![[field:title/]](/uploads/allimg/250324/2-250324150255506-lp.png)

Rubber powder test sieve is a special device used for particle size analysis and particle size detection of rubber powder. It separates rubber powder according to particle size through the vibration or rotation of the standard sieve to determine its particle size distribution.

Number of layers: 1-8 layers

Screening particle size: 0.025mm-20mm

Application: rubber products, chemical industry, material science and other fields

Port: Any port in China (Mainland)or as you need.

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

Rubber powder test sieve is a laboratory device used to analyze and screen the particle size distribution of rubber powder. It usually consists of a set of standard sieves that separate rubber powder by particle size through vibration or manual operation. It plays a key role in the production, recycling and quality control of rubber products.

1️⃣ Vibration source drive: The motor or electromagnetic vibrator generates high-frequency vibration to drive the sieve body to vibrate.

2️⃣ Material diffusion: After the rubber powder is evenly put into the sieve, it diffuses along the sieve surface under the action of vibration force.

3️⃣ Particle classification:

Fine particles pass through the sieve holes and enter the lower sieve.

Large particles remain in the upper layer and continue to vibrate until discharged.

4️⃣ Final screening: The rubber powder is classified through sieves of different mesh sizes to obtain the particle size that meets the requirements.

Classification by vibration mode

|

Type |

Picture |

Features |

Scenario |

|

Mechanical vibrating screen |

|

Produces vibration through an eccentric block driven by a motor; vibration amplitude and frequency are adjustable |

Suitable for most rubber powder screening |

|

Electromagnetic vibrating screen |

|

Produces high-frequency vibration through an electromagnetic vibrator; high vibration frequency, low energy consumption, low noise |

Suitable for fine screening |

|

Ultrasonic vibrating screen |

|

Combines ultrasonic technology to prevent screen clogging |

Suitable for ultrafine powder screening |

Classification by screening method

|

Type |

Picture |

Feature |

Scenario |

|

Vibrating screen |

|

Screening through vibration |

Suitable for most rubber powder screening |

|

Airflow screen |

|

Blowing up the powder through airflow to achieve screening |

Suitable for ultra-fine powder screening to prevent screen clogging |

|

Rotary screen |

|

Screening through screen frame rotation |

Suitable for rubber powder screening with high viscosity |

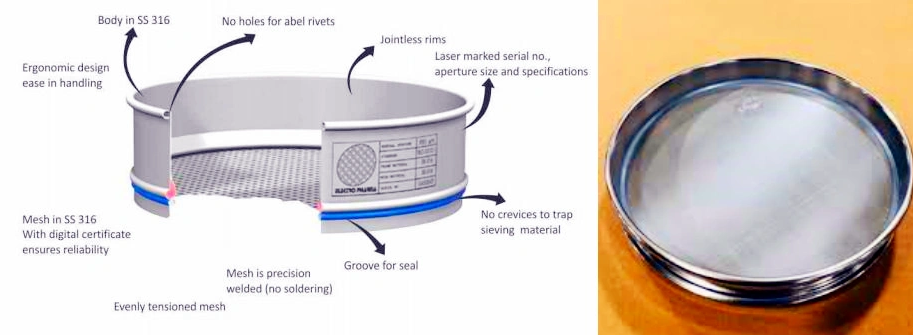

1、High-precision screening: using standard test sieve, it can be screened to 200 mesh (or even finer), suitable for fine rubber powder screening to ensure uniform particle size of rubber powder.

2、Multi-layer screen design: usually equipped with 2-5 layers of screen, which can complete multi-level screening at one time to improve efficiency.

3、Diverse screen materials: common materials include stainless steel, nylon mesh, etc., and the appropriate screen can be selected according to the characteristics of rubber powder.

4、Vibration screening technology: electromagnetic vibration or mechanical vibration is mostly used to improve screening efficiency and accuracy.

|

Mesh number (mesh) |

Particle size (μm) |

Applicable range |

|

10 mesh |

2000μm |

Large particle rubber powder, suitable for coarse screening |

|

20 mesh |

850μm |

Applicable for primary screening, removing large particle impurities |

|

40 mesh |

425μm |

Applicable for general rubber powder classification |

|

60 mesh |

250μm |

Fine rubber powder, suitable for recycled rubber manufacturing |

|

80 mesh |

180μm |

Applicable for fine rubber powder, widely used in rubber products |

|

100 mesh |

150μm |

Applicable for high-precision rubber powder screening |

|

200 mesh |

75μm |

Ultrafine rubber powder, suitable for precision rubber filler |

|

300 mesh |

50μm |

Ultrafine rubber powder, suitable for special purposes, such as rubber plastic composite materials |

Coarse sieve (10-20 mesh): suitable for primary processing or low precision requirements, such as primary screening of waste tire recycling.

Medium sieve (30-50 mesh): suitable for most industrial uses, such as rubber particle recycling.

Fine sieve (60-200 mesh): used for fine processing or high value-added products, such as rubber modifiers.

Ultrafine sieve (>200 mesh): laboratory research or high-end applications, such as dispersion testing of rubber micropowder in polymers.

|

Purpose |

Recommended mesh |

Aperture range |

Description |

|

Coarse particle screening |

10 mesh-20 mesh |

2mm-0.85mm |

Used for primary screening to remove large rubber particles or impurities, such as initial separation after rough grinding of tires |

|

Medium particle classification |

30 mesh-50 mesh |

0.6mm-0.3mm |

Suitable for recycled rubber raw materials or rubber fillers, requiring medium particle size uniformity, such as building material additives |

|

Fine particle screening |

60 mesh-100 mesh |

0.25mm -0.15mm |

Used for filling or modification of rubber products, such as rubber pads and seals, which require finer powders |

|

Ultrafine powder preparation |

120 mesh-200 mesh |

0.125mm-0.075mm |

Suitable for high-precision applications, such as rubber additives, coating additives or high-performance composite materials, which require fineness and no impurities |

|

Micro powder analysis |

200 mesh-400 mesh |

0.075mm-0.038mm |

Used for laboratory analysis or special purposes (such as nano-grade rubber powder), which requires high-precision equipment support |

Rubber powder test sieve has a wide range of applications in rubber recycling, product production, quality inspection, rubber modified materials, rubber products, chemical industry, material science, recycled rubber, laboratory research, environmental protection and other fields. Its main uses include particle size analysis, quality control, production process optimization, new product development, etc. Through accurate screening analysis, it can improve product quality, optimize production processes, and support scientific research and resource recycling.

|

Parameter |

typical value / range |

description |

|

Screen mesh number |

10 mesh-200 mesh |

corresponding aperture of about 2mm-0.075mm, select according to needs |

|

Diameter |

200mm/300mm |

common laboratory size, 200mm is standard, 300mm is suitable for large samples |

|

Material |

stainless steel 304 or brass |

corrosion resistance, prevent rubber powder from adhering or contaminating |

|

Height |

50mm (full height) / 25mm (half height) |

full height is suitable for large capacity, half height is convenient for multi-layer stacking |

|

Vibration frequency |

3000 times/minute (if equipped with vibrator) |

high-frequency vibration improves screening efficiency, suitable for fine powder |

|

Number of layers |

1-8 layers |

multi-layer design can separate multiple particle sizes at the same time |

Screen blockage: Rubber powder may cause screen blockage during screening, affecting the screening effect. Clean the screen regularly to avoid excessive accumulation of rubber powder on the screen.

Low screening efficiency: low screening efficiency and slow screening speed. Rubber powder test sieve Adjust the vibration parameters of the vibrating screen; Check whether the screen is damaged or aged, and replace it in time.

Inaccurate particle classification: Inaccurate particle classification cannot achieve the expected screening effect. Check the wear of the screen and replace the damaged screen in time.

Unstable equipment vibration: The vibration of the vibrating screen is unstable, which affects the screening effect. Check whether the supporting structure is firm, adjust the vibration parameters of the vibrator, and ensure stable vibration.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

Packaging material belt conveyor

Packaging material belt conveyor is a kind of equipment widely used in the packaging industry. It is used to...

Fertilizer belt conveyor is a mechanical device that continuously transports various fertilizers from the feeding...

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to sieve vitamin powder. It achieves sieving through vibration and slapping action. It is often used to remove impurities, grade part...

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control, and is widely used in food, chemical, pharmaceutical and o...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy...

Ultrasonic test sieve for wheat flour

Ultrasonic test sieve for wheat flour is a special device that combines ultrasonic technology with traditional screening principles to efficiently screen wheat flour. The device can...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap