Friday April-25 2025 17:27:44

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which is 100 times finer than cement. The micro silica powder particle size analysis test sieve is a laboratory equipment used to analyze and detect the particle size distribution of micro silica powder, mainly used to determine the particle size distribution of micro silica powder (such as D10, D50, D90, etc.), evaluate its applicability, dispersibility, and blending performance, and is crucial in silica powder quality control and new material development.

Micro silicon powder is an ultrafine silicon powder produced during ferroalloy smelting or industrial silicon production, mainly composed of SiO ₂ (content 90% -97%), with the following characteristics

Extremely fine particle size: The average particle size is usually 0.1-10 μ m, with D50 mostly between 1-3 μ m, which is prone to agglomeration and formation of flocculent particles;

High surface activity: The particle surface energy is large, and during dry screening, it is prone to clogging of the sieve due to electrostatic adsorption;

Special application scenarios: often used for concrete admixtures, refractory materials, etc., particle size distribution directly affects product performance.

Core objective of particle size analysis: to determine the particle size distribution of micro silica powder (such as D10, D50, D90); Detect the content of coarse particles (such as the proportion of particles larger than 45 μ m) to determine whether it meets industry standards.

① Pore size control of sieve: The test sieve is equipped with different mesh sizes, each corresponding to a specific pore size. The higher the mesh size, the smaller the aperture. The material to be analyzed will be sequentially passed through a series of sieve layers with varying pore sizes.

② Mechanical vibration: typically driven by a vibration motor or electromagnetic exciter, producing horizontal, vertical, or composite vibrations.

③ Movement and stratification of micro silica powder: Under the action of vibration, micro silica powder particles jump, roll, and disperse on the screen surface. During the movement of smaller particles, when they encounter sieve holes larger than or equal to their own size, they will fall through the sieve holes under the action of gravity to the next layer of sieve with smaller aperture. Particles larger than the current sieve aperture will remain on that layer of the sieve and ultimately be collected.

④ Grading process: After a certain period of vibration, particles of different size ranges will stay on different mesh screens or in the receiving tray at the bottom.

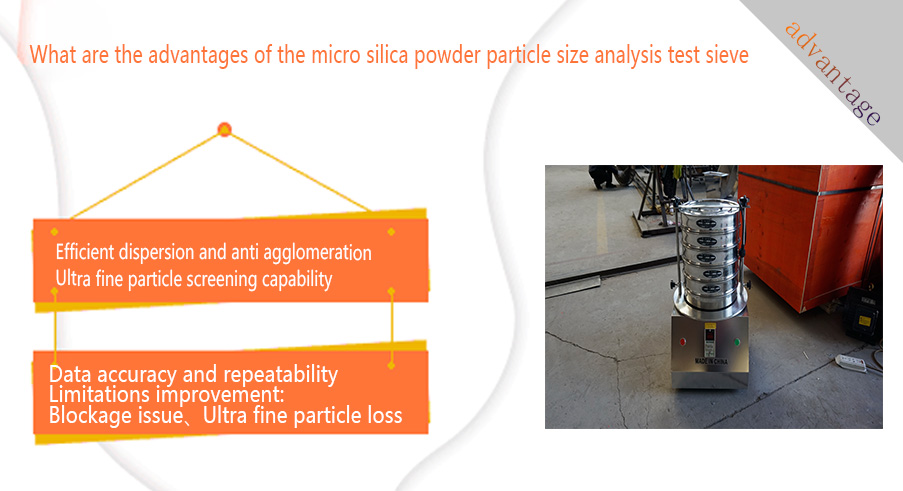

Efficient dispersion and anti agglomeration: Static electricity can seriously hinder the separation of micro silica powder on the test sieve. Through high-frequency vibration and three-dimensional motion of the test sieve, the van der Waals forces and electrostatic adsorption between micro silica powder particles are broken, reducing agglomeration and improving screening efficiency. Some devices are equipped with ultrasonic vibration modules to further disperse ultrafine particles (such as<10 μ m).

Ultra fine particle screening capability: Electroformed microporous screens (such as nickel based etched screens) or laser perforated screens are used, with higher aperture accuracy (error<± 1 μ m), avoiding deformation problems of ordinary metal wire woven screens. By monitoring the blockage of the screen mesh in real-time and automatically adjusting vibration parameters (such as amplitude and frequency), the screening stability is maintained.

Data accuracy and repeatability: For the particle size distribution range of micro silica powder (typical particle size 0.1~1 μ m), extending the screening time and optimizing vibration parameters ensure a more scientific judgment of the screening endpoint (such as based on a mass change rate<0.1%). Supporting sample pretreatment methods (such as drying, dispersant addition) and calibration procedures to reduce human error.

Limitations improvement: The main defects of ordinary test sieves for micro silica powder (such as low screening efficiency and large result deviation) have been significantly alleviated in micro silica powder particle size analysis test sieve equipment:

Blockage issue: By using coated screen mesh and airflow assistance, the clogging rate of micro silica powder is reduced by more than 50%.

Ultra fine particle loss: The sealed design reduces dust and combines negative pressure adsorption to recover scattered particles, improving the accuracy of mass balance.

|

Mesh size |

Corresponding aperture |

recommended usage instructions |

|

400 mesh |

38 μ m |

ultra-fine silicon powder detection, boundary screening, non-standard application |

|

325 mesh |

45 μ m |

commonly used finest sieve, key control points, industrial conventional testing standards |

|

270 mesh |

53 μ m |

used for auxiliary judgment of particle size boundaries such as D10 and D25 |

|

200 mesh |

75 μ m |

coarse particle removal, determine if there are any impurities or agglomerated particles mixed in |

|

150 mesh |

106 μ m |

used to detect the presence of agglomeration, wet clumps |

|

100 mesh |

150 μ m |

initial sieve, usually used for pre screening or determining the content of crude impurities in raw materials |

|

80 mesh |

180 μ m |

Only used in coarser or unqualified batches of silicon powder, generally not commonly used |

Construction materials industry: Quality control of high-performance concrete Micro silica powder, as an active mineral admixture in high-performance concrete, can significantly improve compressive strength, impermeability, and durability. The particle size distribution directly affects its activity index, dispersibility, and filling effect. Conduct particle size analysis on micro silica powder raw materials in concrete admixture factories and commercial mixing station laboratories, screen suitable micro silica powder particles to optimize concrete mix proportions.

Refractory industry: Micro silicon powder is usually added as ultrafine filler and high-temperature binder to castables and plasticizers, which affects the compactness and thermal shock stability of molding. Using micro silicon powder particle size analysis test sieve to control the particle size range of micro silicon powder and avoid the influence of coarse particles on sintering performance; Ensure that the particle size distribution matches other aggregates, optimize sintering and construction performance.

Metallurgical industry: Suitable particle size ensures sufficient reaction and uniform distribution during the smelting process. Use a test sieve to ensure that the particle size of micro silica powder meets the requirements of the blowing equipment; Avoid uneven reaction caused by excessively coarse particle size; Monitor particle size changes to ensure stable quality in metallurgical processes.

New material development: Micro silicon powder is commonly used as a reinforcement/filler in the development of conductive coatings, sealants, ceramic based composite materials, and other new materials. The particle size has a significant impact on the surface energy, reactivity, and dispersibility of materials. Determine the particle size through experimental screening and evaluate its compatibility with other materials; Control particle size stability to ensure experimental reproducibility and product consistency.

Quality Inspection and Standardization Control Laboratory: Testing institutions at all levels and internal quality inspection departments of enterprises need to conduct routine testing on micro silica powder, and quickly detect particle size compliance through experimental screening; Conduct a comprehensive quality assessment in conjunction with other indicators such as specific surface area and ignition loss; Provide particle size analysis data for factory inspection, third-party certification, and customer inspection.

The core advantage of the micro silica powder particle size analysis test sieve lies in its targeted adaptation to the physical characteristics of ultrafine and highly adhesive particles. Through the optimization of materials, structures, and control technologies, it solves the problems encountered in micro silicon powder analysis and addresses the demand for "fine control" of micro silicon powder particle size in different industries.

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to screen vitamin powder. It screens materials through mechanical vibration and slapping...

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Stainless steel sieve shaker model features

Yeast powder is a commonly used pharmaceutical excipient, widely used in fermentation preparations, nutritional supplements or as a component of...

Apr 25, 2025

Micro silica powder particle size analysis test sieve

The micro silica powder particle size analysis test sieve is a laboratory equipment designed specific...

Apr 25, 2025

Mineral analysis multi-layer slap sieve

Mineral analysis multi-layer slap sieve is a sieveing equipment specifically used for mineral particl...

Apr 21, 2025

A laboratory or small batch screening equipment designed for fine, sticky or hygroscopic pharmaceutic...

Apr 17, 2025

Fines content tester is a device used to quickly and quantitatively analyze the fines powder content ...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap