![[field:title/]](/uploads/250422/1-2504221F054952.jpg)

Polyester Sieve Shaker is a device that uses a screen made of polyester material and combines the vibration principle to screen materials.

$650.00 - $1,200.00/ Sets

1. Excellent chemical corrosion resistance: Polyester materials can resist corrosion from a variety of chemicals, which enables polyester test sieves to safely handle a variety of corrosive materials.

2. Accurate screening accuracy: The mesh is uniform and accurate, which can achieve accurate screening of materials and meet the needs of high-precision particle size analysis.

3. Good wear resistance and elasticity: Polyester fiber has high strength and wear resistance, can withstand the friction and impact of materials, and extend the service life of the screen.

Port:Any port in China (Mainland)or as you need.

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

Polyester sieve shaker is a kind of equipment specially used to measure particle size distribution, determine the impurity content or solid content in liquid, and is widely used in scientific laboratories and quality inspection departments. The mesh size of polyester sieve shaker is strictly regulated, with diameters of 200mm and 300mm. 75mm can be provided for special requirements. The mesh number of the screen frame ranges from 8 mesh to 500 mesh. The larger the mesh number, the smaller the aperture.

Polyester sieve shaker is a mechanical device that uses vibration as a power source and polyester (usually refers to a screen woven from polyester fibers) as the main screening medium. Its core function is to classify, remove impurities, and filter granular or powdery materials according to the characteristics of the material through a polyester screen with a specific mesh number and size. 20-60 mesh is suitable for coarse screening of large-particle polyester (such as chips), 80 to 200 mesh is used for fine classification or impurity removal of polyester powder, and 300 mesh or above is used for screening of ultra-fine polyester powder (such as nano-grade).

Polyester sieve shaker is a laboratory or industrial instrument that uses a vibrating or shaking motion to separate particles of different sizes through a series of sieves with polyester mesh. The polyester mesh acts as a filter medium, allowing smaller particles to pass through while retaining larger particles. The equipment can be used for particle size classification, impurity removal, quality control, and improving production efficiency.

Particle size classification: separate polyester particles according to different particle sizes to ensure uniform products. In the chemical, plastic and textile industries, polyester sieve shakers are used to grade polyester particles to meet different production needs.

Remove impurities: separate foreign matter or agglomerates from polyester particles to improve purity. In the polyester production process, polyester sieve shakers are used to remove impurities from raw materials to ensure product quality.

Quality control: ensure that polyester particles meet particle size standards to meet the needs of different uses. In laboratories and quality control departments, polyester sieve shakers are used to detect and ensure that the particle size of polyester particles meets standards.

Improve production efficiency: quickly separate polyester particles of different particle sizes to improve production efficiency. In the production line, polyester sieve shakers are used for automated screening, reducing manual operations and improving production efficiency.

Polyester sieve shakers can be classified into different types according to different standards. The following classification is based on four sections: material, mesh shape, number of mesh layers, structure and function.

Classification by material

Polyester sieve shakers can be divided into metal mesh screens, synthetic fiber mesh screens and polymer mesh screens according to their materials.

Metal mesh screen

Made of metal materials such as stainless steel, it has good corrosion resistance and wear resistance.

Suitable for general polyester material screening.

Synthetic fiber screen

Made of synthetic fiber materials such as polyester or nylon, it has better elasticity and wear resistance than metal mesh screen.

Suitable for high-precision screening, especially for screening of fiber materials such as polyester.

Polymer screen

Made of plastic material, it can be used to handle high humidity and corrosive substances.

Suitable for polyester materials that require corrosion-resistant screening.

Classification by mesh shape

Polyester sieve shakers can be classified into round holes and square holes according to the shape of the screen mesh. These two different mesh designs enable polyester vibrating screens to adapt to different material properties and screening requirements.

| Type | square hole screen | round hole screen |

| Picture |

|

|

| Purpose | In the screening of polyester materials, it can be used for preliminary screening or removal of large impurities | Suitable for screening of polyester powder or fine particles |

| Applicable scenarios | large mesh, suitable for screening of coarse particles | regular mesh shape, suitable for screening of fine-grained materials |

Classification by the number of mesh layers

According to the number of mesh layers, polyester vibrating screens can be mainly divided into single-layer polyester vibrating screens and multi-layer polyester sieve shakers. This classification by the number of mesh layers directly determines the grading effect and processing capacity that the equipment can achieve.

Single-layer polyester sieve shaker:

Only one layer of polyester mesh, simple structure and low cost.

It is suitable for scenarios where the screening accuracy is not high and the materials only need to be simply divided into two levels: the oversize and undersize.

For example, small food processing plants simply screen the raw materials to remove obvious impurities; some chemical raw materials with no strict particle size requirements are screened initially, such as simple screening of industrial salt.

Multi-layer polyester sieve shaker:

Equipped with multiple layers of polyester screens with different mesh sizes, the materials can be screened into multiple particle size grades at one time

The screening efficiency is high, which can meet the production needs with high requirements for material particle size classification, and the mesh combination of the screen can be flexibly adjusted according to actual production needs.

It is commonly used in the fine classification of Chinese medicine powder and Western medicine raw materials in the pharmaceutical industry to ensure that the particle size of pharmaceutical raw materials meets strict standards; in the food industry, the precise classification of granular foods such as candies and nuts meets different packaging and sales requirements; in the chemical industry, the high-precision classification of high-performance plastic particles and special powdered raw materials ensures product quality.

Classification by structure and function

According to the structure and function, polyester sieve shaker can be divided into standard sieve shaker, polyester mesh sieve shaker and ultrasonic sieve shaker. In practical applications, the appropriate screening equipment may be selected based on a variety of factors such as material characteristics, screening accuracy requirements, and application scenarios.

| Type | Standard sieve shaker | Polyester mesh sieve shaker | Ultrasonic sieve shaker |

| Picture |

|

|

|

| Features | Conforms to international standards (such as ISO, ASTM), the sieve frame and mesh are made of metal (such as stainless steel) or polyester | The mesh is made of polyester material, corrosion-resistant and anti-static, suitable for fine screening | Combined with ultrasonic vibration technology, it prevents mesh clogging and is suitable for ultrafine powder screening |

| Application scenarios | Used for particle size analysis, quality control and research and development of polyester particles | Used for fine screening of polyester powder or particles, especially for materials that are prone to static electricity | Used for screening and quality control of polyester ultrafine powder |

| Advantages | Standardized design, reliable results, suitable for precise screening in the laboratory | Anti-static, corrosion-resistant, suitable for high-precision screening | High efficiency anti-blocking, suitable for high-precision screening |

The working principle of polyester sieve shaker is to use the exciting force generated by the vibration motor to make the screen box vibrate, so that the material on the screen jumps, loosens, and layers, and the material is graded through the screen aperture.

The working mode of polyester sieve shaker is similar to other types of vibrating screening machines in basic principle. Its core is to use the energy of vibration, combined with the specific aperture of polyester screen, to achieve separation and classification of materials.

Polyester sieve shaker generates mechanical energy through the vibration mechanism, which is transferred to the screen frame equipped with a polyester screen with a specific aperture, so that the material moves on the screen. Particles smaller than the mesh are separated through the screen, and particles larger than the mesh are retained and discharged.

Polyester sieve shaker is mainly composed of vibration motor, screen box, polyester screen, support spring, base and other parts. The vibration motor provides the power source of vibration force, the screen box is installed with the frame structure of the screen, the polyester screen is used as the screening medium for screening materials, the support spring is used to support the screen box and provide the elasticity required for vibration, and the base supports the structure of the entire screening equipment.

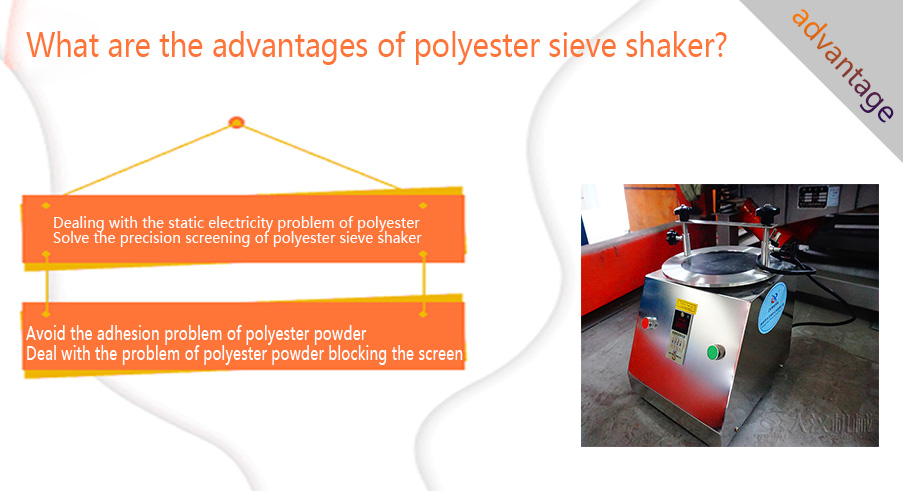

Polyester sieve shaker uses a screen made of polyester mesh, which has multiple advantages over screening machines using traditional metal mesh screens in specific applications and can handle static electricity problems, screening accuracy problems, adhesion and mesh blocking problems of polyester powder.

Dealing with the static electricity problem of polyester: Polyester materials are prone to static electricity, which causes powder materials to be adsorbed on the screen, affecting the screening efficiency. By using anti-static polyester screen, special treatment is carried out to reduce the generation of static electricity. Appropriately increasing the humidity of the working environment will help eliminate static electricity. Ensure that the equipment is well grounded and release static electricity.

Solve the precision screening of polyester sieve shaker: For high-precision screening, the accuracy of polyester screen may be affected by factors such as temperature and humidity. Maintain stable temperature and humidity to reduce the impact on screening accuracy. Choose a screen with precise mesh size and stable quality to ensure that the screen has appropriate tension.

Avoid the adhesion problem of polyester powder: Polyester materials may be sticky, causing the material to adhere to the screen, affecting the screening effect. Use screen materials with smooth surfaces and not easy to adhere. Increase the vibration intensity to allow the material to pass through the screen quickly.

Deal with the problem of polyester powder blocking the screen: Polyester powder is fine and easy to block the screen. Polyester sieve shaker reasonably selects the screen aperture and screen material, and selects the appropriate screen according to the material characteristics.

| serial number | name | unit | parameter |

| 01 | sieve frame | layer | 1~8 |

| 02 | Screen frame diameter | mm | Φ200 |

| 03 | Sieve particle size | mm | 0.025~3 |

| 04 | noise | dB | less than 50 |

| 05 | amplitude | mm | 0~3 |

| 06 | vibration frequency | times/min | 1440 |

| 07 | Dimensions | length*width*height | 350:350:300+N*50 |

| 08 | power supply | V;HZ | 220;50 |

| 09 | Total Weight | Kg | 36 |

| 10 | Vibration motor | power | 0.12KW |

| Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) | Number | Mesh(mm) |

| 2 | 13 | 26 | 0.71 | 90 | 0.16 | 260 | 0.06 |

| 3 | 6.5 | 28 | 0.63 | 100 | 0.154 | 280 | 0.055 |

| 4 | 5 | 30 | 0.6 | 110 | 0.14 | 300 | 0.054 |

| 5 | 4 | 32 | 0.55 | 115 | 0.13 | 320 | 0.048 |

| 6 | 3.2 | 36 | 0.5 | 120 | 0.125 | 325 | 0.045 |

| 7 | 2.8 | 40 | 0.45 | 130 | 0.111 | 350 | 0.041 |

| 8 | 2.5 | 45 | 0.4 | 140 | 0.105 | 360 | 0.4 |

| 9 | 2.2 | 50 | 0.355 | 150 | 0.1 | 400 | 0.0385 |

| 10 | 2 | 55 | 0.315 | 160 | 0.098 | 500 | 0.03 |

| 12 | 1.6 | 60 | 0.3 | 180 | 0.09 | ||

| 14 | 1.43 | 65 | 0.25 | 190 | 0.08 | ||

| 16 | 1.25 | 70 | 0.22 | 200 | 0.075 | ||

| 18 | 1 | 75 | 0.2 | 220 | 0.07 | ||

| 20 | 0.9 | 80 | 0.18 | 240 | 0.065 | ||

| 24 | 0.8 | 85 | 0.17 | 250 | 0.063 | ||

| Stainless steel sieve specifications, if you need special specifications, you can contact online customer service consultation. | |||||||

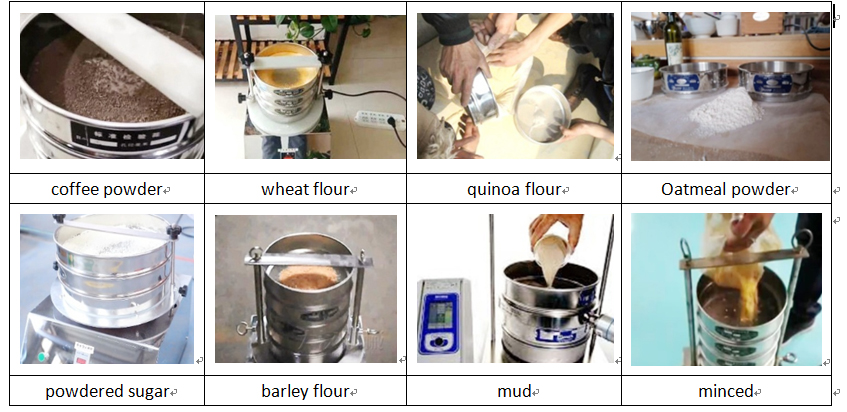

Polyester sieve shakers are widely used in polyester production, plastic processing, textile industry and laboratory testing, chemical industry, food and other industries. In polyester production, polyester sieve shakers are mainly used for screening and grading of materials such as polyester granules and polyester powder; in the plastic processing industry, they are used for screening and impurity removal of plastic granules; in the chemical industry, they can be used for screening and grading of various chemical raw materials; in the food industry, they can be used for fine screening of foods such as flour and starch.

The price of polyester shakers can vary greatly depending on a variety of factors, including size, capacity, function, brand and supplier. Here is an overview of the price range and factors that affect cost:

Basic model: Small, manual or semi-automatic polyester sieve shakers usually cost between 500 and 2,000.

Mid-range model: Medium-sized automatic sieve shakers with additional functions may cost between 2,000 and 5,000.

High-end models: Large, fully automatic, high-capacity polyester sieve shakers with advanced features range in price from 5,000 to 15,000 or more.

As a polyester sieve shaker manufacturer, Dahan Machinery provides flexible screen frame purchase, non-standard customization, and polyester sieve shakers of various models or functions, such as stainless steel screening machines, brass screening machines, magnetic suspension screening machines, ultrasonic screening machines, etc. This kind of equipment can better meet the personalized needs of different customers and has strong competitiveness in the market.

The price of polyester polyester sieve shaker will be affected by many factors. Dahan Machinery will provide belt conveyors of different models and specifications. For example, power, vibration frequency, screening amount, etc. will affect the price. You can contact customer service through our official website or email to inquire about the latest product quotation.

Polyester sieve shaker customer cases

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

Yeast powder is a commonly used pharmaceutical excipient, widely used in fermentation preparations, nutritional supplements or as a component of microbial culture medium. ...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which is 100 times finer than cement....

Resemary Chemical Reagent Standard Test Sieve

Rosemary Chemical Reagent Standard Test Sieves is a device dedicated to analyzing and grading rosemary powder, extracts and processing intermediates. The device effectively solves t...

Test Sieves for Testing Chemicals Powders Oils

The Φ200mm test sieve for testing chemical powder oil is specially designed for analyzing the particle size of chemical powder and oil mixture. It can achieve particle classificati...

Introduction and related specifications of standard test sieves

Standard test sieves are the core tools for particle size analysis. They are used to grade and detect particle size distribution of granular materials through precision sieves with ...

Micro silica powder particle size analysis test sieve

The micro silica powder particle size analysis test sieve is a laboratory equipment designed specifically for analyzing ultrafine and easily agglomerated micro silica powder. It eff...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap