![[field:title/]](/uploads/allimg/250318/2-25031Q43550421-lp.png)

Salt test sieve usually refers to the sieving equipment used for salt (such as table salt, industrial salt or sea salt) particle classification and particle size analysis, which is a tool in laboratory or industrial testing.

1. Sieve material: stainless steel or corrosion-resistant material

2. Use: quality control, material analysis, scientific research experiments

3. Application: suitable for food, chemical, pharmaceutical, water treatment and other industries

Salt test sieve is a standardized sieving tool, usually made of stainless steel or corrosion-resistant materials, used to determine the particle size distribution of salt particles. It grades salt particles based on the size of the sieve holes and is often used in quality control, process optimization or research and development. The pore size of the sieve ranges from a few microns (such as 20µm) to a few millimeters (such as 4mm), depending on the test requirements.

① Sieving salt particles (particle grading)

Purpose: Grading salt according to particle size, such as separating coarse salt from fine salt and ultrafine salt.

Application areas: Commonly used in food processing, chemical production, and water treatment industries to ensure that the particle size of salt meets the requirements for subsequent use.

② Removing impurities (impurity removal)

Purpose: Remove impurities, foreign matter or agglomerates in salt to improve the purity and quality of salt.

Application areas: In the chemical industry and food industry, remove impurities and unqualified particles to ensure product quality.

③ Detect the humidity of salt

Purpose: Test the humidity of salt by screening to prevent salt from agglomerating and maintain its fluidity.

Application: During salt production, storage and transportation, avoid salt agglomeration or difficulty in flowing due to excessive humidity.

|

Classification standard |

Type |

Features |

Applicable scenarios |

|

Screen material |

Wire mesh screen |

High precision, wear resistance, easy to clean, corrosion resistance |

Most salt samples, especially fine salt |

|

Nylon screen |

High wear resistance |

Suitable for high hardness salt particles |

|

|

Perforated plate screen |

High strength, not easy to deform, corrosion resistance |

Salt with larger particle size, coarse salt, industrial salt |

|

|

Screen shape |

Round screen |

Strong versatility |

Most salt samples |

|

Square screen |

Specific standard requirements |

Scenarios with specific standard requirements such as cement fineness detection |

|

|

Application field |

Food grade salt test sieve |

Comply with food hygiene standards |

Edible salt production, food processing |

|

Industrial grade salt test sieve |

Strong corrosion resistance |

Industrial salt production, chemical industry |

|

|

Pharmacopoeia sieve |

Comply with pharmacopoeia standards |

Drug production, pharmaceutical industry |

Sieve frame: round or square frame, with a common diameter of 200mm or 300mm, mostly made of stainless steel, resistant to salt corrosion.

Screen: made of woven or punched wire, with apertures that meet international standards (such as ISO 3310 or ASTM E11).

Number of layers: single or multiple layers stacked to form a sieve group, used to classify multiple particle sizes at one time.

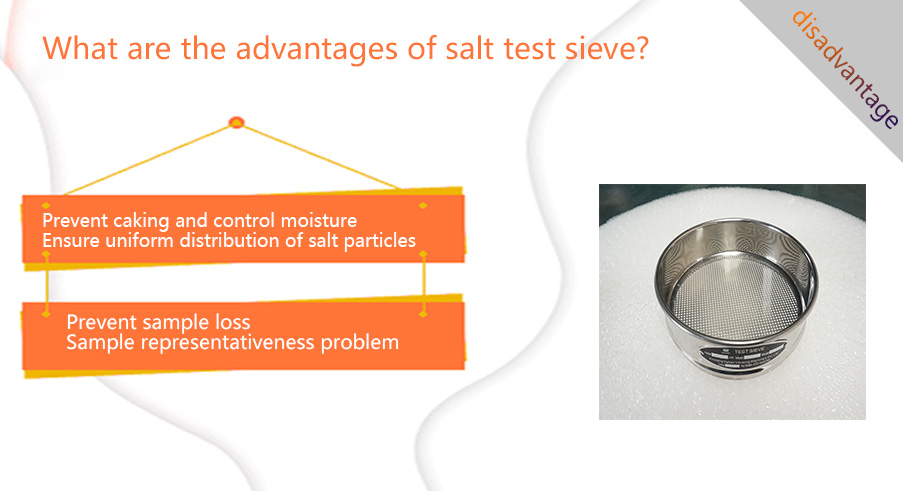

1. Prevent caking and control moisture: Salt test sieve uses vibration to break up caking and ensure that salt particles can pass through the sieve smoothly. During the wet salt screening process, salt test sieve uses a sealed design to reduce water evaporation and avoid moisture.

2. Ensure uniform distribution of salt particles: By reasonably designing the sieve aperture and vibration frequency, salt test sieve uses a refined sieve and a multi-stage screening system to achieve more accurate particle classification and ensure product consistency and quality.

3. Prevent sample loss: During the screening process, fine salt particles may be lost through the gap, or the sample may overflow due to improper operation. The edge of the sieve frame of the salt test sieve is processed with high precision, and a collection tray is installed at the bottom to capture fine powder.

4. Sample representativeness problem: The particle size distribution of the salt sample may be uneven, and improper sampling will affect the test results. Salt test sieve adopts a scientific sampling method to ensure the representativeness of the salt sample, conduct multiple tests, take the average value, and reduce sampling errors.

|

Parameters |

Specifications |

Parameters |

Specifications |

|

Sieve frame diameter |

200mm,300mm |

Sieve mesh aperture |

0.02mm-10mm |

|

Sieve frame material |

stainless steel |

Vibration frequency |

50Hz-60Hz |

|

Vibration amplitude |

1 mm-3 mm |

Power supply requirements |

220V/380V, 50/60 Hz |

|

Equipment weight |

10kg-30kg |

Working temperature |

-10°C to +50°C |

|

Noise level |

<70dB |

Automation control |

Optional PLC control system |

|

Maintenance cycle |

every 6 months or 500 hours |

Equipment life |

5-10 years |

|

Application scenario |

Recommended mesh number |

Particle size range |

|

Food grade salt |

10-60 mesh |

2.00mm-0.25mm |

|

Industrial grade salt |

8-50 mesh |

2.36mm-0.3 0mm |

|

Water treatment salt |

8-30 mesh |

2.36mm-0.60mm |

|

Road deicing salt |

4-16 mesh |

4.75mm-1.18mm |

|

Laboratory research |

10-200 mesh |

2.00mm-0.075mm |

|

Agricultural salt |

10-40 mesh |

2.00mm-0.425mm |

|

Pharmaceutical salt |

20-60 mesh |

0.85mm-0.25mm |

|

Feed salt |

10-40 mesh |

2.00mm-0.425mm |

Salt test sieve is widely used in food, chemical, pharmaceutical, water treatment and other industries, and plays an important screening role. Through screening, salt can be graded, impurities removed and finely processed according to particle size, purity requirements, etc., thereby improving production efficiency, ensuring product quality, and meeting industry standards.

1. Clear standards: Prioritize industry specifications (such as food-grade salt must comply with GB/T 5461).

2. Multi-layer combination: Complex samples can be stacked with multiple mesh sieves (such as top layer 20 mesh + middle layer 80 mesh + bottom layer 200 mesh).

3. Equipment adaptation: The efficiency of the vibrating screen affects the screening results, and the time needs to be adjusted according to the equipment power.

4. Verification test: Use a standard sample to verify the accuracy of the sieve before first use.

Case 1: Salt quality inspection

①The mesh size is 20-40-60-100 mesh②The result is >850µm accounts for 5%, 150-850µm accounts for 90%, and <150µm accounts for 5%, which meets the standard.

Case 2: Industrial salt classification

①The mesh size is 10-20-40 mesh②The result is >2mm returned for crushing, and 0.5-2mm is used for chemical industry.

Case 3: Ultrafine seasoning salt

①The mesh size is 100-200-325 mesh②The result is <75µm accounts for 95%, which meets the requirements of instant dissolution.

Dahan Machinery is a company specializing in the production of screening equipment. When purchasing a salt test sieve, you should choose the appropriate model and mesh size based on factors such as the type of salt, particle size range, test volume and application scenario. You can consult the sales staff customer service of Dahan Machinery to understand the characteristics and applicable scope of different models of salt test sieves in order to make a more appropriate choice.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control, and is widely used in food, chemical, pharmaceutical and o...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy...

Ultrasonic test sieve for wheat flour

Ultrasonic test sieve for wheat flour is a special device that combines ultrasonic technology with traditional screening principles to efficiently screen wheat flour. The device can...

Laboratory Lactose Stainless Steel Test Sieve

Laboratory lactose stainless steel test sieve is a device used to accurately determine the size distribution of lactose particles. It is often used for laboratory particle analysis ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap