![[field:title/]](/uploads/250427/2-25042G50PH31.png)

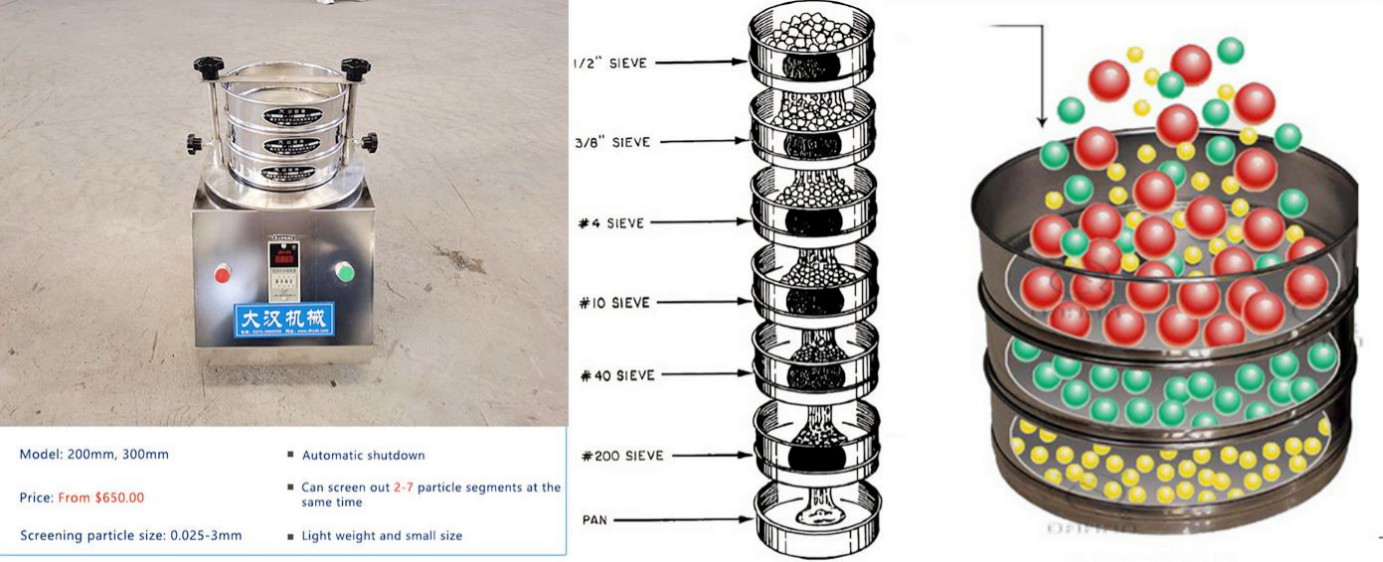

Sieve shaker testing equipments also known as sieving machine or sifter, is a common device used to determine the particle size distribution of granular materials. It vibrates the material through a series of sieves with different sieve sizes, thereby separating the material into different particle size grades.

Number of layers: 1-8 layers

Screening particle size: 0.025mm-20mm

|

Quantity(sets) |

1-2 |

>2 |

|

Delivery time(days) |

5 |

To be negotiated |

Sieve shaker Testing equipments are designed for laboratories and quality control, and can quickly and accurately analyze the particle size of granular materials. The equipment uses an advanced vibration motor as the excitation source to generate stable three-dimensional vibration to ensure that the material is fully dispersed and layered on the surface of the screen. The equipment can be adapted to various specifications of circular standard screen frames, with optional diameters of 200mm or 300mm. The screen mesh range is wide, from 4 to 500 mesh, and can be flexibly configured according to different test requirements.

Sieve shaker testing equipment is primarily used in laboratories to accurately grade and test the particle size of materials. Based on their operating principles and application scenarios, common types include laboratory shakers, electric shakers, ultrasonic test sieves, and tap sieves. When selecting equipment, consider material characteristics (such as particle size, density, and agglomeration potential), test accuracy requirements, and budget. For example, ultrasonic test sieves are a better choice for fine powders requiring high precision, while electric shakers offer a wider range of applications for general particulate material analysis.

There are many types of Sieve shaker testing equipments, the most common ones are laboratory vibrating sieves, electric vibrating sieves, ultrasonic test sieves, and slap sieves. Laboratory shakers are the more basic type, using electromagnetic or mechanical vibrations to grade materials within a standard sieve. Electric shakers offer precise control of vibration frequency and amplitude, making them suitable for a wide range of materials. Ultrasonic test sieves use high-frequency vibrations to clear blockages and are particularly suitable for fine powders and materials with strong electrostatic adsorption. Tap sieves use up-and-down beating and rotational motions to fully grade materials within the sieve. The following is a detailed introduction to these four types of vibrating screens:

|

Type |

Laboratory vibrating screen |

Electric vibrating screen |

Ultrasonic test screen |

Slap screen |

|

Image |

|

|

|

|

|

Definition |

Suitable for particle size analysis of small batch materials in the laboratory |

Uses electric motor as the power source, and generates strong vibration through eccentric vibrator |

Combines the vibration principle of traditional vibrating screen and ultrasonic wave |

Makes the material pass through the screen by rapid slapping or impact |

|

Features |

Suitable for particle size analysis, product quality control, etc. |

High screening accuracy |

Effectively prevents material from adhering or clogging on the screen surface |

Effectively avoids the problem of poor screening effect caused by material adhesion or excessive humidity |

|

Application |

Commonly used for particle size distribution test of powder and granular materials |

Suitable for efficient screening of powder and granular materials |

Used for precision screening, especially particle size analysis of nano-level and ultrafine powders |

Commonly used for screening of granular or block materials, especially suitable for screening larger particles |

|

Mesh |

20 to 500 mesh |

Supports screening of larger particles to fine particles |

Suitable for sieves with higher mesh counts (such as 100 mesh or more) |

Generally suitable for coarser granular materials, with a lower mesh count range |

During the test, put the material into the top sieve, start the vibrator, the sieve starts to vibrate, the material keeps moving on the sieve, particles smaller than the sieve hole size pass through the sieve, and particles larger than the sieve hole size remain on the sieve. After a period of vibration, stop the vibration, take out each layer of sieve, weigh the weight of the material left on each layer of sieve, and you can get the particle size distribution of the material.

High-efficiency screening capability: Vibrating screens use high-frequency vibrations to move materials on the surface of the screen to achieve separation of materials of different particle sizes. The equipment can efficiently handle large amounts of materials while maintaining high screening accuracy.

Various types available: There are many different types of sieve shaker testing equipments according to different needs. For example, laboratory vibrating screens are suitable for small batch sample analysis, electric vibrating screens are suitable for conventional production screening, and ultrasonic test sieves are suitable for high-precision screening.

Various types available: Suitable for screening of various powders, particles, liquids and other materials, widely used in chemical, mining, food, pharmaceutical, building materials and other industries. Able to handle various types of materials, adapt to the characteristics of different materials such as particle size, humidity and viscosity.

High screening accuracy: By adjusting the vibration frequency, amplitude and screen aperture, sieve shaker testing equipments can achieve fine screening. For ultrafine powders or particulate materials, especially in ultrasonic vibrating screens, the screening accuracy can meet very high requirements.

|

Serial number |

name |

unit |

parameter |

|

1 |

sieve frame |

layer |

1~5mm |

|

2 |

sieve frame diameter |

mm |

ф200ф100ф75 |

|

3 |

sieve particle size |

mm |

0.025~3 |

|

4 |

noise |

dB |

less than 50 |

|

5 |

amplitude |

mm |

0~3 |

|

6 |

vibration frequency |

times/part |

1440 |

|

7 |

outline dimensions |

length, width and height |

360×300×300 |

|

8 |

power supply |

V: HZ |

220;50 |

|

9 |

Machine weight |

kg |

42 |

|

10 |

Setting time |

min |

1-60 |

|

11 |

Motor power |

KW |

0:18 |

|

There are 37 in total, including 12 wire woven screens with mesh size of 200μm-300μm, in line with ISO3001-1:1990 standard and GB/T60031-1997 standard. There are 25 R40/3 series precision electroforming screens with mesh size of 455μm-41μm, and the allowable deviation of mesh size is ≥139μm±3μm, ≤127μm±2μm. The screen frame, screen cover and screen bottom are all made of stainless steel. |

|||

|

Shape |

Diameter |

Effective screen surface diameter |

Height |

|

|

Min |

Max |

|||

|

Round hole |

75mm |

75mm |

65mm |

25mm |

|

200mm |

200mm |

185mm |

25mm, 50mm |

|

|

300mm |

300mm |

275mm |

75mm |

|

|

Square hole |

300mm |

300mm |

|

75mm |

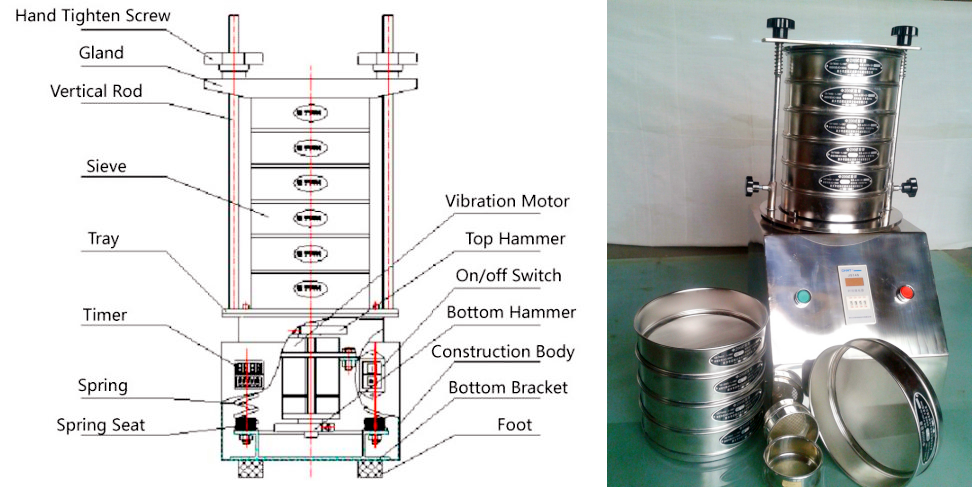

Sieve shaker testing equipments usually consists of a vibrator, sieve, clamping device and timer.

Vibrator: generates vibration, which can be an eccentric wheel driven by a motor, an electromagnet, etc.

Sieve: A series of sieves with different sizes of sieve holes, usually made of stainless steel, stacked in order of particle size.

Clamping device: used to fix the sieve to ensure the sealing and stability of the sieve during the screening process.

Timer: controls the screening time to ensure the accuracy and repeatability of the screening results.

Sieve shaker testing equipments are widely used in many industries and can handlethe screening, grading and particle size analysis of various materials. It can not only meet the screening needs in mass production, but also be used for fine screening and high-precision analysis. Choosing the right vibrating screen equipment can greatly improve production efficiency and ensure product quality.

Laboratory research and development: In scientific research and laboratories, sieve shakers are used for particle size distribution analysis and testing of particulate matter, and are widely used in research in physics, chemistry, materials science and other fields.

Chemical industry: Chemical production often involves the screening of various powders and granular materials. Sieve shakers are used for screening and grading of materials such as fertilizers, coatings, and plastic particles. Especially in the production of fine chemicals and catalysts, high screening accuracy is required.

Pharmaceutical industry: Particle size control is crucial for the solubility and bioavailability of drugs. Sieve shaker testing equipments are used for fine screening of pharmaceutical raw materials, granules, powders, etc. to ensure that the quality of drugs meets the standards.

Food industry: The food industry needs to strictly control the particle size of raw materials to ensure the consistency and quality of products. Sieve shaker is used to separate powders of different particle sizes, such as flour, powdered sugar, spices, seasonings, etc. It is also used to clean impurities in food.

The price of sieve shaker testing equipments varies by type, specification, brand and configuration (such as mesh size, material, additional functions).

Factors affecting price:

Equipment type and configuration: Ultrasonic test sieves are more expensive because they are equipped with high-frequency ultrasonic systems (36kHz); laboratory vibrating screens are cheaper because of their simple structure.

Screen material and mesh size: Stainless steel 304/316L screens or high-precision electroformed screens (5-500μm) are more expensive; the finer the mesh size (such as >200 mesh), the higher the price.

Processing capacity: Laboratory equipment with a processing capacity of 10-50kg/h is cheaper, and electric vibrating screens with a processing capacity of 50-150kg/h are more expensive.

Additional functions: Such as digital display screens, time relays, dust covers or customized screen layers (1-5 layers) will increase costs.

Brand and service: Well-known brands such as Dahan Machinery provide ISO9001 certification, free delivery, and 30-day returns, and the price is slightly higher than that of small manufacturers.

If you need equipment selection and accurate quotation for specific powders or scenarios, please provide more details (such as processing volume, mesh size requirements) and we can further assist!

In the field of Sieve shaker testing equipments, a manufacturer's customization capabilities are a key indicator of their technical strength and expertise.First, customization is reflected in the precise adjustment of equipment parameters. Different materials have varying particle size, density, moisture content, and shape. Manufacturers can adjust the equipment's vibration frequency, amplitude, and vibration mode based on these material characteristics. For example, for fine powders prone to agglomeration or static electricity, manufacturers can provide vibrating screens equipped with ultrasonic systems. This high-frequency vibration effectively prevents clogging of the screen holes and ensures classification accuracy. Second, customization also includes structural and functional optimization. Some customers may have special safety or environmental requirements for equipment, such as explosion-proof motors or fully enclosed designs to prevent dust contamination. Manufacturers can tailor these requirements to the equipment's material, sealing, and control systems. Furthermore, for industries handling specialized chemicals or foods, manufacturers can provide screen frames made of specialized materials such as 304 or 316L stainless steel to meet hygiene and corrosion resistance requirements. Finally, manufacturers often offer comprehensive system integration services and can provide solutions for integration with other testing equipment. In short, Sieve shaker testing equipments manufacturers can provide flexible, precise and specific solutions to help users complete material particle size analysis more accurately.

Test Analysis Sieve is a sieve for separating mixtures. It mainly makes the mixture of particles of different...

Sieve Analysis Test is mainly used for grading the particle size composition of various powder materials,...

Soil Test Sieve can be used for soil grading, screening, analysis, testing, filtering various soils, widely used...

Standard Sieves standard sieve is a tool for particle size classification and particle size detection of material...

What is 0.075mm soil sieve ? The 0.075mm soil sieve is primarily used for soil particle size analysis, separating and classifying particles by size. 0.075mm is considered the critic...

What is 4.75mm soil sieve ? The 4.75mm soil sieve is primarily used for particle grading analysis of bulk materials such as soil, sand, gravel, and aggregate. The core component of ...

What is 2mm soil sieve? A 2mm soil sieve is a fundamental and crucial tool. Its primarily used for pre-processing and sorting soil samples, separating coarse particles (larger than ...

Size sieve for soil mainly refers to the sieve frame diameter (commonly used 200mm, 300mm, etc.) and the sieve hole size (ranging from 0.075mm to 60mm). The sieve frame diameter is ...

Are you interested?

![]()

Then we look forward to hearing from you

Contact Us

Industrials

Yanjin county forest park gate to the west 1000 meters north road sitemap