Thursday June-19 2025 17:47:54

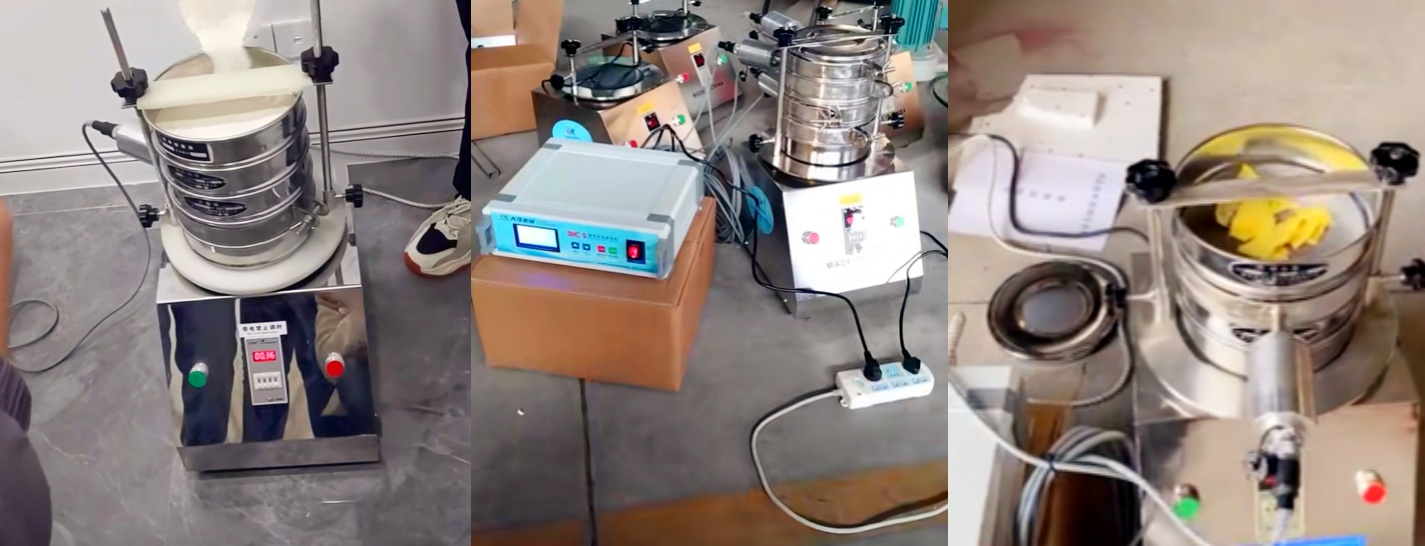

Negative electrode material ultrasonic test sieve is a high-precision sieving equipment designed for negative electrode materials of lithium batteries. It is widely used in the particle size detection of fine powders such as graphite, silicon-carbon, and carbon nanomaterials. Because these materials have fine particle sizes, are easy to agglomerate, and carry static electricity, they are prone to clogging and inaccurate classification in traditional mechanical vibrating sieves.

Ultrasonic test sieve is based on ordinary electric sieve, and high-frequency ultrasonic system is added. By superimposing high-frequency micro-vibration of about 20kHz on the sieve, it effectively breaks the electrostatic adsorption and agglomeration between materials. It is suitable for particle size classification with mesh size up to 500 mesh (25μm) or even finer.

|

Project |

Ultrasonic test sieve |

Ultrasonic vibration sieve |

|

Image |

|

|

|

Structural features |

Mostly integrated small structure, with supporting test sieve frame |

Large structure, using standard sieve machine structure with ultrasonic device |

|

Used sieve frame |

Standard test sieve frame (generally Φ200mm/Φ300mm) |

Customized sieve frame, the sieve surface diameter is generally 400mm and above |

|

Precision requirements |

Extremely high, suitable for particle size analysis |

High precision, but taking into account output and continuity |

|

Screen mesh support |

Support up to 500 mesh and above |

Support high Precision sieve, but more suitable for 100-325 mesh common screening |

|

Application scenarios |

Laboratory analysis, research and development, small sample testing |

Fine screening in industrial production processes |

Ultrasonic test sieves are suitable for screening of negative electrode materials with various characteristics due to their efficient screening performance and anti-blocking net function, including fine powder and ultrafine powder materials below 10μm, such as nano-silicon powder, graphene-modified negative electrode materials; surface-modified graphite powder (coated with asphalt or carbon layer) and other easy-to-agglomerate, sticky materials, as well as high-density, high-hardness materials such as tin powder and aluminum powder.

Highly corrosive materials: such as negative electrode precursors containing strong acids/strong alkalis (which may corrode the sieve material).

Inflammable and explosive materials: Pure metal powders (such as lithium powder) may generate static electricity due to friction under ultrasonic vibration, which poses a safety hazard and needs to be used with explosion-proof devices.

Large-particle block materials: Materials with a particle size exceeding the upper limit of the sieve mesh (such as greater than 300μm) are recommended to be pre-treated by coarse screening first.

The ultrasonic test sieve can effectively overcome the limitations of traditional screening methods by introducing high-frequency, low-amplitude ultrasonic vibrations, and is particularly suitable for the screening of negative electrode materials. Ultrasonic vibrations produce high-frequency micro-vibrations on the screen, which can destroy the adhesion, agglomeration, friction between powder particles and eliminate electrostatic effects, so that particles blocked in the screen holes are "bounced", thereby effectively preventing the screen from being blocked.

① High-precision screening: It can effectively control the screening particle size range and achieve high-precision screening, and the screening accuracy can be increased by 10%-70%.

② High pass rate: It can make the material pass through the screen holes faster, improve the penetration efficiency of the screen, increase the screening rate by 50%-400%, and increase the output by 0.5-10 times.

③ Anti-blocking net function: The thorough self-cleaning function of the screen, through high-frequency ultrasonic vibration, keeps the material on the surface of the screen in a suspended state at all times to prevent the material from blocking the mesh holes. Screening greater than 500 mesh can also achieve no mesh blockage and no screening efficiency attenuation.

|

Mesh number (mesh) |

corresponding particle size (μm) |

screening accuracy level |

|

10~50 |

1700~300 |

coarse screen |

|

50~200 |

300~75 |

medium screen |

|

200~400 |

75~38 |

fine screen |

|

400~635 |

38~20 |

ultrafine screen |

The ultrasonic test sieve of negative electrode materials is mainly used for particle size analysis and fine screening of negative electrode materials of lithium batteries (such as artificial graphite, natural graphite, silicon-carbon composite materials, silicon-based materials, etc.). In the laboratory, it solves the screening problems of easy agglomeration, strong adsorption and high static electricity of negative electrode materials through high-frequency ultrasonic vibration (36,000 times per second), ensuring that the screening accuracy of 80-600 mesh ultrafine powder reaches more than 99.5%.

Production of negative electrode materials for lithium batteries: In the production process of negative electrode materials such as graphite powder and silicon-based materials, it is used to screen powders of different particle sizes to ensure the performance of negative electrode materials and the energy storage effect of batteries.

Experiments in scientific research institutions: When scientific research institutions conduct research and development and testing of negative electrode materials, it can be used to accurately screen negative electrode material samples of different particle sizes to provide high-quality test materials for research.

In short, the ultrasonic test sieve is a device used for particle size analysis of powder materials. It uses ultrasonic vibration to improve screening efficiency and accuracy. It is an indispensable precision screening equipment in the production and development of negative electrode materials for lithium batteries. It effectively solves the problem of fine powder screening and is of great significance to improving the quality of negative electrode materials and battery performance.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Soil sieve size is a key parameter in soil particle analysis and is used to classify soil texture or engineering purposes. There are multiple standards for the hole size of soil...

Jun 19, 2025

Negative electrode material ultrasonic test sieve

The negative electrode material ultrasonic test sieve is a laboratory sieving equipment used for high...

Jun 18, 2025

Soil sieve size is a key parameter for soil particle analysis, for soil classification or engineering...

Jun 12, 2025

Test sieve sugar powder size detection

Test sieve sugar powder size detection is a physical detection method that uses multiple layers of st...

Jun 10, 2025

Chemical Material Standard Laboratory Vibrating Sifter

Chemical Material Standard Laboratory Vibrating Sifter is a precision equipment used for particle siz...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap