![[field:title/]](/uploads/250401/2-25040109335W10.jpg)

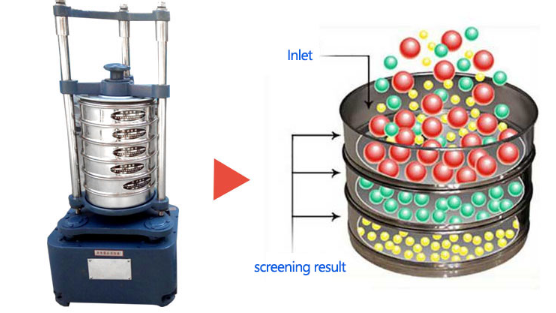

Mechanical Sieve Shaker is a laboratory instrument used to separate particles based on their size. It utilizes a combination of mechanical motions to agitate a stack of sieves containing the sample material.

Screening particle size: 0.025-3mm

Number of layers: 1-7 layers

Timing time: 1s-99h

Vibration frequency: 3000 times/minute

Sieving particle size range: 20–125μm

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

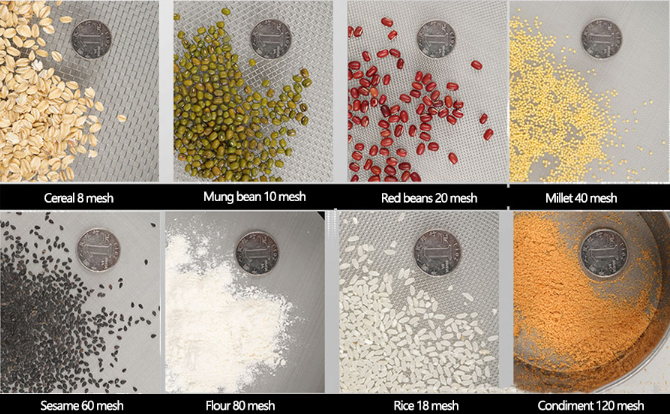

Mechanical Sieve Shaker is used for particle size classification and sieving of granular and powdered materials. Its sieve mesh range can be flexibly adjusted according to the standard sieve configuration, with common mesh sizes covering 20 to 500 mesh (approximately 850 μm to 25 μm), depending on experimental requirements. It can be equipped with micron-level precision sieves to achieve finer particle size separation.

Mechanical sieve shakers allow for selection of appropriate equipment based on material properties. When sample sizes are minimal or only quick and simple particle size checks are required, test sieves are a reliable choice due to their operational flexibility. For easily agglomerated, statically charged, or high-precision fine powders, ultrasonic sieves are the best choice, as their high-frequency vibrations effectively deagglomerate and ensure sieving accuracy. When handling sticky particles that easily clog the screen, impact sieves effectively prevent sieve clogging through their combined rotational and impacting motions. For general-purpose particles, especially those with higher specific gravity or requiring a certain impact force, top-impact sieves offer efficient sieving through their up-and-down impact and horizontal rotational motions.

Mechanical sieve shakers come in many types, and can be divided into four types according to the different structures of the equipment components: test sieves, tapping sieves, top-impact sieves, and ultrasonic sieves. The appropriate equipment can be selected according to the specific properties of the material being sieved.

| Type | Picture | Details | Features |

| Test screen |

|

The screen is vibrated at high frequency by a vibration motor or electromagnetic drive device, and the material is screened on the screen surface |

1. High screening efficiency, suitable for rapid screening of a variety of materials. 2. Simple structure and easy operation. 3. Suitable for materials with a wide range of particle sizes. |

| Slap test screen |

|

The screen frame is periodically slapped bya mechanical slapping device, so that the material is sifted on the screen surface by jumping motion |

1. Suitable for viscous, easyto agglomerate or difficult to screen materials. 2. The slapping force can be adjusted to a dapt to different material characteristics. 3. High screening a ccuracy, but high noise. |

| Magnetic suspension test screen |

|

The magnetic suspension technology is used to make the screen vibrate without contact, and the material is efficiently screened on the screen surface. |

1. Nomechanical friction, low noise, and long life. 2. Suitable for ultra-fine particles and high-precision screening. 3. Low energy consumption and low maintenance cost. |

| Ultrasonictest screen |

|

The electromagnetic drive generates high-frequency vibration, and the sieve vibrates quickly to achieve efficient screening |

1. High-frequency vibration 2. prevent sieve holes from being blocked, suitable for fine particles oreasily adhered materials |

The Mechanical Sieve Shaker consists of a screen box, a vibrator, a support device, and a transmission system. The screen box contains a screen mesh, and the vibrator drives the screen box to generate high-frequency vibration, causing the material to separate into layers on the screen surface and completing particle size separation.

Screen frame: The screen frame is the main body of the test sieve, usually made of stainless steel or other corrosion-resistant materials. Screens with different apertures are provided on the screen frame.

Screen: The screen is the core component of screening and is made of stainless steel, brass and other materials. The aperture size of the screen determines the accuracy of the screening particle size.

Vibration device: A device that provides vibration force, which can be an electric vibrator, pneumatic vibrator, etc.

Clamping device: Used to stack and fix multiple screens.

Base: Supports the entire mechanical sieve shaker.

Mechanical sieve shakers utilize vibration, tapping, or impact to move materials on the sieve surface and separate them according to particle size; particles smaller than the sieve openings pass through the sieve, while larger particles remain on the sieve surface. Experimental sieve separators rely on motor vibration to move materials horizontally and vertically for grading; tapping sieves improve sieving efficiency through the combined action of vibration and an upper tapping device; top-impact sieves use upper and lower impacts to loosen and stratify materials, suitable for fine powder sieving; ultrasonic sieves superimpose high-frequency ultrasonic vibrations within the sieve mesh, causing fine particles to resonate, preventing clogging, and improving accuracy and speed.

Mechanical sieve shakers are compact and suitable for use in laboratory or small-scale production environments, facilitating movement and deployment. Their flexibility allows users to easily change sieves of different aperture sizes to meet specific screening needs, enabling precise classification and testing of materials of various particle sizes. The machine's simple and intuitive design allows even non-professionals to quickly learn how to use it. Its components are easy to disassemble, clean, and maintain, reducing operating costs. To improve screening efficiency, mechanical sieves are typically equipped with vibrators or oscillation devices. High-frequency micro-amplitude vibration effectively promotes particle separation and passage through the sieve, preventing clogging.

| serial number | name | unit | parameter |

| 1 | sieve frame | layer | 1~5 |

| 2 | screen frame diameter | mm | 300,200,100 |

| 3 | sieve particle size | mm | 0.025~3 |

| 4 | noise | dB | less than 50 |

| 5 | amplitude | mm | 0~3 |

| 6 | vibration frequency | times/min | 1400 |

| 7 | external dimensions | length*width*height | 350:350:300+N*50 |

| 8 | power supply | V; HZ | 220; 50 |

| 9 | machine weight | Kg | 36 |

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.36 | 15 | 70# | 0.212 |

| 2 | 10# | 2 | 16 | 80# | 0.18 |

| 3 | 12# | 1.7 | 17 | 100# | 0.15 |

| 4 | 14# | 1.4 | 1.4 | 120# | 0.125 |

| 5 | 16# | 1.18 | 19 | 140# | 0.106 |

| 6 | 18# | 1 | 20 | 170# | 0.09 |

| 7 | 20# | 0.85 | 21 | 200# | 0.075 |

| 8 | 25# | 0.71 | 22 | 230# | 0.063 |

| 9 | 30# | 0.6 | 23 | 270# | 0.053 |

| 10 | 35# | 0.5 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.3 | 27 | 500# | 0.028 |

| 124 | 60# | 0.25 |

Mechanical sieve shakers are used for particle size analysis, grading, impurity removal, and filtration of materials, playing a crucial role in sample preparation and material pretreatment. They separate particles of different sizes, remove impurities, and ensure uniform and pure materials, providing accurate and reliable basic data and high-quality raw materials for subsequent production and testing.

Particle size analysis: Through sieves with different apertures, the content of particles of different particle sizes in the material can be accurately determined, so as to obtain the particle size distribution curve of the material. In the production process, particle size analysis can be used to control the quality of the product and ensure the uniformity and stability of the product. According to the results of particle size analysis, the production process parameters can be optimized to improve product quality and production efficiency.

Sieving and grading: Separate particles of different particle sizes in the mixed material to obtain products of different specifications. For example, in the pharmaceutical industry, drug powders can be graded by particle size to meet different formulation requirements.

Sample preparation: Remove large particles or impurities in the sample to provide pure samples for subsequent analytical tests.

Quality control: Through sieving analysis, the quality of the product can be controlled to ensure that the product meets the specified quality standards.

The mechanical sieve shaker can perform precision sieving of fine powders, and can also sieve materials with higher specific gravity, irregular particle shape, or abrasiveness at high frequency. It can also be used as a rapid classification or preliminary screening tool. Specific applications of the equipment are as follows:

Powder metallurgy: Determine the particle size distribution of metal powder and control the density and strength of the product.

Ceramic industry: Control the particle size of ceramic raw materials and affect the performance of ceramic products.

Food industry: Screen flour, powdered sugar, etc. to control the taste and quality of food.

Pharmaceutical industry: Screen drug raw materials, control the particle size distribution of drugs, and affect the dissolution rate and bioavailability of drugs.

Building materials industry: Screen cement, sand and gravel, etc. to control the quality of building materials.

The price of a mechanical sieve shaker varies greatly depending on factors such as brand, model, capacity, features, and region. Additionally, larger sieve sizes, more sieve layers, and higher daily or hourly throughput generally result in higher prices. Below are approximate price ranges and factors influencing price:

| Type | Price Range (USD) | Description |

| Basic Manual Sieve Shaker | 100-500 | Simple, hand-operated models for light-duty use. |

| Standard Mechanical Shaker | 500-2,000 | Motor-driven, suitable for general lab or industrial use. |

| High-Capacity Shaker | 2,000-5,000 | Designed for heavy-duty use, with larger capacity and advanced features. |

| Specialized Shakers | 5,000-10,000+ | Includes features like digital controls, multiple sieves, or custom applications. |

Mechanical Sieve Shaker is a small screening equipment with high precision and strong flexibility, which is widely used in laboratories and quality inspection fields. Through reasonable selection and regular maintenance, the accuracy and reliability of screening results can be ensured. It is one of the indispensable tools in scientific research and production control.

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

Soil sieve analysis is a soil particle size determination method based on the principle of mechanical separation...

Juice Powder Ultrasonic Sieve test

The ultrasonic sieve test for juice powder is a fine screening equipment designed for delicate, moisture-absorbing...

Standard Test Method for Particle-Size Analysis of Soils

Standard Test Method for Particle-Size Analysis of Soils (ASTM D422)aims to accurately determine the size distribution of soil particles...

Laboratory woven wire mesh sieves

Laboratory woven wire mesh sieves are screening tools made of 250 mm stainless steel frame and precision woven wire mesh. The high quality of the equipment ensures reliable screenin...

Sieve Mesh is a metal or non-metal device used to separate materials. Its mesh count refers to the number of holes per square inch. It sorts powders by particle size through vibrati...

For Laboratory Sieves Price ranges from $100 to $500 USD, and the price varies depending on the sieve diameter, mesh range, material, and quantity.......

For Laboratory Sieves Suppliers

For Laboratory Sieves Suppliers manufactures sieve frames in 3-inch, 8-inch, and 12-inch diameter sizes, including perforated plate screens, wet-washed screens, and woven wire mesh ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap