Monday May-26 2025 14:17:40

The laboratory vibrating screen for iron ore pelletizing is a small screening equipment designed for the characteristics of iron ore pelletizing. It is used to carry out small sample screening experiments and process research in a laboratory environment. Due to the characteristics of high hardness and irregular particles of iron ore, the particle size distribution needs to be accurately controlled during the pelletizing process to ensure the quality of the finished product.

It is usually equipped with 1-3 layers of screens. The screen material is mostly stainless steel woven mesh or punched plate. The aperture accuracy is extremely high, up to micron level, which can meet the fine classification needs of iron ore particles. Driven by electromagnetic vibration or small motor, its vibration frequency and amplitude are adjustable, and the inclination angle of the screen surface can also be adjusted in a small range according to experimental needs to ensure the simulation of the screening effect under different working conditions.

The laboratory vibrating screen for iron ore pelletizing: mainly used for scientific research, quality control and process optimization. In the process of iron ore pelletizing, in order to study the influence of different particle size distribution on the pelletizing effect, optimize the ratio or separation of binders, To analyze the particle size uniformity of the pelletizing product, it is necessary to accurately and repeatably screen a small amount of sample. This type of screening is usually to obtain detailed particle size data to guide production.

① The diameter of the screen is mostly φ200mm, φ300mm, φ400mm.

② Multi-layer structure (usually 1~8 layers) for grading and screening.

Industrial iron ore vibrating screen: used for large-scale industrial production. Its main purpose is to screen a large amount of materials efficiently and continuously in the process links of iron ore crushing, grinding, beneficiation and sintering, so as to achieve coarse and fine grading of materials, remove impurities, control the particle size of feed or grade the finished products, thereby improving production efficiency and product quality.

① The size ranges from a few hundred millimeters to several meters (such as 2000×6000mm).

② The structure is strong and the steel plate is thick, which is suitable for ore impact and wear.

③ Mostly single-layer or double-layer, which is convenient for rapid screening of large particles.

Coarse sieve: 20~40 mesh (850~425μm), used to separate oversized particles (such as ore debris and impurities) in iron ore raw materials, provide uniform initial materials for pelletizing, and is suitable for raw material pretreatment experiments.

Medium sieve: 40~80 mesh (425~180μm), controls the medium particle size distribution of iron ore particles, is often used to simulate the preliminary classification in the pelletizing process, and is suitable for pelletizing process optimization.

Fine sieve: 80~200 mesh (180~75μm), accurately screens fine particles to ensure that the finished particle size meets high-precision requirements (such as the particle size uniformity of pelletized ore raw materials), suitable for fine classification experiments and quality inspection.

Ultrafine sieve: 200~325 mesh (75~45μm), analyzes the particle size distribution of iron ore micro powder (such as the mixing uniformity of bentonite additives and mineral powder), suitable for additive ratio experiments and micro powder research.

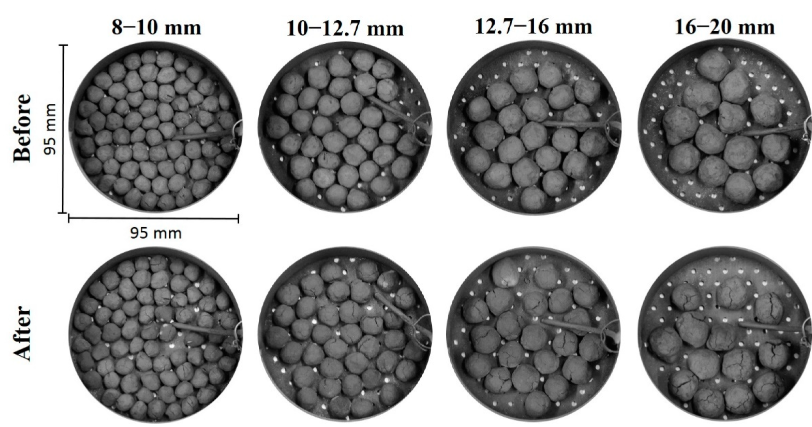

Iron ore pelletizing Laboratory vibrating screens are mainly used for particle size analysis and classification of iron ore powder before and after pelletizing, and play an important role in pelletizing research and development, pelletizing process optimization and raw material quality control. Specific application scenarios include: before pelletizing, the particle size distribution test of iron ore powder is carried out to determine whether it meets the requirements of pelletizing, such as the proportion of fine powder and particle size concentration; after pelletizing, the finished pellets are screened to evaluate the distribution of pellet size, and the influence of pelletizing efficiency and process parameters on particle size is analyzed; in addition, it can also be used to screen samples of different particle sizes to conduct comparative experiments on pelletizing performance, or to detect the effect of additives on the regulation of pellet size structure.The sieve has a compact structure and is easy to operate. It is suitable for the quality inspection department of the ore dressing plant laboratory, university research units and pelletizing plant, and provides important data support for optimizing the iron ore pelletizing process.

According to the sample characteristics and research objectives, select a sieve with a suitable mesh size, usually including 0.5 mm, 1 mm, 0.25 mm and other different specifications to cover the range from coarse particles to fine particles.

Pre-treat the iron ore samples, such as drying and crushing, to ensure that the samples are uniform and avoid particle agglomeration affecting the screening results.

Place the prepared samples evenly on the sieve, set the appropriate vibration frequency and amplitude to promote the effective separation of particles through the sieve. Use multi-layer sieves for continuous screening, collect particles of different particle sizes step by step, and ensure that the distribution data of different particle sizes are accurately obtained. Collect the sieved particles, weigh and record the mass of each particle size segment, perform data analysis, and draw a particle size distribution curve.

According to Screening results, evaluate the physical properties of iron ore, and adjust subsequent pelletizing process parameters to optimize production efficiency and product quality.

In short, the laboratory vibrating screen for iron ore pelletizing is a powerful tool for achieving refined production, ensuring product quality, and promoting technological progress in the field of iron ore processing. It plays a key role in the research and development and quality control of iron ore pelletizing processes, aiming to simulate and optimize the screening process in industrial production. Using high-frequency vibration and precisely controlled amplitude, various particle size analysis tasks can be completed efficiently and accurately.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Sieve particle size analyzer is a professional instrument used to determine the particle size distribution of granular materials. It simulates the traditional sieving process...

May 26, 2025

Laboratory Vibrating Screen for Iron Ore Pelletizing

The laboratory vibrating screen for iron ore pelletizing is a small precision equipment designed for ...

May 24, 2025

The sieve particle size analyzer is a professional instrument used to determine the particle size dis...

May 22, 2025

stainless steel pollen laboratory test sieve

Stainless steel pollen laboratory test sieve is a precision tool for pollen separation, classificatio...

May 21, 2025

The low-priced coffee test sieve is a key tool for evaluating the particle size distribution of coffe...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap