Friday April-25 2025 17:08:07

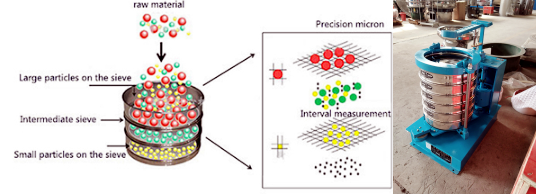

Mineral analysis multi-layer slap sieve is a sieveing equipment designed specifically for mineral particle size analysis, mainly used to determine the particle size distribution of mineral particles in laboratory or industrial environments. It separates mineral particles quickly according to different particle size ranges by stacking multiple layers of different mesh sieves and combining slap and vibration, providing data support for mineral composition analysis, processing technology optimization or quality control. It is widely used in geological exploration, mineral processing, building materials, metallurgy, chemical industry and other fields.

Mineral analysis multi-layer slap sieve achieves sieveing through the synergistic effect of slap motion and horizontal vibration:

① Periodic vertical slap of the top sieve cover creates an upward and downward slap force on the entire sieve assembly, preventing fine particles from being adsorbed onto the sieve due to static electricity or surface tension, ensuring smooth passage of particles through the sieve.

② The vibration motor or cam mechanism at the bottom of the sieve box drives the horizontal vibration of the sieve group, causing mineral particles to undergo lateral diffusion motion on the sieve surface, evenly distributed and in contact with the sieve mesh.

③ Multi layer sieve stacking: usually equipped with 2-10 layers of different mesh sizes (increasing mesh size from top to bottom and decreasing pore size). After pouring the sample from the top, coarse particles remain in the upper layer of the sieve, while fine particles pass through the sieve holes step by step. Finally, they are collected in layers according to particle size in each layer of the sieve and the bottom receiving tray.

Multi layer grading for higher efficiency: The design of multi-layer sieves enables the slap sieve to separate mineral samples into multiple particle size levels in one operation, greatly improving analysis efficiency. By using a set of mesh stacks with different mesh sizes, the slap sieve can provide more detailed and comprehensive particle size distribution data for mineral samples, which is crucial for subsequent analysis and research.

More suitable for specific mineral characteristics: The slap action of mineral analysis multi-layer slap sieve is more effective for irregularly shaped, bridging or adhesive mineral particles, which can overcome the clogging problem easily caused by these particles on ordinary vibrating sieves and improve sieveing efficiency.

Complex material handling capability: The slap sieve can handle dry, wet, viscous, and fine particle sized materials. In the beneficiation plant, the slap sieve can detect the particle size of the grinding product every 2 hours to guide the adjustment of ball mill parameters, while the ordinary test sieve is only suitable for small-scale laboratory analysis.

Outstanding fine-grained sieveing ability: When equipped with 20 μ m, 10 μ m, or even 5 μ m sieves, effective classification of ultrafine minerals (such as kaolin and bentonite) can be achieved by extending the slap time (such as 30 minutes), while ordinary test sieves are prone to "clogging" due to fine powder adhering to the sieve.

Mineral analysis can select a set of multi-layer sieve sieves from coarse to fine for classification according to specific needs. For example, a typical mineral analysis may use a stack of 20 mesh, 60 mesh, 100 mesh, and 200 mesh sieves to divide the sample into multiple particle size levels such as>850 μ m, 250-850 μ m, 150-250 μ m, 75-150 μ m, and<75 μ m.

|

Mesh size |

corresponding aperture (mm) |

applicable particle size range |

typical applications |

|

4 mesh |

4.75 mm |

coarse-grained ore, |

Gravel raw ore coarse sieve, weathered crust debris |

|

10 mesh |

2.00 mm |

medium coarse mineral particles |

geological sample initial sieveing, coarse particle control before flotation |

|

20 mesh |

0.85 mm |

medium grained ore |

ore grading before ball milling, sintering raw material sorting |

|

40 mesh |

0.425 mm |

medium fine mineral powder |

conventional particle size range for mineral processing experiments |

|

60 mesh |

0.25 mm |

fine mineral particles |

concentrate, mineral particle distribution in flotation |

|

80 mesh |

0.18 mm |

Fine samples |

Grading of kaolin and non-metallic powders |

|

100 mesh |

0.15 mm |

fine powder |

quartz powder, feldspar powder, pellet powder and other fine materials |

|

150 mesh |

0.106 mm |

ultrafine mineral powder |

flotation concentrate, fly ash materials |

|

200 mesh |

0.075 mm |

Ultra fine classification lower limit |

Fine mineral sample sieveing final layer, often used as a bottom sieve |

Mineral analysis using multi-layer slap sieves plays a crucial role in multiple fields and processes, providing important foundational information for mineral research, processing, and utilization through precise particle size classification.

Geological exploration and mineral resource assessment: Rock cores, ore vein outcrops, or crushed ore samples are graded through multiple layers of slap sieves (usually equipped with multi specification sieves ranging from 500 μ m to 20 μ m) to separate mineral particles of different sizes. Analyze the proportion of minerals in different particle sizes, determine the enrichment of useful minerals in different particle sizes, and assist in determining the direction of mineral processing technology.

Production process control of beneficiation plant: sieve the ore after coarse and medium crushing (such as sieve mesh size of 100 mesh and 200 mesh), detect the proportion of coarse particles, and avoid "coarse running" that may cause excessive grinding load in the subsequent process. The mineral analysis multi-layer slap sieve can simultaneously separate multiple particle sizes (such as -74 μ m, -45 μ m, -30 μ m), helping engineers accurately adjust the overflow concentration or sand return amount of the classifier.

Mineral Processing Laboratory and R&D: Multi layer sieveing (mesh size can be as fine as 325 mesh or 500 mesh) is performed on small batch samples (such as 500g ore samples) to study the effect of particle size on flotation recovery rate. By controlling the mineral particle size distribution and comparing the effects of different particle sizes of agents (such as collectors and inhibitors), optimize the formulation of the agents.

Deep processing of building materials and non-metallic minerals: In industries such as cement, ceramics, glass, and refractory materials, particle size control is applied to mineral raw materials such as quartz sand, limestone, dolomite, and fly ash to ensure product performance. sieve the finished product of cement clinker after grinding (sieve aperture 30 μ m, 45 μ m), detect the content of coarse particles (>80 μ m), and avoid affecting the early strength of cement.

1. Clearly define the analysis purpose and target granularity range.

2. Determine the required number of mesh layers

Single particle size separation: If you only need to separate minerals of a specific particle size, choose a single-layer or double-layer slap sieve.

Particle size distribution analysis: To obtain complete particle size distribution data, you need to use a multi-layer slap sieve, usually 3-7 layers or even more, with the mesh size gradually decreasing from top to bottom.

3. Select the appropriate mesh size based on particle size range and standards.

The difference in mesh size between adjacent layers of sieve should not be too large, and the mesh size of the topmost layer of sieve should be slightly smaller than the maximum particles that may appear in the sample to protect the finer sieve in the lower layer. The bottom layer usually places a chassis to collect the finest particles.

4. Select the appropriate mesh material (usually stainless steel) based on mineral characteristics.

5. Select the appropriate slap sieve model based on sample size and experimental requirements (sieve frame diameter, slap method, vibration frequency, timing function, etc.).

6. Considering budget: The prices of different brands and models of slap sieves vary greatly. Choose instruments with appropriate performance and configuration based on your budget.

I hope these suggestions can help you choose the appropriate mineral analysis multi-layer slap sieve! If you can provide more detailed mineral types and analysis requirements, I can give more specific suggestions.

Mineral analysis multi-layer slap sieve is an important tool for mineral analysis and laboratory grading. The principle of combining vibration and slap can effectively separate mineral samples, providing a foundation for subsequent analysis and research. Choosing the appropriate mesh size is the key to obtaining accurate grading results, which needs to be determined based on the specific analysis purpose and sample characteristics.

Phosphate Test Sieve is an experimental tool used to screen different particle sizes in phosphate samples and detect the phosphate...

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to screen vitamin powder. It screens materials through mechanical vibration and slapping...

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Apr 25, 2025

Mineral analysis multi-layer slap sieve

Mineral analysis multi-layer slap sieve is a sieveing equipment specifically used for mineral particl...

Apr 25, 2025

Micro silica powder particle size analysis test sieve

The micro silica powder particle size analysis test sieve is a laboratory equipment designed specific...

Apr 21, 2025

A laboratory or small batch screening equipment designed for fine, sticky or hygroscopic pharmaceutic...

Apr 17, 2025

Fines content tester is a device used to quickly and quantitatively analyze the fines powder content ...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap