![[field:title/]](/uploads/250401/2-250401092435934.jpg)

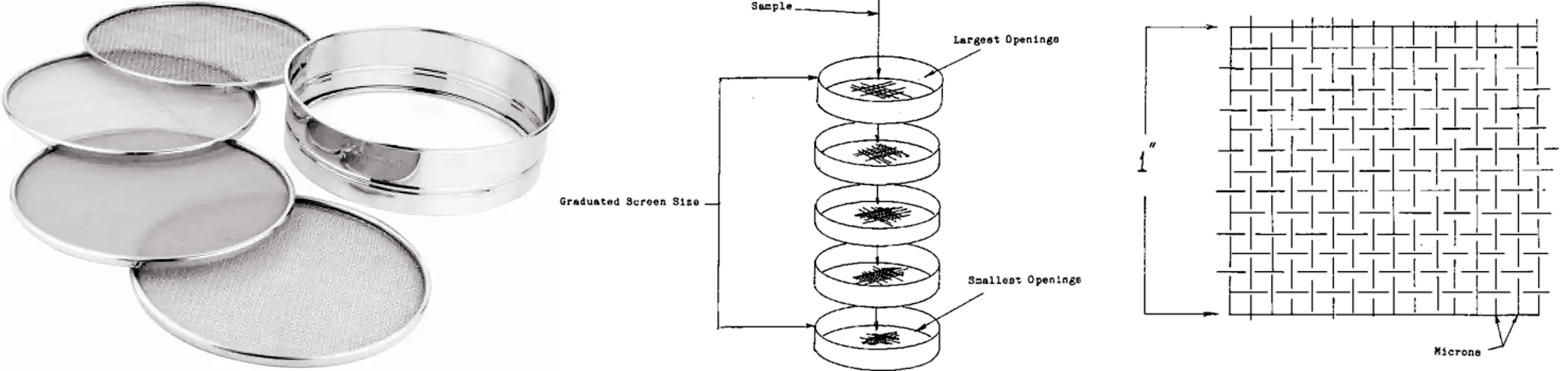

Sieve Mesh is a piece of equipment used to screen and classify granular materials, usually mounted on screening equipment (such as a test sieve) to filter and separate particles according to their size.

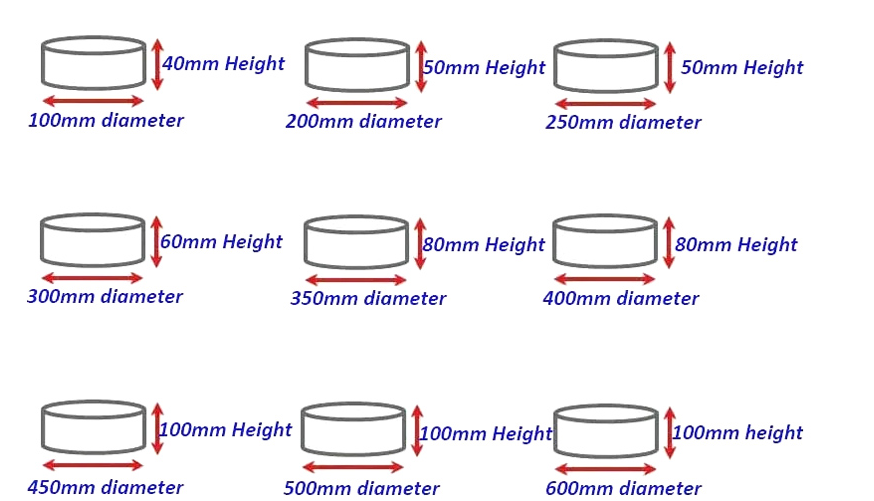

Aperture size: 20µm-63mm

Sieve frame wall thickness: 0.6mm-0.7mm

Diameter: 75mm/100mm/200mm/300mm

Application: suitable for various fields such as industrial production, agriculture, food processing, laboratories, etc.

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

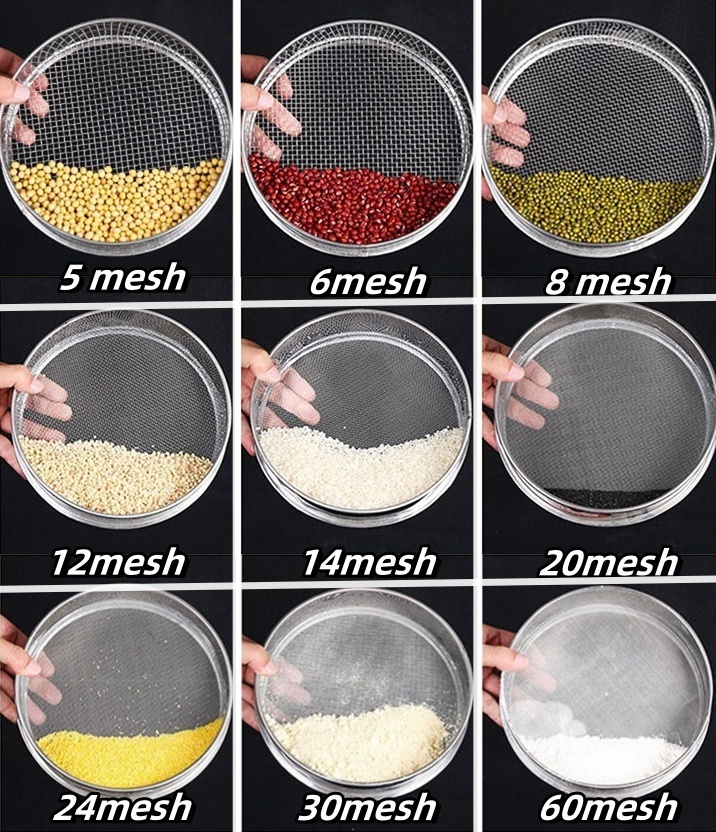

Sieve Mesh come in mesh sizes of 2, 4, 50, 80, 100, 200, and 635. Products are typically categorized by application, including standard test sieves, industrial sieves, and filter meshes. Material types include stainless steel wire mesh, copper mesh, nylon mesh, and polyester mesh. Common suppliers include labsieve in the United States, the United Kingdom, and China. Sieving results are often used to assess the uniformity and processing characteristics of powders or granular materials, providing a basis for production control, quality testing, and process optimization.

Sieve Mesh is a mesh tool used to separate particles or powders by particle size, usually woven or stamped from wire, nylon, polyurethane or other materials. The core function of a sieve is to classify materials by particle size through its aperture size, and is widely used in industry, agriculture, food, medicine, construction and other fields.

1. Classification by weaving method

Plain weave sieve mesh has a tight structure and precise screening; twill weave is wear-resistant and stable, suitable for heavy-duty screening; hook and loop mesh is flexible and impact-resistant, often used for grading filtration; fine wire mesh has a flat surface, which is beneficial for screening fine powders; gold wire mesh combines strength and corrosion resistance.

Plain Weave Screen: Features a tight plain weave with uniform pore size and high strength, making it suitable for fine screening. Common mesh sizes range from 20–200, making it suitable for screening fine materials such as pharmaceutical powders, chemical raw materials, and grain powders.

Twill Weave Screen: Features a staggered twill weave for increased strength and the ability to screen finer particles. Mesh sizes typically range from 40–300, making it suitable for demanding materials such as chemical powders, pigments, and metal powders.

Hook and Loop Screen: Features a larger pore size and a looser structure, making it suitable for screening coarser particles. Mesh sizes typically range from 5–50, making it commonly used for screening quarried stone, sand and gravel, cement, and construction materials.

Grinding Wire Mesh: Features a cross-weave structure for increased stability and is suitable for high-intensity screening. Mesh sizes typically range from 30–150, making it suitable for high-intensity screening of ores, chemical granules, and wear-resistant powders.

Gold Wire Mesh: Uniform wire material, wear-resistant and corrosion-resistant, with a stable pore size. Screening mesh sizes typically range from 40–200 mesh, making it suitable for screening materials requiring corrosion and wear resistance in the chemical, food, pharmaceutical, and metal powder industries.

2. Classification by material

Sieve Mesh can be divided into punching mesh, woven mesh, polyurethane mesh, electroformed mesh, sintered mesh and other types according to the material. Some materials are corrosion-resistant, some are high-temperature resistant, and some have high screening accuracy. You can choose according to specific needs.

|

Type |

Picture |

Structural features |

Applicable scenarios |

Advantages |

Limitations |

|

Woven screen |

|

Wire/synthetic fiber warp and weft weaving |

Medium and fine particles (0.045~20mm) |

High porosity (35%~75%) |

Easy to deform, short life |

|

Punching screen |

|

Metal plate stamping |

Large particles (5~100mm) |

High strength, wear resistance |

Low porosity (≤50%) |

|

Polyurethane screen |

|

PU elastomer molding |

Wet materials or high wear scenarios |

Anti-blocking net, corrosion resistance |

High price (2~3 times that of metal mesh) |

|

Electroforming screen |

|

Electrolytic process precision molding |

Ultra-high precision screening (5~500μm) |

Aperture tolerance ±1μm |

Only for small areas (extremely high cost) |

|

Sintered screen |

|

Metal powder sintering |

High temperature/high pressure environment (such as petroleum screening) |

Resistant to 800℃ high temperature, multi-layer filtration |

Heavy weight, not easy to replace |

3.Sieve Mesh is classified by screen frame material

Sieve meshes are commonly categorized into stainless steel, nylon, brass, and aluminum alloy types, depending on the material used in the screen frame.

Stainless steel screens: These use a stainless steel frame and mesh, offering excellent corrosion resistance, high strength, and a long service life. They are suitable for applications requiring high hygiene and precision, such as the chemical, pharmaceutical, food, and metal powder industries.

Nylon screens: The screen frame or mesh is made of nylon, offering lightweight and excellent flexibility, making them suitable for screening non-metallic particles or powders, such as plastic granules and flour.

Brass screens: Made of brass, they offer excellent electrical conductivity and are primarily used for screening non-magnetic materials in laboratory analysis, powder metallurgy, and the electronics industry.

Aluminum alloy screens: The screen frame is constructed of a lightweight aluminum alloy, offering light weight and oxidation resistance. They are suitable for applications requiring frequent handling or outdoor use.

|

Screen type |

material |

features |

scope of application |

picture |

|

Wire mesh |

stainless steel, brass, phosphor bronze, etc. |

corrosion-resistant, high strength, uniform mesh, widely used in various screening operations |

food, medicine, chemical and other industries |

|

|

Perforated plate screen |

stainless steel, carbon steel, etc. |

large aperture, various hole shapes, often used for coarse screening |

mining, construction, food and other industries |

|

|

Electroforming screen |

stainless steel |

high aperture accuracy, good screen stability, suitable for high-precision screening |

electronics, medicine and other industries |

|

|

Polyester screen |

polyester fiber |

acid and alkali resistant, high temperature resistant, often used for liquid filtration and gas filtration |

chemical, food, medicine and other industries |

|

|

Nylon screen |

nylon fiber |

good flexibility, wear resistance, often used in food and medicine industries |

food, medicine, electronics and other industries |

|

Soil can contain particles of varying sizes, such as gravel, sand, silt, and clay. Construction materials, like sand, cement, and aggregate, contain other components. Sieve Mesh uses mesh sizes like 10, 60, and 200 to separate particles into suitable sizes. For example, the coarse gravel and stone removed can be used as construction backfill, concrete aggregate, roadbed, garden paving, or drainage layer. The clay removed can be used to make pottery, porcelain, bricks, and tiles; as a component of waterproofing materials; and, in gardening, for cultivating specific plants.

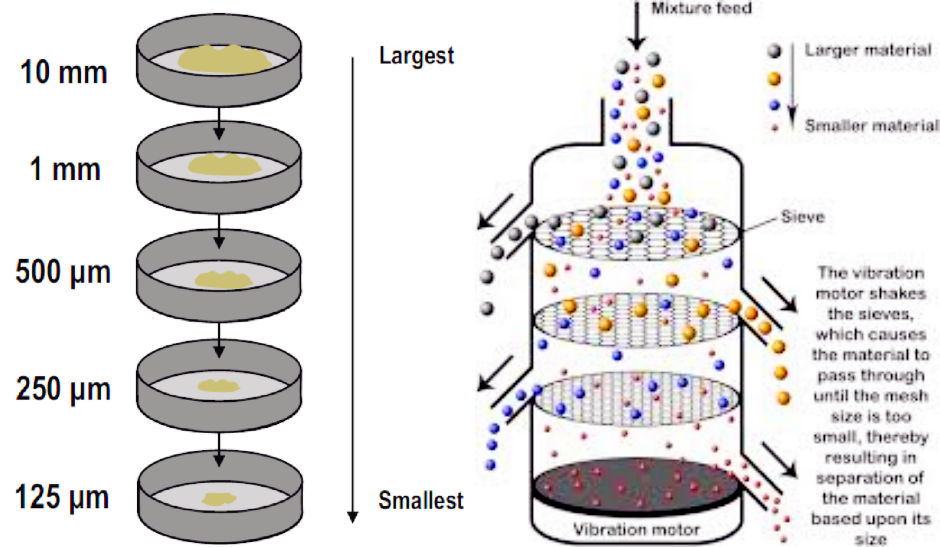

The main function of a sieve is to classify particles into different grades or size ranges based on their size. The structure of a sieve is usually made up of parallel filaments (wires or synthetic fibers) interwoven to form a series of holes or meshes. The size of these holes can be adjusted as needed to meet the screening requirements of different particle sizes.

Sieve Mesh has the characteristics of complete aperture specifications, controllable precision, flexible material selection, stable and durable weaving structure, and reduced replacement frequency and maintenance costs.

Aperture size: The aperture of the screen determines the size of the particles that can pass through, usually expressed in mesh (number of holes per inch) or millimeters (mm).

Various materials: Depending on the application, screens can be made of stainless steel, high carbon steel, nylon, polyurethane and other materials.

Weaving method: The screen can be a woven mesh (woven from wire or fiber) or a punched plate (made by stamping process).

Wear and corrosion resistance: High-quality screens are wear-resistant, corrosion-resistant, and tensile-resistant, suitable for long-term use.

Sieve Mesh separates materials through meshes of varying pore sizes. As the mixture moves across the mesh, particles smaller than the pore size pass through and fall as undersize, while particles larger than the pore size move along the mesh until discharged, completing the grading or filtration process by size.

Material conveying: The material to be screened is evenly conveyed to the screen surface.

Vibration or rotation: The screen moves by vibration or rotation, causing the material to move relative to the screen surface.

Particle separation: Particles larger than the sieve holes are retained on the screen surface, while particles smaller than the sieve holes fall through the sieve holes to achieve particle size separation.

Sieve mesh is used in mining, construction, and agriculture to screen sand, gravel, and grain. In the chemical, pharmaceutical, and food industries, it performs precise raw material separation and liquid filtration tasks. It is also a core component in water and gas treatment in environmental protection projects. Furthermore, in the textile, electronics, and automotive manufacturing industries, sieve mesh provides reliable guarantees for improving product quality and production efficiency through its efficient sorting and filtration capabilities.

|

Number |

Mesh size (mm) |

Number |

Mesh size (mm) |

Number |

Mesh size (mm) |

Number |

Mesh size (mm) |

|

2 |

13 |

26 |

0.71 |

90 |

0.16 |

260 |

0.06 |

|

3 |

6.5 |

28 |

0.63 |

100 |

0.154 |

280 |

0.055 |

|

4 |

5 |

30 |

0.6 |

110 |

0.14 |

300 |

0.054 |

|

5 |

4 |

32 |

0.55 |

115 |

0.13 |

320 |

0.048 |

|

6 |

3.2 |

36 |

0.5 |

120 |

0.125 |

325 |

0.045 |

|

7 |

2.8 |

40 |

0.45 |

130 |

0.111 |

350 |

0.041 |

|

8 |

2.5 |

45 |

0.4 |

140 |

0.105 |

360 |

0.4 |

|

9 |

2.2 |

50 |

0.355 |

150 |

0.1 |

400 |

0.0385 |

|

10 |

2 |

55 |

0.315 |

160 |

0.098 |

500 |

0.03 |

|

12 |

1.6 |

60 |

0.3 |

180 |

0.09 |

|

|

|

14 |

1.43 |

65 |

0.25 |

190 |

0.08 |

|

|

|

16 |

1.25 |

70 |

0.22 |

200 |

0.075 |

|

|

|

18 |

1 |

75 |

0.2 |

220 |

0.07 |

|

|

|

20 |

0.9 |

80 |

0.18 |

240 |

0.065 |

|

|

|

24 |

0.8 |

85 |

0.17 |

250 |

0.063 |

|

|

|

If you need special specifications, please contact online customer service for consultation. |

|||||||

Screen manufacturers can be categorized into large-scale, comprehensive screen manufacturers, specialized screen manufacturers, and small-scale screen processing plants based on production scale, product variety, and service scope. Dahan Machinery boasts comprehensive production lines and testing equipment, offering a comprehensive product range. Whether it's large-scale batch orders or personalized customization, Dahan Machinery leverages its strong technical capabilities and comprehensive service system to provide customers with reliable products and comprehensive solutions.

Five Advantages of Rotap Sieve Shaker

Rotap Sieve Shaker is mainly composed of machine base, sieve and transmission mechanism. It can be equipped with special fixtures, which can be used to clamp 200 test sieves, as wel...

Slap Type Test Sieve is mainly used in laboratories within universities/research institutes/enterprises, with standard test sieves for particle size analysis and detection of granul...

Soil sieve analysis is a soil particle size determination method based on the principle of mechanical separation...

Juice Powder Ultrasonic Sieve test

The ultrasonic sieve test for juice powder is a fine screening equipment designed for delicate, moisture-absorbing...

Standard Test Method for Particle-Size Analysis of Soils

Standard Test Method for Particle-Size Analysis of Soils (ASTM D422)aims to accurately determine the size distribution of soil particles...

Size sieve for soil primarily involves the sieve frame diameter and sieve aperture size...

Sieve Mesh is a metal or non-metal device used to separate materials. Its mesh count refers to the number of holes per square inch. It sorts powders by particle size through vibrati...

For Laboratory Sieves Price ranges from $100 to $500 USD, and the price varies depending on the sieve diameter, mesh range, material, and quantity.......

For Laboratory Sieves Suppliers

For Laboratory Sieves Suppliers manufactures sieve frames in 3-inch, 8-inch, and 12-inch diameter sizes, including perforated plate screens, wet-washed screens, and woven wire mesh ...

size sieve for soil is made of stainless steel and can sieve out dust and soil. The fine sieve sizes are 0.075mm and 2mm, and the coarse sieve sizes are 4.75mm, 25mm, and 75mm.......

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap