Tuesday July-15 2025 17:12:14

Powder test sieve is an experimental device used to analyze and detect the particle size distribution of powdered materials. It is widely used in the fields of medicine, metallurgy, chemical industry, food, new materials, etc. This equipment is usually used with a standard sieve, with mesh sizes ranging from 20 to 500, covering a particle size range of about 850 microns to 25 microns.

Due to its inherent physical properties, such as fine particles, easy to fly, easy to absorb moisture, and easy to agglomerate, powders face unique technical challenges when sieving particles. Powders can easily form piles or "bridges" on the sieve, hindering the passage of particles. Therefore, powder test sieves usually use high-frequency, multi-dimensional or three-dimensional vibration modes, such as slapping, shocking or ultrasonic-assisted vibrating sieves. Powder test sieve allows materials to be graded and distributed on multiple layers of sieves. By weighing the material intercepted on each layer of the sieve, the proportion of materials in different particle size segments can be obtained, and then the particle size distribution curve of the powder can be accurately depicted, providing key data support for product quality control, process optimization and scientific research.

The powder test sieve is classified according to the application accuracy. The ordinary test sieve is suitable for screening conventional powders in the range of 80~200 mesh, and is often used for rapid quality inspection; the high-precision test sieve can achieve 300~500 mesh ultrafine powder classification, with fine vibration and good repeatability, and is often used in material research and development and high-end industrial powders. Coarse-screen test sieves are used to screen large-particle powders or agglomerated powders below 40 mesh, focusing on removing foreign matter or large particles.

Ordinary precision test sieves (conventional screening) are suitable for conventional particle size detection of most industrial powders and granular materials; they are often used in factory inspections, raw material screening, and other occasions where screening accuracy is not required. High-precision test sieves (precision screening) are used for particle size analysis and grade classification of fine powders and ultrafine particles; they are used in pharmaceutical, fine chemical, 3D printing metal powder, lithium battery materials and other industries. Coarse-screen test sieves (fast screening/grading) are used to quickly remove large particles, agglomerates, impurities or perform preliminary particle size classification; they are used in preliminary screening or industrial links that do not require strict particle size control.

Powder test sieve is mainly used for particle size classification and particle distribution analysis of powder materials, and is widely used in laboratories, quality inspection, scientific research institutions, etc.

|

Model |

sieve frame diameter (mm) |

sieve mesh range |

sieve mesh aperture (mm) |

sieve frame material |

sieve mesh material |

height (mm) |

|

Φ200 type |

200 |

5 mesh~500 mesh |

4.0mm~0.025mm |

stainless steel/copper/aluminum alloy |

stainless steel/copper wire mesh |

50 or 75 |

|

Φ100 type |

100 |

5 mesh~300 mesh |

4.0mm~0.053mm |

stainless steel |

stainless steel wire mesh |

25 or 40 |

|

Φ300 type |

300 |

5 mesh~400 Mesh |

4.75mm~0.038mm |

stainless steel/carbon steel |

stainless steel wire mesh |

60 or 75 |

|

ASTM8 inch |

203 (8 inch) |

No.4~No.400 (ASTM) |

4.75mm~0.038mm |

stainless steel/brass |

ASTM stainless steel mesh |

50.8 |

|

ISO200 type |

200 |

ISO5μm~4mm |

4mm~0.005mm |

stainless steel |

ISO stainless steel woven mesh |

50 or 60 |

The powder test sieve is a core tool for particle size analysis and classification of powder materials. It uses the aperture difference of different mesh screens (such as 200 mesh screen aperture 75μm) to separate the mixed powder into different levels according to particle size, such as sieving calcium carbonate powder into coarse powder (>150 mesh), fine powder (150-325 mesh), and ultrafine powder (>325 mesh).

In addition, the powder test sieve can also screen out large particle impurities in the powder (such as crushed stones in ore powder, straw debris in grain powder), or remove excessively fine dust (such as ultrafine particle agglomerates in paint pigments).

For ultrafine powders (<45μm) or highly viscous, hygroscopic materials (such as milk powder, carbon black, talcum powder, etc.), the screen is easily blocked, resulting in reduced screening efficiency or even failure to pass through the screen. Especially under high mesh screen, the speed of fine powder passing through the screen is slow, and it takes a long time to obtain effective screening results; if the screening time is not properly controlled, false screening is likely to occur, affecting the accuracy of the data.

The powder test sieve is designed for small sample quantities (such as tens of grams to hundreds of grams), which is not suitable for continuous processing of large batches of materials and cannot meet the large production capacity requirements of industrial production.

|

Powder type |

Common material name |

Recommended mesh range (Mesh) |

Corresponding particle size (μm) |

|

Metal powder |

Iron powder, copper powder, tungsten powder, nickel powder |

100~400 mesh |

150~38μm |

|

Drug and auxiliary powder |

Starch, glucose powder, vitamin powder |

80~300 mesh |

180~48μm |

|

Food powder |

Milk powder, coffee powder, flour, spice powder |

40~200 mesh |

420~75μm |

|

Chemical raw material powder |

Calcium carbonate, barium sulfate, talcum powder, graphite powder |

100~325 mesh |

1 50~45μm |

|

Battery material powder |

graphite powder, lithium iron phosphate, lithium manganese oxide |

200~500 mesh |

75~25μm |

|

Ceramic/pigment powder |

ceramic powder, alumina, titanium dioxide, carbon black |

200~400 mesh |

75~38μm |

|

Abrasive/mineral powder |

corundum, corundum powder, silicon carbide |

60~300 mesh |

250~48μm |

|

Plastic powder |

PVC powder, polyethylene powder, TPU powder |

40~200 mesh |

420~75μm |

In pharmaceutical companies, powder test sieves are used for particle size detection of raw materials and excipients. The difference in particle size will directly affect the dissolution rate of the drug and the quality of tableting. For example, a tablet manufacturer will use a standard test sieve of 200 mesh to 300 mesh to detect whether the raw material meets the particle size uniformity requirements to ensure that the content of each tablet is consistent and there is no hard spot in the tablet. In metallurgical powder pressing or 3D printing processes, when companies produce metal materials such as iron powder, copper powder, and aluminum powder, they will use a powder test sieve of 100~325 mesh to grade the finished powder and remove overly coarse or overly fine particles.

Food powders such as milk powder, cocoa powder, and seasonings have extremely high requirements for taste and solubility. Food factories often use sieves of 80~200 mesh to regularly check whether the powder is agglomerated or the particle size is deviated to prevent moisture absorption or process problems from affecting the dissolution rate and sensory quality. New material powders such as graphite powder and lithium iron phosphate are widely used in batteries and high-performance materials, and their particle size distribution directly affects the conductivity or reaction efficiency of the material. The powder test sieve is used to analyze the particle size consistency of different batches of raw materials, and a sieve of 300~500 mesh is often used for fine grading to optimize coating and electrode processing.

The test results of the powder test sieve are mainly based on the particle size distribution and mesh number of the sieved material, which is used to evaluate whether the particle size of the powder (such as quartz powder, mineral powder, etc.) meets the process requirements.

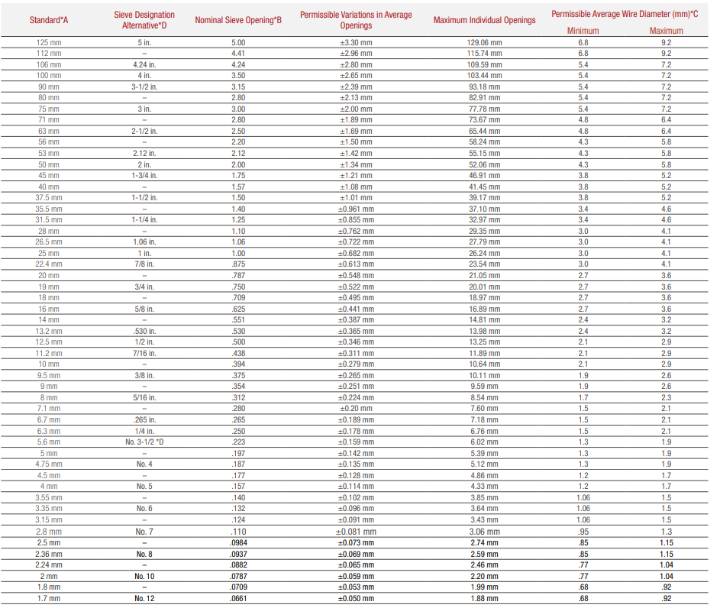

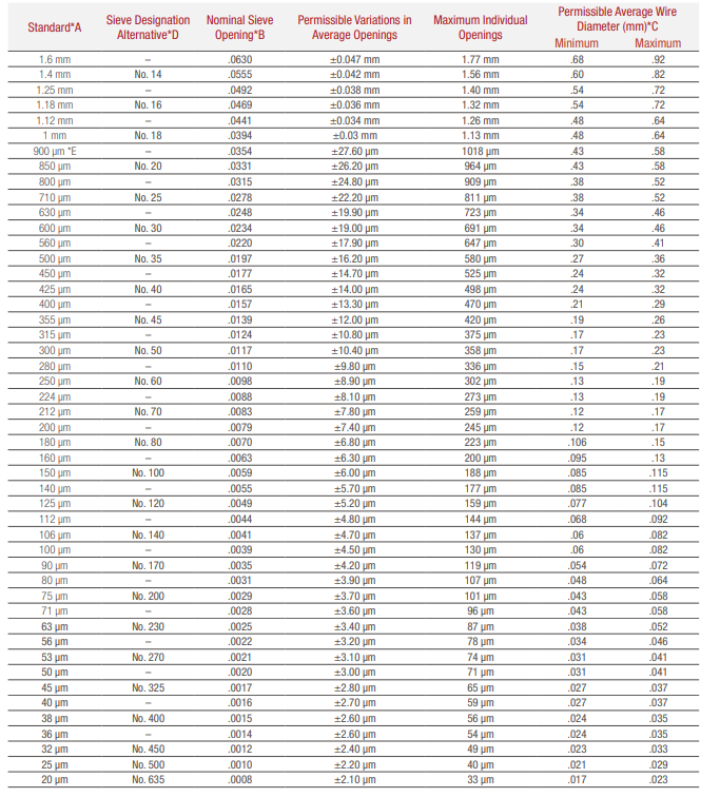

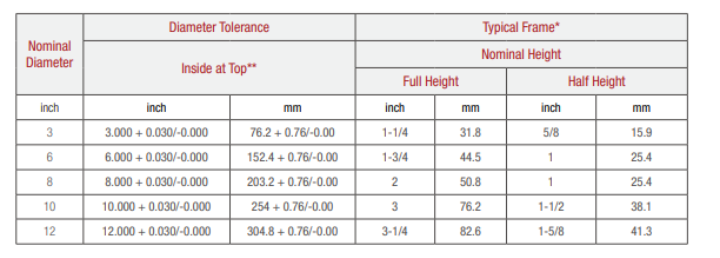

The test sieve usually uses a standard sieve with a mesh range of 10 mesh (2mm) to 400 mesh (0.038mm), and each layer of the sieve corresponds to a specific aperture.

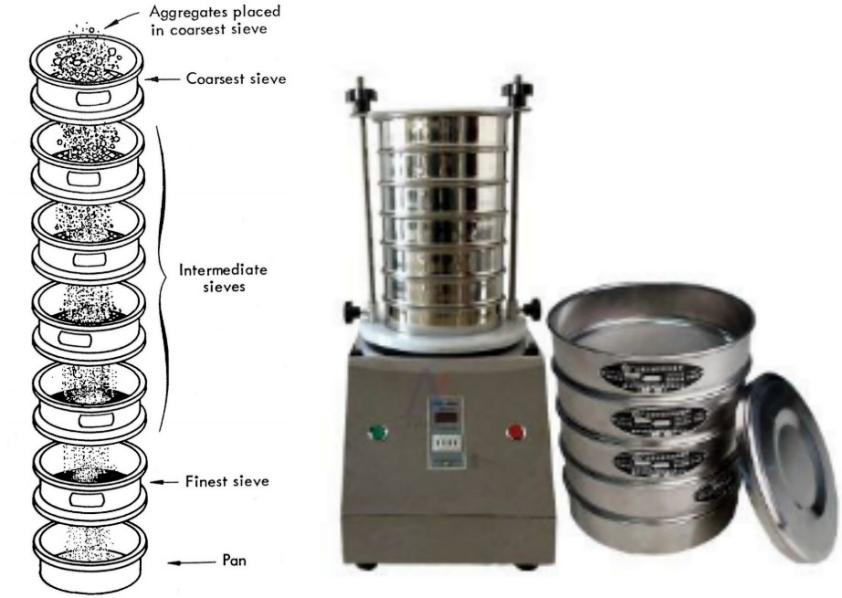

During the test, the powder sample is placed on the top of a multi-layer test sieve (generally 2-8 layers), and the material is layered according to the particle size through a vibration device, and the fine particles pass through the sieve, while the larger particles remain on the sieve surface.

The test results are expressed as the weight percentage of the sample retained on each layer of the sieve. For example, after 50g of quartz powder sample is sieved through 100 mesh, 200 mesh, and 325 mesh, the 100 mesh sieve accounts for 10% (5g), the 200 mesh accounts for 30% (15g), the 325 mesh accounts for 50% (25g), and the sieve bottom accounts for 10% (5g), indicating that the particle size is mainly concentrated in the range of 0.075-0.038mm.

The results need to be compared with the process standards to determine whether the target particle size distribution is met (such as 80% passing 200 mesh).

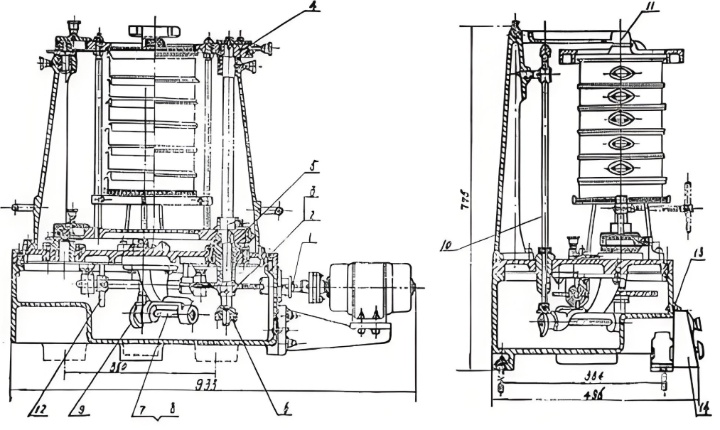

The core principle of powder test sieve is to use mechanical vibration and precise sieve mesh size to classify powder samples. This technology aims to separate mixed powder samples into several components with narrower particle size ranges according to particle size, so as to determine its particle size distribution. Its basic workflow is: the powder sample to be analyzed is placed on the top layer of a set of stacked test sieves. This set of sieves usually consists of multiple layers of sieves, with the aperture of each layer decreasing from top to bottom, and a receiving tray at the bottom. After the equipment is started, the sieve machine vibrates. This vibration is not a simple up and down movement, but a composite type, often a three-dimensional vibration (including horizontal, vertical and rotational movement), or with additional slapping and shaking movements. The role of vibration is to provide enough energy for the powder particles to jump, roll and change direction on the sieve surface. When the particles encounter the sieve holes, if their size is smaller than the sieve holes, they will pass through the sieve holes and fall to the next sieve layer under the combined influence of gravity, vibration and interaction between particles. If the particle size is larger than the sieve hole, it will be intercepted by the sieve layer. This process is carried out simultaneously on each layer of the sieve. The longer sieving time also ensures that fine particles have enough opportunities to pass through the corresponding sieve holes, avoiding premature stopping of vibration and causing fine powder to be retained on the coarse sieve, thereby affecting the accuracy of the analysis. After the preset sieving time, stop the vibration, collect and weigh the materials intercepted on each layer of the sieve and the fine particles in the receiving tray. By calculating the percentage of the mass of each layer of material to the total mass of the original sample, the particle size distribution data of the powder sample can be obtained.

Powder test sieve plays an important role in powder particle size analysis. Its advantages are mainly reflected in accurate particle size analysis, relatively simple operation, traceability of results, wide adaptability, etc. The following is an introduction to its advantages:

Providing accurate particle size distribution data: This is the core advantage of Powder test sieve. Through the step-by-step classification of multiple layers of precision sieves, it can accurately separate complex powder samples into different particle size components. This meticulous classification capability allows the operator to obtain a detailed particle size cumulative distribution curve and the percentage content of each particle size segment.

Relatively simple and popular operation: Compared with some more complex particle size analyzers (such as laser particle size analyzers), the operation of Powder test sieve is relatively intuitive and easy to master. The device itself has a relatively simple structure and has a wide range of applications in many laboratories and production sites. This makes it a practical and popular particle size analysis tool, especially suitable for daily quality inspection and routine research and development work.

The results are traceable and standardized: Under the premise of complying with standard operating procedures, the sieving results obtained by different laboratories using the same or standard equipment and methods are highly comparable and traceable. This standardization is essential for cross-regional and cross-departmental quality control and product specification formulation, ensuring data consistency and reliability.

Able to handle various types of powders: Whether it is dry, non-sticky powder, or powder with a certain degree of stickiness and easy to agglomerate, or even some slightly abrasive materials, Powder test sieve can perform effective particle size analysis by selecting the appropriate vibration mode, sieving time and sieve material. For example, for powders that are easy to agglomerate, a slapping or shocking vibration mode can be used, or even combined with ultrasonic assistance to ensure that the particles are fully dispersed and pass through the sieve holes.

Intuitive physical separation process: Powder test sieve directly separates particles by physical methods, which makes the analysis process and results very intuitive. The operator can directly observe the state of the material on different sieves and have a more direct understanding of the macroscopic characteristics of the powder. This physical separation characteristic also makes its results less susceptible to complex influences such as the refractive index of the medium and irregular particle shape.

The powder test sieve is a standardized tool for measuring and analyzing the particle size distribution of powder and granular materials. It consists of a series of sieves with precise mesh sizes, which are usually stacked in order from large to small. It is crucial to choose the right mesh size, which depends on the characteristics of the powder to be tested. By placing the powder sample on the sieve and vibrating it mechanically, particles of different sizes will pass through the corresponding sieve holes in turn, thereby achieving accurate separation and quantification of the powder particle size composition.

Test sieve for pharmaceutical powder

Test sieve for pharmaceutical powder is a special equipment used in the pharmaceutical industry for accurate screening and detection of pharmaceutical powder particle size. Through ...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy...

Chinese medicine powder test sieve

Chinese medicine powder test sieve is a screening equipment specifically used for particle size analysis and quality control of traditional Chinese medicine powder. It effectively s...

Metal powder test sieve is a device used to accurately measure the particle size distribution of metal powder. It classifies and screens metal powder through a high-precision sieve ...

What is a ceramic powder test sieve? Ceramic powder test sieve is a screening device used to accurately measure the particle size distribution of ceramic powder and analyze the part...

Jul 15, 2025

Powder test sieve is a laboratory device that physically separates powder samples according to partic...

Jul 14, 2025

Standard Test Method for Particle-Size Analysis of Soils

Size analysis of soils is a standard laboratory procedure used to determine the proportion by weight ...

Jul 08, 2025

Soil sieving analysis uses dry or wet sieving to separate soil particles by size. Dry sieving is suit...

Jul 07, 2025

Top impact sieve for particle size inspection

Top impact sieve for particle size inspection is set with 2-5 layers of screens. Mesh size of each la...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap