![[field:title/]](/uploads/allimg/250310/2-250310144452J4-lp.png)

Plastic pellets test sieve is a device used to detect the quality of plastic particles. It separates plastic particles of different sizes, shapes or containing impurities by screening, thereby ensuring the quality of plastic raw materials.

Number of layers: 1-8 layers

Screening particle size: 0.025mm-20mm

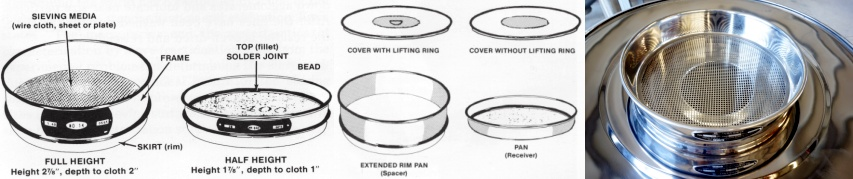

Structural composition: screen frame, screen, vibration motor, ultrasonic system (optional), control system, base and bracket.

Application: Plastic pellets test sieve is widely used in plastic production, processing and recycling.

Port:Any port in China (Mainland)or as you need.

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

Plastic pellets test sieve is essentially a tool used to determine whether the size of plastic particles meets the requirements. It can perform fine particle size analysis on plastic particle samples of various shapes and relatively low density. Its purpose is to accurately determine the size distribution of plastic particles, identify and separate unqualified products, fine powder and impurities.

Through standardized sieve mesh and efficient structural design, it ensures the accuracy, repeatability and ease of operation of the screening process, and provides key data for quality control of plastic raw materials, process optimization and product performance evaluation.

Plastic pellets test sieves have a wide range of uses and are essential for quality control and process optimization in the plastics industry. Recycling, increased production efficiency and compliance with industry standards are the main reasons for their use.

Quality control

Particle size control: Plastic pellets test sieve ensure that the particle size distribution of plastic particles is within the required range, which is crucial for subsequent processing (such as injection molding, extrusion). Uneven particle size will lead to unstable product quality.

Impurity removal: Plastic pellets test sieve remove impurities in plastic particles, such as metal chips, dust, foreign matter, etc.

Shape detection: Plastic pellets test sieve can detect whether the shape of particles is regular, and remove unqualified particles such as deformation and damage.

Improved production efficiency: Plastic pellets test sieves are automatically screened to reduce the workload of manual inspection, timely screen out unqualified particles, and reduce the generation of waste caused by raw material problems.

Recycling: Plastic pellets test sieves sort recycled plastics, separate different types of plastics, remove impurities in recycled plastics, and improve the quality of recycled plastics.

Meet industry standards: Plastic pellets test sieve ensure that the quality of plastic raw materials and products meets relevant industry standards and customer requirements.

The working process of plastic pellets test sieve is as follows:

Feeding: Plastic particles enter the screen from the feed port.

Vibration: The vibration motor provides power to vibrate the screen surface, prompting the plastic particles to move along the surface of the screen.

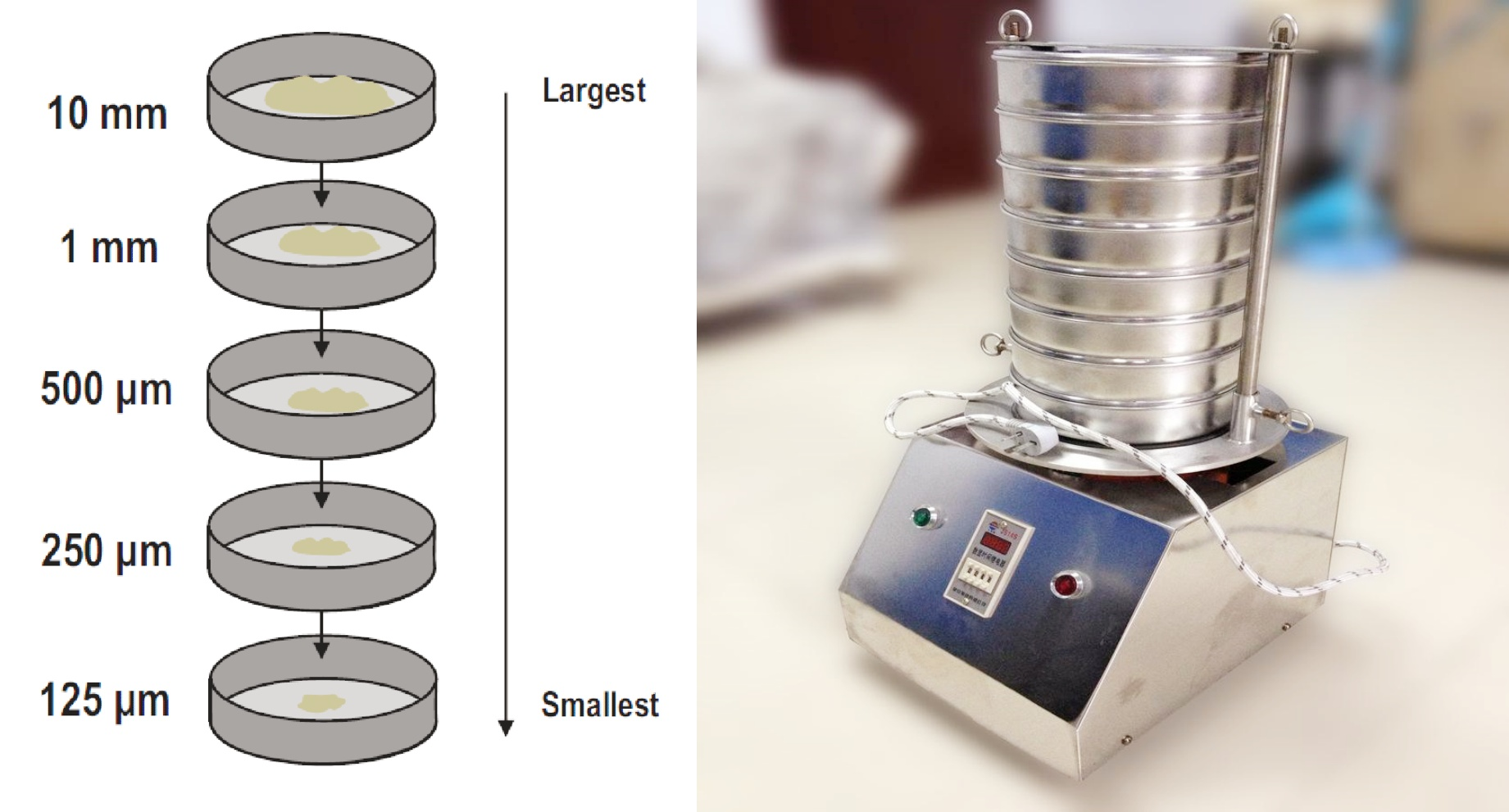

Screening: According to the size of the plastic particles and the aperture of the screen, larger plastic particles are blocked on the screen, while smaller plastic particles pass through the holes of the screen.

Grading: Plastic particles of different particle sizes are divided into different levels, collected in different screening areas, and finally output through the discharge port.

Plastic pellets test sieves can be divided into many types according to the screening method, detection technology and sieve structure. These types are specially designed for particle size analysis, classification or quality control of plastic granules.

Classification by screening method: sonic detection screen, magnetic suspension detection screen, standard detection screen, ultrasonic detection screen

| Sonic detection screen |

|

using sonic vibration for screening, suitable for screening of fine particles | high-precision screening occasions |

| Magnetic suspension detection screen |

|

using magnetic suspension technology to reduce mechanical friction and improve screening efficiency | high-precision and high-efficiency screening |

| Standard detection screen |

|

traditional mechanical vibration screen, simple structure, easy operation | conventional particle size classification and quality control |

| Ultrasonic detection screen |

|

using ultrasonic vibration to prevent sieve hole clogging and improve screening accuracy | high-precision, easy-to-clog screening occasions |

Classification by detection technology:

Optical detection screen: Optical detection screen uses optical imaging technology to detect the size, shape, color, etc. of plastic particles, which is suitable for high-precision and automated detection.

X-ray detection screen: X-ray detection screen uses X-ray technology to detect impurities inside plastic particles, such as metals, foreign matter, etc.

Applicable to high-demand impurity detection.

Classification according to screen structure: woven mesh screen, perforated plate screen, electroformed screen

| Screen structure | Picture | Features | Application scenarios | Picture |

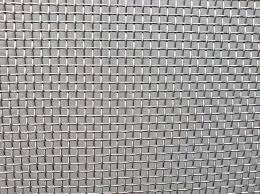

| Woven mesh screen |

|

The screen is woven by metal wire, with uniform aperture | Conventional particle size screening |

|

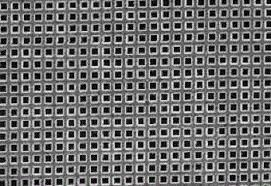

| Punching plate screen |

|

The screen is punched by metal plate, with high strength and durability | Large particle screening and high-strength occasions |

|

| Electroformed screen |

|

The screen is made by electroforming process, with high precision and consistent aperture | High-precision screening and small particle screening |

|

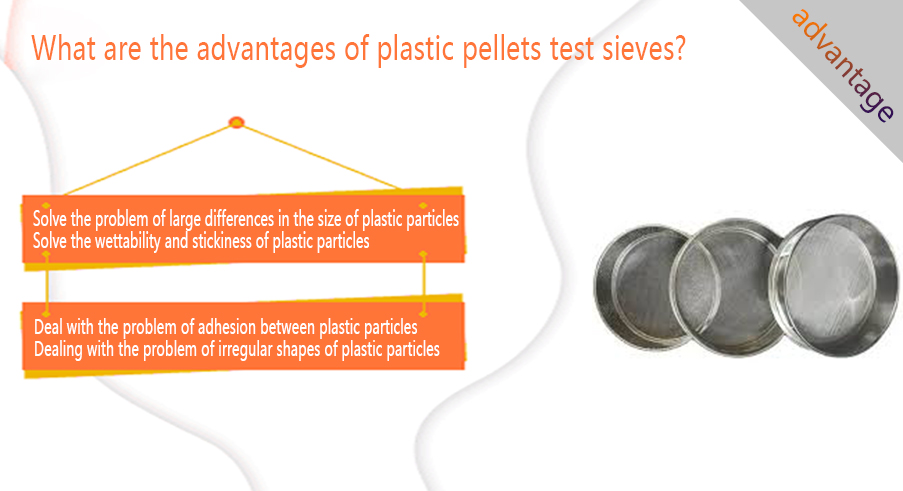

Plastic pellets test sieve is specially designed for screening plastic granules or similar materials. It has many advantages due to its material properties and design. Compared with other test sieves, it can solve the problems of plastic granules becoming sticky when wet, irregular shapes, large particle size differences, and static electricity on the surface of plastic granules.

Solve the problem of large differences in the size of plastic particles: large particles and small particles may be mixed during the screening process. Plastic pellets test sieve gradually screens the particles through multiple layers of screens. Different levels of screens can handle particles of different sizes to achieve finer classification.

Solve the wettability and stickiness of plastic particles: plastic particles may become sticky when wet, causing adhesion between particles, increasing screen resistance and reducing screening efficiency. Plastic pellets test sieve can increase the vibration frequency and amplitude of the screening equipment, allowing particles with strong stickiness to separate from the screen surface.

Deal with the problem of adhesion between plastic particles: Since the surface of plastic particles is prone to static electricity, the particles may adhere to each other. During the screening process, by installing an anti-static device on plastic pellets test sieve, the static charge of the particles is reduced to prevent the particles from sticking together.

Dealing with the problem of irregular shapes of plastic particles: The shapes of plastic particles are often irregular, which may be spherical, long strips or fragments. The vibration of plastic pellets test sieve is used to ensure that the irregularly shaped particles are fully in contact with the screen surface and pass through the screen pores.

| Model | Screen diameter | Number of screening layers | Motor power | Processing capacity | Applicable materials |

| DH-400 | 400mm | 1-3layers | 0.25-0.55kW | 100-300kg/h | Small batch, fine particle screening |

| DH-800 | 800mm | 1-4layers | 0.75-1.1kW | 300-600kg/h | Medium batch, conventional particle screening |

| DH-1200 | 1200mm | 1-5layers | 1.5-2.2kW | 600-1000kg/h | Large batch, multiple particle size screening |

| Number | mesh (mm) | Number | mesh (mm) | Number | mesh (mm) | Number | mesh (mm) |

| 2 | 13 | 26 | 0.71 | 90 | 0.16 | 260 | 0.06 |

| 3 | 6.5 | 28 | 0.63 | 100 | 0.154 | 280 | 0.055 |

| 4 | 5 | 30 | 0.6 | 110 | 0.14 | 300 | 0.054 |

| 5 | 4 | 32 | 0.55 | 115 | 0.13 | 320 | 0.048 |

| 6 | 3 .2 | 36 | 0.5 | 120 | 0.125 | 325 | 0.045 |

| 7 | 2.8 | 40 | 0.45 | 130 | 0.111 | 350 | 0.041 |

| 8 | 2.5 | 45 | 0.4 | 140 | 0.105 | 360 | 0.4 |

| 9 | 2.2 | 50 | 0.355 | 150 | 0.1 | 400 | 0.0385 |

| 10 | 2 | 55 | 0.315 | 160 | 0.098 | 500 | 0.03 |

| 12 | 1.6 | 60 | 0.3 | 180 | 0.09 | ||

| 14 | 1.43 | 65 | 0.25 | 190 | 0.08 | ||

| 16 | 1.25 | 70 | 0.22 | 200 | 0.075 | ||

| 18 | 1 | 75 | 0.2 | 220 | 0.07 | ||

| 20 | 0.9 | 80 | 0.18 | 240 | 0.065 | ||

| 24 | 0.8 | 85 | 0.17 | 250 | 0.063 |

The application of plastic pellets test sieve covers multiple links such as plastic production, recycling, quality control, process optimization and research and development. Through screening, the uniformity of particles can be ensured, impurities can be removed, product quality can be improved, and production efficiency can be optimized. Its application is not limited to the plastic industry, but also extends to chemical, food, medicine and other fields. It is an indispensable equipment in modern industrial production.

The recommended mesh size for test plastic pellets depends largely on the size range of the plastic pellets being tested (e.g., fines, oversized pellets, or overall size distribution).

Coarse particle screening: You can choose a sieve with a lower mesh number, such as 20 mesh or 40 mesh, which is suitable for coarse particle plastic or impurity removal.

Medium particle screening: You can choose a sieve with a medium mesh number, such as 60 mesh or 80 mesh, which is suitable for conventional plastic particle classification.

Fine particle screening: You can choose a sieve with a high mesh number, such as 120 mesh or higher, which is suitable for fine or ultra-fine particle screening, such as high-precision quality control.

The price of plastic pellets test sieve depends on many factors, including brand, model, etc. The price will also be affected by market supply and demand, material price fluctuations and other factors. It should be noted that when purchasing a plastic particle detection sieve, it is recommended to choose a suitable model according to your own needs and budget, or you can communicate directly with Dahan suppliers to obtain the most accurate quotation.

Dahan Machinery is a professional screening equipment manufacturer. Its plastic particle detection sieve is known for its high efficiency, precision and durability, and is suitable for a variety of screening needs in the plastics industry. If you have related needs, you can directly contact customer service through the bottom right or email to get more information or customized solutions.

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

Vitamin powder slapping screen is a device used to screen vitamin powder. It screens materials through mechanical vibration and slapping action. It is particularly suitable for...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos, compost, organic fertilizer...

A laboratory or small batch screening equipment designed for fine, sticky or hygroscopic pharmaceutical excipients such as yeast powder. It achieves particle size classification, im...

Fines content tester is a device used to quickly and quantitatively analyze the fines powder content in materials. Fines powder usually refers to the part with a particle size small...

Nylon sieve shaker mesh is a mesh filter material woven from nylon material (usually nylon 6, nylon 66, nylon or polyester), which has the characteristics of high strength, wear res...

Stainless steel frame and woven cloth

The stainless steel frame provides a sturdy support structure, while the precision-woven stainless steel cloth ensures accurate particle size separation, making the test sieve an in...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap