![[field:title/]](/uploads/allimg/250319/2-250319155123C4-lp.png)

Pigments test sieve is an instrument used to determine the particle size distribution of pigments. It uses a series of sieves with different apertures to sieve the pigments sample into components of different particle sizes, thereby analyzing the particle size characteristics of the pigments.

Purpose: To evaluate the physical properties of pigments by sieving

Application: Widely used in research and development, quality inspection and production control.

Sieve frame material: stainless steel (304/316L), copper, nylon coating

Sieve type: metal woven mesh, electroformed mesh

Metal Powders Test Sieve is a screening tool used to determine the particle size distribution of metal powder. Its main function is to screen the metal powder through sieves of different apertures to determine its particle size distribution.

Pigments test sieve is a device used for screening and grading pigments particles. It is usually used in laboratories or small-scale production to test the screening and grading of pigments particles. The design and principle of this pigments test sieve are similar to large-scale screening equipment in industrial production, but on a smaller scale and for more experimental and research purposes.

① Particle size distribution: Determine the size range of pigments particles (such as <45μm accounts for 90%), which affects dispersibility, hiding power and color uniformity.

② Fineness detection: Determine the fineness of the pigments after grinding (such as the percentage passing through a 325 mesh sieve) to ensure that the application standard is met.

③ Impurity removal: Screen out oversized particles or foreign matter to avoid affecting the appearance and performance of the final product.

Pigments test sieve uses vibration force to make the sieve body and the screen vibrate, and the pigments particles are screened on the screen.

The pigments particles are divided into particles of different sizes according to the aperture size of the screen, thereby achieving the screening and grading of pigments particles.

|

Material type |

Common applications |

Remarks |

|

Inorganic pigments |

Red iron oxide, yellow iron oxide, titanium dioxide, carbon black, ultramarine, etc. |

Widely used in coatings, plastics, inks, ceramics and other industries |

|

Organic pigments |

Phthalocyanine blue, phthalocyanine green, azo pigments, quinacridone pigments, etc. |

Widely used in coatings, plastics, inks, textiles and other industries |

|

Metallic pigments |

Aluminum powder, copper powder, zinc powder, etc. |

Widely used in anti-corrosion coatings, metal coatings, printing inks and other industries |

|

Fluorescent pigments |

Phosphor, luminous powder, etc. |

Widely used in safety signs, Advertising, special coatings and other industries |

|

Pearlescent pigments |

mica titanium pearlescent pigments, glass pearlescent pigments, etc. |

widely used in automotive coatings, cosmetics, plastic products and other industries |

|

Dyes |

acid dyes, alkaline dyes, reactive dyes, etc. |

widely used in textiles, leather, paper and other industries |

|

Color fillers |

talcum powder, kaolin, calcium carbonate, barium sulfate, etc. |

widely used in coatings, plastics, rubber, papermaking and other industries |

|

Other powdered materials |

ceramic powder, metal powder, food powder, pharmaceutical powder, etc. |

suitable for various powdered materials that require particle size analysis |

1. Single-layer test sieve

Structural features: single-layer sieve, usually round or square, with a common diameter of 200mm or 300mm, equipped with a single mesh sieve (such as 325 mesh, pore size 45μm).

Function: used for single-target screening, such as detecting pigments fineness or removing oversized particles.

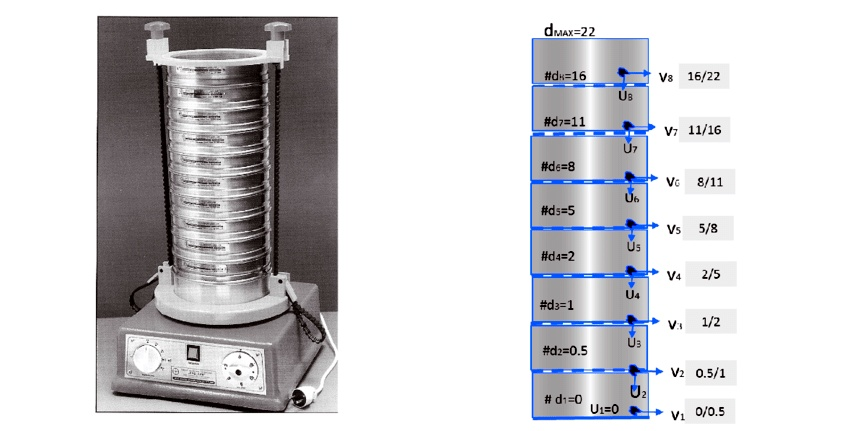

2. Multi-layer test sieve (double or triple layer)

Structural features: 2-3 layers of sieves are stacked, with decreasing mesh numbers (such as 100 mesh on the upper layer, 200 mesh on the middle layer, and 325 mesh on the lower layer), which can be driven by a screening machine (such as a vibrating screen or a swinging screen).

Function: Simultaneously achieve grading and impurity removal, and separate a variety of particle size ranges.

3. Wet screening test sieve

Structural features: single or multi-layer sieves, the sieve material is corrosion-resistant (such as stainless steel).

Function: Through water washing and screening, it can handle pigments that are easy to agglomerate or contain moisture.

|

Type |

Number of screen layers |

Screen surface size |

Screening capacity |

Common mesh |

Power |

|

Single-layer screen |

1 |

1m×2m |

1-15t/h |

100-400 mesh |

1.5-3kW |

|

Double-layer screen |

2 |

1.5m×2.5m |

2-20t/h |

50-325 mesh |

2.2-5kW |

|

Multi-layer screen |

3 |

2m×3m |

3-25t/h |

50-400 mesh |

3-7.5kW |

Pigments test sieve is usually composed of the sieve body (sieve frame), screen mesh, vibration mechanism, feed port and discharge port, support structure, base and other main parts. These parts together constitute the structure of pigments test sieve, and through collaborative work, the screening and grading of pigments particles can be achieved.

1. Handling small pigments particles that are easy to clog the screen

Pigments particle size is often <45μm (such as titanium dioxide), which is easy to embed into the sieve hole. Pigments test sieve is equipped with a bouncing ball to vibrate the screen to remove the blockage. When screening carbon black, the blockage rate can be reduced from 15% to 2%.

2. Easy to agglomerate and affect the screening accuracy

Pigments (such as ultramarine) agglomerate after absorbing moisture and are difficult to disperse. Wet screening is done by washing with water or pre-drying the material. For example, after wet screening of ultramarine pigments, the screening accuracy is increased to 98%.

3. The particle size distribution of pigments particles is complex

Pigments particle size range is wide (such as 1-100μm), and multi-stage separation is required. Pigments test sieve adopts a multi-layer screen design and one-time classification. For example, when screening and recovering pigments, the three-layer sieve divides the particles into three specifications to meet different uses.

4. Prevent dust from flying and polluting the environment

When dry screening pigments (such as iron oxide yellow), fine powder is easy to generate dust. Pigments test sieve adopts a fully enclosed design. When screening 1 ton of pigments, the dust collector controls the dust concentration below 0.3mg/m³.

Low mesh number (50-150 mesh): suitable for pigments with larger particle size (such as fluorescent pigments, metallic pigments), screening coarse particles or grading.

Medium mesh number (150-325 mesh): suitable for most pigments (such as iron oxide, ultramarine), balancing fineness and efficiency.

High mesh number (325-500 mesh): used for ultrafine pigments (such as carbon black, silica), testing fineness or removing dust.

|

Item |

Parameter/Specification |

Description |

|

Screen aperture |

20 microns-several millimeters |

Select according to the particle size of pigments particles |

|

Screen material |

stainless steel, brass, nylon, etc. |

corrosion-resistant, wear-resistant, adapted to pigments characteristics |

|

Screen frame size |

diameter 200 mm, 100 mm, etc. |

Select according to screening requirements |

|

Screen frame material |

stainless steel, brass, plastic, etc. |

corrosion-resistant, wear-resistant, adapted to pigments characteristics |

|

Bottom cover and top cover |

stainless steel, plastic, etc. |

prevent pigments particles from splashing and leaking |

|

Sealing ring |

rubber, silicone, etc. |

ensure that pigments particles do not leak during screening |

|

Number of screening layers |

1-5 layers |

multi-layer screens can be customized according to screening requirements |

|

Screening accuracy |

conform to international standards such as ISO and ASTM |

ensure the accuracy and repeatability of screening results |

|

Mesh number |

Aperture (micrometer) |

Applicable material particle size range (micrometer) |

|

20 mesh |

850 |

500-850 |

|

40 mesh |

425 |

250-425 |

|

60 mesh |

250 |

150-250 |

|

80 mesh |

180 |

100-180 |

|

100 mesh |

150 |

75-150 |

|

120 mesh |

125 |

60-125 |

|

140 mesh |

106 |

50-106 |

|

170 mesh |

90 |

45-90 |

|

200 mesh |

75 |

38-75 |

|

230 mesh |

63 |

32-63 |

|

270 mesh |

53 |

25-53 |

|

325 mesh |

45 |

20-45 |

|

400 mesh |

38 |

15-38 |

|

500 mesh |

25 |

10-25 |

|

635 mesh |

20 |

5-20 |

The application scenarios of pigments test sieve in the pigments industry are very wide, covering multiple links such as particle size analysis, quality control, application research, production process improvement, and R&D experiments. Its high-precision screening and other characteristics can effectively solve the problems faced by pigments particles in the production and application process, and it is an indispensable key equipment in the pigments industry.

1. When selecting a pigments test sieve, it is necessary to select a suitable mesh aperture and screening method according to the particle size range, properties and test requirements of the material.

2. For materials that are easy to agglomerate, sticky or have strong static electricity, it may be necessary to use ultrasonic test sieves or add antistatic agents and other auxiliary measures.

3. Before screening, pigments should be pretreated, such as drying and crushing, to ensure the accuracy of the screening results.

4. After screening, sieve should be thoroughly cleaned to prevent cross-contamination of samples.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control, and is widely used in food, chemical, pharmaceutical and o...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy...

Ultrasonic test sieve for wheat flour

Ultrasonic test sieve for wheat flour is a special device that combines ultrasonic technology with traditional screening principles to efficiently screen wheat flour. The device can...

Laboratory Lactose Stainless Steel Test Sieve

Laboratory lactose stainless steel test sieve is a device used to accurately determine the size distribution of lactose particles. It is often used for laboratory particle analysis ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap