![[field:title/]](/uploads/250423/2-2504231K429640.png)

Ro-Tap sieve shaker is a sieving device used for particle size analysis and classification of granular materials. It is widely used in laboratory particle size distribution analysis and is particularly suitable for particle size sieving tests of dry powder materials such as metal powder, mineral powder, plastic powder, and pharmaceutical powder.

Screen diameter: 200mm (8 inches), 300mm (12 inches), etc.

Maximum number of screen layers: 6–13 layers (including chassis)

Knocking frequency: about 60 times/minute

Rotation frequency: about 278 times/minute

Power supply: 220V / 50Hz

Dimensions: about W88cm x D41cm x H88cm

Weight: about 98 kg

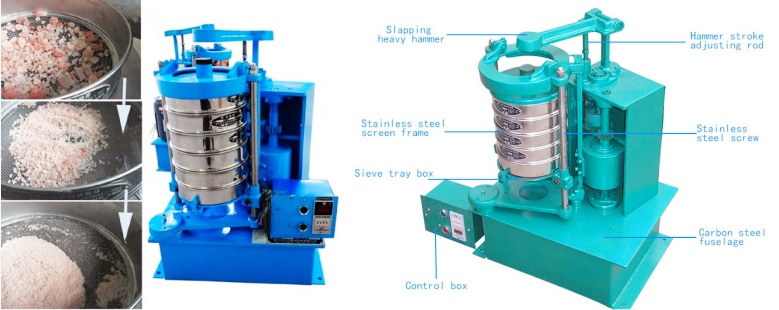

Ro-Tap sieve shaker is a laboratory-grade precision screening equipment, mainly used for particle size analysis and material particle gradation detection. It is famous for its unique two-dimensional motion (horizontal circular motion and vertical tapping motion). Its core principle is to use the compound motion of rotation and vertical tapping to make the material produce efficient dispersion and screening effect on the screen surface, which is particularly suitable for scenes that require high-precision and repeatable particle size analysis.

The unique working mode of Ro-Tap sieve shaker lies in its dual motion. By cleverly combining horizontal circular motion with vertical tapping, it not only simulates the traditional manual screening process but also ensures accurate and reliable particle size analysis results in a stable and repeatable manner. This operating mode effectively solves the problems of particle clogging and adhesion, improving screening efficiency and data quality.

Horizontal circular motion: The device produces a rotating motion in the horizontal direction, which disperses and moves the sample on the sieve surface, increasing the contact opportunity between particles and the sieve mesh.

Vertical tapping motion: A top tapping hammer will tap the sieve frame at a certain frequency, which helps particles stuck in the mesh to loosen and pass smoothly.

The combination of these two motions simulates the rotation and tapping action of manual sieving, but is more stable and efficient, and can provide more reliable particle size analysis results.

|

Specification |

RX-29 (8" Sieves) |

RX-30(12" Sieves) |

RX-29-E(Electronic, 8"Sieves) |

RX-30-E (Electronic, |

|

Sieve Diameter |

8 in (200 mm) |

12 in (300 mm) |

8 in (200 mm) |

12 in (300 mm) |

|

Sieve Capacity (Full Height) |

6 sieves + pan |

4 sieves + pan |

6 sieves + pan |

4 sieves + pan |

|

Sieve Capacity (Half Height) |

13 sieves + pan |

10 sieves + pan |

13 sieves + pan |

10 sieves + pan |

|

Oscillations per Minute |

278 ± 10 |

278 ± 10 |

Adjustable |

Adjustable |

|

Taps per Minute |

150 ± 10 |

150 ± 10 |

Adjustable |

Adjustable |

|

Motor Power |

1/4 HP |

1/4 HP |

1/4 HP |

1/4 HP |

|

Timer |

Digital, 99 min x 0.1sec |

Digital, 99 min x 0.1sec |

Digital, adjustable |

Digital, adjustable |

|

Dimensions (W x Dx H) |

28 x 21 x 25 in(71 x53 x 64 cm) |

28 x 21 x 25 in(71 x53 x 64 cm) |

18 x 18 x 30 in(46 x46 x 76 cm) |

15 x 17 x 38 in (38 x43 x 96 cm) |

|

Weight |

180 lbs (82 kg) |

180 lbs (82 kg) |

80 lbs (36 kg) |

117 lbs (53 kg) |

|

Power Supply |

110V/60Hz or 220V/50-60Hz |

110V/60Hz or 220V/50-60Hz |

110V/60Hz or 220V/50-60Hz |

110V/60Hz or 220V/50-60Hz |

|

Noise Level |

~85 dB (78 dB with enclosure) |

~85 dB (78 dB with enclosure) |

Reduced with dampening |

Reduced with dampening |

|

Standards Compliance |

ASTM C136,C702,D6913 |

ASTM C136,C702,D6913 |

ASTM C136,C702,D6913 |

ASTM C136, C702,D6913 |

|

Comparison item |

Ro-Tap Sieve Shaker |

Sieve Shaker |

|

Image |

|

|

|

Movement mode |

Rotation vibration + tapping (double action) |

Horizontal or vertical vibration only |

|

Anti-blocking net ability |

Very strong (tapping to clear the net) |

Easy to block, need to be cleaned manually |

|

Screening accuracy |

High |

General (depends on operating experience) |

|

Applicable particle size range |

20μm~25mm (ultra-fine powder requires airflow assistance) |

50μm~10mm (more suitable for coarse particles) |

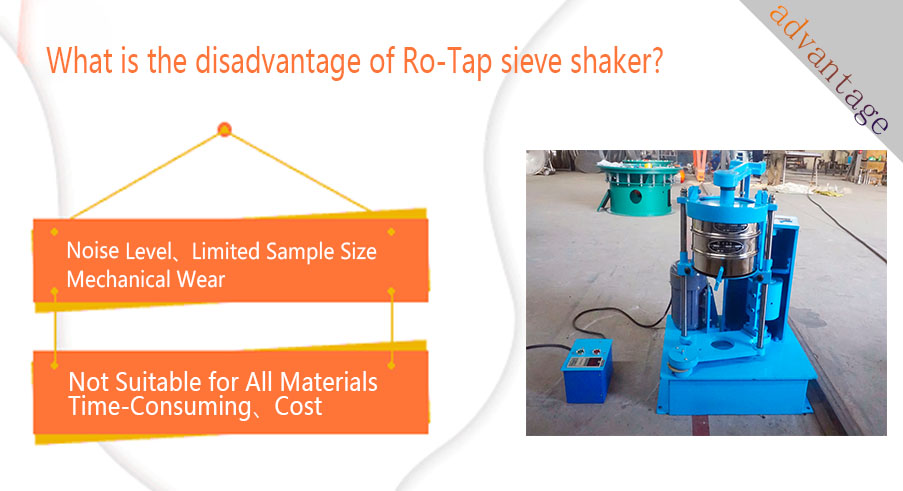

While the Ro-Tap Sieve Shaker performs well in particle size analysis, it is not without limitations. Before using it, consider a number of potential challenges, including noise generation, limited sample handling capacity, wear caused by mechanical motion, and poor screening performance with certain materials. Furthermore, its relatively long test cycle and high maintenance costs are also factors that need to be weighed.

Noise Level: It generates significant noise during operation, which can be disruptive in lab environments.

Limited Sample Size: It can only handle relatively small sample volumes, making it less suitable for large-scale analysis.

Mechanical Wear: The rotating and tapping mechanisms can experience wear over time, requiring regular maintenance or part replacement.

Not Suitable for All Materials: It may not effectively handle cohesive, sticky, or very fine powders that can clog sieves.

Time-Consuming: The process can be slow for certain materials, especially when high precision is needed.

Cost: The equipment and maintenance can be expensive compared to simpler sieving methods.

The mesh size of Ro-Tap sieve shaker should be determined according to the particle size range of the material being tested. The following are some mesh size recommendations for common materials (for reference):

|

Mesh size |

aperture (μm) |

Applicable scenarios |

|

4~20 mesh |

4,750~850μm |

Coarse particles (such as sand, ore, feed particles) |

|

25~60 mesh |

710~250μm |

Medium particles (such as cement, plastic particles, grain powder) |

|

80~200 mesh |

180~75μm |

Fine powder (such as flour, medicinal powder, cosmetic raw materials) |

|

230~400 mesh |

63~38μm |

Ultrafine powder (such as graphite powder, metal powder, lithium battery materials) |

|

>400 mesh |

<38μm,Need to match |

Electroforming screen or airflow auxiliary device (such as nanomaterials, high-precision chemical powder) |

Combination screen recommendation: It is recommended to configure a set of descending mesh screens (such as 100 mesh, 120 mesh, 150 mesh, 200 mesh, 250 mesh, chassis) according to the "full open screening method", so that a complete particle size distribution spectrum can be obtained.

The Ro-Tap sieve shaker is used to perform particle size analysis by separating and sorting particles of a material sample into different size fractions. It agitates a stack of sieves with a rotating and tapping motion, allowing particles to pass through mesh openings based on their size. This process ensures accurate and reproducible results for quality control, research, or material characterization in industries like construction, pharmaceuticals, and mining.

The Ro-Tap Sieve Shaker is widely used across various industries, providing precise and reliable solutions for particle size analysis, grading, and quality control. From coarse particle analysis in the construction and mining industries to fine powder testing in the pharmaceutical and R&D sectors, the Ro-Tap Sieve Shaker's vibration and tapping mechanism ensures accurate particle size distribution data, helping improve product quality and production efficiency across various industries. The following are the main application areas:

Construction and Civil Engineering: Used to analyze the particle size distribution of soil, aggregates (such as sand, aggregate) and cement. For example, the particle size of concrete mixes is tested to ensure strength and stability.

Mining and Geology: Classify ore, mineral and geological samples to determine the particle size distribution (such as from 5 inches to 20 microns). For example, analyze ore particles and refining and beneficiation processes.

Pharmaceutical: Analyze the particle size of pharmaceutical powders to ensure consistency and solubility, such as checking whether the powder meets the fineness requirements of 400 mesh to 635 mesh.

Research and Development: Used for particle size analysis experiments in the laboratory to support new material development and test the particle size characteristics of new alloys or composite materials.

Special Applications: Use wet sieving kits to analyze suspensions in liquid stocks, suitable for sticky or easily agglomerated samples. Or designed for coarse particles (such as 80 mesh and above), suitable for aggregate testing.

Ro-Tap sieve shaker prices vary significantly depending on model, function, manufacturer and configuration. In general, you can expect the following price range (for reference only, please consult dahan suppliers for specific prices):

Basic Ro-Tap sieve shaker (8-inch sieve): roughly between RMB 15,000 and RMB 30,000, which usually has basic functions.

Models with more functions or larger sieve sizes (12-inch sieve): The price may be between RMB 30,000 and RMB 50,000 or even higher. These models may have more precise control, higher capacity or special designs.

Complete system including accessories such as soundproof box, automatic loading/unloading, etc. The price will increase further.

Determine the screen size you need, the number of stacking layers, whether special functions are required, etc. Clearly inform the supplier of your application field and specific needs so that they can provide the most suitable model and quotation.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

What is 0.075mm soil sieve ? The 0.075mm soil sieve is primarily used for soil particle size analysis, separating and classifying particles by size. 0.075mm is considered the critic...

What is 4.75mm soil sieve ? The 4.75mm soil sieve is primarily used for particle grading analysis of bulk materials such as soil, sand, gravel, and aggregate. The core component of ...

What is 2mm soil sieve? A 2mm soil sieve is a fundamental and crucial tool. Its primarily used for pre-processing and sorting soil samples, separating coarse particles (larger than ...

Size sieve for soil mainly refers to the sieve frame diameter (commonly used 200mm, 300mm, etc.) and the sieve hole size (ranging from 0.075mm to 60mm). The sieve frame diameter is ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap