Monday November-24 2025 17:02:26

Particle analysis is a method for determining the particle size distribution of particulate materials by sieving and weighing them using standard sieves. The Mechanical Sieve Shaker for Particle Analysis is suitable for particles with a diameter range of approximately 20 micrometers to 125 millimeters, covering a variety of materials from fine sand to coarse gravel.

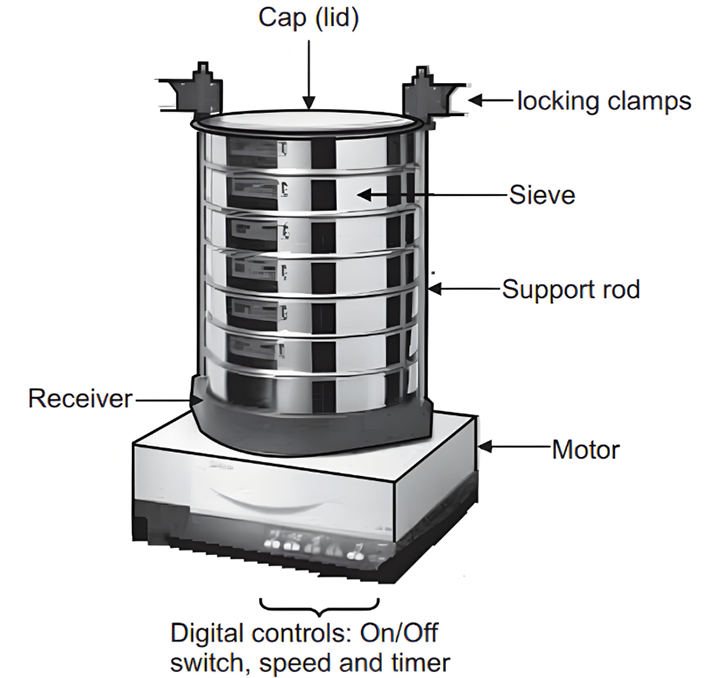

A standard Mechanical Sieve Shaker for Particle Analysis typically holds 8 to 10 standard sieves with a diameter of 200 mm and is equipped with a digital timer and amplitude adjustment function to adapt to different sample characteristics—such as using low amplitude to prevent breakage of fragile particles and high amplitude to aid dispersion of adhesive samples. Its effective sieving range covers particle sizes from 125 mm to 20 μm. By providing continuous, uniform, and repeatable vibration, it effectively overcomes problems such as agglomeration caused by friction, static electricity, or humidity, ensuring accurate and reliable analytical results.

Based on the different vibration generation methods and motion characteristics, Mechanical Sieve Shaker is divided into the following three types: impact and top-impact vibrating sieves are powerful and suitable for granular materials; electromagnetic vibrating sieves are high-precision and low-noise, suitable for fine analysis.

Impact vibrating sieves (such as the RO-TAP series) are suitable for various dry particle analysis, especially fine particles that are prone to agglomeration and clogging of the sieves, or samples with adhesive properties. This type of vibrating screen combines horizontal rotary motion with vertical tapping motion. The tapping action effectively loosens particles, prevents screen clogging, and offers high screening efficiency and good reproducibility. It is the equipment specified by many standard methods (such as ASTM and ISO).

Top-impact vibrating screens are used for most common granular materials, including chemical raw materials, grains, and minerals. The vibration source is located at the top of the screen tower, generating high-frequency vibrations with a predominantly small circular trajectory through an eccentric mechanism. Its structure is relatively compact, and its operating noise is generally lower than that of tapping screens. However, its effectiveness may be slightly less than tapping screens when processing fine powders that are prone to clogging.

Electromagnetic vibrating screens are suitable for particle analysis of fine powders, fragile particles, and materials sensitive to static electricity. They utilize electromagnets to generate high-frequency, low-amplitude vertical vibrations or three-dimensional micro-amplitude vibrations. Operation is very quiet, and the vibration intensity can be precisely and steplessly adjusted. For fragile particles, it provides gentle yet effective screening, reducing particle breakage.

The Mechanical Sieve Shaker for Particle Analysis boasts advantages such as robust structure, ease of operation, high repeatability, stable results, excellent accuracy, clear particle analysis, and diverse functions to meet different particle analysis needs.

The structure is typically made of high-quality metal. Internally, it contains a precisely calculated eccentric wheel or cam mechanism, driven by a motor to generate stable three-dimensional compound motion, ensuring sieving efficiency. The sieve tower is secured by a reliable locking device to prevent loosening during testing.

The instrument's mechanical structure ensures consistency in parameters such as amplitude and frequency for each run. As long as the operation is standardized, multiple sievings of the same sample yield excellent repeatability, reducing random errors caused by human operation and ensuring data comparability.

Accuracy is built upon repeatability. Its standardized motion pattern ensures that the material is fully and uniformly dispersed and sieved on the sieve surface, effectively simulating the principle of manual sieving while avoiding deviations caused by fatigue or uneven force in manual sieving, thus obtaining true and accurate particle size distribution data.

The main function is to achieve efficient and standardized sieving of particulate materials. It can simultaneously process multiple stacked sieves, obtaining particle size distribution data for multiple particle sizes in one go. Some high-end models also feature amplitude adjustment to adapt to the sieving needs of materials with different materials or adhesion properties.

A built-in precise electronic timer allows users to preset the sieving time. The equipment automatically stops when the time is up, eliminating subjective errors and oversights from manual timing and ensuring consistent sieving time for each process. This is a key factor in guaranteeing the repeatability and comparability of results.

| Mesh | Screen Wire Diameter (mm) | Approximate Aperture (mm) | Description |

| 4 mesh | 1.0–1.2 | 4.75–5.0 | Coarse |

| 5 mesh | 0.8–1.0 | 4.0 | Coarse |

| 8 mesh | 0.6–0.8 | 2.36 | |

| 10 mesh | 0.5–0.7 | 2.0 | |

| 14 mesh | 0.45–0.6 | 1.4 | |

| 16 mesh | 0.35–0.45 | 1.18 | |

| 20 mesh | 0.32–0.40 | 0.85–0.90 | Medium |

| 30 mesh | 0.22–0.32 | 0.55–0.60 | |

| 40 mesh | 0.18–0.25 | 0.38–0.42 | |

| 50 mesh | 0.14–0.20 | 0.28–0.30 | Fine |

| 60 mesh | 0.12–0.17 | 0.23–0.25 | |

| 70 mesh | 0.10–0.15 | 0.19–0.21 | |

| 80 mesh | 0.10–0.12 | 0.16–0.18 | |

| 100 mesh | 0.08–0.11 | 0.14–0.15 | |

| 120 mesh | 0.07–0.10 | 0.12–0.125 | |

| 150 mesh | 0.06–0.08 | 0.10 | Very Fine |

| 180 mesh | 0.05–0.07 | 0.08 | |

| 200 mesh | 0.045–0.065 | 0.075 | |

| 250 mesh | 0.04–0.06 | 0.063 | |

| 300 mesh | 0.035–0.05 | 0.053 | Ultra Fine |

| 325 mesh | 0.03–0.045 | 0.045 | |

| 400 mesh | 0.025–0.04 | 0.038 | |

| 500 mesh | 0.02–0.03 | 0.025–0.030 |

When Mechanical Sieve Shaker for Particle Analysis working, a series of standard sieves with decreasing aperture sizes from top to bottom are assembled into a sieve tower. After the sample is added, it is fixed to the equipment, and the time and vibration parameters are set before starting. Under the combined motion of impact and rotation, the particles pass through the corresponding sieves layer by layer, and are finally separated into individual sieves and a base according to particle size. After sieving, the material of each particle size fraction is collected and weighed, and the mass percentage is calculated and the particle size distribution is analyzed.

Particle Analysis can analyze the particle size distribution of sand, gravel, and cement; determine the particle size distribution of powder coatings, resins, fillers, etc.; monitor the particle size of powders such as pharmaceutical raw materials, excipients, sugar, and flour, which is related to product solubility, flowability, and taste; evaluate the particle size composition of ores, coal, and metal powders for process control and product quality assessment; perform soil texture analysis; and be used in the laboratory for particle size characteristic studies of new materials and processes.

Mechanical Sieve Shaker for Particle Analysis are indispensable tools in particle size analysis. Their working principles, diverse types, and high repeatability make them valuable in quality control and scientific research. Whether classic tapping, general-purpose top-impact, or precision electromagnetic, they efficiently and accurately separate mixtures into defined particle sizes through standardized mechanical vibrations, providing crucial particle size data for various industries and thus contributing to product quality improvement and process optimization.

Test sieves for reliable sieve analysis

Test sieves for reliable sieve analysis are tools used in laboratories to determine particle size distribution...

Fine aggregate test sieve is a special instrument for determining the particle gradation of fine aggregates...

Nov 24, 2025

Mechanical Sieve Shaker for Particle Analysis

Mechanical Sieve Shaker for Particle Analysis automatically stirs and separates particles. This devic...

Nov 24, 2025

For Laboratory Sieves Price ranges from $100 to $500 USD, and the price varies depending on the sieve...

Nov 22, 2025

laboratory sieve with material

Laboratory sieves with materials include brass, stainless steel, or a brass frame with a stainless st...

Nov 22, 2025

laboratory sieve with material

Laboratory sieves with materials include brass, stainless steel, or a brass frame with a stainless st...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap