![[field:title/]](/uploads/250401/2-250401092604608.jpg)

Sieve Shaker is a device used for screening, grading, filtering and testing of granular materials. It makes the materials move on the screen through vibration to achieve separation of different particle sizes.

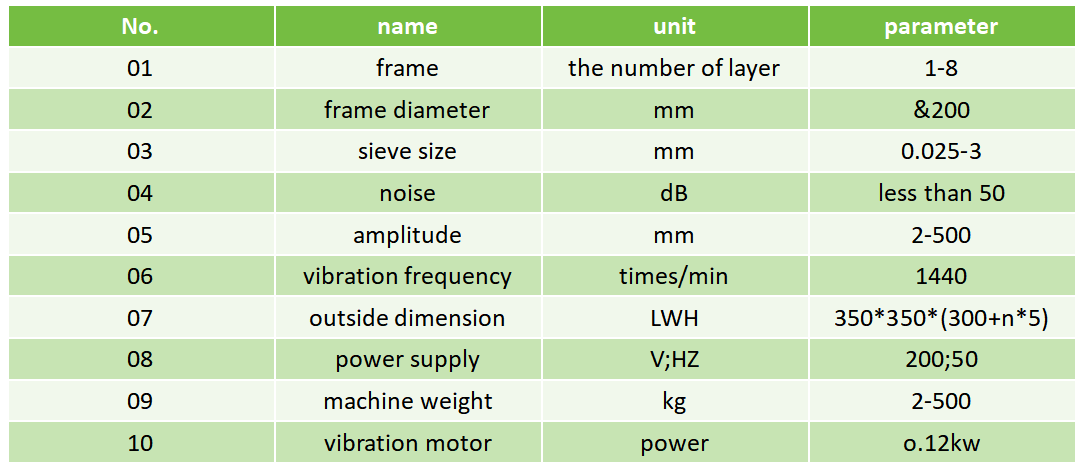

Measuring range: 20µm-25mm

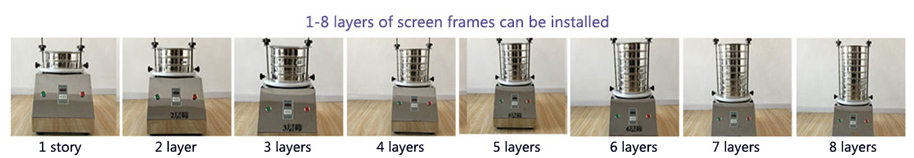

Screen frame layers: 1-8 layers

Key point: Acid and alkali corrosion resistance、Automatic shutdown

Screening motion: Throwing motion with angular momentum

International standard: ISO3310-1:1990 R20/3, R20, R40/3 series

Screen diameter: 75mm, 100mm, 200mm, 300mm, 400mm, 500mm

Application: Widely used in chemical, food, pharmaceutical, metallurgical and other industries

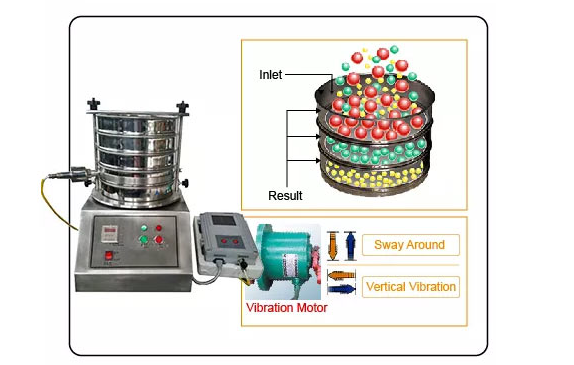

Sieve shaker generates vibration force through the motor, so that the granular materials on the sieve are screened in the sieve holes. The sieve shaker is equipped with sieves of different specifications. The appropriate sieve is selected according to the material requirements to achieve material screening and grading. The platform of the sieve shaker will generate horizontal or vertical vibrations, so that the material moves on the sieve, thereby achieving the screening effect.

Particle analysis: used to screen and grade granular materials in the laboratory for particle analysis and research.

Particle shape analysis: the sieve shaker can be used to analyze and study the shape of granular materials to understand the morphological characteristics of particles.

Particle distribution research: helps researchers understand the particle distribution of granular materials and provide data support for subsequent experiments and research.

1. Efficient screening: The sieve shaker can screen materials quickly and efficiently, improving production efficiency.

2. Particle size control: The sieve shaker screen can accurately control the particle size of the material to meet different requirements.

3. Finished product quality assurance: The sieve shaker can ensure the quality and particle uniformity of the finished product and improve product quality.

4. Energy saving: Compared with traditional screening methods, sieve shakers can usually save energy and improve energy efficiency.

5. Versatility: The sieve shaker can be used for a variety of applications such as raw material screening, particle grading, finished product inspection, pre-packaging treatment, and waste recycling.

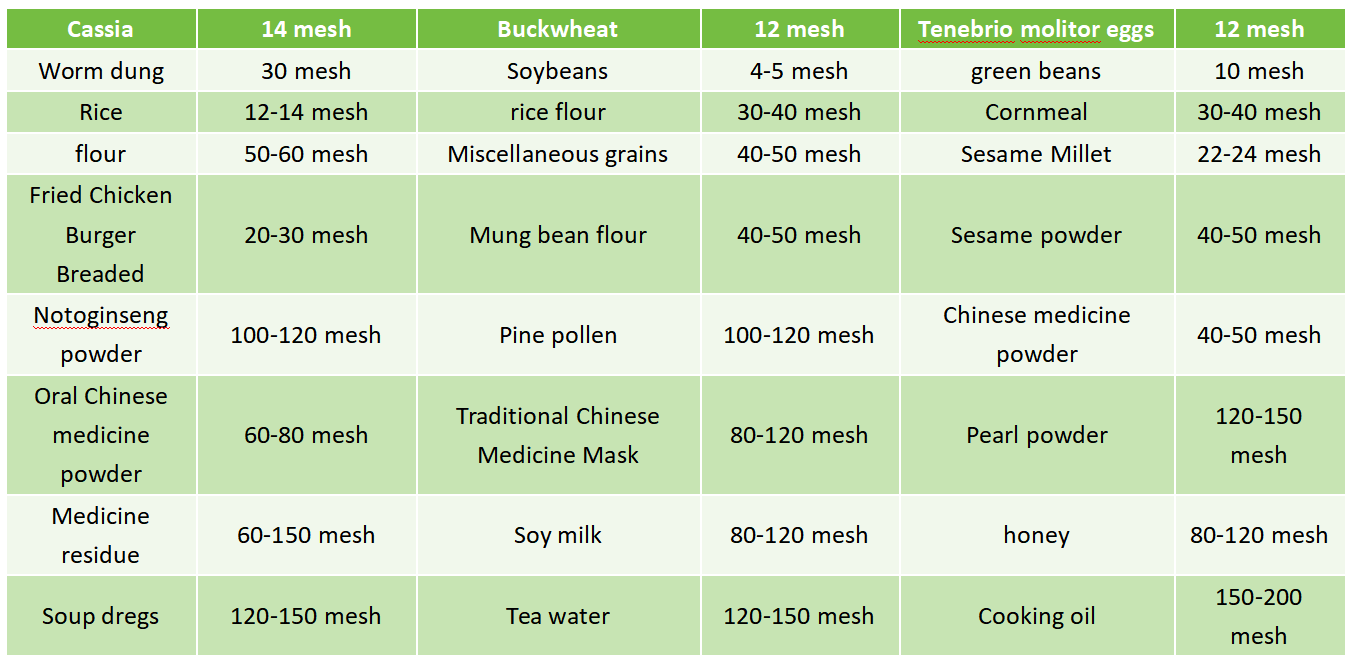

1. Food industry: used for screening and grading of granular food raw materials in the food industry to ensure product quality and food safety, and to help food researchers analyze and study food ingredients to understand the composition of food.

2. Chemical and pharmaceutical industries: used for screening and grading of raw material particles in the chemical and pharmaceutical industries to ensure the quality of materials in the production process. Help the pharmaceutical industry to analyze and study the ingredients of drugs to ensure the quality and efficacy of drugs.

3. Building materials industry: used for screening and grading of granular building materials in the building materials industry to ensure the quality and performance of building materials. Help the building materials industry to analyze and study concrete raw materials to ensure the quality and strength of concrete.

4. Environmental protection and waste treatment fields: used for screening and grading of waste particles in the waste treatment field to achieve resource utilization of waste. Help the environmental protection field to analyze and study particulate materials in environmental samples and monitor environmental quality.

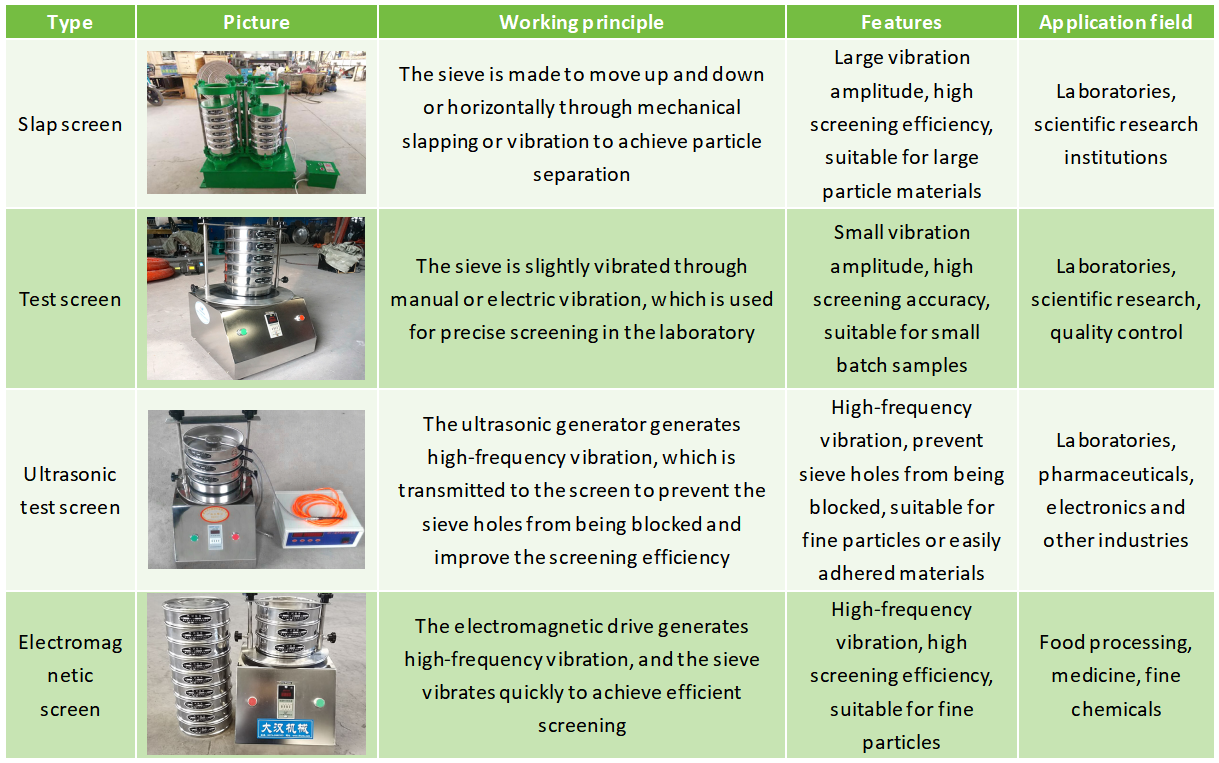

Vibration/shaking mode: Common sieve shakers include mechanical vibration, electromagnetic vibration, rotary shaking, etc.

High screening efficiency: Vibration or shaking accelerates the particles through the screen and improves screening efficiency.

Adjustable parameters: Vibration frequency, amplitude, time and other parameters can be adjusted according to needs.

Multi-stage screening: Supports multi-layer screens and can perform multi-stage screening at the same time.

Wide range of applications: It can be used for screening a variety of materials such as soil, sand and gravel, chemical raw materials, food, and medicine.

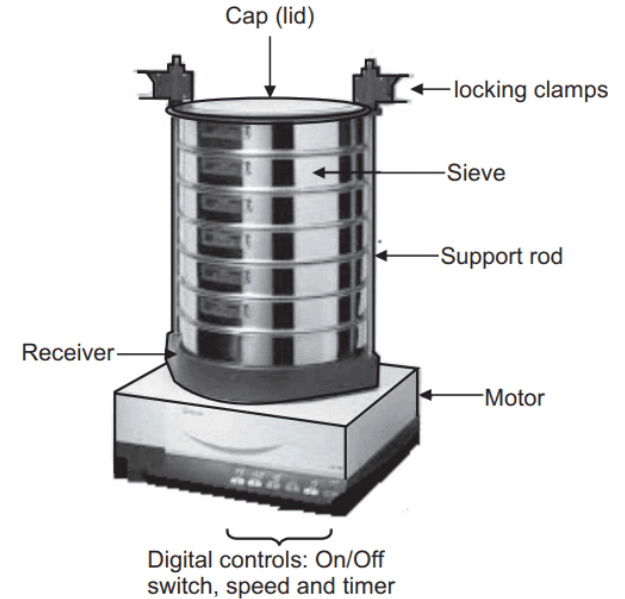

Screen box: The screen box is the core component of the screen machine, usually made of stainless steel or carbon steel, and has the characteristics of corrosion resistance and wear resistance. A screen is set in the screen box to separate materials of different particle sizes.

Screen: The screen is a key component in the screening process, and its material, aperture and mesh number directly affect the screening effect.

Vibration source: A device that provides vibration force, usually a vibration motor.

Drive device: Converts the rotational motion of the motor into the vibration of the screen box.

Spring: Installed between the screen box and the frame, it plays a role in shock absorption and buffering.

Bracket: Supports the entire vibrating screen to ensure the stability of the equipment.

Feed inlet and discharge port: Used for material input and output respectively.

The cost of a sieving machine depends on a variety of factors, such as the type of sieving machine, its brand, its features, and where you buy it. Here are general price ranges for different types of sieving machines:

Electric sieving machines: Electric sieving machines provide automatic and consistent sieving and can range in price from $500 to $2,000 or more, depending on the brand and features.

Ultrasonic sieving machines: Ultrasonic sieving machines use ultrasonic vibrations for fine particle separation and are generally more expensive, ranging in price from $2,000 to $5,000 or more.

It is important to note that these are approximate price ranges and actual prices may vary.

Stainless steel corn grits test sieve

Stainless steel corn grits test sieve is a screening device specially used for particle size analysis and quality control, and is widely used in food, chemical, pharmaceutical and o...

Laboratory Lactose Stainless Steel Test Sieve

Laboratory lactose stainless steel test sieve is a device used to accurately determine the size distribution of lactose particles. It is often used for laboratory particle analysis ...

Industrial Ultrasonic Metal Powder Test Sieve

Industrial ultrasonic metal powder test sieve is mainly used in laboratories or small batch production to analyze and classify fine particle materials such as metal powder and alloy...

Vitamin powder slapping screen

Vitamin powder slapping screen is a device used to sieve vitamin powder. It achieves sieving through vibration and slapping action. It is often used to remove impurities, grade part...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap