![[field:title/]](/uploads/250418/2-25041Q45615406.png)

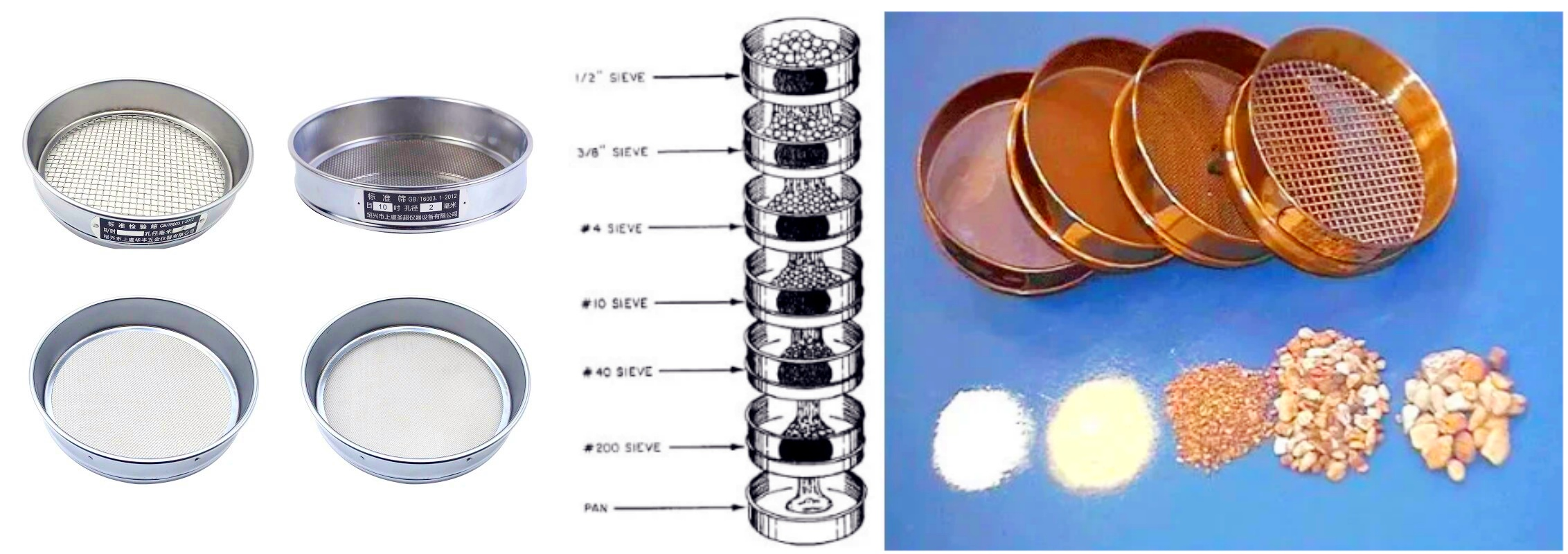

Metal Powders Test Sieve is a screening tool used to determine the particle size distribution of metal powder. Its main function is to screen the metal powder through sieves of different apertures to determine its particle size distribution.

Number of layers: 1-8 layers

Screening particle size: 0.025mm-20mm

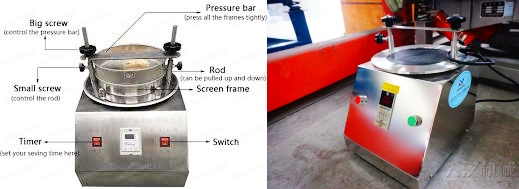

Structural composition: screen frame, screen, vibration motor, ultrasonic system (optional), control system, base and bracket.

Application: It is usually used in powder metallurgy, material science, 3D printing, chemical industry and pharmaceutical industry.

Port:Any port in China (Mainland)or as you need.

| Quantity(sets) | 1-2 | >2 |

| Delivery time(days) | 5 | To be negotiated |

Metal Powders Test Sieve is an experimental device used to determine the particle size distribution of metal powder. The metal powder test sieve is generally made of stainless steel and equipped with screens of different mesh sizes (for example, multiple grades from coarse powder to ultrafine powder) to separate metal powders by particle size.

Metal Powders Test Sieve uses precise mesh size to classify powders, providing detailed particle size distribution data. The test sieve's manufacturing material, mesh accuracy, and structural design directly impact the accuracy of test results. Types of test sieves are primarily categorized by mesh material and shape, including woven mesh sieves and electroformed sieves (also known as electroformed sieves). Woven mesh sieves are made of woven metal wire, with apertures ranging from tens of microns to millimeters. Electroformed sieves are manufactured using an electrochemical process, resulting in extremely precise apertures and a smaller screening range. They are primarily used for fine powders in the micron and even submicron ranges.

The working principle of a metal powders test sieve is based on particle size separation using a series of standardized sieves with precisely sized mesh openings.

The screen is vibrated at high frequency by a vibration motor.

The metal powder jumps and rolls on the screen. Metal powders particles smaller than the screen aperture pass through the screen aperture, while metal powder particles larger than the screen aperture are retained on the screen.

The vibration frequency and amplitude of the metal powders test sieve can be adjusted to adapt to metal powders of different particle sizes and properties.

| Project | Specification details |

| Screen type | Wire mesh, perforated plate screen |

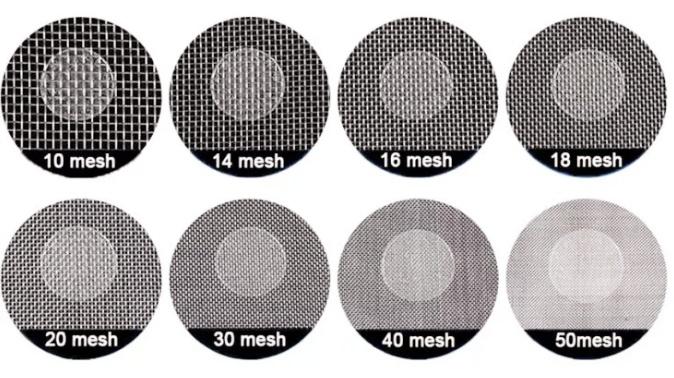

| Screen mesh range | Commonly 20-400 mesh, can be customized to a wider range according to needs |

| Screen frame material | 304 stainless steel, carbon steel, etc. |

| Screen frame size | Φ100mm, Φ200mm, Φ300mm, etc. |

| Number of sieve layers | 1-7 layers (depending on the specific equipment and needs) |

| Applicable particle size range | Generally can handle metal powders from a few microns to a few millimeters |

| Article | Standard | Sieve Diameter | Sieve Depth (H1) |

|---|---|---|---|

| Woven Wire Cloth Sieve 630 µm | DIN ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 500 µm | DIN ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 400 µm | DIN ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 315 µm | DIN ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 250 µm | DIN ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 180 µm | DIN ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 125 µm | DIN ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 100 µm | DIN ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 90 µm | DIN ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 63 µm | DIN ISO 3310-1 | 200 mm | 32 / 50 mm |

| Collecting Pan | 200 mm | 25 / 50 mm | |

| Sieve Lid | 200 mm | 27 mm |

| Article | Standard | Sieve Diameter | Sieve Depth (H1) |

|---|---|---|---|

| Woven Wire Cloth Sieve 355 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 250 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 180 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 125 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 90 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 63 µm | ISO 3310-1 | 200 mm | 32 / 50 mm |

| Woven Wire Cloth Sieve 40 µm* | ISO 3310-1 | 200 mm | 32 / 50 mm |

|

Mesh number (Mesh) |

Mesh size (mm) |

Mesh size (μm) |

Application example |

| 4 | 4.75 | 4750 | Coarse particle screening |

| 10 | 2.00 | 2000 | Ore sand, coarse powder |

| 20 | 0.85 | 850 | Spray powder |

| 30 | 0.60 | 600 | Powder metallurgy coarse screening |

| 50 | 0.30 | 300 | Medium particle size powder |

| 100 | 0.15 | 150 | 3 3D printing, fine powder |

| 200 | 0.075 | 75 | battery materials, ultrafine powder |

| 325 | 0.045 | 45 | fine screening |

| 400 | 0.038 | 38 | ultrafine powder |

| 800 | 0.020 | 20 | limit fineness, special purpose |

| Number | Name | Unit | Data |

| 1 | Layers | Layer | 1-8 |

| 2 | Diameter | mm | 200 |

| 3 | Granularity | mm | 0.038-3 |

| 4 | Noise | dB | 50 |

| 5 | Feeding Capacity(once) | G | 200 |

| 6 | Amplitude | mm | 5 |

| 7 | Voltage | v | 220 |

| 8 | Speed | R/min | 1420 |

| 9 | Power | Kw | 0.125 |

| 10 | Overallv Dimension | mm | 360*300*736 |

| 11 | Weight | Kg | 45 |

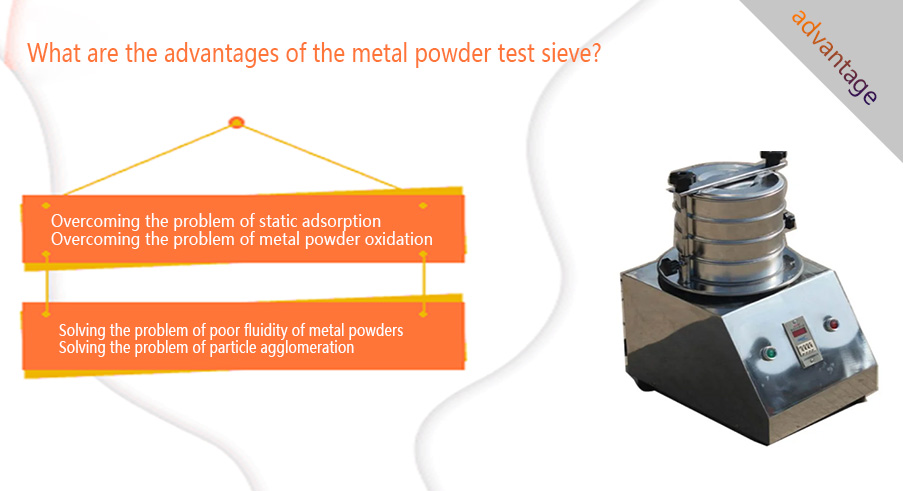

The metal powders test sieve offers several advantages, making it a widely used method for particle size analysis in industries like overcoming the problem of static adsorption, Overcoming the problem of metal powder oxidation, Solving the problem of poor fluidity of metal powders, Solving the problem of particle agglomeration, additive manufacturing, powder metallurgy, and more.

Overcoming the problem of static adsorption: Use anti-static materials to make the screen and screen body, reduce the adsorption of static electricity on metal powder, allow the powder to pass through the screen smoothly, and improve screening efficiency and accuracy.

Overcoming the problem of metal powder oxidation: Some metal powders are easily oxidized in the air, affecting the screening results. Screening is carried out in an inert gas environment to prevent powder oxidation.

Solving the problem of poor fluidity of metal powders: Some metal powders have poor fluidity and are difficult to pass through the screen. Improve the fluidity of the powder by vibrating the metal powder test screen or add a flow aid to the powder to improve its fluidity.

Solving the problem of particle agglomeration: Generate high-frequency vibration through a vibration motor. The vibration action causes the agglomerated metal powder particles to be subjected to impact and shear forces, thereby dispersing the agglomerates for easy screening.

The purpose of a metal powders test sieve is to determine and control the particle size distribution of metal powders, ensuring they meet specific quality and performance standards for industrial applications.

Ensure product performance: By accurately controlling the particle size of metal powder, the metal products produced subsequently have good physical, mechanical and chemical properties, such as strength, toughness, conductivity, etc.

Improve production efficiency: The appropriate powder particle size helps to improve the formability, fluidity and sintering properties in the production process, reduce defects and scrap rates in production, and improve production efficiency and economic benefits.

The Metal Powders Test Sieve is primarily used for precise classification and particle size analysis of metal powders of varying properties and particle sizes. Its wide range of applications covers powders of various conventional metals, alloys, and specialty metal materials. It can also be used to screen non-metallic powders related to metals, such as electromagnetic materials and metal oxides, to meet the powder particle size control and quality testing needs of various industrial sectors.

Common metal powders: iron powder, aluminum powder, lead powders, copper powders, etc.

Alloy and special metal powders: alloy powder, electrolytic copper powder, stainless steel powder, molybdenum powder, etc.

Other related materials: electromagnetic material powder, metal oxide powders such as zinc oxide, metal carbide powders such as tungsten carbide.

The recommendation for mesh numbers in metal powder test sieves heavily depends on the particle size distribution (PSD) of the metal powder you are analyzing. Metal powders used in various applications, such as additive manufacturing (3D printing) and powder metallurgy, can have a wide range of particle sizes, typically from a few micrometers to several hundred micrometers.

Coarse powders screening: If the metal powder particle size is large, such as greater than 1mm, you can choose a 20-40 mesh test sieve for preliminary screening.

Medium powders screening: For medium metal powder with a particle size of 0.1-1mm, a 40-100 mesh sieve is more suitable.

Screening of fine powders: When the powder size is 0.05 - 0.1mm, the 100 - 200 mesh test sieve can screen well.

Screening of fine powders and ultrafine powders: For fine powder and ultrafine powder less than 0.05mm, it is usually necessary to use a sieve with a mesh size of 200 or even 400 for accurate screening.

Metal powder test sieves play a key role in various fields, primarily for particle size distribution analysis and quality control of various metal powders. Through precise screening, they can separate powder samples into different particle size fractions, thereby obtaining powder particle size distribution data. This is crucial for ensuring stable and consistent product performance. In R&D and production, test sieves are used to evaluate the properties of new materials and monitor powder quality during the production process to prevent performance defects caused by uneven particle size. Furthermore, they are a common tool for quality inspection before materials are received into storage, verifying that powders provided by suppliers meet specified particle size standards. Through these applications, metal powder test sieves provide fundamental data support for material quality control, ensuring the reliability of subsequent processing and final products.

The application of metal powder test sieve applies in the accurate analysis of granularity structures of particle and power materials, and the testing analysis of solid content in liquid for laboratories, quality control rooms, and scientific research departments. Metal powder test sieve is widely used in testing analysis of chemical, building materials, powder metallurgy, and material in the processing process of sewage and wastewater from the environmental protection industry.

The Metal Powders Test Sieve operates through a rigorous classification and separation process. Its core principle is to use mechanical or ultrasonic vibrations to drive powder particles of varying sizes through a series of sieves arranged in descending order of aperture, ultimately achieving size classification. The process begins with the preparation of a standard sieve set, continues through sample loading, vibratory sieving, classification, and finally, weighing and calculating the mass percentage of each particle size range.

Preparation stage: According to the particle size range to be measured, select a set of standard sieves (arranged in order from large aperture to small aperture) to form a sieve group. Usually the top is the large aperture sieve and the bottom is the receiving tray.

Sample loading: Place the metal powder sample to be tested on the top sieve. The sample quantity must meet the standard requirements (such as GB/T1480-2012, the sample mass is generally 50g or 100g).

Screening:

Vibration: Move the metal powder on the sieve surface through mechanical vibration (such as vibrating screen machine) and ultrasound. The vibration force causes the particles to roll or jump on the sieve.

Grading separation: Particles with a particle size larger than the sieve aperture are retained on the current sieve layer, and particles with a particle size smaller than the aperture fall through the sieve aperture into the next sieve layer, and so on, until all particles are graded.

Collection and weighing: After the screening is completed, the powder on each sieve layer and the fine powder in the bottom plate are collected and weighed separately, and the mass percentage of each particle size segment is calculated.

Particle size distribution of powder: If the particle size distribution range of the metal powder is wide, it is necessary to select a series of test sieves with different mesh sizes to more accurately measure the powder content of different particle sizes.

Purpose of the test: If the purpose is to determine the average particle size of the powder, you can select several representative meshes for screening. If the purpose is to understand the particle size distribution of the powder in detail, you need to select test sieves with more meshes to obtain more accurate data.

Industry standards and specifications: Different industries and application areas may have specific standards and specifications that specify the mesh selection of test sieves.

|

|

|

|

| Quality Control in Additive Manufacturing | Particle Size Optimization in Powder Metallurgy | Quality Control of Metal Powders for Coatings | Metal Powder Recycling |

These case studies illustrate the diverse applications of metal powder test sieves in different industries, all centered around the critical need for accurate particle size analysis for quality control, process optimization and research.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

Agricultural soil testing sieve

What is Agricultural soil testing sieve ? Agricultural soil testing sieves are primarily used to separate soil samples into particles of varying sizes. Testing sieves come in variou...

What is 0.075mm soil sieve ? The 0.075mm soil sieve is primarily used for soil particle size analysis, separating and classifying particles by size. 0.075mm is considered the critic...

What is 4.75mm soil sieve ? The 4.75mm soil sieve is primarily used for particle grading analysis of bulk materials such as soil, sand, gravel, and aggregate. The core component of ...

What is 2mm soil sieve? A 2mm soil sieve is a fundamental and crucial tool. Its primarily used for pre-processing and sorting soil samples, separating coarse particles (larger than ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap