Tuesday May-20 2025 16:52:17

Laboratory test sieve is a precision screening equipment used for grading and testing fertilizer particles and other materials, suitable for multiple industries such as chemical, food, pharmaceutical, metallurgical, etc. In the process of fertilizer production, laboratory test sieves are commonly used to detect and analyze the particle size distribution of fertilizer particles (particle size 0.045-125mm), determine the particle size distribution of fertilizer particles, to ensure that the finished product particle size meets quality standards, especially in the development of new formulas, small-scale trial production, and quality control processes, which play an important role.

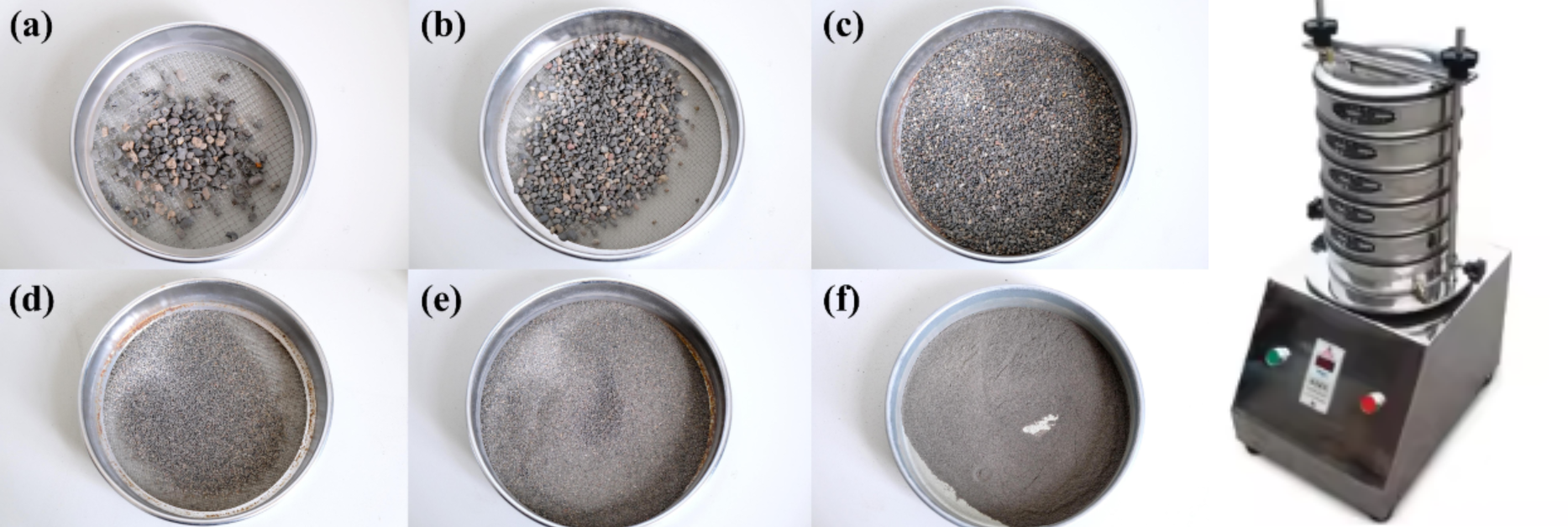

In the screening of fertilizer particles, laboratory test sieves usually use dry sieving, which places the dried fertilizer sample on the upper sieve and uses electromagnetic vibration or mechanical vibration to gradually sieve the particles through each layer of sieve, collecting them in layers according to particle size. The particle size distribution curve can be calculated by weighing the mass of each layer of sieve residue.

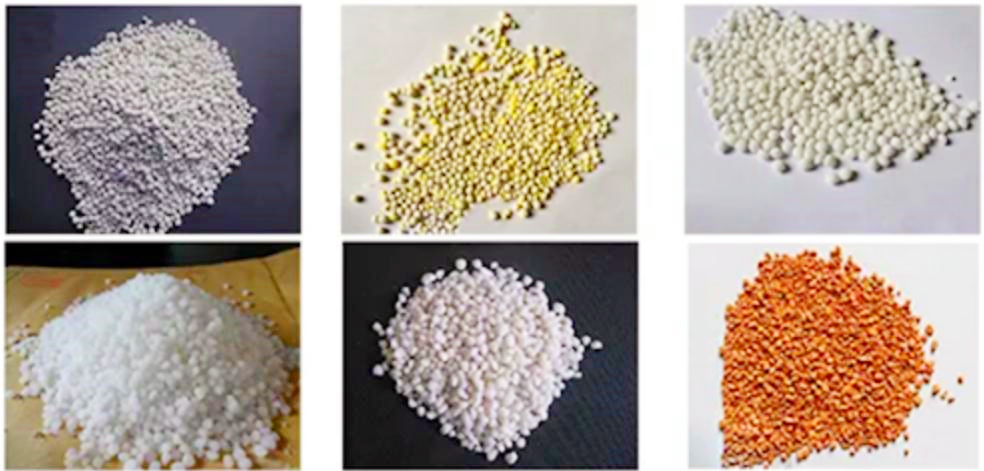

The laboratory test sieve is suitable for various types of fertilizer particles, including but not limited to:

Compound fertilizer (NPK compound fertilizer)

organic fertilizer

biological-organic fertilizer

Single component particles such as urea particles and phosphate fertilizer particles

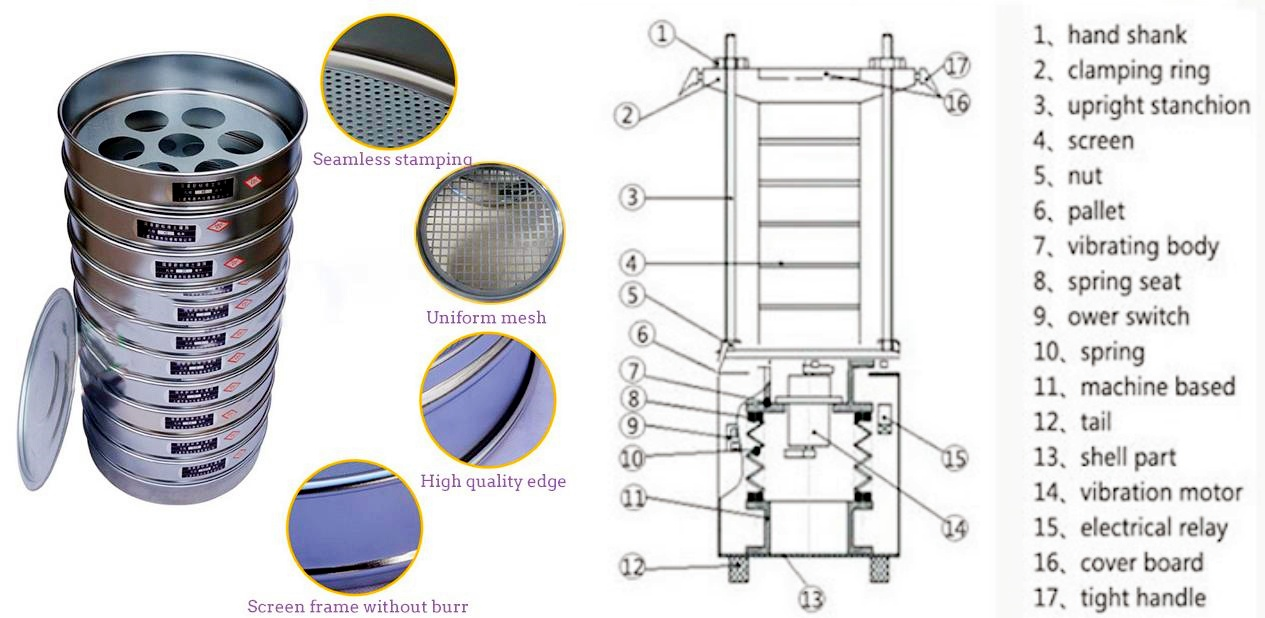

A typical laboratory test sieve structure is as follows:

Screen frame and mesh: Made of stainless steel material, the diameter is commonly 200mm (there are also specifications such as 300mm, 100mm, etc.), and multiple layers of mesh can be configured, with mesh diameters ranging from tens of micrometers to several millimeters.

Screening machine base: generally made of cast iron or steel plate structure, with good stability.

Motor drive system: By electromagnetic vibration or mechanical eccentric drive, the screen body produces up and down or reciprocating motion to achieve particle classification.

Time controller: used to set the screening time, ensuring that the screening process is controllable and repeatable.

|

Mesh size |

corresponding aperture (mm) |

applicable particle size range |

examples of applicable scenarios |

|

4 mesh |

4.75 mm |

>4.75 mm |

Large particle fertilizer pre screening, such as primary granulation detection |

|

6 mesh |

3.35 mm |

3.35-4.75 mm |

large particle screening, suitable for coarse grading of granular fertilizers |

|

8 mesh |

2.36 mm |

2.36-3.35 mm |

Medium particle size fertilizer particle size control, such as urea, ammonium sulfate, etc |

|

10 mesh |

2.00 mm |

2.00-2.36 mm |

Commonly used for particle size detection standards of granular fertilizer products |

|

14 mesh |

1.40 mm |

1.40-2.00 mm |

Medium particle size analysis of granular fertilizer, commonly used for screening compound fertilizers |

|

20 mesh |

0.85 mm |

0.85-1.40 mm |

Used for fine particle detection, such as screening of some organic fertilizer powder particles |

|

30 mesh |

0.60 mm |

0.60-0.85 mm |

Micro particle recognition to determine the degree of pulverization or particle breakage rate |

|

40 mesh |

0.425 mm |

0.425-0.60 mm |

Fine powder detection, analyze the lower limit of fertilizer particles |

|

60 mesh |

0.25 mm |

0.25-0.425 mm |

Powder material control, such as analysis of fine powder content in fertilizers |

|

80 mesh |

0.18 mm |

0.18-0.25 mm |

Ultra fine particle analysis, suitable for evaluating powdered organic fertilizers |

|

100 mesh |

0.15 mm |

<0.18 mm |

Powder impurity analysis or fine particle research |

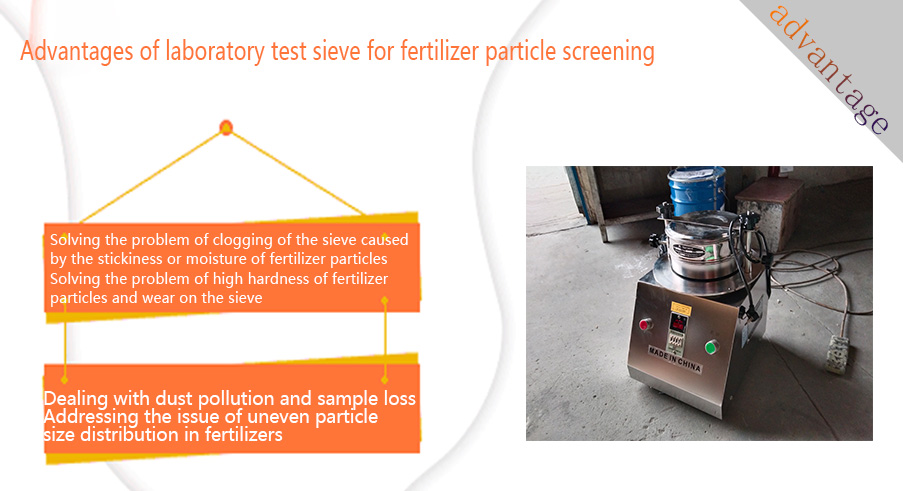

Solving the problem of clogging of the sieve caused by the stickiness or moisture of fertilizer particles: Organic fertilizers or high humidity fertilizers may adhere to the sieve, affecting the screening efficiency. Ensure that the fertilizer sample is dry (moisture content<10%) before use, and if necessary, dry the sample. Adopting ultrasonic testing screen, preventing particle adhesion through high-frequency vibration, suitable for sticky fertilizers. Regularly clean the sieve and use a nylon brush or compressed air to remove residue.

Solving the problem of high hardness of fertilizer particles and wear on the sieve: Some fertilizers (such as urea) have hard particles that may wear on the sieve and affect long-term use. Choose high wear-resistant stainless steel mesh (such as 304 or 316 stainless steel), which is corrosion-resistant and wear-resistant. Control the intensity and duration of vibration to avoid excessive wear on the screen mesh.

Dealing with dust pollution and sample loss: Fine fertilizer particles may generate dust, affecting the laboratory environment or causing sample loss. Use a test sieve with a sealed lid to reduce dust emissions. Equipped with a vacuum cleaner or operated in a fume hood to protect the environment and the health of operators.

Addressing the issue of uneven particle size distribution in fertilizers: By using sieves with different pore sizes (such as 0.5mm, 1mm, 2mm, 4mm, etc.), fertilizer particles are classified according to their particle size, and the product is evaluated for compliance with standards (such as particle size uniformity and the ratio of coarse/fine particles).

1. Particle size testing in the laboratory of fertilizer production enterprises

In the quality inspection process of compound fertilizer, organic fertilizer or biological fertilizer production enterprises, test sieves are commonly used for sampling and testing each batch of products. By using a set of standard test sieves (such as 2.0mm, 1.0mm, 0.5mm, 0.25mm and other aperture sieves) to screen the sample, the particle size distribution curve can be quickly obtained to determine whether the particle size is concentrated within the qualified range. The screening results are often compared with the standards to determine whether the batch of products is qualified or needs to be reworked.

2. Particle size optimization in the development process of new fertilizer formulas

In the research and development stage of new fertilizers (such as controlled-release fertilizers, water-soluble fertilizers, etc.), experimental sieves are used to evaluate the particle size distribution of particles obtained under different process conditions. Technicians can adjust granulation parameters such as spray pressure, drying temperature, and binder addition ratio based on screening results to obtain particles within the target particle size range, thereby improving application efficiency and uniformity of operations.

3. Particle size control of raw material pretreatment

Some organic fertilizer raw materials (such as livestock manure compost, straw crushing materials, etc.) need to be particle size controlled before mixing to avoid large particles or aggregates affecting the uniformity of granulation. The laboratory uses experimental screening to test whether the particle size of the raw materials after pretreatment meets the standard, providing data support for subsequent granulation.

4. Verification of Finished Screen Selection

In actual production, finished fertilizers need to be screened out of oversized or undersized particles through equipment such as rotary vibrating screens and drum screens. Before selecting or replacing the specifications of production screen mesh, enterprises often conduct verification through experimental screening in the laboratory. For example, selecting a suitable particle range (such as 2-4mm) through experimental screening, and then customizing the screen specifications for the production line based on this, to avoid material waste caused by mismatched screening accuracy.

The laboratory test sieve, as a key detection tool for fertilizer particle screening, plays an irreplaceable role in multiple aspects such as production control, formula development, and quality verification. Through precise screening and experimental screening, it helps ensure that fertilizer particles meet agricultural needs, improve production efficiency, and enhance product competitiveness. In practical operation, it is necessary to select appropriate sieve specifications and screening equipment according to the type and purpose of fertilizer to ensure the accuracy and practicality of the results.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Lab sieve equipment for calcium carbonate

Lab sieve equipment for calcium carbonate refers to instruments and devices used to grade and analyze the particle size of calcium carbonate samples in a lab environment. According to...

May 20, 2025

Laboratory test sieve used for fertilizer particle screening

Laboratory test sieve is a precision screening equipment widely used for detecting the particle size ...

May 19, 2025

Lab Sieve Analysis Equipment for Calcium Carbonate

lab sieve equipment for calcium carbonate is a key instrument for accurately analyzing and grading th...

May 17, 2025

test sieve for sieving corundum

The test sieve for sieving corundum is a laboratory tool widely used in abrasives, building materials...

May 16, 2025

Test Analysis sieves For Fine-Grained Soil

The test analysis sieve for fine-grained soil is a key tool for determining the particle size distrib...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap