Wednesday July-30 2025 16:40:53

The primary function of a Perforated plate soil sieve is to analyze and separate various types of granular materials. Using precisely controlled pore sizes, a mixed sample is separated into different particle size fractions. The core of this sieve lies in its sieve plate, stamped from a solid sheet metal (usually stainless steel). The pores come in a variety of shapes, including round, square, and slotted. These wide-ranging pore sizes effectively process particles ranging from millimeters to hundreds of millimeters. Compared to woven mesh sieves, perforated plate sieves are known for their superior structural strength and durability, maintaining a stable and consistent pore size under heavy loads and wear.

Perforated plate soil sieves are commonly used in soil analysis, primarily for screening larger, coarse, or abrasive soil particles. Compared to woven mesh sieves, perforated plate sieves offer greater strength and durability. Perforated plate soil sieves are classified primarily based on their pore shape, size, and sieve frame specifications.

Classification by Hole Shape

Round Hole Screens

Features: Holes are round, with diameters typically ranging from 1 mm to 125 mm.

Applications: Suitable for screening irregularly shaped particles or those that easily clog the mesh, such as grains, coffee beans, and certain building materials. They ensure more accurate particle size separation, as round holes provide more consistent particle size determination.

Square Hole Screens

Features: Holes are square, with diameters typically ranging from 4 mm to 125 mm.

Applications: Suitable for screening most common materials, such as soil, aggregate, and sand and gravel. Square hole screens typically offer a larger open area for the same hole diameter, potentially leading to higher screening efficiency.

Slotted/Oblong Hole Screens

Features: Holes are elongated or oblong.

Applications: Primarily used for sorting particles of specific shapes (such as grains and seeds). They can be screened based on length or width, for example, to separate long impurities.

Perforated Screens

Features: High strength and wear resistance, capable of withstanding heavy loads and abrasion, and resistant to deformation. Compared to woven mesh screens, perforated screens typically have a lower porosity (the ratio of hole area to total surface area). They are typically suitable for larger apertures, but smaller apertures can also be produced.

Applications: Widely used in architectural decoration (such as curtain walls and ceilings), acoustic panels, protective covers, equipment housings, filtration and separation (for screening coarse particles), food processing, and ventilation systems.

Woven Mesh Screens

Features: Compared to perforated screens, woven mesh screens are generally more flexible at the same wire diameter, but may be slightly weaker overall, and fine mesh may be more susceptible to wear and deformation.

Applications: Widely used in precision filtration (liquid and gas filtration), particle sizing, laboratory screening, safety nets, insect repellent nets, petroleum, chemical, mining, and other industries requiring high filtration accuracy.

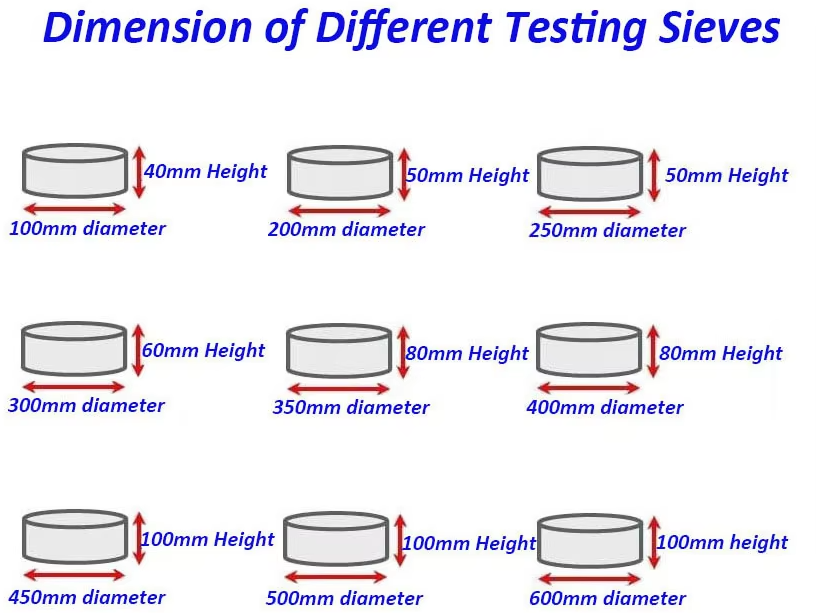

Classification by Screen Frame Size and Height

Diameter: Common screen frame diameters include 200 mm, 300 mm, 400 mm, and 450 mm, as well as 8-inch and 12-inch sizes. Choosing the appropriate diameter depends on the volume of material to be screened and the screening equipment used.

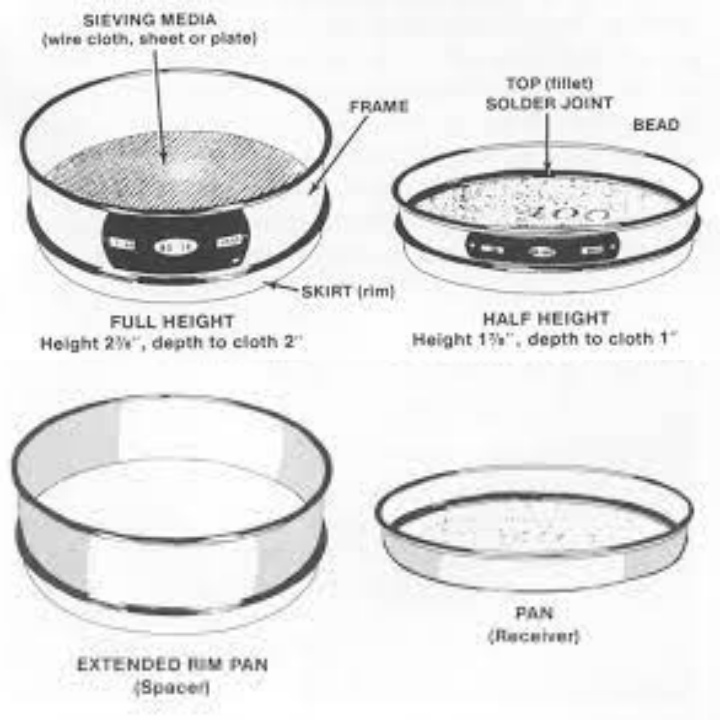

Full-height screens: Provide greater capacity and are suitable for screening larger samples.

Half-height screens: Save stacking space and are suitable for smaller sample volumes or when more screen layers are required for fine separation.

Classification by Material

Stainless steel

Features: Offers excellent corrosion resistance and high strength, is easy to clean, and meets laboratory standards. Widely used in soil, minerals, building materials, food, and other fields.

Grades: Commonly used are 304 or 316 (L) stainless steel.

Brass

Features: Lower cost, but less corrosion resistance than stainless steel and may wear over time.

Applications: Still used in some non-corrosive applications or where precision is less critical.

Coated steel

Features: Coated steel is applied to ordinary steel for increased corrosion resistance. Moderate cost.

|

Type |

Screening Mesh |

Applicable Materials |

|

Round Hole Screens |

1mm to 125mm |

Grains, seeds, nuts |

|

Square Hole Screens |

4mm to125mm |

Ore, coal, sand, gravel |

|

Perforated Screens |

0.2mm to100mm |

Soil particles, gravel, sand |

|

Woven Mesh Screens |

0.038mm to 25.4 mm |

Chemical granules, powders |

| No. | Type | Mesh(mm) | No. | Type | Mesh(mm) |

| 1 | 8# | 2.360 | 15 | 70# | 0.212 |

| 2 | 10# | 2.000 | 16 | 80# | 0.180 |

| 3 | 12# | 1.700 | 17 | 100# | 0.150 |

| 4 | 14# | 1.400 | 18 | 120# | 0.125 |

| 5 | 16# | 1.180 | 19 | 140# | 0.106 |

| 6 | 18# | 1.000 | 20 | 170# | 0.09 |

| 7 | 20# | 0.850 | 21 | 200# | 0.075 |

| 8 | 25# | 0.710 | 22 | 230# | 0.063 |

| 9 | 30# | 0.600 | 23 | 270# | 0.053 |

| 10 | 35# | 0.500 | 24 | 325# | 0.045 |

| 11 | 40# | 0.425 | 25 | 400# | 0.038 |

| 12 | 45# | 0.355 | 26 | 500# | 0.028 |

| 13 | 50# | 0.300 | 27 | >500# | <0.028 |

| 14 | 60# | 0.250 |

The structure of a perforated plate soil sieve is relatively simple, yet its sophisticated design ensures accurate and durable screening. It primarily consists of a sieve frame and a perforated sieve plate. The main structural components of a perforated plate soil sieve are as follows:

Sieve Frame

The sieve frame is the external support structure of the sieve, securing the sieve plate and facilitating operation.

Material: Stainless steel, such as 304 or 316, is a common and recommended material. Stainless steel offers excellent corrosion and wear resistance, is easy to clean, and complies with laboratory standards, ensuring the long life of the sieve and preventing sample contamination. A few sieve frames are made of brass or plated steel, but these are not as durable or sanitary as stainless steel.

Size: Sieve frames are typically available in a variety of standard diameters, such as 200mm, 300mm, and 400mm, as well as 8-inch and 12-inch sizes, to accommodate different screening equipment and sample sizes.

Height: Sieve frames are available in either full-height or half-height configurations. Full-height sieves have a higher capacity and are suitable for larger samples; half-height sieves save stacking space and are suitable for smaller samples or when more sieve layers are needed for finer separation.

Connection Method: The top of the sieve frame is typically designed with a groove that fits snugly into the upper sieve or sieve cover, while the bottom has a flange that fits into the groove of the next sieve, ensuring a secure and leak-proof stack of sieves and preventing sample leakage.

Perforated Sieve Plate

The perforated sieve plate is the core functional component of the sieve and directly determines the particle size that can be screened.

Material: Made of the same material as the sieve frame, typically stainless steel, this ensures the same excellent performance in contact with the product.

Hole Type: Round Hole: The most common hole type, a series of regularly arranged circular holes are formed in a metal plate through a precision stamping process. Hole sizes are generally larger, ranging from 1mm to 125mm. Round hole sieves provide more consistent screening results when screening irregular or angular particles.

Square Hole: Square holes are also punched to form square holes. Hole sizes typically range from 4mm to 125mm. Square-hole sieves typically have a larger open area for the same aperture, potentially leading to higher screening efficiency.

Slotted/Oblong Holes: Special hole patterns used for screening particles with specific shapes, such as separating long, rectangular impurities.

Thickness: The thickness of the sieve plate depends on the aperture size and the overall strength requirements of the sieve. Generally, larger sieves require thicker sieve plates to increase durability.

Securing Method: The perforated sieve plate is securely fastened to the sieve frame by welding or snap-fitting. To prevent material buildup at the connection between the frame and the plate, high-quality sieves typically have smooth edges and interiors.

Perforated plate soil sieves offer significant advantages in soil and other particulate screening applications, particularly when handling coarse, abrasive, or uniformly shaped materials. These advantages include durability, ease of cleaning, and a wide range of applications. These advantages make them an indispensable tool in many fields. Superior Strength and Durability: Perforated plate screens are precision-stamped from solid metal plates (usually stainless steel), giving them greater mechanical strength and wear resistance than woven mesh screens. This means they can better withstand high vibration, heavy material impact, and prolonged use, making them particularly suitable for screening abrasive soil particles such as gravel, coarse sand, and crushed stone, without deforming or damaging.

Precise and Stable Aperture: The holes in perforated plate screens are formed through a precision stamping process, ensuring highly consistent size and shape. Unlike woven mesh, which can experience fluctuations in aperture due to wear and tear or uneven loads, the aperture of perforated plate screens maintains high stability and accuracy over time, ensuring reliable and repeatable screening results.

Resistant to Clogging, Improving Screening Efficiency: Because perforated plate screens typically have smoother edges and a more regular shape (particularly round or square holes), they are less likely to become lodged or clogged by particles. This is particularly important when screening soils containing sticky or irregularly shaped particles, significantly improving screening efficiency and reducing the need for manual cleaning. Easy to Clean and Maintain: Perforated plate screens typically have a smoother surface than woven mesh screens, lacking the cross-points and gaps of woven mesh, making them easier to clean. This helps prevent cross-contamination, and a simple rinse or wipe effectively removes residue.

Wide Application: Perforated plate screens can handle a wide range of particle sizes, from a few millimeters to hundreds of millimeters, making them suitable for screening a variety of coarse-grained soils, aggregates, ores, and other materials. A variety of hole shapes (round, square, and slotted) can be selected based on the characteristics of the material and the screening purpose, achieving more precise classification.

Perforated plate soil sieves, with their unique durability and sieving accuracy, play an important role in a variety of fields. A perforated plate soil sieve is an essential laboratory and field tool, with its core purpose being to analyze and separate soil and similar particulate matter. Using precisely controlled pore sizes, it separates samples into fractions of varying particle sizes, thereby helping us understand the physical properties of the material.

Particle size analysis

This is the primary use of a perforated plate soil sieve. Using a series of perforated plate sieves with varying pore sizes (typically stacked from large to small), a soil sample can be fractionated into multiple particle size intervals.

Understanding Soil Texture: Particle size analysis is fundamental to determining soil texture (e.g., sand, loam, clay). Understanding soil texture is crucial in agriculture (crop selection, irrigation management), civil engineering (foundation design, roadbed stability), and environmental science (pollutant transport, hydrological properties).

Assessing Material Quality: For construction materials (e.g., sand, gravel, aggregates), particle size distribution directly impacts their performance. Perforated plate sieves are used to inspect materials for compliance with engineering specifications, ensuring that their strength, density, and permeability meet required specifications.

Studying Particle Properties: In scientific research, precise particle size analysis provides insights into particle shape, specific surface area, and other properties, which influence a material's physical and chemical behavior.

Material Separation and Classification

In addition to particle size analysis, perforated plate soil sieves are also commonly used to isolate specific particle size components within a mixture or to grade materials for subsequent processing.

Coarse Particle Screening: Perforated plate sieves are particularly suitable for screening samples containing large or irregular particles, such as removing rocks, plant debris, or other impurities from soil for subsequent detailed analysis or processing.

Sample Pretreatment: Before conducting more detailed analyses (such as chemical analysis), perforated plate sieves may be required to remove coarse particles from a sample to ensure accuracy.

Quality Control: In certain production processes, perforated plate sieves can be used to quickly grade raw materials or semi-finished products to ensure consistent particle size, thereby achieving quality control.

The Perforated Plate Soil Sieve demonstrates numerous advantages in practical applications. First, its main structure is stamped from sheet metal, imparting remarkable strength and durability, enabling it to withstand rigorous operating conditions and resist abrasion from coarse materials. Second, through precision manufacturing, the perforated plate's hole size is highly precise and stable, ensuring consistent and reliable screening results—critical for various analyses requiring strict control of particle size distribution. Furthermore, compared to traditional woven mesh sieves, the perforated plate sieve's hole design is generally less prone to clogging, making it particularly useful when processing samples containing sticky or irregular particles, helping to maintain a smooth sieving process. These characteristics collectively form the foundation for the Perforated Plate Soil Sieve's practical application.

Jul 30, 2025

The primary function of a perforated plate soil sieve is to analyze and separate various types of gra...

Jul 25, 2025

Standard Test Sieve is a commonly used particle analysis tool in laboratories and industrial sites. I...

Jul 17, 2025

As a basic tool in geotechnical tests, the core function of geotechnical soil sieve is to analyze the...

Jul 16, 2025

Electromagnetic powder ultrasonic test sieve

Electromagnetic powder ultrasonic test sieve combines traditional mechanical vibration with high-freq...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap