr 28, 2025

Test Sieves for Testing Chemicals Powders Oils

The Φ200mm test sieve for testing chemical powder oil is specially designed for analyzing the partic...

Apr 26, 2025

Introduction and related specifications of standard test sieves

Standard test sieves are the core tools for particle size analysis. They are used to grade and detect...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap