Tuesday April-29 2025 17:01:20

Rosemary chemical reagent standard test sieve is a special device for particle size analysis and grading detection of rosemary powder, extracts or processing intermediates. This equipment is suitable for particle size analysis of rosemary plant extract powder; detection of whether rosemary dry powder and crushed materials meet the specified particle size standard; quality control before use of rosemary as a chemical reagent, natural medicinal raw material, food additive, etc.

Rosemary contains a variety of biologically active chemical components, such as:

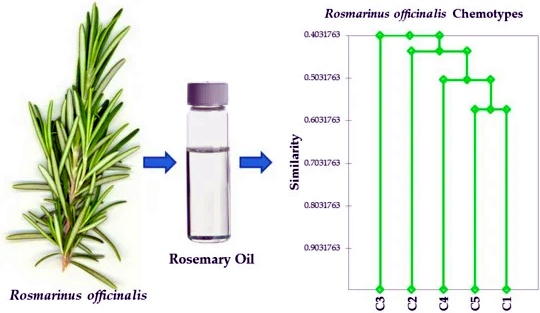

Essential oil components: such as eucalyptol, camphor, α-pinene, etc. These are usually liquids and may not require direct particle size analysis, but may be required when prepared into microcapsules or other solid forms.

Antioxidants: such as rosmarinic acid, carnosic acid, carnosol, etc. These are usually solid powders or extracts, and particle size analysis is required to control their physical properties.

Other extracts or active ingredients: Depending on the different extraction processes and target components, chemical reagents in different forms may be obtained.

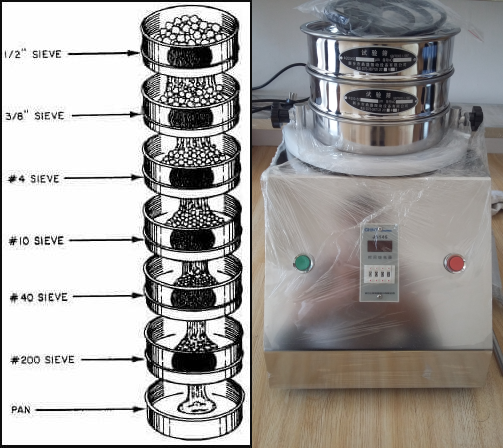

The standard test sieve is generally composed of a sieve frame and a sieve mesh. The sieve is vibrated by mechanical vibration, electromagnetic vibration, etc., so that the rosemary chemical reagent can make a directional jumping motion on the sieve surface. Under the action of vibration, the reagent particles smaller than the sieve hole pass through the sieve mesh to become the undersize, and the particles larger than the sieve hole remain on the sieve surface to become the oversize, thereby realizing the screening and particle size classification of the reagent.

Solve the problem of strong hygroscopicity and easy agglomeration: Many rosemary extract powders or dried plant materials have strong hygroscopicity and are easy to absorb moisture in the air and agglomerate, or even clog the screen. Consider a slight pretreatment, such as gently dispersing with a soft brush, but avoid destroying the structure of the particles themselves.

Reduce rosemary sample loss: Some high-purity rosemary active ingredients are expensive, and sample loss needs to be minimized during the sieving process. Be careful when weighing and transferring samples to avoid spilling. Use a vibrating sifter with a sealing device to reduce dust flying and sample loss.

Solve the problem of complex ingredients and uneven particle size distribution: Rosemary chemical reagents are usually a mixture of multiple ingredients with a very wide particle size distribution, and a suitable sieve combination needs to be selected for effective separation. According to the particle size distribution range of the sample, a series of standard test sieves with gradually decreasing apertures are selected for grading.

Solve the problem of rosemary easily entangled in the screen: For crushed rosemary leaves or stems and other plant materials, there may be more fibers, which are easy to entangle on the screen. Square holes are easier to entangle fibers than round hole screens. Using lower frequency and larger amplitude will help the movement and passage of fibers.

|

Application scenario |

Recommended mesh number range |

Particle size range (μm) |

Description |

|

Preliminary screening of rosemary dry powder |

20 mesh~60 mesh |

850μm~250μm |

Preliminary removal of larger particles to ensure powder fluidity and facilitate subsequent refinement |

|

Screening of extract coarse powder |

40 mesh~80 mesh |

425μm~180μm |

Control of coarse powder particle size, often used for pretreatment before extracting rosmarinic acid and ursolic acid |

|

Fine powder (high-purity extract) |

80 mesh~200 mesh |

180μm~75μm |

Applicable to extract powder or purified products, Ensure solubility and reactivity |

|

Ultrafine powder detection |

200 mesh ~ 400 mesh |

75μm ~ 38μm |

Precision chemical reagents, cosmetic grade powder detection, control ultrafine particles, improve fineness |

|

Impurity screening detection |

>18 mesh, <325 mesh combination |

1000μm sieve large particles, 45μm sieve fine impurities |

Upper and lower limit screening combined to ensure product purity and qualified particle size distribution |

1. Particle size control of rosemary dry powder raw materials

After crushing the rosemary dry leaves, it is necessary to remove coarse particles or fibers through a standard sieve to ensure uniform subsequent extraction effect. Generally, a standard sieve of 40~80 mesh is used. The test sieve can be used to remove incompletely crushed leaf residues to ensure that the raw materials are evenly exposed to the solvent and improve the extraction rate and purity.

2. Rosemary extract powder particle size detection

After extraction, the active ingredients such as rosmarinic acid and ursolic acid are usually dried into powder, and their particle size needs to be tested to see if it meets the reagent standards. 100-200 mesh sieves are more common, ensuring good dispersibility and high solubility of chemical reagents. Particle size stability helps control the reaction rate and ensure experimental repeatability.

3. Impurity screening of pharmaceutical-grade extracts

Rosemary extracts used in medicines and nutritional supplements need to be tested and screened for inactive impurities. The rosemary chemical reagent standard test sieve can remove crude fibers and undried agglomerates to control the impurity content.

4. Particle size detection of cosmetic raw materials

For rosemary powder used in skin care products, 200-400 mesh sieves can effectively control the particle size and ensure uniform distribution. Scientific research institutions or chemical research and development laboratories need to test the particle size distribution of rosemary chemical reagent samples. Obtain particle size curves to support material comparative analysis.

Rosemary chemical reagent standard test sieve is an important tool for ensuring the quality of rosemary-related chemical reagents and conducting scientific research. Its standardization, chemical inertness, precise mesh size and good sealing are the key to ensuring accurate and reliable test results. The selection of appropriate test sieves requires comprehensive consideration based on the specific chemical reagent characteristics, analysis purpose and relevant standards.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

Test sieve for testing chemicals powders oils

Test sieve is designed for particle size testing of chemical powders and oil mixtures, and is suitable for fine screening and analysis...

Apr 29, 2025

Resemary Chemical Reagent Standard Test Sieve

Rosemary Chemical Reagent Standard Test Sieves is a device dedicated to analyzing and grading rosemar...

Apr 28, 2025

Test Sieves for Testing Chemicals Powders Oils

The Φ200mm test sieve for testing chemical powder oil is specially designed for analyzing the partic...

Apr 26, 2025

Introduction and related specifications of standard test sieves

Standard test sieves are the core tools for particle size analysis. They are used to grade and detect...

Apr 25, 2025

Micro silica powder particle size analysis test sieve

The micro silica powder particle size analysis test sieve is a laboratory equipment designed specific...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap