![[field:title/]](/uploads/allimg/250118/2-25011Q11523S4-lp.png)

Powder sieve analysis is a technical method used to determine the distribution of particles of different particle sizes in powder samples, and has important applications in many fields.

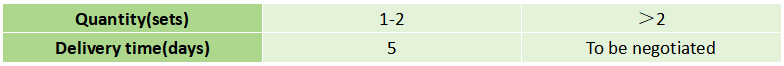

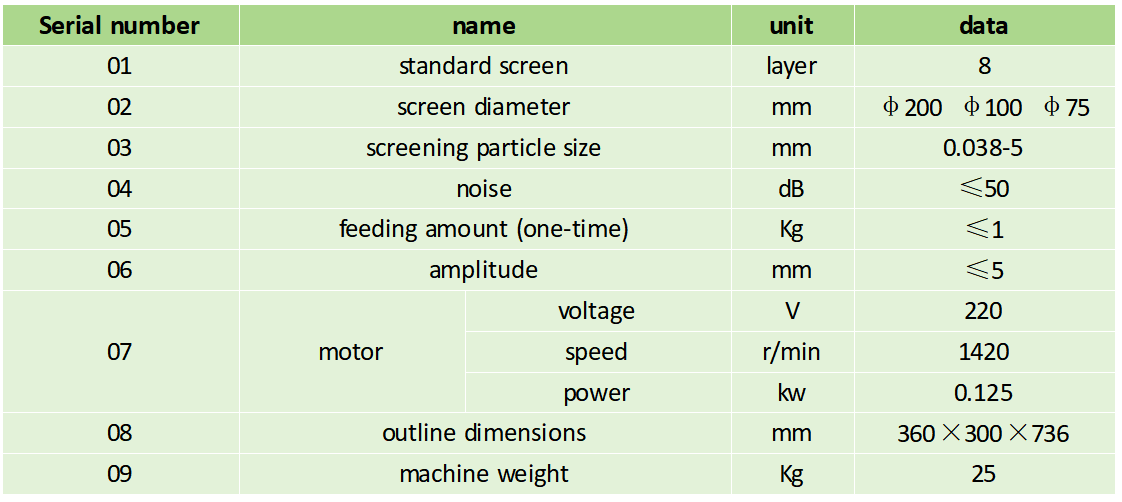

Screen diameter: 75mm, 100mm, 200mm, 300mm, 400mm

Screen depth: 32, 50 or 65 mm

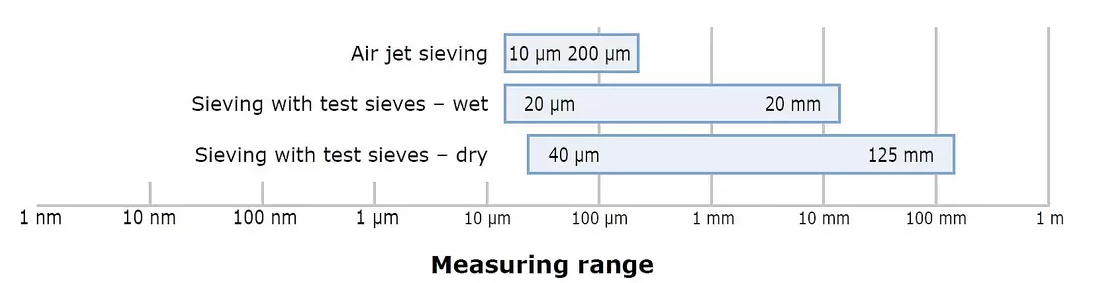

Measuring range: 20µm-125mm

Feeding amount: 200g

Amplitude: 1-4mm

Power: 0.125KW

Type: Woven mesh (0.02mm-2.36mm)/Perforated plate (1mm-125mm)/Electroforming (75μm-5μm)

Material: Stainless steel/Brass/Plastic

Screen hole: Round hole/Square hole

Powder sieve analysis is an analysis method that uses a series of standard sieves to classify powder samples according to particle size to obtain the particle size distribution data of the powder. It is a basic and important test method in powder science and is widely used in metallurgy, building materials, chemical industry, medicine and other fields.

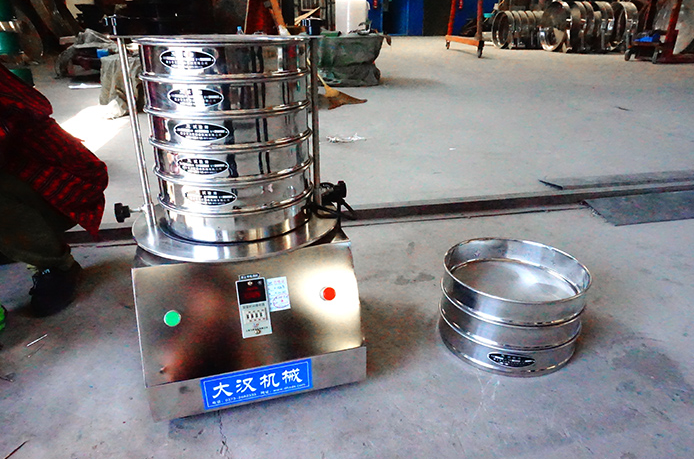

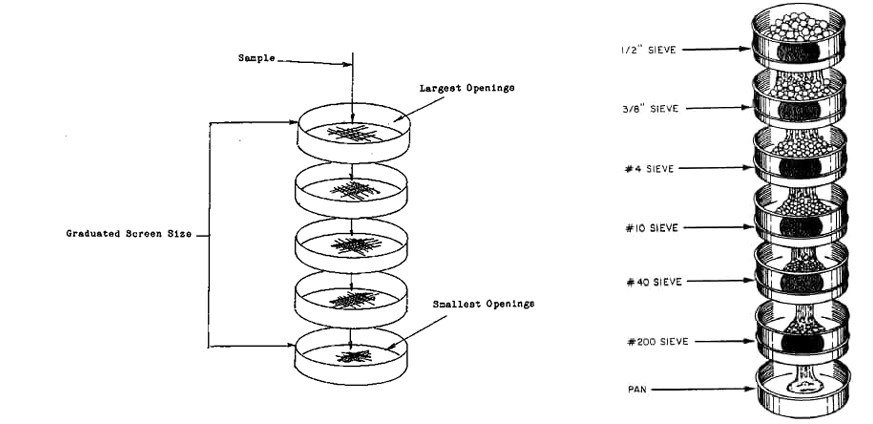

The principle of Powder sieve analysis is based on the fact that different powder particle sizes have different abilities to pass through the sieve apertures. The powder sample to be tested is placed on a set of sieves with gradually decreasing apertures, and through vibration or sieving, the powder particles of different particle sizes are retained on different sieves, thereby obtaining the particle size distribution data.

1. Sieving method: separate particles of different sizes through a sieve, and determine the particle size range of the particles according to the sieve aperture.

2. Laser particle size analysis: using the principle of laser scattering, measure the scattered light of particles in liquid or gas, and then calculate the particle size distribution of particles.

3. Sedimentation method: based on the different sedimentation speeds of particles of different sizes in liquid, the particle size is determined by measuring the sedimentation speed.

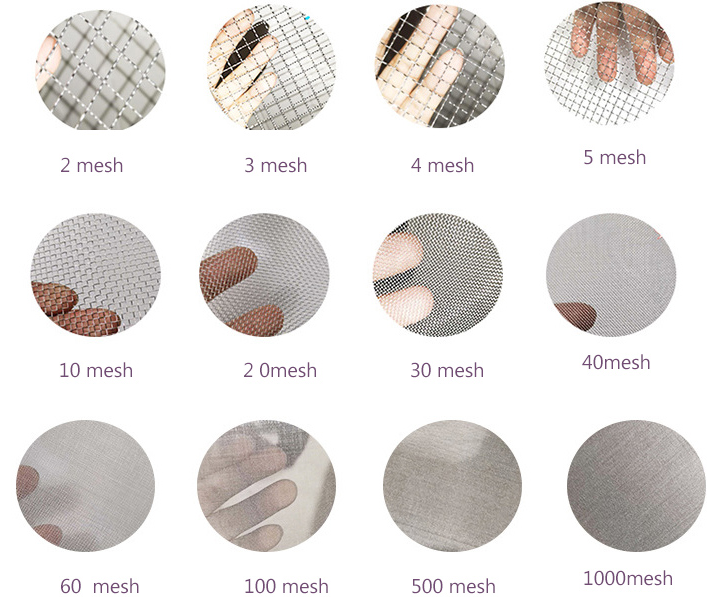

The selection of sieve size for fine powder depends on the specific application requirements. Generally speaking, the sieve size of fine powder is smaller, that is, the sieve aperture is smaller. Common fine powder sieve sizes include 200 mesh, 325 mesh, 400 mesh, etc.

200 mesh sieve: The aperture is 75 microns, suitable for screening of general fine powder.

325 mesh sieve: The aperture is 45 microns, suitable for screening of ultrafine powder.

400 mesh sieve: The aperture is 38 microns, suitable for screening of extremely fine powder.

Understanding the particle size distribution of powder samples is crucial for many industrial production and scientific research processes. For example, in the pharmaceutical industry, the particle size distribution of drug powders affects the solubility, stability and bioavailability of drugs; in the ceramic industry, the powder particle size distribution affects the density, strength and sintering properties of ceramic products.

Dry sieving method

Place the powder sample on a set of standard sieves, and sieve the powder particles on the sieves by mechanical vibration or manual shaking. After a period of time, weigh the mass of powder retained on each sieve to calculate the proportion of particles in different particle size ranges.

Scope of application: Suitable for powder samples with larger particle size, better fluidity, and less prone to agglomeration.

Wet sieving method

Mix the powder sample with an appropriate amount of liquid into a suspension, then pour the suspension into the sieve, and rinse the sieve with liquid at the same time, so that the particles can pass through the sieve holes more easily under the action of the liquid.

Scope of application: Suitable for some powder samples that are easy to agglomerate or have high viscosity.

Powder sieve analysis is the process of separating powder particles of different sizes. By placing the powder sample on a series of sieves with gradually decreasing apertures and applying vibration or other mechanical forces on the sieves, particles of different sizes are made to pass through sieves of different apertures respectively, thereby obtaining particle size distribution data.

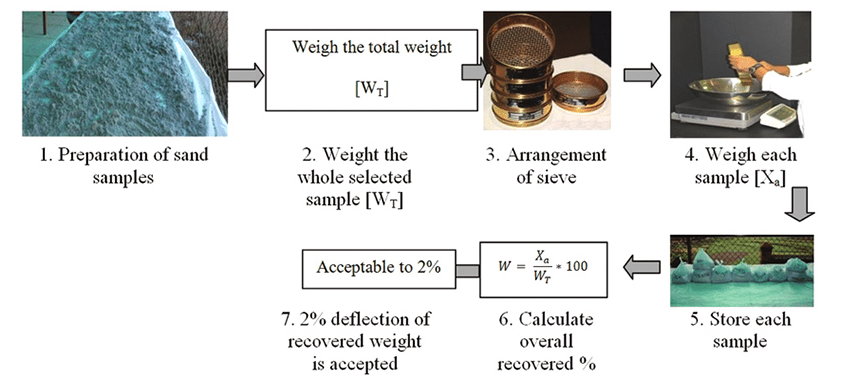

The sieving process generally includes the following steps:

1、Sample preparation: Dry and crush the sample to be tested, and pass it through a coarse sieve to remove large particles.

2、Sieve preparation: Select a suitable sieve group according to the particle size range of the sample.

3、Sample loading: Spread the sample evenly on the top sieve.

4、Sieving: Sieve by vibration or sieving.

5、Weighing: Weigh the mass of the sieve and the undersize at each level.

6、Calculation: Calculate the percentage of different particle sizes based on the mass of the sieve and the undersize at each level, and draw a particle size distribution curve.

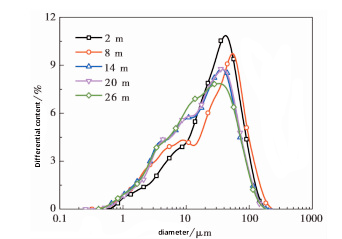

The results of Powder sieve analysis are usually expressed in the form of a particle size distribution curve, with the horizontal axis representing the particle size and the vertical axis representing the percentage of each particle size. By analyzing the particle size distribution curve, the following information can be obtained:

1. Average particle size: represents the average size of powder particles.

2. Particle size distribution range: represents the degree of dispersion of powder particle size.

3. Content of each particle size: represents the proportion of particles of different particle sizes in the sample.

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

The 20cm sieve is used for grain sieving, separating particles of different sizes through screens with different aperture sizes, and evaluating grain quality It has the advantages o...

Juice 20cm test sieve is a screening tool specially used in juice production and related research fields. It usually has specific size specifications, the diameter or side length of...

20cm test sieve for garden soil

20cm test sieve for garden soil is used in horticultural soil management to analyze particle size distribution to determine soil type, texture, and fertility and to screen out impur...

Chinese herbal medicine vibrating screen

Chinese herbal medicine vibrating screen is a piece of equipment specially used for screening Chinese medicinal materials. ......

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap