Saturday May-24 2025 16:49:36

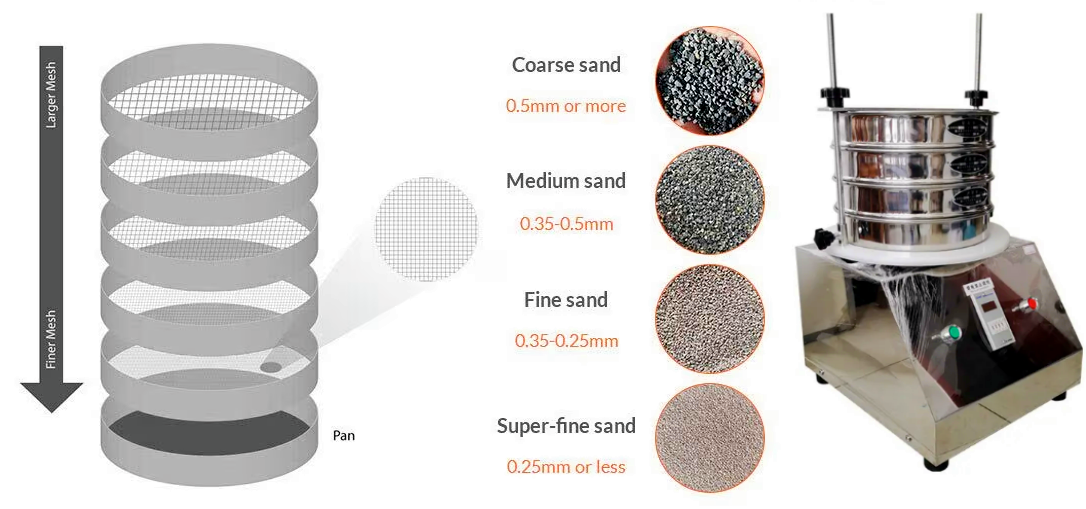

Sieve particle size analyzer is a professional instrument used to determine the particle size distribution of granular materials. It simulates the traditional sieving process and combines modern precision technology to achieve efficient and accurate particle size analysis. Its significant feature is that it can quickly and accurately separate particles of different particle sizes. It can set a variety of sieving modes and parameters according to sample characteristics to meet the needs of different industries. By combining different mesh sizes, the instrument can classify granular materials according to particle size, thereby obtaining detailed particle size distribution data.

Sieving particle size analyzer is suitable for various dry powders, granules and bulk materials, as well as suspensions processed by wet sieving. Its applicability mainly depends on the particle size range, physical properties and experimental requirements of the material.

Dry powder and granular materials: suitable for solid particles that are not easy to agglomerate and have a certain fluidity.

Examples: cement, various chemical powders, plastic particles, ore powder, flour, raw material powder, sawdust, etc.

Wet sieving materials (suspensions and fine samples that are easy to agglomerate)

For some very fine, easy to agglomerate or existing in the form of suspension, dry sieving may be difficult to obtain accurate results. In this case, wet sieving can be used. Use water or other liquids as dispersion media to disperse the sample and then sieve it.

Slurries and muds: such as coal washing mud, ore slurry, ceramic slurry

Extremely fine powders that are easy to agglomerate: Especially for samples with a particle size of less than 45μm, wet sieving can effectively avoid static electricity and agglomeration effects.

Samples that are suspensions themselves: such as some coatings, emulsions, and dispersions.

Sieving particle size analyzers are generally suitable for particle size analysis of coarser particles, and the measurement range is usually between 20µm and 40mm, or even larger (some industrial sieving can reach more than 100 mm).

Advantage range: For particles with a particle size greater than about 45 µm (even 75µm), the sieving method has good accuracy and reproducibility and is a commonly used standard method.

Limitations: For very fine particles (such as nano- or submicron-sized particles less than 20µm), the accuracy and efficiency of the sieving method will be significantly reduced, because problems such as sieve hole blockage, particle agglomeration, and difficulty in completely sieving will become prominent.

Sieving particle size analyzer usually consists of a vibrating screen frame, a screen (standard test screen), a vibration device, a timer and a collection plate.

The electric vibration device drives the sieve to produce vertical and horizontal composite vibrations. A set of standard aperture screens are stacked from large to small according to the particle size. The sample is placed in the top screen, so that the sample placed on the screen is sieved layer by layer within a certain period of time. The particles are layered through the screen holes through mechanical vibration. Each layer of the screen retains particles of different particle size ranges. Finally, the mass of the residue on each layer of the screen and the bottom plate is weighed, and the mass percentage of each particle size range is calculated.

|

Features |

Dry sieving particle size analyzer |

Wet sieving particle size analyzer |

|

Image |

|

|

|

Sample state |

Dry, free-flowing powder, granules, bulk |

Samples that are easy to agglomerate, very fine, or slurry/suspension in themselves. |

|

Dispersion medium |

Air |

Liquid (such as water, ethanol, or non-polar solvent, etc.). |

|

Applicable particle size range |

Usually suitable for medium to coarse particles (such as 45 µm to tens of millimeters) |

More suitable for fine particles (especially less than 45 µm, or even finer) to avoid agglomeration |

|

Typical applications |

Cement, sand, grains, coffee beans, plastic particles, ores, etc. |

Clay, mud, ceramic slurry, certain drug powders, flour, pigments, etc. |

Sieving particle size analyzers can be widely used in material particle size analysis and quality control in many fields. In the building materials industry, it is used to analyze the particle size distribution of sand and cement particles to ensure the reasonable grading of concrete aggregates and the strength of building structures; in the pharmaceutical field, by detecting the particle size of active ingredients and excipients of drugs, the solubility and bioavailability of drugs are optimized, such as controlling the particle size of raw materials in tablets to improve disintegration time. In the food industry, the particle size of powders such as flour and milk powder is analyzed, which plays a key role in dough strength, texture of baked products and dissolution of milk powder. In the chemical industry, it is used to control the particle size of fertilizers and resin particles, improve product molding efficiency and performance; in the research and development of new materials, it helps characterize the particle size of nanomaterials and lithium battery electrode materials, and provides data support for optimizing material performance; in environmental monitoring, it analyzes soil and dust particles to evaluate soil fertility and air pollution.

In short, the screening particle size analyzer is a precision device for measuring the particle size distribution of granular materials. It uses one or more sets of standard sieves to grade samples by vibration or shaking. The larger the mesh size of each sieve, the smaller the aperture. During the screening process of the sample, particles smaller than the sieve aperture will pass through, while particles larger than the aperture will be retained. It is widely used in geology, mining, pharmaceuticals, chemicals, food and other fields, providing key data support for production quality control and product research and development.

What is the wet sieving process?

Wet sieving process is a sieving process assisted by a liquid (usually water or a solution containing a dispersant) to more effectively...

Fines content tester can be defined as an instrument used to quantitatively determine the content of fines powder components of a specific fineness...

Micro silica powder particle size analysis test sieve

Micro silica powder, also known as silica fume, is an ultrafine active silica material with a very small particle size, usually between 0.1-0.3 microns, which...

Agricultural gruesos Test sieves

Agricultural gruesos test sieves are experimental equipment used for particle size analysis, grading and testing of agricultural soil, gruesos...

Stainless steel frame and woven cloth

The test sieve is a laboratory equipment used for particle size analysis. Its core components usually include a stainless steel frame and woven cloth (also called a sieve)...

stainless steel pollen laboratory test sieve

Stainless steel pollen laboratory test sieves are precision tools specifically used for pollen separation, grading and purity testing....

May 24, 2025

The sieve particle size analyzer is a professional instrument used to determine the particle size dis...

May 22, 2025

stainless steel pollen laboratory test sieve

Stainless steel pollen laboratory test sieve is a precision tool for pollen separation, classificatio...

May 21, 2025

The low-priced coffee test sieve is a key tool for evaluating the particle size distribution of coffe...

May 20, 2025

Laboratory test sieve used for fertilizer particle screening

Laboratory test sieve is a precision screening equipment widely used for detecting the particle size ...

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap